Blade alignment in the clamp: sweet spot & constant bevel angle/width

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Blade alignment in the clamp: sweet spot & constant bevel angle/width

Tagged: Sweet Spot Theory

- This topic has 89 replies, 11 voices, and was last updated 01/11/2018 at 12:42 pm by

graphite.

-

AuthorPosts

-

12/29/2017 at 2:38 pm #44253

One point to consider when you see a wider bevel at the tip: It’s not always because the bevel angle changed. It’s usually because the manufacturer doesn’t taper the tip at the same angle as the rest of the edge. The reason is that such a low-angle (thin) taper would weaken the tip, making it more likely to break or bend when abused. The only exceptions to this are knives with straight blades.

4 users thanked author for this post.

12/30/2017 at 12:10 pm #44259Redheads: I don’t consider my angle cube to be much more than a rough angle reference. If I take 10 measurements of the exact same point I’ll get a range of values, maybe .4-.5 degrees of variance among those values. I have a Wixey, but I had another brand with essentially the same problem. On youtube videos, I see people having the same issue with other brands, but they seem to take the one that is closest to the one they want as the “correct” one, and once they see that value they stop. Or they keep taking new readings until they get the value they want.

So I think the manufacturer’s claims of .1 degree accuracy just means that one of the many reading you get will probably be within .1* of correct. Not to mention that the packaging of the cube itself probably doesn’t have flatness or angular tolerances of the sides relative to the base that’s anywhere close to that. Anyway, I don’t see much value in trying to compare measurements of my Wusthof results to the simulations of another knife that is only roughly the same shape, no matter what the result would be. We shouldn’t be trying to hold the circle contour jig to a standard that is way more strict than what people had been using previously, which was mostly “looks good to the naked eye.” Good points several of you made about the varying knife thickness/taper affecting the bevel.

BTW, in my Wusthof posts with the photos, if you click on the photos of the full-length knife, it opens a new window and if you then click on that it opens the full resolution file so you can pan across the full edge.

2 users thanked author for this post.

12/30/2017 at 12:46 pm #44260You probably need to calibrate your cube. It is also important the hold the diamond handle in the exact position each time to remove the rod/handle wobble. You can also flip the cube 180 deg to check biases. I think the cube is accurate to 01 deg. Your statement of: “So I think the manufacturer’s claims of .1 degree accuracy just means that one of the many reading you get will probably be within .1* of correct.” is not fair (of course it also could be true).

I am going to do a setup with it right now, take some data and will share it today.

2 users thanked author for this post.

