Edge Finishing

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Edge Finishing

- This topic has 3 replies, 2 voices, and was last updated 05/08/2021 at 8:50 am by

rummels.

-

AuthorPosts

-

05/06/2021 at 9:31 am #56698

I recently followed a link from another post on cutting boards to Vadim Kraichuk, a professional sharpener in Australia. KG, as he is known on several boards and forums, does a scientific study on deburring/finishing and it’s effect on longer edge stability (ie. sharpness) verified with many repetitions and BESS testing. Basically he brings up the need to address the burr “root” after standard deburring because this stressed out material is still there at the apex and it breaks down, diminishing the edge stability over time. He uses the Tormek 8 setup. He has done many, many tests and has determined that felt of a certain density is best at eliminating the burr root and greatly improving the edge longevity. He now manufactures the felt but it is for Tormek-type machines only .

He had partnered with BESS and communicates with Todd Simpson (Mr. SEM) and Larrin Thomas (Mr. Steel) among many others to determine the root (sic) cause of edge failure. While of course he pushes his own stuff, in his writings and videos he comes across as another older guy (like me) who is extremely interested and persistent in his evaluations of edge failure. He does not manufacture his felt in strips which I would like to apply to my WEPS paddles.

Does anyone have any experience in finishing the edge relative to burr root removal with maybe BESS measurements to back it up ?

My thought is that the WEPS diamond films should remove the burr root but I do not have BESS data to back it up.

05/06/2021 at 3:01 pm #56701I have read Mr. Kraichuk’s book, and have found it to be very helpful. His multi-step approach to burr removable works much better than anything else I have tried.

I have “adapted” his methods for burr removal to the Wicked Edge, and have been able to sharpen Henckels and Wusthof knives that will push cut the edge of a newspaper ¾ of an inch from where I am holding it using the 90-90-90 rule.

When setting the original bevel, I follow his advice with respect to the grit of the last diamond stone to use, except when he stops at 1000 and then goes to a 10 micron paper wheel. I substitute a 1500 diamond stone for the wheel. And I always skip the autosol step.

I deburr using the three-step approach he recommends using diamond lapping films. First, I do edge-trailing strokes with the 1.5 micron diamond lapping film at the original sharpening angle. Then I do edge-trailing strokes with the 1.5 micron diamond lapping film at an angle that is 1 degree more obtuse that the original sharpening angle, and finally I do edge-trailing strokes with the 0.1 micron diamond lapping film, again at the original sharpening angle.

I hope this helps.

Rummels05/07/2021 at 7:59 pm #56705A few questions if I may:

- What is the 90-90-90 rule ?

- What is the autosol step ?

- In the three-step approach, “1 degree more obtuse” would start a micro bevel I think yet I suppose this is to address the burr root ?

- In the three-step approach, “0.1 micron … at the original sharpening angle” is quite a jump from 1.5 micron ?

- Also, I wonder if this is all necessary because after raising (edge-trailing) the hanging burr at 100, 200 diamond grit; then all the rest of the diamond grits I do edge-leading through 1000, 1500, 2200, 3000. Then edge-trailing with 3 grits of diamond film and finally 2 leather strops each with finer poly diamonds. It would seem to me that the burr root should be addressed by this but maybe not. I guess the proof would be in controlled BESS testing (maybe I will get one).

I am mostly interested in the concept of extending the longevity of a very sharp edge. I also wonder how the Tormek wheel geometry compares to the flat WEPS paddles in his approach. I need to read Verhoeven’s Experiments in Knife Sharpening again.

Attachments:

You must be logged in to access attached files.

05/08/2021 at 8:50 am #567101 – This is a good description of the 90-90-90 Rule. If you Google it, you will find discussions of the rule on multiple forums.

https://www.youtube.com/watch?v=aMTVagksvBE

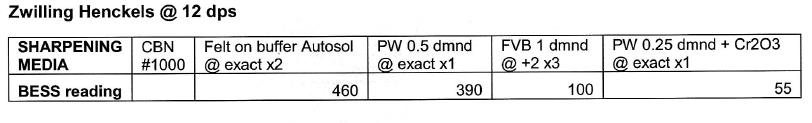

2 – My apologies. I was basing some of my answers on Kraichuk’s book ” Knife Deburring – Science Behind the Lasting Razor Edge By Vadim Kraichuk”. In it he gives several example of how to sharpen various knife steels using Tormek sharpening equipment. With softer steels he often uses a paper wheel with Autosol, a 0.3 micron grit, on the wheel. For example:

3 – I guess it does. But deburring softer steels often requires using a more obtuse angle.

4 – It is, but that last step is intended to only further clean the apex of any damaged/stressed/weakened steel. My experience is that this last step makes a noticeable difference in the sharpness of the edge.

5 – There are definitely many ways to deal with burrs, and I can’t say that one is better than the other. I like Kraichuk’s approach because it has made a huge improvement in my sharpening, and because I don’t have to include stropping in my sharpening progression.

Note that Kraichuk has explained his research and his approach to sharpening on both the Bladeforum (aka wootzblade) and the Australian Blade forum (aka wootz).

Attachments:

You must be logged in to access attached files.

-

AuthorPosts

- You must be logged in to reply to this topic.