JS

Forum Replies Created

-

AuthorPosts

-

05/12/2015 at 1:27 am #25578

I think mine is starting to get pretty bent out of shape to the point it needs replacing. Are the WE guys out of town right now? I tried sending a couple emails to customer service last week and haven’t heard anything back yet.

It’s been crazy around here with the move, implementing new inventory software and getting ready for a couple of shows. All lame excuses aside, I’ll make sure Kyle gets right back to you.[/quote]

No worries, Clay. I figured something big must be going on right now as you guys have always been lightning fast in responding to emails. As always, I appreciate you guys’ help.05/11/2015 at 6:46 pm #25567I think mine is starting to get pretty bent out of shape to the point it needs replacing. Are the WE guys out of town right now? I tried sending a couple emails to customer service last week and haven’t heard anything back yet.

04/21/2015 at 4:17 pm #25337Is the bottom knife a SOG Seal Pup?

Yes, it is.

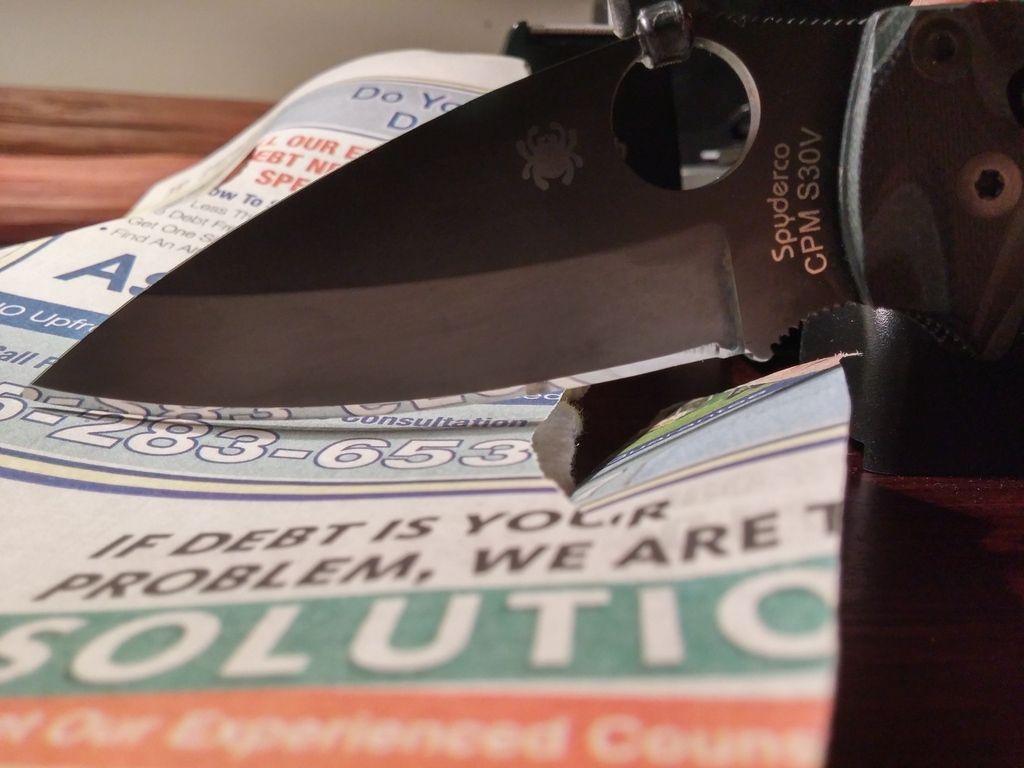

04/20/2015 at 6:02 pm #25315Here are a couple from over the weekend.

The first was a true example of making chicken salad out of chicken (scratch), and I wish I had a before pic. The owner had nearly destroyed the blade with a grinder, and the edge was literally an S. Therefore a decent bit of work was needed just to get a straight and consistent edge. I personally would’ve sent it in for a new blade, but this one has been revived for now.

