Pinkfloyd

Forum Replies Created

-

AuthorPosts

-

01/20/2023 at 1:49 pm #58375

Nice Setup!

1 user thanked author for this post.

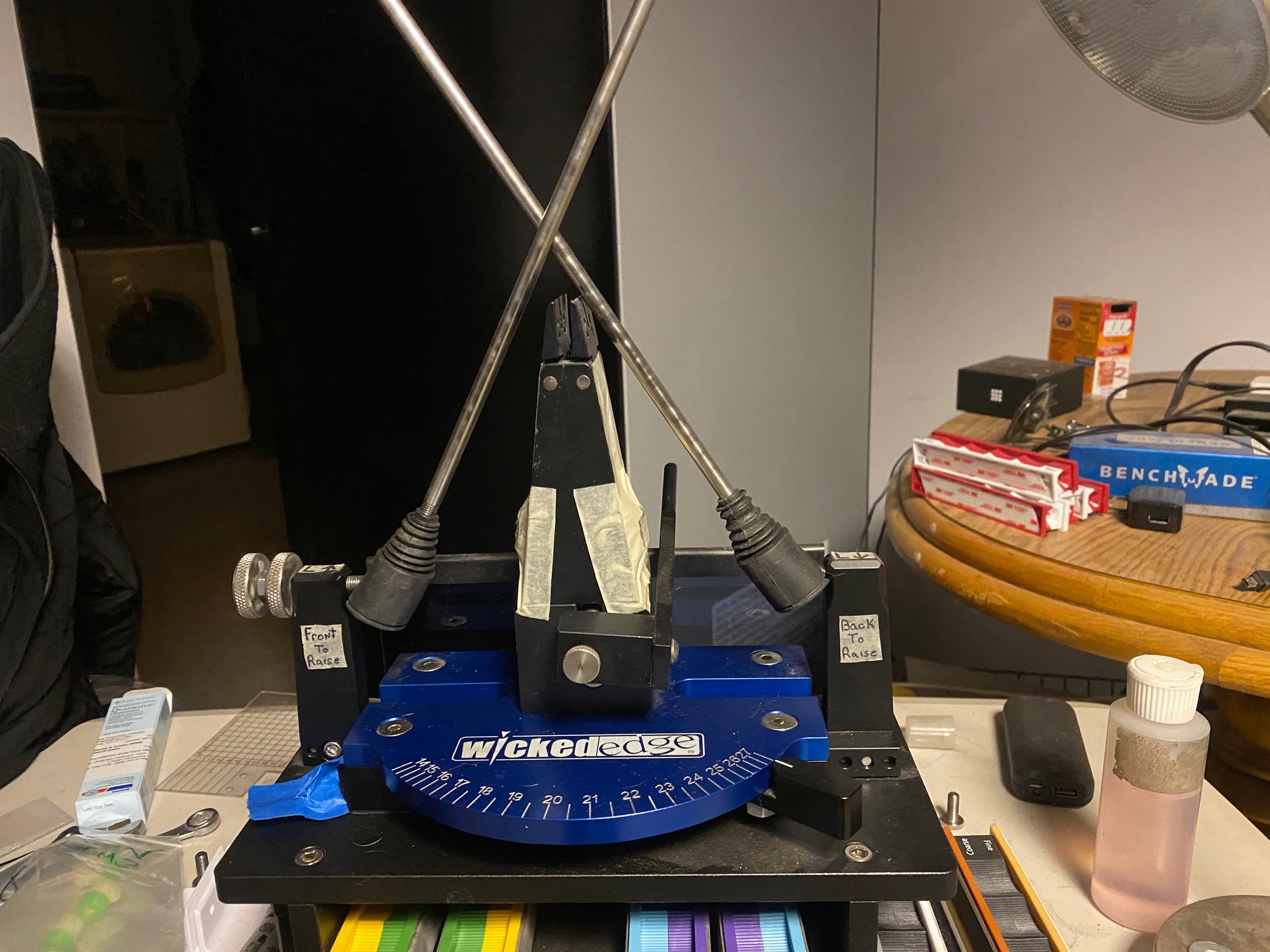

12/06/2022 at 9:30 am #58278The WE66 is a very solid sharpener. Really liked the split clamp jaws, they clamped everything i had to put in them. Very nice kit!

1 user thanked author for this post.

11/12/2022 at 6:20 am #58248Tom,

Nice find, really nice scope for that price. when i got mine they replied if i would write a review they would send their “Professional Aluminum Alloy Scope Base”

Works really well with the scope

-

This reply was modified 2 years, 3 months ago by

Pinkfloyd.

Pinkfloyd.

