resin bonded diamond stones?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Abrasives › resin bonded diamond stones?

- This topic has 16 replies, 5 voices, and was last updated 11/25/2021 at 6:09 pm by

Henry.

-

AuthorPosts

-

12/18/2020 at 3:56 pm #55461

Hi everyone and welcome to my quest for the wickedest edge in Massachusetts.

I’ve been a whetstone freehand sharpener for decades and am looking to finally get with it and move to a guided system for precision, accuracy, repeatability, and possible to make a few side-hustle bucks to maybe cover the hobby expense or at least bring joy and delight to people who will see what a sharp and durable knife really is.

Anyway, I’ve been enchanted with the WE system for a few years but just haven’t pulled the trigger. I was frankly ready weeks ago during the sale, but WE has been all sold out every time I checked in. I’m hoping Clay will cut me a break and offer same pricing when systems get back in stock… however, the point of this posing is to ask if anyone’s familiar with resin bonded diamond stones and if WE had any plans to bring that offering to the ecosystem.

Everything I’m reading about resin bonded diamond stones seems fantastic. Longer life, embedded diamonds rejuvenate (as long as very little pressure is used), a much more polished and refined finish, smother and faster cutting, and the Chosera whetstone user feedback. You know, when you’re sitting on a good stone the stone and knife resonate like a fine violin and sing a pleasurable note back when you’re playing the system well… ok, maybe I’m not a poet, but there is lot to be said for stone/knife feedback.

Can anyone comment on resin bonded diamond stones and does anyone have any idea if WE intends to add these to the ecosystem?

with sincere advanced thanks,

1 user thanked author for this post.

12/22/2020 at 5:13 pm #55498I know nothing about them, but it sounds very interesting. Hoping someone else who does know will post an answer. Thanks

12/23/2020 at 8:02 am #55501Thanks for the note Roger. I wouldn’t think many on this forum use this as it seems to be in a format for the “other” big 3 style guided sharpeners. With that being said, every review comes just short of calling this format miraculous.

I look forward to any input.

04/07/2021 at 5:19 pm #56537This is my latest “concept project”. I was curious if this type of diamond stones were any good. Henry, the original poster certainly seems impressed by this diamond sharpening medium. They seem very cool. It’s a good idea to be able to refresh the abrasive surface. Still, I found myself with mixed feelings after digesting everything I could find to read about them. Afterall, these still are diamond sharpening stones which I’ve found through experiences aren’t always the best choice of sharpening medium to use with every steel. Especially with the super hard, more brittle, Japanese steels. These sometimes suffer from carbide bust outs with diamond sharpening stones.

I couldn’t get the stone’s maker of these Diamond Resin Matrix sharpening stones to make me a set that would be sized to mount on Wicked Edge paddles. So I worked with what I could get. I just finished making the set and haven’t even tried them yet. I still have some other projects I’m in the middle of so it’ll just have to keep till I have time to sit down to sharpen some knives.

Here’s some pictures of the set I made. It was a fun project!

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

04/07/2021 at 5:51 pm #56547Hi Marc,

You’ve been busy it seems! I guess my idea resonates enough with you to invest a few bucks (or more) and a lot of time to put these together.

They look fabulous. Well done?

Thanks!

I look forward to your expert feedback!

good luck and thanks again for taking the effort!

-

This reply was modified 4 years, 5 months ago by

Henry.

1 user thanked author for this post.

04/07/2021 at 7:07 pm #56549Just trying to stay on “the cutting edge” with the Wicked Edge. Pun intended!

Marc

(MarcH's Rack-Its)04/07/2021 at 8:08 pm #56550Marc, you crack me up. You must be “wicked sharp”!

04/07/2021 at 8:08 pm #56551From boston area here where everything is wicked edgy!

04/13/2021 at 3:13 pm #56562This is my latest “concept project”. I was curious if this type of diamond stones were any good.

