Bill Kirkley

Forum Replies Created

-

AuthorPosts

-

04/01/2022 at 7:22 am #57761

I will try an edited video again.

trim.4559201F-2F4A-4C77-846D-E9874C1CA1B8

Attachments:

You must be logged in to access attached files.

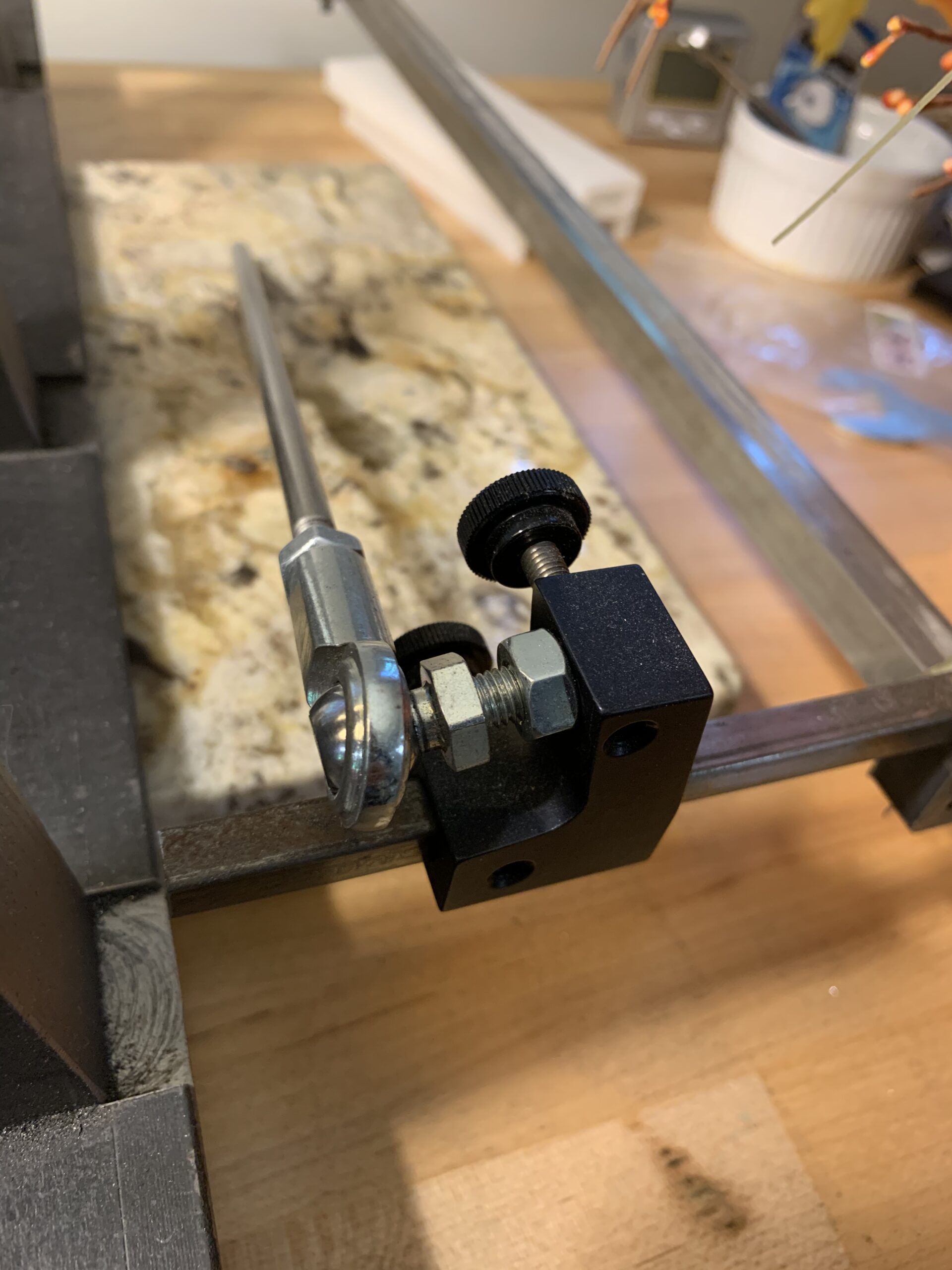

04/01/2022 at 7:18 am #5775707/21/2020 at 12:25 pm #54644I may be missing something, but a simple solution is to add a nut and tighten it against the hex key.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

02/20/2020 at 4:48 pm #53588Interesting. Thanks.

