Henry

Forum Replies Created

-

AuthorPosts

-

12/27/2021 at 6:46 pm #57407

Hi Mark et Al.

unfortunately the setup is put away so I can’t take a cell phone shot. And yea… the pix are too close up to make sense of this without my secret decoder ring interpreting my writing; as I wrote:

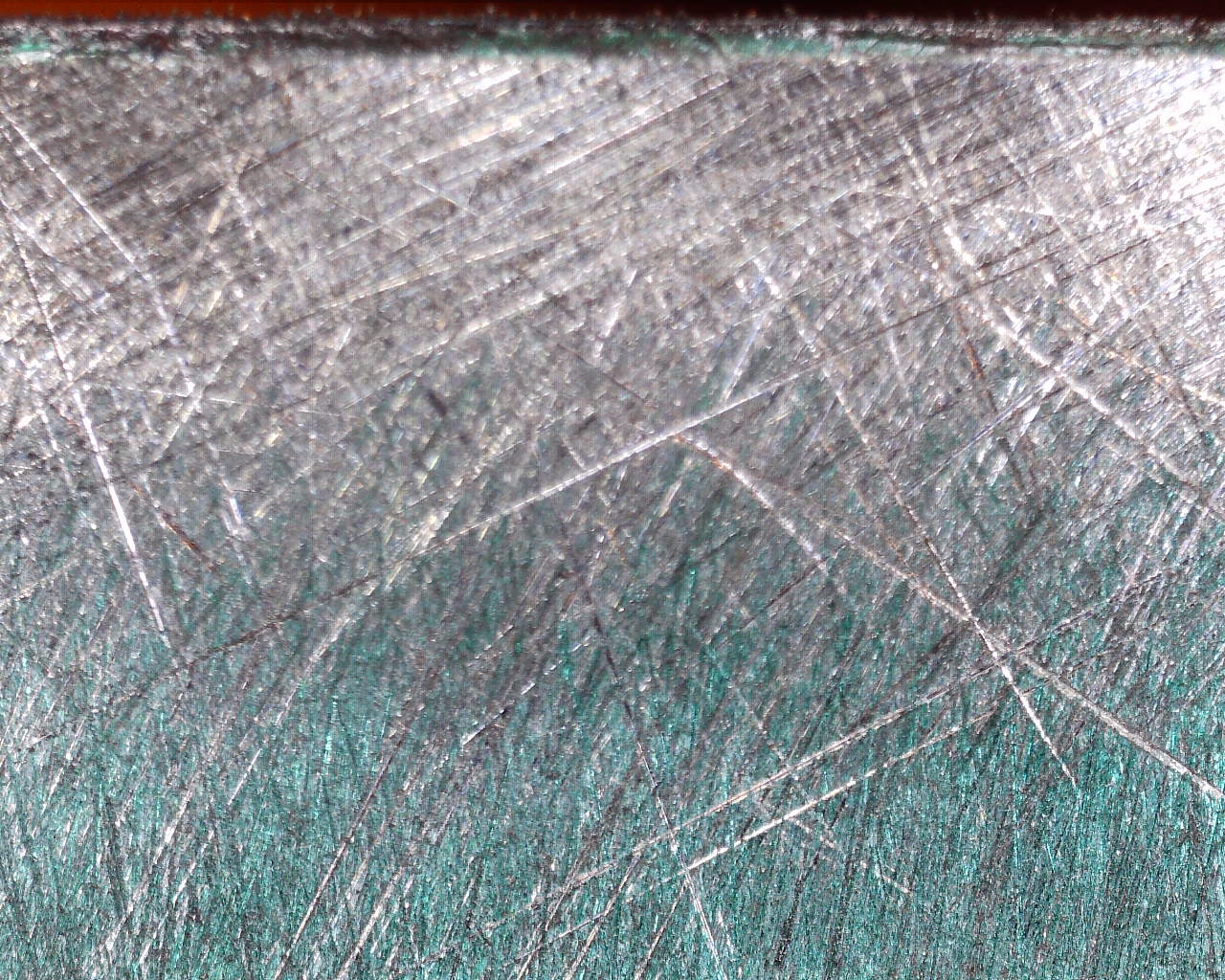

2. These show the same moment in time but the rest of the blade (will not fit, even on low power, into a single photo. One is of the bottom of the shenogi and the other is at the top (kind of a duplicate of the above pic, but I’m trying to “blend” the 2 together.