That looks expensive. You must be quite a perfectionist to not just use his 4″ stones. https://www.cgsw.us/1×4%20Resin%20Bond%20Diamond%20Stones.html

-

This reply was modified 4 years, 5 months ago by

Mr.Wizard.

04/13/2021 at 3:54 pm #56564I wanted these Diamond Matrix stones to be sized similarly to all my other W.E. handles. That way I can better compare the abrasives because all factors considered, my sharpening strokes, methods and techniques should stay pretty much the same.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

04/14/2021 at 4:41 am #56565From boston area here where everything is wicked edgy!

And wicked edgy when referring to the prices as well! Wife and I were there in ’94 for proton beam treatments at Harvard. I think I paid $18 to park for a 20-minute breakfast near Harvard Square. Otherwise, a great time.

04/24/2021 at 4:16 pm #56633Hey Marc,

i hope you’re well. I’m looking forward to hearing any feedback on these stones, -pun intended.

1 user thanked author for this post.

04/29/2021 at 8:45 am #56665I finally made the time to use the Resin Bonded Diamond Matrix Stones. I did my first knife with them last night. I had to sharpen this knife. My barter guy who trades me food for services brought me “Gulf of Mexico” fresh fish, (snapper and grouper) for sharpening his knives. He showed up with an awful knife and two bags of fresh frozen seafood delight.

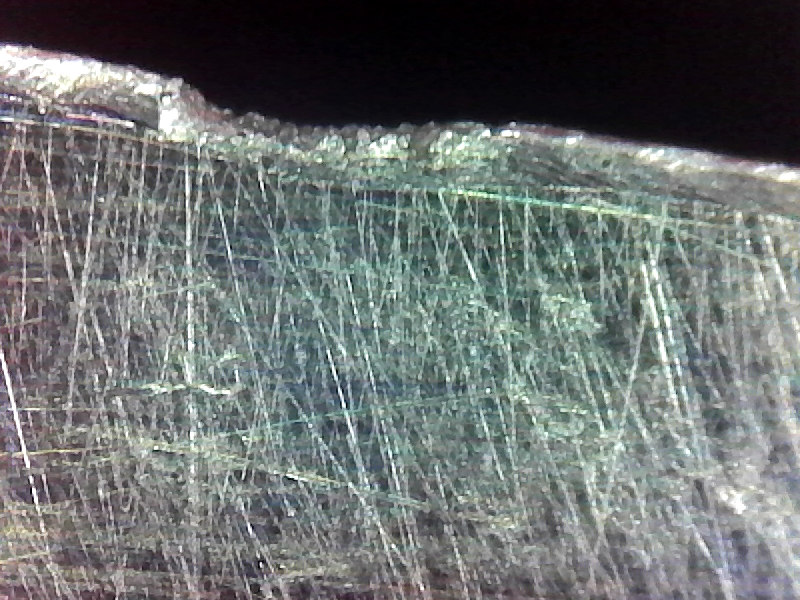

The knife was an absolute disaster. From the look of the torn edge he’s been sharpening it again with a pull-through carbide “V” sharpener. Those are only good for tearing the sh*t out of a knife edge. Here’s a couple of before photos:

As you can see by the longitudinal scratches, gouges and the bevel tear-out that the carbide sharpener can destroy a knife’s steel. This knife is a German Forshner boning knife, (X55CrMo14 steel, HRc 56). The steel is well suited for fish bones. It looks like this knife is visiting the dishwasher too. The Rosewood handles is bleached white, dried out and cracking. What a shame.I started with the 80 grit coarsest Diamond Matrix Resin Stone, (DMR). The stone feels like a hybrid between a whetstone and a diamond stone. They are non-magnetic like whetstones so I used “airscapes” Non-Magnetic Stone adapter. These adapters are perfectly suited for this application.