02/20/2020 at 3:49 pm #53586I have been under the impression that a steel has nothing to do with sharpening. It merely straightens the edge which bends over with use.

12/09/2019 at 2:04 pm #52684As tcmeyer pointed out, in the past people have had a variant of 1/2 degree and ended up with a good result.

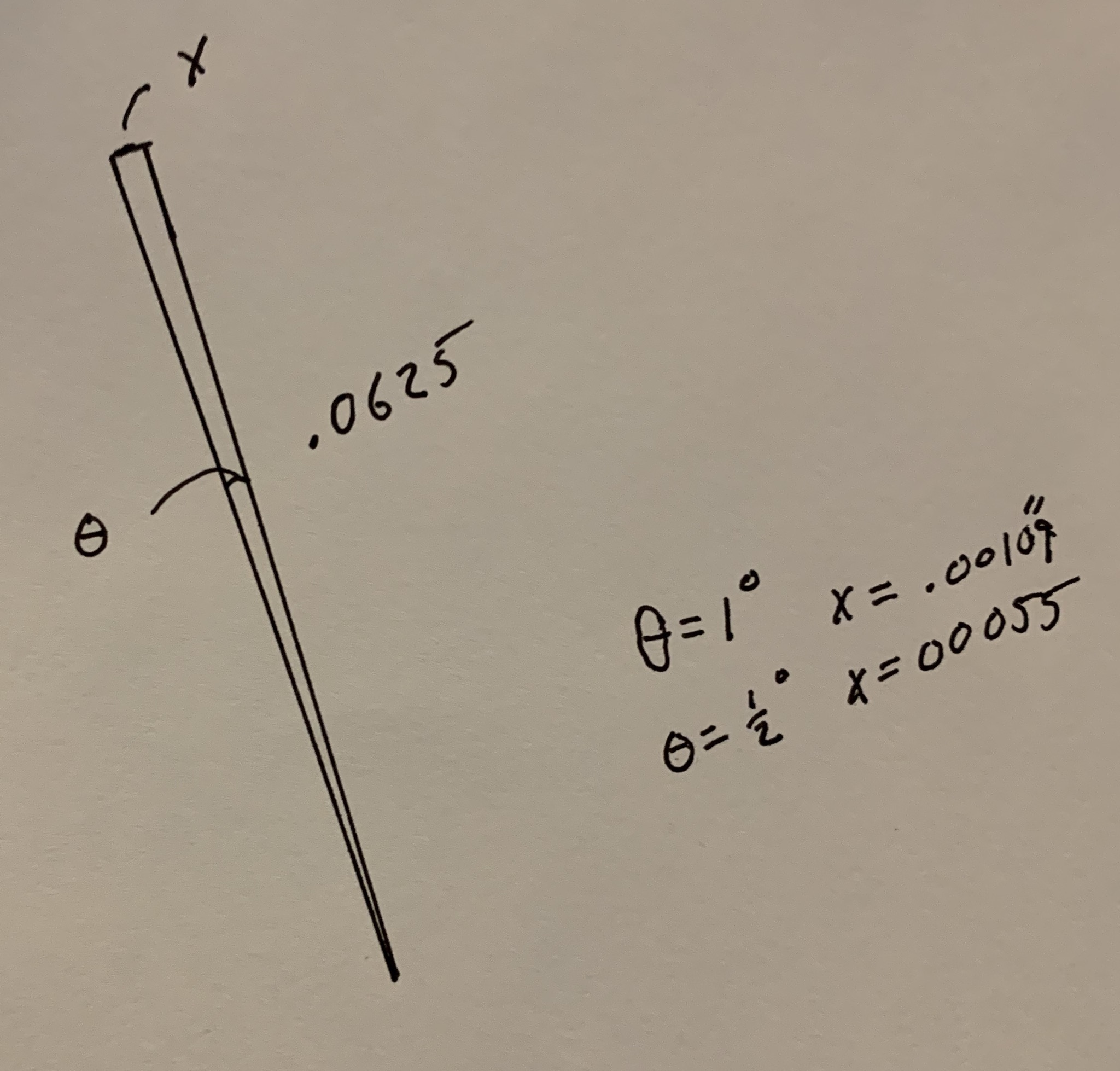

As the attached photo illustrates if your secondary bevel is 1/16″ and you are off one degree between stones you only have to remove .001″ material to creat a burr if you are off – 1 degree. If you are off + 1 degree you would get a burr right off.