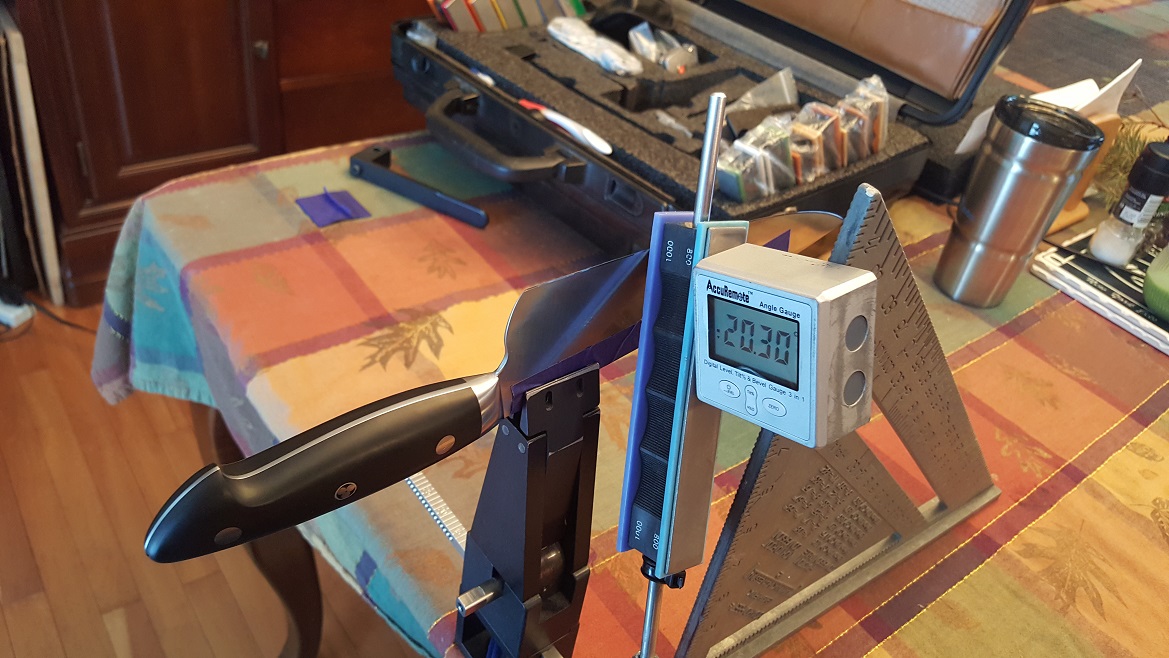

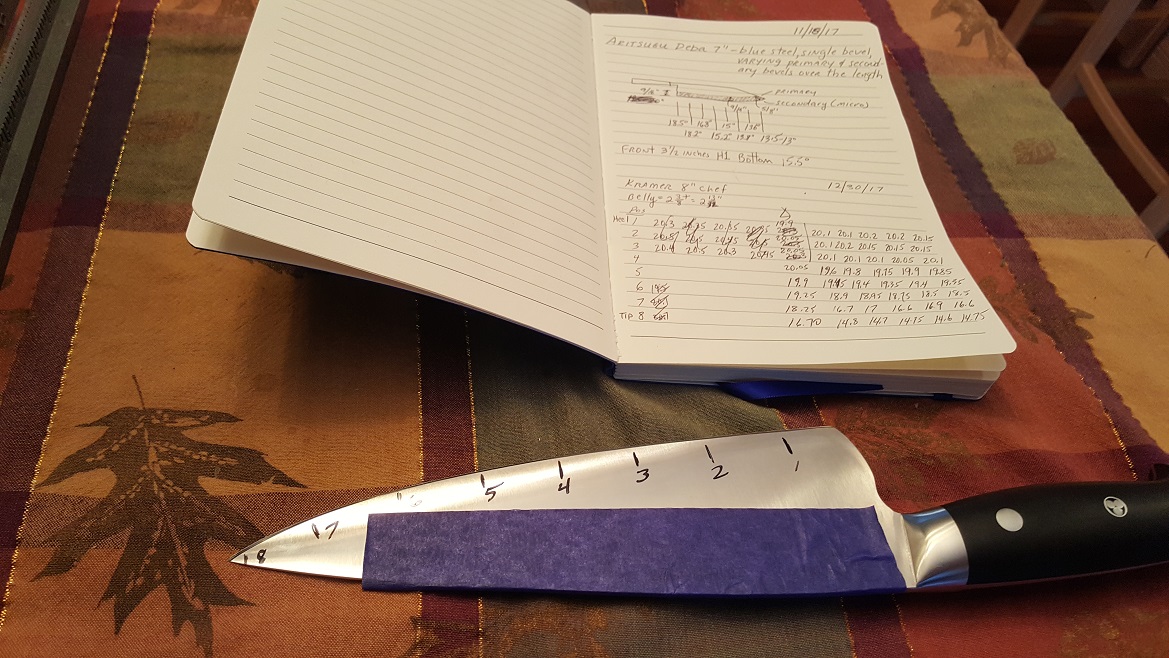

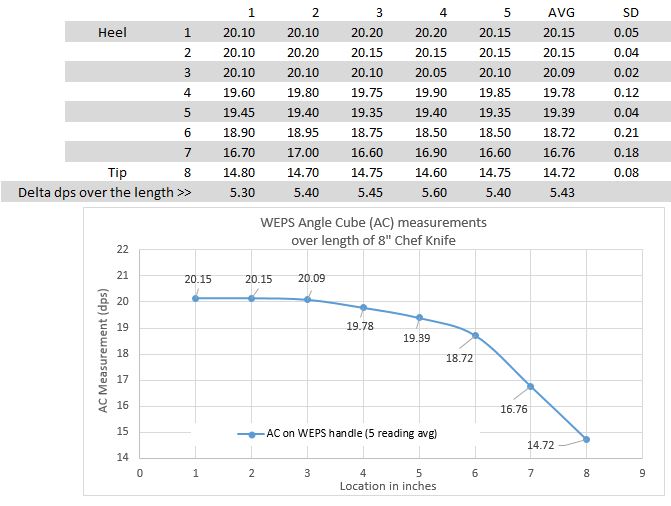

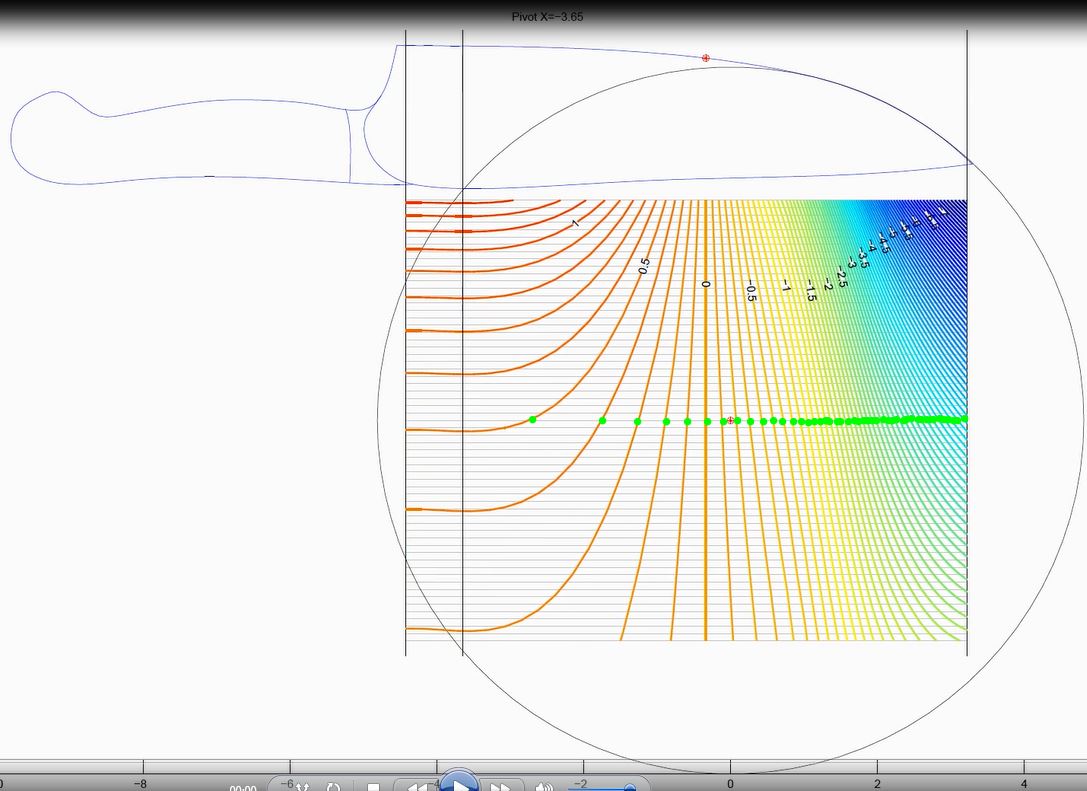

12/30/2017 at 4:07 pm #44264I completed my measurements on my 8 inch Kramer chef knife which is reasonably close to the knife Anthony uses in his simulation. His movie is a great resource to see the impact of knife placement. His simulation predicts about 4.7 dps variation at worst case placement at the heel of the knife (counting the green dots I put in the pic). This knife was previously sharpened on WEPS at around 16 dps. For this exercise I put the angle at ~20 dps to make sure I was riding the apex over the whole length. I measured ~5.7 dps variation from the heel to the tip using the plumbed angle cube. The cube reading (riding on the handle diamond flat) is tough especially near the tip because the flat part rocks on a curve (point impact). I think this all correlates to the simulation and highlights the need to know what the impact of your angle variations will be and where you want to put them.

I also think is pretty cool that the variation graph (scaled correctly) follows the edge profile (at least for this knife), I wonder if that observation could be used to come up with “rules of thumb” for the clamp placement vs. angle variation (or changing the set angle when you get to a major non-linear segment).

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