So basically I’m showing the top and bottom 1/2 of the shenogi, at the same place on the blade, demonstrating how on the same setting, same paddle, opposite abrasive side, I’m seeing a different sharpening angle. I’m only scrubbing the top ( edge) portion of the shenogi and missing the bottom 1/2 completely when switched the paddle over to the 200 grit side.

This demonstrates that each paddle side has a different enough thickness or distance from inside face of the bore to the outside of the abrasive ti affect the sharpening angle.

I ultimately used the micro-adjust on most paddle sides to dial in the same angle and called it a day.

I do realize I’m writing heavily and doing a deep dive into how this jig operates.

The conclusion I’ve drawn is that using the micro-adjust is mandatory to maintain the same sharpening angle, and it’s at least noticible when sharpening a bevel that’s long (8 mm ish in this case).

Perhaps I may find time next weekend to re-wright this more succinctly and clearly and maybe an admin will post a stickie “Evidence of why we need to use the micro adjusting knobs for wide bevels”. But , it sure would have been helpful if I had taken a wider angle view of this with my cell. Dope!

The learning curve continues as I’m developing my competency and skills while learning the nuances of this jig. Yes it’s an art, and yes the results of a sharp edge can be accomplished many ways, and as you said above, and I paraphrase, “It’s a knife for God’s sake, it’s not a semiconductor Lithograph machine nor a vascular surgical robot.

I’m enjoying the journey and look forward to mastering this contraption some day.

Thanks again Mark for putting on effort to help and guide.

12/27/2021 at 2:40 pm #57405LOL,

Yes I’m getting a bit OCD, and yes my career is involves nanometer level precision. I get this is a knife sharpener and on a hobby budget. But I’m going crazy chasing that apex / flat shenogi on this blade!

My take away is to suck it up and micro-adjust on every sharpening medium (as long as it matters – aka in the case of a large flat bevel). I have NOT seen this on more reasonable bevels that are 1-3 mm in length!

Mark, Thank you as always!

I may still keep this post going as a journal of learning for other crazy enthusiasts chasing as much as they can from the tool.

-Henry

12/27/2021 at 2:28 pm #57396Very Interesting observations:

I discovered with the help of a sharpie that I needed to sharpen now at 13.8 deg to best hit the full 50/80 grit scratch pattern shenogi s that’s what I did.

After re-calibrating and chasing the Apex using the 100/200 grit stone, I started getting a better shinogi, but had a devil of a time chasing the apex for about 1 1/2″ of knife blade. I was very careful to have gentle pressure, not enough to visibly bend (or move) the blade yet enough to feel and hear the diamonds working. After ~ 25 minutes of the 100 with multiple checks and still a hair away from the apex, the knife still easily pull cut paper (left in the jig to run test). I flipped the stone, colored the shinogi in a green sharpie, and did the exact same scrubbing using gentle pressure and careful of hand placement consistency on the paddle.