Being off one degree might mean some extra strokes to remove the material, but weigh that against the time it takes to check and reposition your stones.

In the end, as long as you creat a burr between stones you should be good to go.

-

This reply was modified 5 years, 3 months ago by

Bill Kirkley.

-

This reply was modified 5 years, 3 months ago by

Bill Kirkley.

-

This reply was modified 5 years, 3 months ago by

Bill Kirkley.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

11/26/2019 at 8:13 am #52598I don’t have the Tormek. I wasn’t aware of it when I researched and ultimately purchased a WE. If I had it to do over again I’d get the Tormek for the following reasons.

1. It’s quicker, and gives a good edge.

2. It’s stone will last my lifetime.

3. It’s safer.

4. It will sharpen almost anything.If you are an edge fanatic and love the act of sharpening I’d get a WE.

If you sharpen as a business I’d get the Tormek. It’s quicker and apparently gives a good edge.

-

This reply was modified 5 years, 4 months ago by

Bill Kirkley.

1 user thanked author for this post.

08/18/2019 at 9:37 am #51538Someone may have already suggested this. I “sharpened” a piece of mild steel flat bar to break in my new stones.

06/26/2019 at 6:45 am #50819Nice job! You might consider first clamping your blade in one vice, loosen the screws that mount the second vise, clamp the blade in the second vise and finally retighten the mounting screws of the second vise. If you don’t do this, if your vises aren’t perfectly aligned you may deflect the blade when you clamp it in the second vise.

06/25/2019 at 9:15 am #50800Expedia, I haven’t looked but I don’t know if you can find stainless with a diameter of .257″, although I think tcmeyer may have, judging from an earlier post.

As for rusting, if you are not lubricating your stones with water the tool steel probably wouldn’t rust. A coating of paste wax from time to time may help as well.

Depending on how sharp the texture is it might cause wear. The diamond stones are textured.

Maybe someone can post a magnified photo to see how “smooth” the textured finish is.

-

This reply was modified 5 years, 9 months ago by

Bill Kirkley.

06/25/2019 at 6:33 am #50793tcmeyer. But aren’t steel shafts smooth? I have not seen the new rods. They are described as rippled. One might describe a round file as rippled. It would be interesting to post a photo, made with your microscope, of the ripples to see if they are smooth or sharp

-

This reply was modified 5 years, 9 months ago by

Bill Kirkley.

1 user thanked author for this post.

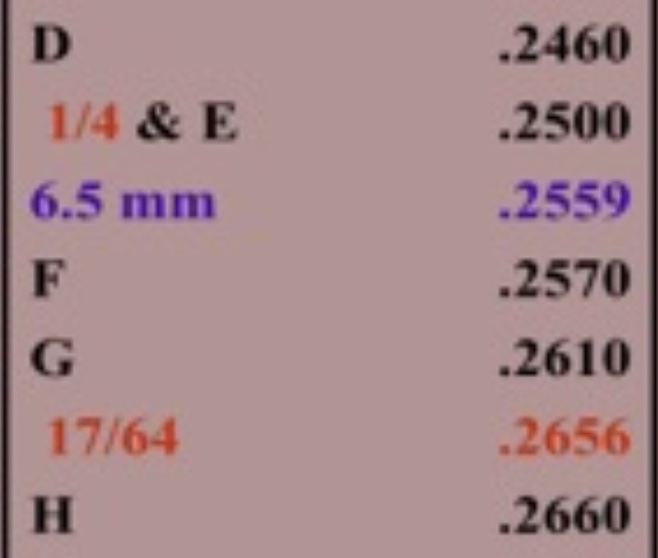

06/24/2019 at 8:09 pm #50789If you want slightly larger than .25″ and don’t mind a steel that might rust you can order drill rod in metric or letter sizes.

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

06/24/2019 at 3:11 pm #50786My WE is several years old. The stones are mounted on plastic. If the current stones are plastic and the new rods “rippled” to the point of vibrating when the stones are used wouldn’t this create wear on the holes in the stones, resulting in a loose fit over time?

1 user thanked author for this post.

06/09/2019 at 2:08 pm #50624Thanks Organic!

06/09/2019 at 9:15 am #50622I looked at Tom Veff’s video on his serrated edge sharpening rods. His diamond coated rods are a single grit. The WE system goes through a series of grits. Why the difference?

-

This reply was modified 5 years, 3 months ago by

-

AuthorPosts