12/30/2017 at 4:58 pm #44270Redheads: I don’t consider my angle cube to be much more than a rough angle reference. If I take 10 measurements of the exact same point I’ll get a range of values, maybe .4-.5 degrees of variance among those values.

I agree that your ‘cube probably needs to go through the mfg’s calibration procedure. My Igaging unit read within of 0.1 and 0.2 degrees repeatability.

My Floureon DXL-360 reads repeatably to within 0.04 degrees within about 3-4 seconds of settling time. I’ve learned that the best way to take a measurement is to hold the ‘cube steady by applying a gentle pressure against the stone with one finger. If you just let it rest against the blade, ambient noises (vibrations) in the table will drive it nuts, just when it’s trying to settle on a final reading.

3 users thanked author for this post.

12/30/2017 at 5:10 pm #44271Redheads: I don’t consider my angle cube to be much more than a rough angle reference. If I take 10 measurements of the exact same point I’ll get a range of values, maybe .4-.5 degrees of variance among those values.

I agree that your ‘cube probably needs to go through the mfg’s calibration procedure. My Igaging unit read within of 0.1 and 0.2 degrees repeatability. My Floureon DXL-360 reads repeatably to within 0.04 degrees within about 3-4 seconds of settling time. I’ve learned that the best way to take a measurement is to hold the ‘cube steady by applying a gentle pressure against the stone with one finger. If you just let it rest against the blade, ambient noises (vibrations) in the table will drive it nuts, just when it’s trying to settle on a final reading.

