Readheads

Forum Replies Created

-

AuthorPosts

-

05/03/2023 at 2:14 pm #58513

Like this

Attachments:

You must be logged in to access attached files.

01/12/2023 at 5:14 pm #58358Well, I was able to get full WE coverage on the 10 deg 5/8″ bevel but after 1.5 hrs of paddling using even my 50/80 grit it has become apparent that I’ll need alot more time and will likely wear out my diamonds. Probably cause it has a 12 deg microbevel and the 10 deg bevel changes by ~1.5 deg over the 9 inch length. Not a job for the WE. Will clean up the scratches on my HF grinder and put a 12 deg microbevel on it. I thought it would be sweet to have a 10 deg bevel to the apex with no microbevel. Makes me wonder why the OEM would put a microbevel on top of a 10 deg bevel. They should have just made the 5/8″ bevel 12 deg to the apex. Fun while it lasted.

01/12/2023 at 11:47 am #58354<!–more–>I filed down one side of the LAA and now I can get to 9 deg single side.

Attachments:

You must be logged in to access attached files.

02/25/2022 at 7:39 pm #57597I’m in. Also, can you incorporate a notch in the the part which rides on the blade. I filed this into mine to allow easy sliding on the edge without slipping off. It also keeps the focus plane consistent and enables easier consistent sliding while looking only at the monitor which usually is via a USB on my phone.

05/07/2021 at 7:59 pm #56705A few questions if I may:

- What is the 90-90-90 rule ?

- What is the autosol step ?

- In the three-step approach, “1 degree more obtuse” would start a micro bevel I think yet I suppose this is to address the burr root ?

- In the three-step approach, “0.1 micron … at the original sharpening angle” is quite a jump from 1.5 micron ?