And another…

04/20/2015 at 5:53 pm #25314I’ve tried different things based on where the knife was finished. I had a PM2 that I sharpened to 15 dps and 0.5 micron and whittled a bunch of wood. The edge got some small rolls in it so I put it back in the vise and started at 5, 3.5, 1, and 0.5 micron and I got my hair whittling edge back with no rolls.

Have also had knives I’ve finished at 1000 grit that were not clean paper slicers after some use. Put it in the vise and only about 5-10 light swipes with the 1000 grit brought it back to original sharpness.

2 users thanked author for this post.

04/18/2015 at 9:54 pm #25302Yep I’d only sharpen other people’s knives on the WEPS no doubt.

I have to admit that I love the factory edge that Spyderco puts on their knives. I’d guess a 220 to 400 grit belt with maybe a light buff? I’m not sure about the buffing since I saw a Spyderco factory video the other day that showed a robot actually sharpening the blades. But those edges will wave cut phone book paper no problem but are plenty toothy. I haven’t been able to sharpen too many of my own knives lately but have wanted to try and re-create that edge.

I’ve heard about some gimmick called a Surgi-Sharp that’s supposed to be some kind of angle guide for belt sanders but don’t think it’d be too difficult to make one.

04/18/2015 at 5:12 pm #25298Yep I went ahead and ordered some new ones yesterday and should have them Monday.

I have toyed around with the idea of getting a 1×30 belt sander. I understand Harbor Freight has them relatively cheap. It’d take a lot of practice, but the idea was if I have a blade that needs repairing with a bunch of chips or needs reprofiling, I could run it across the sander and then take it to the WEPS to finish. Do you guys use some kind of angle guide to keep a consistent angle on a sander?

04/17/2015 at 9:54 pm #25287Sweet edge I put on my buddy’s Boker!

Sent from my iPhone using Tapatalk

Nice! What’s your progression?

04/17/2015 at 9:37 pm #25284So you’re saying I’ve probably gotten my money’s worth out of them? Lol

I was sitting here thinking of ordering a new set from Oldawan (just who I’ve always used in the past) and wishing I’d done it earlier in the week as I have a ton of sharpening to do this weekend.

I’d think my old 100/200s would be good to have around as a good progression after the new 100/200s before moving on to the 400s

Never thought about apexing with the 50/80s and then running a 1000 grit stone over. I did make the mistake a long time ago of apexing with them and then progressing all the way up to the 600s without visually examining the edge with a loupe. I noticed after the 600s it just didn’t feel as sharp as it could be. With close inspection I had a ton of tiny microchips. Good learning experience.

When you apex with the 50/80s are you skipping the 100s and going straight to the 200s to apex?

04/17/2015 at 5:16 pm #25276Just my experience so TIFWIW. After the 1000s I only have the 1200/1600 ceramics along with the 5/3.5 strops and kangaroo strops that I have 1/0.5 CBN spray on. I haven’t polished any of my own blades in awhile as I prefer a toothier edge, and I’ve never lapped my ceramics, just occasionally rub them together.

I have somewhere between 175-200 knives on my stones (I think I need to finally break down and get some new 100/200s) so I have a very very fine finish coming off the 1000 grit. Something I have noticed especially when doing a wider bevel is that even if I use the angle cube on the ceramics to match the angle I’ve been sharpening at, when I match the angle exactly, the ceramics seem to only hit the shoulder portion (upper part of the bevel). It gets very sharp, but only a strip along the shoulder gets polished. I’ve found that in the end, I usually have to widen the angle by about 2 complete turns of the micro adjust to hit the rest of the bevel. Doing this, I’ve been able to achieve better results with my setup. It’s also something to take notice of if you drop your angle 2 degrees to strop and the goal is an extreme polish.