Does the dual axis allow you to get direct readings when out of plumb or does it just indicate the out of plumb reading (then you have to rotate the cube) ?

1 user thanked author for this post.

12/30/2017 at 6:09 pm #44274Wow, Redheads, you resharpened that knife clamped at the heel, all in the name of gathering data? Way to take one for the team! I’d be interested to hear what you think of its cutting performance with food, sharpened like that.

What did you use the triangle (60-60-60?) for?

Also, how did you set the tilt of the knife in the clamp so that the tip curve would align with the ideal circle?

1 user thanked author for this post.

12/30/2017 at 6:22 pm #44275I did not resharpen it. I just edited my post to be more clear. BTW, I also took some measurements with the blade angled up at ~20 deg and I got a very similar curve while struggling to put the plumb cube against the non-magnetic rod. Delta variation = 3.2 dps. This eliminated the flat rocking but it was a pain to hold, write, etc.

The triangle is 45-90-45 to make sure the cube was plumb.

I did not bother with the tip curve alignment because I wanted to follow the setup in Anthony’s movie simulation as best as I could.

I would love to get a hollow rod and integrate a wireless dual axis inclinometer into it (and an audio pickup which would give us scratch feedback) — NOW that would be something.

Link to the simulation: https://drive.google.com/open?id=1qFEZRtyAcy20C1AFatt5XlmAeuYed-ag

2 users thanked author for this post.

12/30/2017 at 6:43 pm #44276Redheads: question about the angle measurements you are doing. If you had a knife with a long straight edge that was also wide enough to clamp it at a steep tilt (let’s say tilting downward, heel to tip), wouldn’t you measure a smaller angle at the heel than at the tip (the rod would hit the edge higher up at the heel). But if you sharpened that knife, wouldn’t it be a constant angle because the edge is straight?

12/30/2017 at 7:05 pm #44277I think sharpened or not sharpened a perfectly straight knife would show the same angle measurement whether tilted or not. It is that counterintuitive brainstretching thing (due to cone circles, et al) that was half part of the start of this topic. I know I took some measurements once on this but let me try again. The thing is I need a piece of steel thin enough to fit in clamp but stiff enough not to flex (the flex part drives me nuts).

12/30/2017 at 8:44 pm #44278I put a solid straight edge in the clamp and did a 30 deg tilt and tried to use the angle cube to verify the angle variation. Even though I kept the cube plumb I still got angle variations and I think it is due to another plumbness type issue of not being 90 deg to the edge similar to the video below using a pretty cool phone app.

I was looking for a youtube video I saw where someone made a real cool wood setup kind of like a roof truss thing and showed the different angles on a large scale but could not find it. I also wonder what that does to our curves which are not on the perfect circle (another rabbit hole) LOL

12/31/2017 at 2:01 am #44283Does the dual axis allow you to get direct readings when out of plumb or does it just indicate the out of plumb reading (then you have to rotate the cube) ?

I don’t know. Keeping the ‘cube plumb (with the face parallel to a line running from the ball joint center through the center of the vise) was something I learned from the get-go. I don’t see any reason not to do it.

Referring to the video, imagine an orthographic 2D projection of the triangle, with the apex representing the edge bevel. Now you are told that the apex is actually pivoted 45 degrees away from you. Your point of reference is the blade, so the drawing doesn’t change. Ergo, the angle of the bevel doesn’t change.

2 users thanked author for this post.

01/11/2018 at 12:01 pm #44511I’ll try to build a sturdier model to test after the Christmas break and see what comes up. Then I guess I’d try it out on some knives to see what it does to bevel widths.

Clay, have you had a chance to do further tests?

01/11/2018 at 12:12 pm #44512I’ll try to build a sturdier model to test after the Christmas break and see what comes up. Then I guess I’d try it out on some knives to see what it does to bevel widths.

Clay, have you had a chance to do further tests?

I have not

it’s been crazy busy around here and will probably be so until after Shot Show in a couple of weeks.

-Clay

01/11/2018 at 12:42 pm #44514I’ll try to build a sturdier model to test after the Christmas break and see what comes up. Then I guess I’d try it out on some knives to see what it does to bevel widths.

Clay, have you had a chance to do further tests?

I have not . it’s been crazy busy around here and will probably be so until after Shot Show in a couple of weeks.

I know what you mean re: crazy busy. It seems like we take “vacation” only to be behind by as many days as we took vacation, when we get back.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.