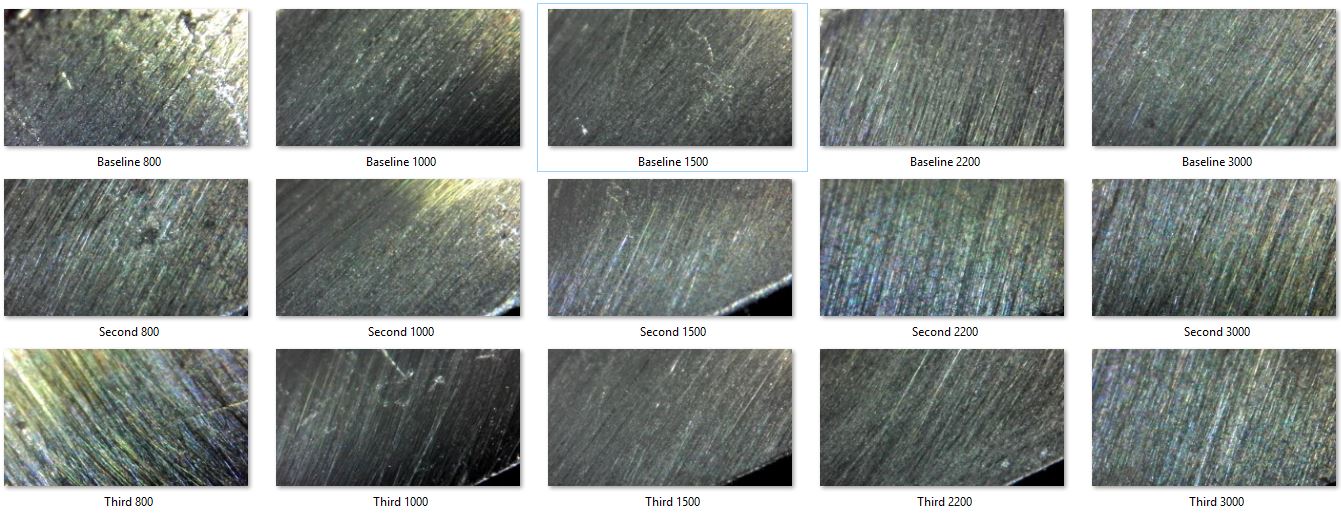

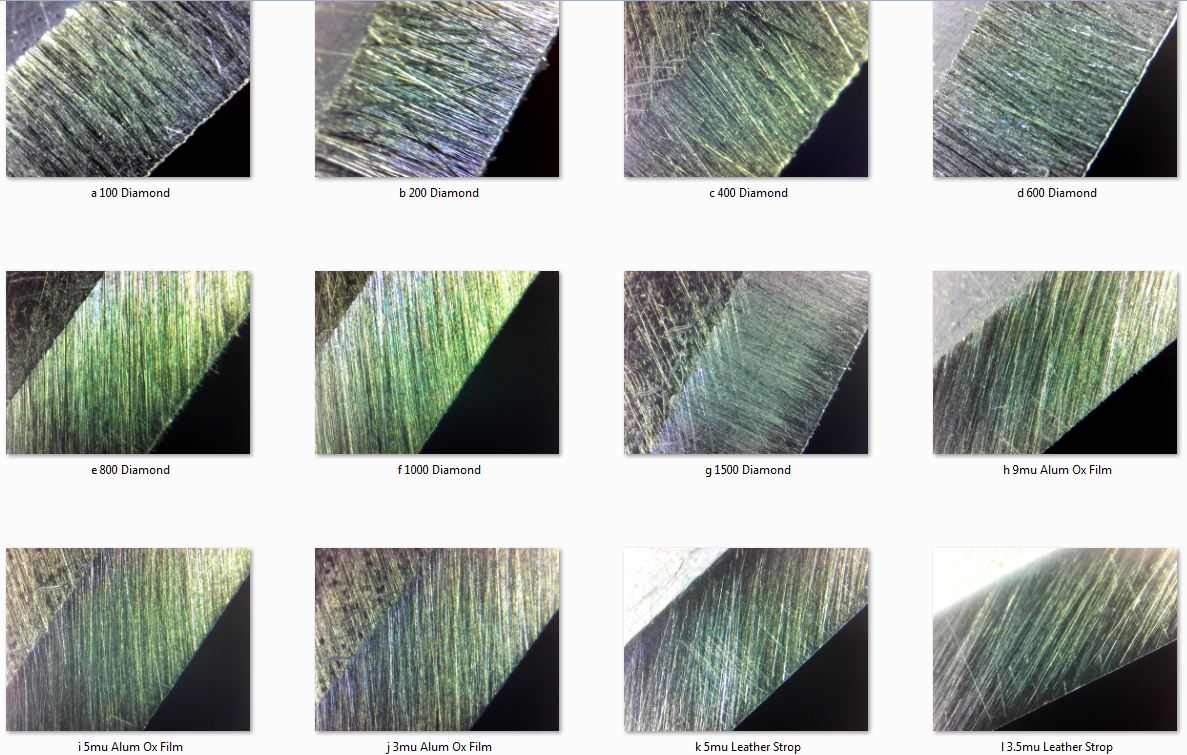

- Also, I wonder if this is all necessary because after raising (edge-trailing) the hanging burr at 100, 200 diamond grit; then all the rest of the diamond grits I do edge-leading through 1000, 1500, 2200, 3000. Then edge-trailing with 3 grits of diamond film and finally 2 leather strops each with finer poly diamonds. It would seem to me that the burr root should be addressed by this but maybe not. I guess the proof would be in controlled BESS testing (maybe I will get one).

I am mostly interested in the concept of extending the longevity of a very sharp edge. I also wonder how the Tormek wheel geometry compares to the flat WEPS paddles in his approach. I need to read Verhoeven’s Experiments in Knife Sharpening again.

Attachments:

You must be logged in to access attached files.

03/04/2021 at 11:01 am #56345Very interesting on the scalpel. It serves to substantiate that their may be cut mediums and techniques that could benefit from it. My thoughts are all raw meats and maybe the steak knife edge for longevity purposes.

I have some cheap non-serrated steak knives and I will try it. Thinking of trying diamond films on one side and the super coarse 50 grit on the other. What do you think about the angles per side and which side to do first ?

-

This reply was modified 4 years, 2 months ago by

Readheads.