I spritzed DMR stones with a mist of soapy water. Your choice, wet or dry is suggested by the stone maker. There is no break-in period for these DMR stones. Some of the time and grits I spritzed, and other grits I left it dry. To help decide which way they worked better for me.

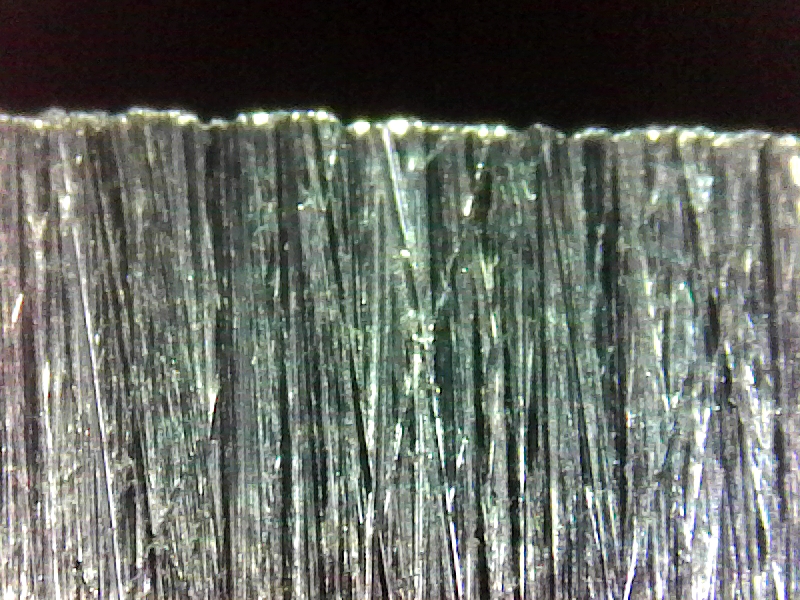

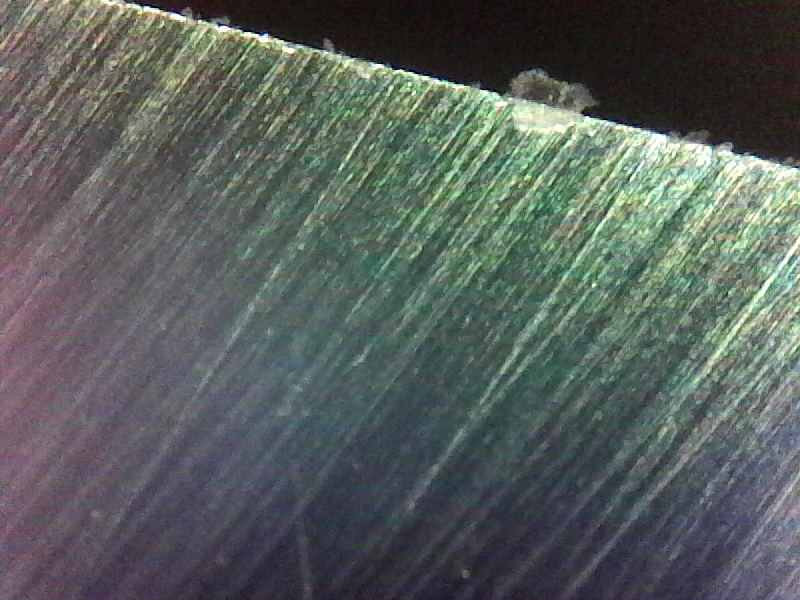

The 80 grit DMR laid a scratch pattern down very similar in width and depth to a well broken-in 50/80 W.E. Diamond stone we use for a reprofiling. When there’s a lot of damaged steel to remove.

The DMR has a softer feel and a more subdued or dampened down grating noise against the knife steel. I believe the scratch pattern is more uniform and more consistent then the W.E. diamond stones. The 80 grit DMR stones don’t seem to make as must steel dust as the W.E. diamond stones either. But the spritz of water may well be the reason for that. Keeping the steel dust wetted down.