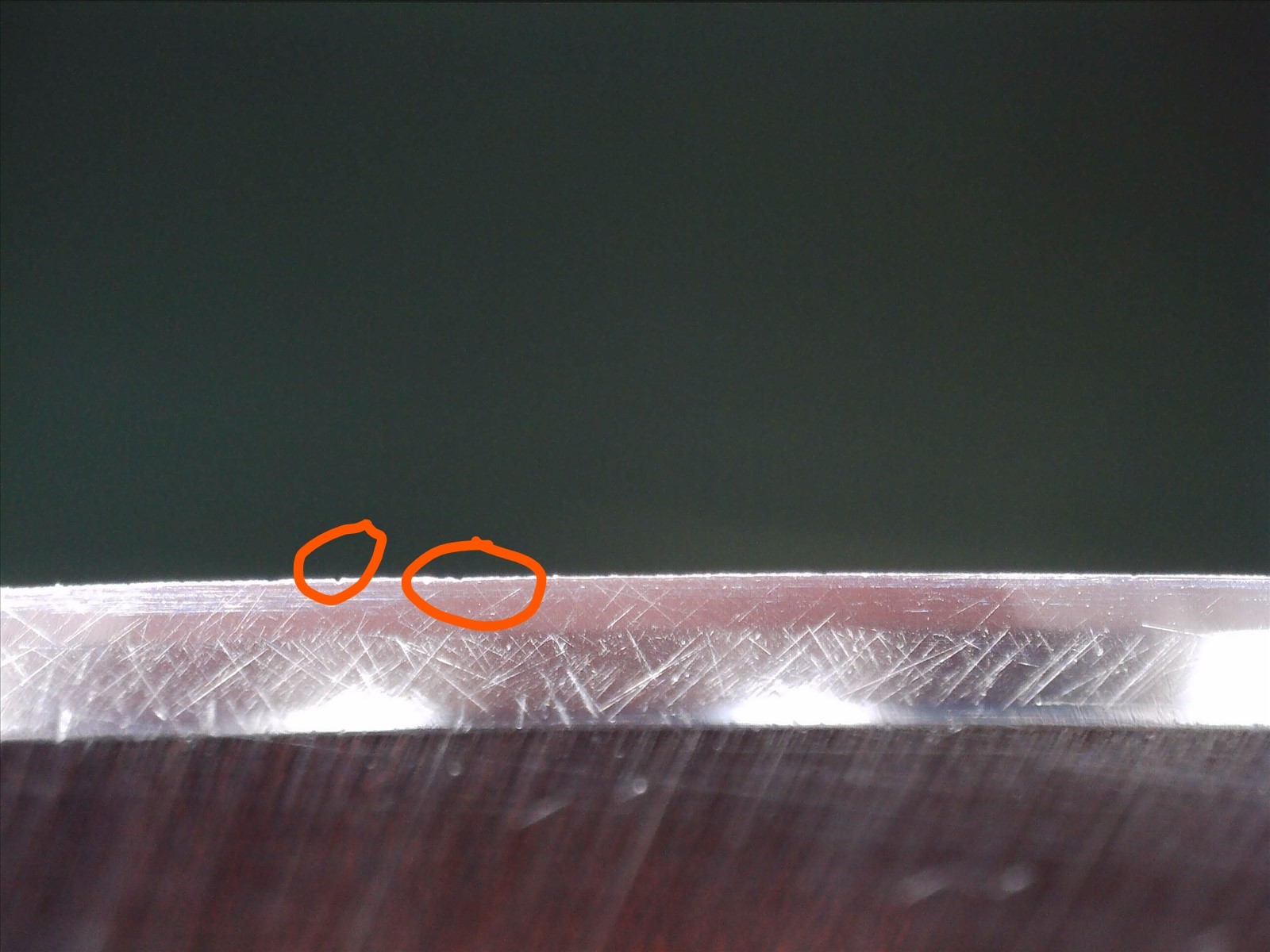

I observed that the angle had changed on the shenogi yet I was still measuring 13.8 deg with the angle cube (supporting it’s height on the rod by pinching the rod below the paddle to not influence the angle by bending the rod). I was now scrubbing the top 1/3 of the shenogi and not really touching the bottom 1/3!

This is perplex and confusing. The same paddle.. I guess that perhaps one side glue may be thicker than the other or the 100 and 200 grits have different diamond stone thicknesses?

Here are a few photos:

- Forget the file names of “5 minutes” (it’s from a starting time 20 + minutes into 100 grit scrubbing. Note the Apex is still missed, but what the photos do not show is the edge easily slices paper. The phots clearly shows I’ve removed metal on the top 1/3 of the shenogi.

2. These show the same moment in time but the rest of the blade (will not fit, even on low power, into a single photo. One is of the bottom of the shenogi and the other is at the top (kind of a duplicate of the above pic, but I’m trying to “blend” the 2 together.Note now the green “fades” in on the bottom 1/3.

I guess the only thing to do is micro-adjust the 200 side of the paddle to remove all green.

I’m still not at the Apex as observed by the green on the blade edge. I must assume it’s sharp from prior sharpening with the micro-bevel???

To be continued. I may just drop the angle of the 200 by an ever slight amount and 200 out the green. This will eventually leave me with a nice shiny shenogi and if I repeat this process it may eventually create a semi-convex shenogi (albeit ever so slight). I’m tired of scrubbing chasing that last 1/25’th (guess) of a mm of the apex and just may live with needing a concaving or micro-bevel at this time. It’ll create a future nightmare or at least a lot more thought and work to flat-sharpen if I do so. Or, I suck it up, back down to the 100 and scrub away till the apex is finally reached on the last 1 1/2′ of blade that currently apparently still has some micro-bevel left on it.

