MODS!!! Lets see em!!

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › MODS › MODS!!! Lets see em!!

- This topic has 292 replies, 53 voices, and was last updated 09/28/2024 at 11:07 am by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

AuthorPosts

-

06/06/2019 at 8:07 am #50615

Ron, you can contact author’s of forum posts by clicking their Forum name. That will direct you to another page where you can click “messages”to compose and send them a private message. This will send the forum poster an email with your inquiry.

FYI: form member “airscapes” 3D prints and sells these stone stops I am using now. These are taller then the narrow collars I used to use and easier to position.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

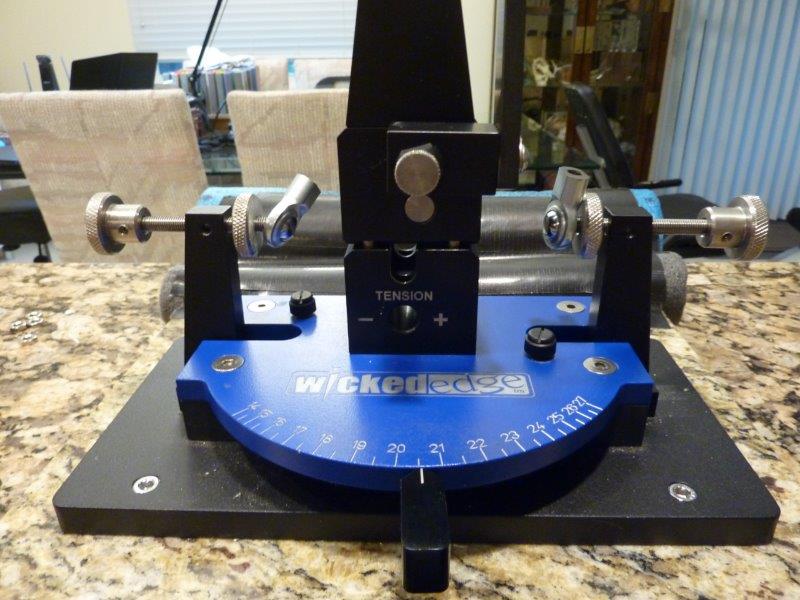

08/28/2019 at 2:22 pm #51709I’m still a new user, and this is a shout-out to some of the mods from fellow users that are helping me develop good sharpening techniques. They include, but are not limited to Doug Probst’s rod stops, and adapter caps for non magnetic mediums, Ed Kenny’s fine and course adjustment knobs, and MarcH’s Rack-It that organizes my stones so that I can find the stones that I’m looking to use. Thanks everyone, please excuse the mess, but it’s my mess. – Mike

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

08/28/2019 at 2:58 pm #51714please excuse the mess, but it’s my mess. – Mike

Thanks Mike!

But to be honest, that is NOT a mess.. I can still see the surface of the desk!!

08/29/2019 at 2:47 am #51718I can guarantee that MY mess qualifies on any number of criteria. At my sharpening workstation, there is no patch of desk visible at any point. In fact, the only evidence that there is in fact a desk there, is that all that stuff is not sitting on the floor. I had to move the current WE system to a different storage location, just to make room for all this stuff. The floor is working hard to achieve the same level of chaotic nirvana. A few more days of wood chips and sawdust might do the trick.

To be honest though, I have a decided advantage here, in that my industrial-strength ADD, in combination with my advanced age, drives me to juggling multiple projects at once, a condition producing a confluence of chaos, which breeds exponentially. I’ve been told that the name Meyer in German means “he who compulsively places objects on any unoccupied horizontal surface.”

1 user thanked author for this post.

08/30/2019 at 7:52 am #51733please excuse the mess, but it’s my mess. – Mike

Thanks Mike! But to be honest, that is NOT a mess.. I can still see the surface of the desk!!

True, the only thing not in the picture is my scope and laptop. I haven’t used it too much yet, but at MarcH’s suggestion, it will now be used at every session.

-

This reply was modified 5 years, 8 months ago by

Mike.

2 users thanked author for this post.

08/30/2019 at 9:47 am #51735I have modified my base to accept clamp-on lites. These 5W LEDs are very bright and allow me to get a good view of scratch patterns on the bevels. I thought about permanently mounting the lites, however this allows for easier storage.

Can you share with us where you bought those lights? I’m in the market for one or two.

08/30/2019 at 9:54 am #51736When you mention an RC boot, are you talking about finding it at like a hobby store with the radio-controlled cars or airplanes? Doing major much needed teardown over the weekend and want to build it back smarter.

08/30/2019 at 10:50 am #51737Amazon .com and Google.com are two great sources for a world of information for modding our Wicked Edge Set-ups

Marc

(MarcH's Rack-Its)08/30/2019 at 12:08 pm #51738Amazon .com and Google.com are two great sources for a world of information for modding our Wicked Edge Set-ups

Well, I mainly wanted clarification on what an RC boot actually was.