It did take some time and effort to get through the 80 grit DMR till I was ready to move on up a grit. Even though the DMR left a nice scratch pattern very similar to the W.E.’s diamond pattern I kind of think the DMR is less aggressive and seems slower to use. I found myself wanting to apply a lot of pressure trying to get some feel or feedback for the steel removal. Here’s the results from the 80 grit reprofiling to 18º:

I followed this up through the complete DMR stone progression: 80, 250, 650, 1100, 2300, then 4000 grit.I’ll continue on the next posts with photo examples of each grit’s results in the progression.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

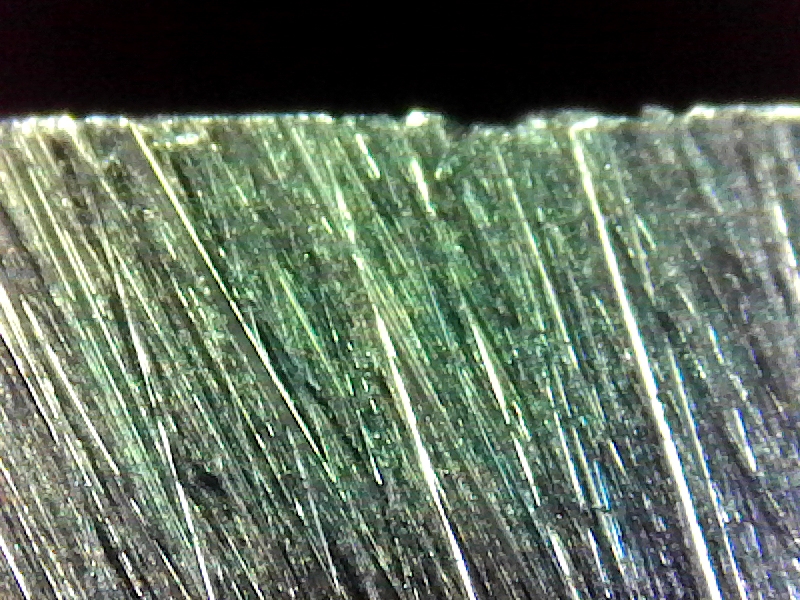

04/29/2021 at 2:56 pm #56681Here are photos from the end of working with each grit when I was ready to move up to the next finer DMR stone. They were taken at high power, 250X, with the Plugable USB scope at 800×600 resolution.

Here is the 80 Grit:

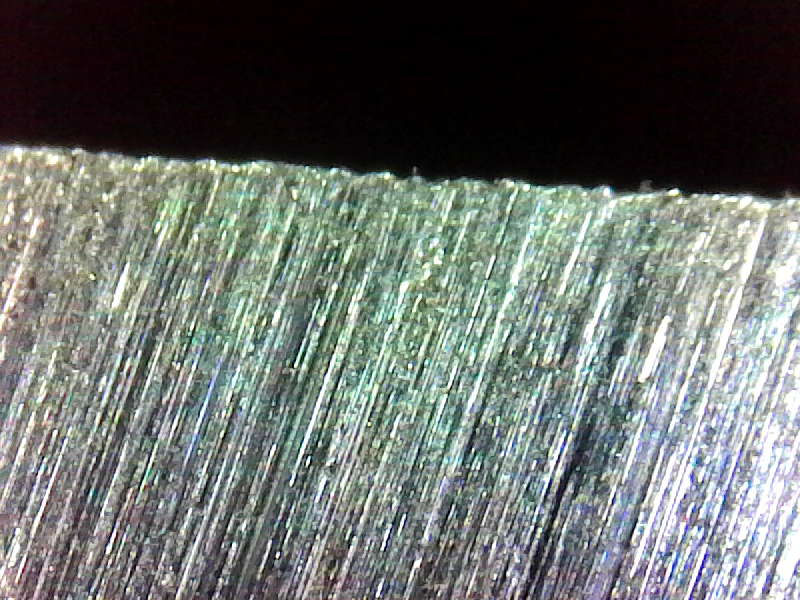

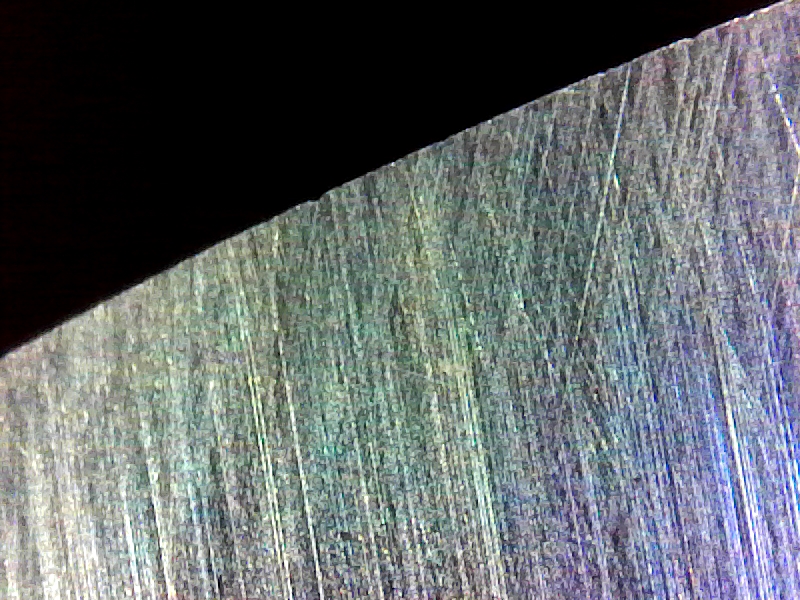

This is the next grit in the sequence, 250 grit:

I’d say this DMR 250 grit scratch pattern is very similar to the a well broken in W.E. 200 or 400 grit stone.

This next photo is the DMR 650 grit:

I find this scratch pattern pretty similar to the W.E. 600 diamond stone.