03/01/2021 at 8:18 am #56320That is a beautiful sketch of the concept. I am going to give it a try and see if my 250x USB scope can detect the results. I’m thinking that it won’t be enough magnification though. Of course I am in the market for a more powerful scope anyway but I digresss.

If the nano-serrations are actually real and effective then it may work well to improve the sustainability of my steak knives which are non-serrated (for the pleasure of slicing steak on a plate). Obviously my steak knives dull quickly due to plate contact but I do not mind truing them up with my ceramic rod. The nano-serrations may improve my time between true ups as well as the cutting action through the charred outside of my steak.

Also, I don’t think a manufacturer would do it on a non-serrated steak knife because to resharpen it you would need special equipment like a WEPS.

02/25/2021 at 4:33 pm #56289MarcH, that link above is excellent with wonderful knives and information.

2 users thanked author for this post.

01/14/2021 at 8:02 am #55770Have you figured out an effective way to handle serrated knives ? The best I came up with is to focus on putting new tips on each serration (using full blade strokes) and not to worry about the “inner” serration curvatures. Its not perfect but it refreshes the initial bite that a serrated knife has.

1 user thanked author for this post.

01/11/2021 at 10:13 am #55738I also strive for speed. Attached is a link to my Jersey Double Stroke.

Also, I currently use the 50/80 stone which will reprofile in 1 minute. I watched your video and you mentioned angles up to 25 DPS I think which is probably appropriate for the cheaper steels because they dull real quick (crap steel) but I prefer 20 DPS.

01/06/2021 at 5:19 pm #55676Hmm, maybe I am leaving some sharpness on the table. I’ll have to try it.

Question: I zero out my angle cube on one side of the clamp on the bar (with the angle divots) and when I put it on the other side of the clamp the angle is off by 0.4 deg. I disassembled the bar and it is not bent. I tried to recal the cube and got the same result. Do you think this matters ? It seems to me that it would.

01/06/2021 at 9:30 am #55663I don’t bother with checking for a burr after the first diamond paddle. I also don’t bother checking/tweaking the angle for each paddle change. I do check my results in process with my USB scope. It’s a big time saver. Tuning up a knife which was previously in the WEPS with the Angle Alignment Gauge takes less than 5 minutes. A new knife will get the 50/80 grit for less than 5 minutes to establish a new profile and full burr. Another 5 minutes and I am done stropping. I tape every knife to protect against rogue and annoying scratches to the face. I do mostly kitchen knives. Goods steels get 14 DPS, Decent steels get 17 DPS or 20 DPS is hard usage is in play. To me it all about the steel quality and projected use.

I do like to do science projects to approach the perfect edge though.

-

This reply was modified 4 years, 3 months ago by

Readheads.

-

This reply was modified 4 years, 3 months ago by

Readheads.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

12/13/2020 at 9:17 am #55439I went with the 1500/glass paddle. After the 800/1000 it does a great finishing job. You can put the coarsest diamond film on the glass. Also, sharpening down to 9 dps while extremely sharp leaves a lot to be desired for edge durability.

1 user thanked author for this post.

12/02/2020 at 3:17 pm #55357I think the new design of extending the original 1/4″ flat square bosses all the way down the jaws may introduce minimal planar contact to the 2 knife faces depending on the geometry of the knife and the as-machined flatness of the extended new bosses. There also needs to be sufficient “self correcting play” within the jaw assembly to “find” sufficient contact. This can be tested by inserting a metal shim of x thickness across the top 1/4″ of the jaws on both sides and see if the wiggle is eliminated.

11/30/2020 at 11:37 am #55335This is a repeat of the post that I put in the second thread that was started on this:

I think that the root cause of your issue is that the current jaws no longer have the square flats on them (see pic). I have the Field version from ~5 years ago. I setup my kitchen knife to check for wiggle and there is none either with my chamois insert or without it. I use the chamois to protect the knife surface from nasty little marks due to clamping. I also designed a simple fixture to handle flexible knives and low angles – cost = $5. No wiggle there either.

Attachments:

You must be logged in to access attached files.

-

AuthorPosts