The reason for this post, consistent with the subject line, is it seems that even within the same paddle, both sides appear to be at enough height differences from the inside bore (on that side) of the paddle to make enough of a difference to show when sharpening a knife with a quite wide shenogi.

To be continued I’m pretty sure.

Attachments:

You must be logged in to access attached files.

12/20/2021 at 5:31 pm #57370To Shapton glass or not at this early stage of my journey. That is the question. <i>Whether ’tis nobler in the mind to suffer The slings and arrows of outrageous outlay, Or to take arms against a sea of perhaps troublesome steels, And, by trying the Glass, have another tool to try.</i>

Lol, ok, I’m leaning towards using my diamonds on sub 61 ish Rockwell steels and the Shapton Pro Kuromaku for a while on harder thin Japanese knives and gaining experience before plunging down beaucoup de dollars on the glass.

But, I’ve been reading and seeing vids on Shapton glass for probably decades as I’ve enjoyed 30 bench whetstone, I’ve never had the experience with them and somehow feel this may be the calling.

That’s all. My post dinner rabble du-jour.

12/20/2021 at 4:43 pm #57368<!–more–>Marc,

No disrespect taken… again…..

and your have no idea how many prior threads I’ve read or reread and bookmarked or copied bits out of and consolidated into a “Notability” note ( like Evernote).

I’m humbled by your wisdom and acute recognition of the rabbit hole of wanting better/ easier.. just because… You are spot on in the ultimate desire to have a scope that’s easy to fucus and use and gives a usable understanding of what I’ve done and need to do that’s about it. Although really cool photos of edges are … really cool .

You do bring up a good point about powering the scope should I find a wireless one to work off an iPad that’s not a Frankenstein. Perhaps tech isn’t quite there yet for such a niche-use / application.

I really do hate the focusing mechanism on my cheap “Pluggable” scope but the Celestron is more then adequate no doubt for my use case. And no, $1000 + for a scientific grade scope to just see where I am in the edge and what needs to be done is … insane. I wish I could capture a pic tapping on the scope on like the pluggable has, and, the darn wire seems to come out 180 deg away from where it should so I use it wire facing up so my image is oriented on my screen as the edge is in real life. The other issue I have is the lighting. I’m always tilting and seeking the best angle to highlight or see what’s important or of interest at that given time. But I suppose lighting and angles is a huge part of any photography so no $billion scope will change that,

I’d rather put those $ towards some Shapton Glass hones…ugggg … saw / got some pricing and… um.. I’m NOT getting the 200-30,000 complete set today! I’ll continue that convo in the appropriate thread though..

-

This reply was modified 3 years, 4 months ago by

Henry.

12/19/2021 at 12:09 pm #57364Good stuff here and I’m replying to simply resurrect this thread to see if anyone has any updates.

Edge-leading, trailing, and -parallel strokes.. hmmmm good stuff.

my $20 scope and my $50 is Celeste on vs 500-100 Dyno lite . hmmmm…. Makes me ponder the next scope… for science sake… I’d love to have a wireless scope with good DOF and magnification and ease of focus (Good mechanism) that I could view on an iPad rather then break out the laptop.. damn are we getting spoiled these days with tech and gadgets…all updated comments and convo are welcome..

12/18/2021 at 9:16 pm #57361Mark,

Thanks.

The Jende vid is good. It’s consistent with all other all good vids on lapping whetstones.

And yes, you’re right about keeping the whetstones flat. Always. I follow your frequent process on my larger stones pretty religiously and thanks for the tip/reminder to do the same in the WE.

Nice hint on 1- use the longer rods. – check- done. And 2- use the upper and bottom stops … hmmmm… may need to treat myself to those soon.

Are you still “preferring” the Shapton pro Kuromaka stones from EBay seller you recommended?

I’m assuming from multiple other threads of yours that you use those for most Japanese knives/steels, particularly the high hardness, powder “tec”, thin blade knives. Any other whetstones come up in your rotation fairly frequently and if so, what steels do you lean on them for and why?

Oh yea, thanks for the tip on using the pressure “you feel appropriate” at various sharpening stages. I have to believe that diamonds really don’t need high pressure even when “roughing out” a bevel, but it’s nice to hear from you that you may lean in a bit more heavily for rougher work while still getting more and more delicate for the polishing.

<p style=”text-align: left;”>Peace!</p>-

This reply was modified 3 years, 4 months ago by

Henry.