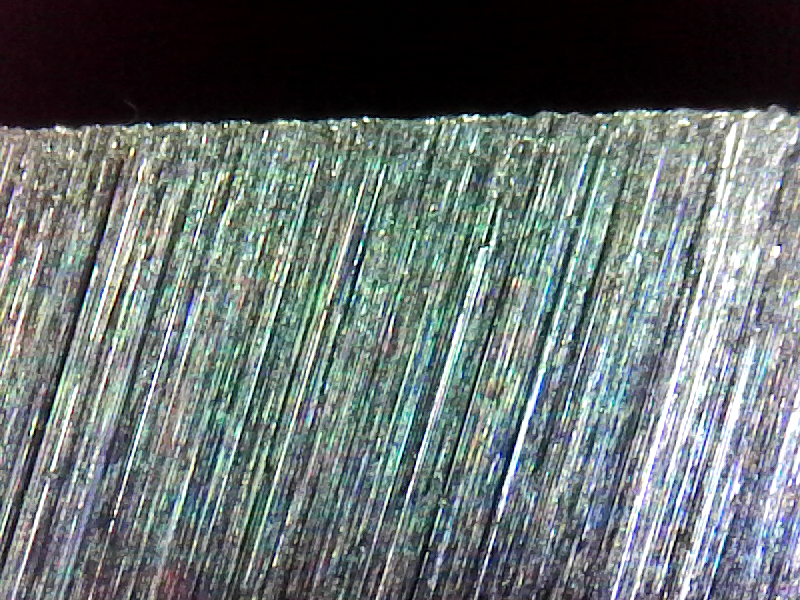

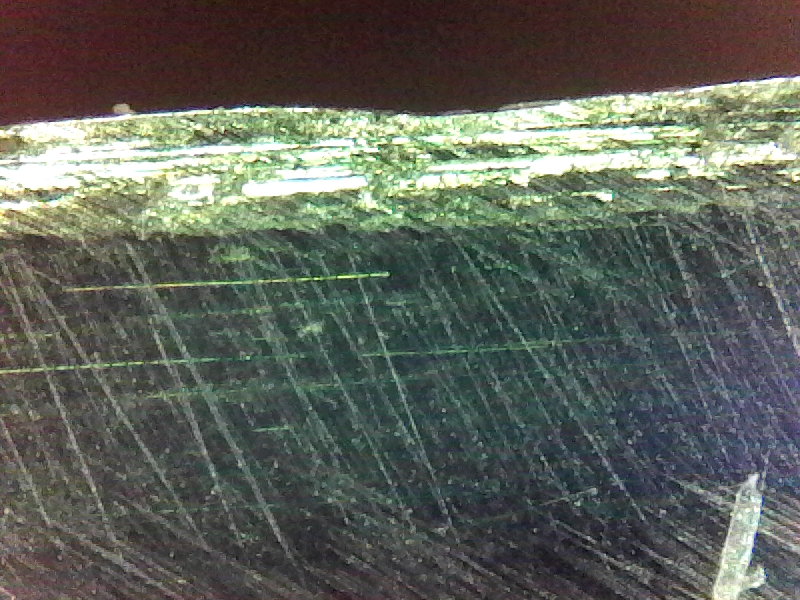

This is the next stone. The DMR 1100 grit:

As you can see the scratch pattern is pretty consistent and evenly spaced apart and even appearing in scratch depths. I think it’s pretty similar again with that seen with the W.E. 1000 grit diamond stones. Although, maybe more linear and defined. I will remark that the feel using these DMR stones is different then the W.E. stones. It’s more like a softer or padded feel. The feel of directly scratching solid steel and the grating feeling of diamonds against steel is now more subtle. It’s almost dampened down with the DMR stones.

This next photo is the 2300 DMR:

I don’t see any great differences in the scratch patterns as the grits get finer and finer. They do appear thinner and shallower. The consistency in the patterns appearances from one grit to next is remarkably similar.