08/30/2019 at 12:25 pm #5173908/30/2019 at 12:31 pm #51741Thanks Mark, I would have never found those if I spent a month trying!

08/30/2019 at 12:39 pm #51743IMO, with persistence, ingenuity and Google.com anything can be found!

Marc

(MarcH's Rack-Its)09/02/2019 at 8:47 am #51772I’ve had some questions concerning what is included in the micro angle adjustment kit. I also wanted to post a detailed picture of how the kit is assembled.

The mini L brackets in the top of this first picture are not included! They are there just to add size perspective.

Those who have the Gen 3 Pro model will not need the spring loaded L lockdown screws.

Rubber axle boots are available by request.

The first small picture, (below) shows my assembled adjuster with boots. Because I cut about 1/2″ off of the ball joint end I added a jam nut to the mod for those users who feel it’s needed to keep the guide rod locked tight into the shorter cut ball end. You may opt to not use it as the rod does tighten without one.

Reducing the ball joint end allows the paddle to be lower relative to the blade edge. This helps a lot on the Gen 3 model when sharpening smaller (edge to spine) pocket knives.

I use two jam nuts on the outer knob, which is probably overkill as well. It will work well with only the single inside jam nut.

When using the spring loaded L screw, I’ve found that flipping the angle bar 180 degrees is how I like it best. This puts the now, not needed, angle positioning detents, on the back side and the smooth face to the front. This gives unlimited course angle adjustments with positive lock-down, by turning the handle from a 9:00 position to a 3:00 position, (after the handle’s positioning has been adjusted with the spring lock). I’ve never had my angle bracket loosen up or move with this setup. Others prefer to use the spring loaded L screw inserted into the screw on the backside of the L bracket avoiding the need to even rotate the square bar.

Not easy to see in the photos, but the plastic knobs have plastic covering the pressed in nut on one side. On the other side the steel nut is visible. I put the plastic covered side facing inward to make contact with the L bracket. Again, I’ve never had my micro adjustment loosen up during sharpening. And, it doesn’t take much force to get positive lock-down.

Ed K.

-

This reply was modified 5 years, 8 months ago by

NotSharpEnuff.

NotSharpEnuff.

-

This reply was modified 5 years, 8 months ago by

NotSharpEnuff.

NotSharpEnuff.

-

This reply was modified 5 years, 8 months ago by

NotSharpEnuff.

NotSharpEnuff.

-

This reply was modified 5 years, 8 months ago by

NotSharpEnuff.

NotSharpEnuff.

-

This reply was modified 5 years, 8 months ago by

NotSharpEnuff.

NotSharpEnuff.

Attachments:

You must be logged in to access attached files.

6 users thanked author for this post.

09/02/2019 at 10:41 am #51783I just wan to help clarify with photos, Ed K’s post above:

The Gen 3 Pro does not utilize the locking “L” handles because the angle settings are controlled and locked by the central lever:

The WE120 and WE130 use “L” brackets sliding on the square to determine the sharpening angles. There are the new mini “L” brackets Ed has in the top of his posted photo and the older larger squarer “L” brackets W.E. used in older version models. Both of these “L” have threaded screw holes in the front and the rear allowing the single “L” bracket design to be used on both sides of the square bar, just the same. Therefore the “L” handles can be used in the backside threaded hole just the same as the front side threaded hole, to lock on the flat rear side of the square bar eliminating the need to remove then rotate the square bar to bring the flat side facing forward. The choice where you prefer to utilize the locking “L” arms is the user’s preference.In the photos I am using the locking “L” handles with the flat bar still in it’s original position with the flat side to the rear. I prefer the “L” handles out of my way facing back.

I am using the older first version of Ed K’s Micro-Angle adjuster locking Mods, he first made available. (These were originally conceived and created by tcmeyer, I believe). This old version was much more costly, parts wise and more labor intensive for Ed to produce. Since I started using them, Ed has been able to source and make available a more economical mod that functions just the same. Now Ed sources the less expensive components that are easier for him to fabricate so he is able to pass the cost savings on to the users. I have used the black plastic models he now offers and they work just the same as intended. I find the single jam nut on the inside of the coarse angle adjuster knob is all that I need. While others are more comfortable utilizing multi jam nuts. User preference.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

09/03/2019 at 2:47 am #51809Did I see somewhere a pic of someone’s WEPS, with the ball joint coupling shortened, so as to allow for a longer stroke range? This was maybe three or four months ago, and I had the impression that the shortened couplings were supplied that way by WE?

Clay, if you’re reading this, have you tried the mods described above? I’ve noticed that you’ve moved the knurled jam nut to outboard of the L-bracket and am wondering if you’ve thought about also adding the outboard adjustment nut.

BTW, most of these mods were born out of my difficulty in tightening the smallish black plastic screws, for locking the L-bracket to the angle bar and locking the micro-adjust, although the latter was less of a problem.

I don’t recall who was the first to implement the locking handles for the L-brackets. Wasn’t me.

-

This reply was modified 5 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.