05/13/2020 at 6:26 pm #54235I have been using a soapy solution while sharpening, first with my EP Pro, now with the WE system (now going on 6-7 years). Not only for the dust, I believe its smoother with the soapy solution. I only use about 2 drops, spread it on the stone with an acid brush, then clean the brush in a cup of water so as not to cross contaminate.

5 users thanked author for this post.

03/18/2020 at 8:14 am #53771Tom,

WE OEM ball joint has a smaller diameter rod than the threads, it is on the inside of the adjustment knob. Which doesn’t hinder the circular range of motion while sharpening. I wasn’t looking for more degree adjustment, just my sharpening motion not being dimisished. Hope that makes sense

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

03/17/2020 at 4:45 pm #537625. Shows modded Micro adjust installed.

6. Shows incresed range of motion with both modded Micro Adjusters installed.

7. Shows setup for working on one of Ed’s Micro Adjusts.

8. Shows difference between Ed’s original, my mod.Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

03/17/2020 at 4:43 pm #53756I purchased Ed’s Stainless Steel Micro adjust mod for my Gen3 Pro, very nice!

I did make a mod to them though (hope Ed doesn’t mind me posting). When i installed i noticed my range of sharpening motion and max angle had decreased, found out it was due to the all thread rods threads hitting on the outer rim of the ball joint. At first i made new rods and used the edge of a flat 1/8″ fine file to remove the threads. I was also able to file the threads away on Ed’s Micro Adjusters also. I have attached pics of what i did

1. Shows Micro Adjust mod installed on left, OEM on right. Shows range of motion with coares adjust at 24.5.

2. Shows Micro Adjust mod installed on left, OEM on right. Shows range of motion with coarse adjust at 27.0.

3. Shows how much thread was removed.

4. Shows All thread rod i made.Will have to add other pics in a second post

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

01/02/2020 at 7:06 am #5286812/05/2019 at 7:38 pm #52668IMO re profiling, a bevel can be very time consuming and possibly frustrating in the amount of time it takes. It can be done quicker with the 50/80 diamond stones, but will still take quite awhile. I think a more powerful loupe would be more beneficial, a usb microscope even better. Some users even use the 1000 or 800 grit diamond stones to run on the blade edge a couple of times to dull before sharpening. Also the magic marker on the bevels of the blade is a great way to see your progress to the apex of the edge. I believe you are on the right track for Honing your skills(pun intended), just be patient, thorough with your sessions. Good luck, Good will to ya. Have Fun!

06/26/2019 at 7:05 pm #50829That is insane! In a good way.

Very nice

1 user thanked author for this post.

04/20/2019 at 2:46 pm #50256Welcome Chuck,

I only raise a burr with the first set of stones. First one side raising a burr counting the strokes, then raise a burr on the other side with matching number of strokes. Then go back to the first side and lightly remove that burr with one or two strokes, then the other side with one or two light strokes. Then a couple of alternating light strokes to finish, then move onto next higher grit with alternating strokes.

3 users thanked author for this post.

04/17/2019 at 1:58 pm #50220Clay,

I think it would take more than 1 model, Gen3 Pro, We130, WE120. Attached is a crude representation of what i am thinking on the Gen3 Pro. It is 12 inches high, 16 inches long. I think a grid pattern with 1/8 inch graduations, 1/4 inch would probably work also.

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

04/16/2019 at 6:31 pm #5020204/05/2019 at 9:19 am #50051Looking to upgrade to the new handles for a strop set for the Gen 3 Pro vice. Listed is planned progression. For the 4,2 micron strops i was thinking on ordering cow leather for the blank handles i already have. For the 1, .5 micron i was thinking cow leather again. Thoughts?

For the .25 micron, .125 micron. Kangaroo leather, or Nano-Cloth? What are your thoughts

For the .050 micron, .025 micron. Kangaroo leather, or Nano-Cloth? What are your thoughts

4 Micron Polycrystalline Diamond Emulsion & 2 Micron Polycrystalline Diamond Emulsion & 4 leather strips for set of new handles i already have.

1 Micron Polycrystalline Diamond Emulsion & .5 Micron Polycrystalline Diamond Emulsion & leather strops

0.25 Micron Polycrystalline Diamond Spray & 0.125 Micron Cubic Boron Nitride Spray. Kangaroo or Nanocloth?

.050 Micron Polycrystalline Diamond Spray & .025 Micron Polycrystalline Diamond Spray. Kangaroo or Nanocloth?04/01/2019 at 4:21 pm #49957Richard,

I too came from the Edge Pro, I have the Pro model. It is still a very good and capable sharpening system, but since i purchased the WE system that is now my go to sharpener.

Airscapes,

Very nice recommendations, advice. Sounds spot on

2 users thanked author for this post.

-

This reply was modified 2 years, 3 months ago by

-

AuthorPosts