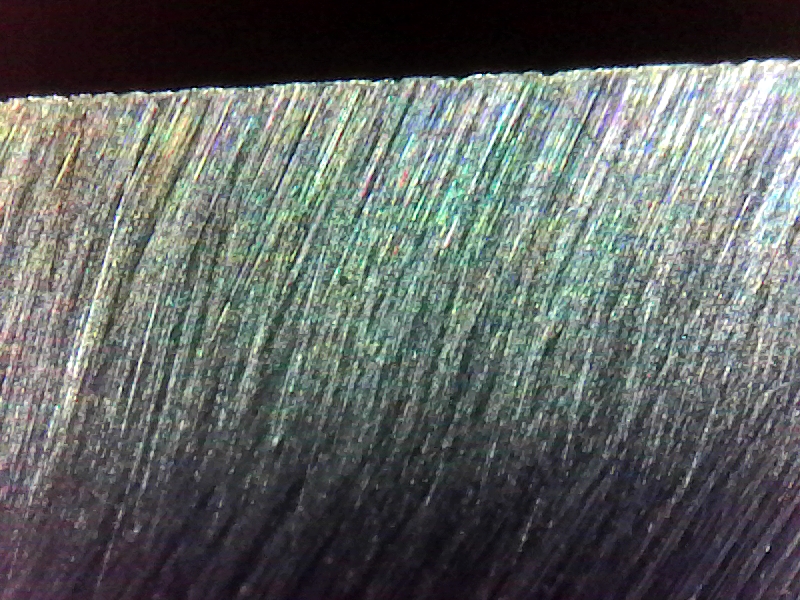

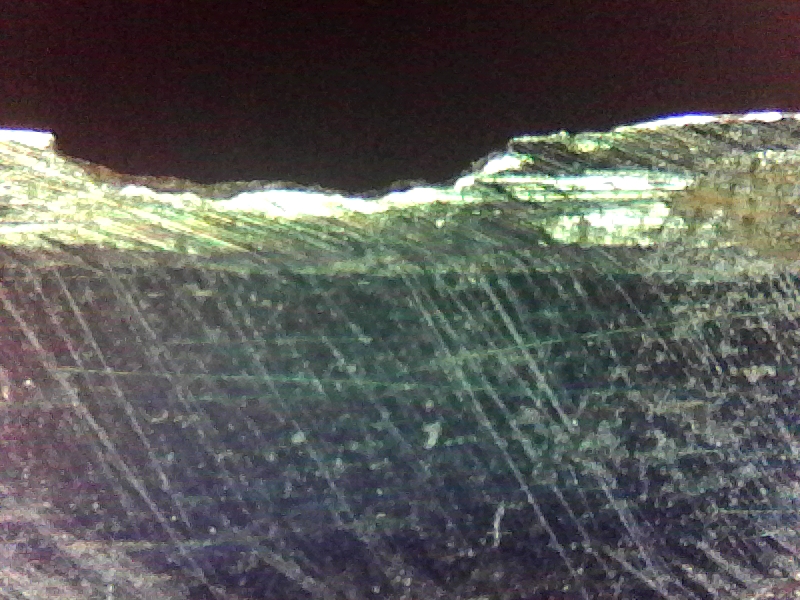

Last is the 4000 grit DMR:

I found that for such a fine grit that the scratch pattern is more evident and maybe less polished then I’d expect. I did a “pull down” paper cut test between each successive grit. I was not impressed with the sharpness feel as the newspaper was dragged down over the sharpened knife edge. The feel was of a very toothy and grabbing knife edge.

I followed the 4000 grit DMR with 4µ then 2µ leather strops. The sharpness again was deceiving. To the finger touch I was unimpressed. It felt sharp but not scary sharp. The bevels did appear clear and well polished. They were bright, shiny and mirror reflective.

I finished up with a 150 sharpness test score on the BESS Edge-on-Up. I guess there’s no argument, for a 25 yr old abused and beat up knife, “It will cut”!

Anticipating questions, I did inspect the surfaces of the DMR stones now that they were used. I did not try to baby the new stones. I didn’t see any wear to the resin matrix or see or feel any exposed diamonds. The DMR remained flat and level. I saw no evidence of dishing. The resin did become a little dirty and blackened from the steel dust. I did not try to clean them except to spritz the stone surfaces with water then wiped them down with a towel when I finished using each grit. The resin matrix appears darker while it’s wet. It seems to dry off and lighten up in appearance quickly. I don’t believe the DMR soaks up water or becomes saturated.

As I look at the posted photos from the 250, 650 and 1100 DMRs, I couldn’t help thinking they’re all remarkably similar in appearances. I went back to saved USB microscope photo files and re-selected another photo example from each grit stone just to be sure I hadn’t duplicated the grits. It’s almost uncanny to me the similarity in their scratch patterns. If you look at the apex you can see they’re smoother and have shallower toothy grooves as the grits get finer.

I’m curious with time if these DMR stones will show wear or maybe break-in with more use. Maybe this will be reflected by a softening in these crisp appearing scratched grooves and with a lighter and more polished appearance??? Time well tell.

These DMR stones are maintained as needed with a lapping procedure done with a powdered abrasive compound. This is done not too differently then the lapping process followed with whetstones.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

11/24/2021 at 1:38 pm #57228Well, I bit the bullet, finally, and ordered a pretty comprehensive WE Gen3 pro setup all the way down to 1 micron strops.

I’m still very very curious if these bonded matrix stones are still in your mix @MarcH.

happy thanksgiving, and let us know your current thoughts on this set-up!

-

This reply was modified 4 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.