With my setup, the key is spending some quality time on the ceramics making sure the entire bevel is getting attention. I’m sure if I had the 14/10 strops and the micro fine ceramics I could get even better results, but in the end I have to hold the knife under light at a certain angle to see any scratches and they’re very very faint.

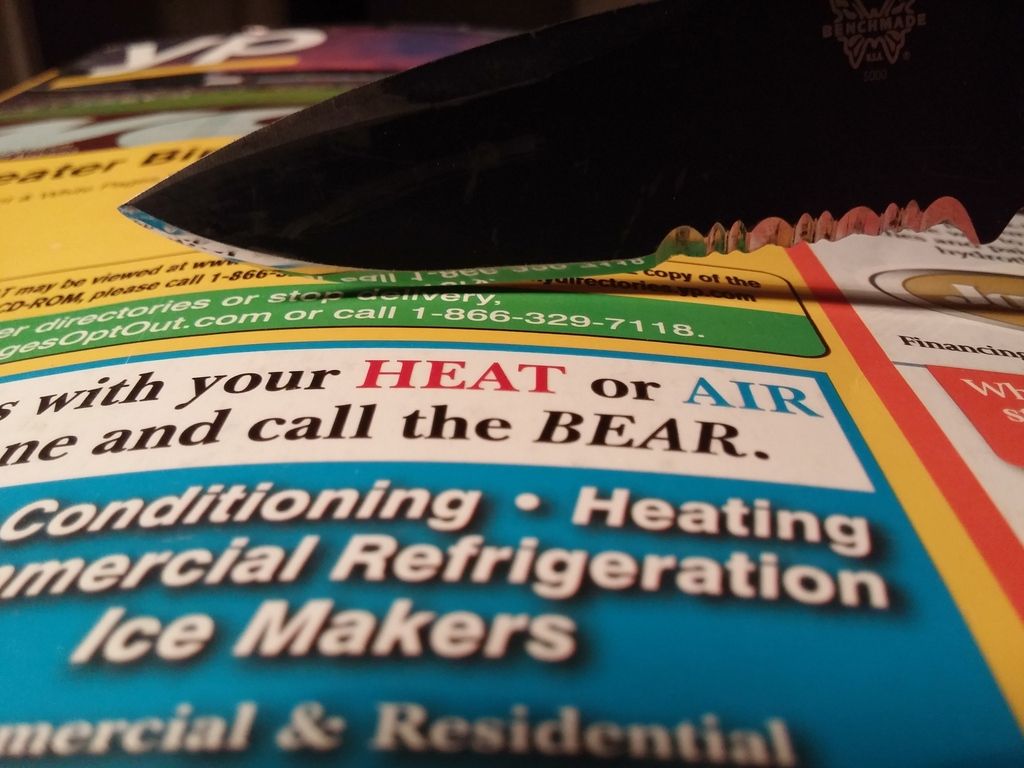

So patience and technique are the keys along with figuring out the little tricks and paying attention to little details such as if you’re hitting the entire bevel. Here is one of the recent knives I’ve done with my setup so I know much better results are possible.

04/11/2015 at 5:49 pm #25186Yes, break it up into 2 portions. When doing the tip mount it parallel to the tops of the vise jaws. Yes your depth key will be useless here, but I believe this is by far the best way to sharpen a tanto on the WEPS. There is plenty enough clamping force to keep the blade steady.

I sharpen all tantoes this way and feel it’s the best way to keep the sharp transition between the main edge and tip.

04/05/2015 at 8:02 am #24992Comet, Bar Keepers Friend. Probably some other methods out there too.

04/05/2015 at 6:19 am #24990Welcome to the forum. I think the 50/80s are a great addition. I’m kinda meh about the eraser though.

04/05/2015 at 6:16 am #24989You could possibly have some microchipping at the edge, or either you didn’t fully apex the edge. A loupe will work wonders for you.

04/02/2015 at 11:09 pm #24937Very nice job!

-

AuthorPosts