12/18/2021 at 7:51 pm #57357Yes I get the all stones and diamonds scratch! It’s the level f scratches that county, and your fingernail test is semi- akin to a “cut a pice of paper – phone book or copier – and if it cuts smooth, Irish hi good enough.

yes Mark seems to have Japanese knife experience and I’ve learned a lot from reading his posts and blog. Looking forward to re-reading for the fourth time some of his stuff! And gaining experience!

Best!

12/18/2021 at 6:17 pm #57355Ps. It’s kind of fun. I’ve learned to save the usb scope pix to a Dropbox director on my Laptop and can now grab from my phone and drop in here after saving to my camera roll. The journey indeed continues !

12/18/2021 at 6:14 pm #57353Robert,

I think j I still like microbevels as it makes sharpening or touching-up so much easier and for me, on some knives and tools (like my Marples chisels), it provides a very nice edge at least in my humble experience. AND, as I said, it makes sharpening so much faster,

I do completely follow your concept of grinding with the lower grits to never touch the working edge as then we will have to just grind away all those deep grooves on the edge and as the initial post discussed, I think I have seen evidence of tear out or at a minimum just deep grooves that needed to be smoothed to become as fine of an edge as possible.

On an aside, I’ve now used the Shapton Glass WE stoned mentioned earlier in a few knives and although the slurry and mess created is a bit “messy”, the results and speed seem quite phenomenal. Ultimately, I did re-do the Yanihaba at 16.00 deg starting at 220 grit Shapton and worked up to 8K and must say the process was quite fast and did leave, what I thought, was a much cleaner edge. Frankly, we shall see how stone maintenance winds up. I can easily enough flatten them on a diamond flattening plate but am trying to use “her whole stone”, as much as possible and practical, to minimize wasted stone due to wasted stone removal in the flattening process.

The journey continues and and some point I shall post a new thread about the journey in the WE learning process. For now, I’m spending time with my kids and family as well as continuing to hone my skills (pun intended).

For now, I’ll post this pic of a few hours into 100 grit honing and still clearly not at the apex!

Attachments:

You must be logged in to access attached files.

12/18/2021 at 2:26 pm #57350I’ve got an interesting twist / update to the theme of microbevels….

Be careful what you decide to micro-bevel. It may be a permanent geometry.

So, as I progress and get more experience and confidence as well as broken in stones, I’m moving to some of my better knives while still avoiding the powdered steels… I decided to go at my Shun Yanagiba which has been hand, whet stone sharpened for probably 25 years. It’s a VG-10 steel and it has had a micro-bevel for a long time. When I did that, it was done to ease sharpening and make quick work of refining it back to what I thought was sharp. Now, it was phone book paper push-cutting sharp, but I wanted to restore the knife to its original geometry with a 16 deg primary bevel.

What a F2c*ing pain in the A$$ that was! No kidding, I probably put 5-6 hours in on grinding away at 100 grit diamond to finally hit the apex. It literally took me 2 days with multiple breaks between grinding sessions so ( have no exact hour count). I tried to keep the pressure light in spite of cursing in multiple languages in my head as I ground away. I had the knife in the low angle adapter and of course was only grinding a single side. Occasionally, after a few hours of thinking I was close to the apex, I’d break out the 3k and lightly stoke the backside ( flat, non-ground) to break any burr. Of course, this was a mental exercise of futility and I hadn’t hit the apex. Finally, after what seemed like my 100,000’th look at the apex on the usb scope, I was really really really close and could smell the fine edge wanting to appear. Yet alas, I grind and grind, edge leading, edge trailing, scrubbing, cross cross to try and introduce “smaller areas that need to be broken off”. I’d flip the stone upside down to try and use as close to 100% of the surface area as possible. I’d swap out to the other 100, again, in efforts to use all 100 grit stone surface evenly, or as evenly as possible. Eventually I thought I had eliminated any or almost the entire micro bevel and moved to the 200 stones as I kissed the apex.

For some clarification, I’d guess the initial micro bevel was at max 1 mm wide while the primary bevel is maybe 4 mm ( I didn’t actually measure…)

There are 4 points to this note:

1. Careful when deciding to use a micro bevel. It’s really permanent unless you have the patience of Jobe and want to put in the effort required to restore the original geometry. I really should have gone to my Tormek to do that work, but I was interested in gaining WE experience.

2. Is VG 10 really that hard to deal with with diamonds? I had sharpened 2 other shun vg10 blades quite easily. A paring knife and the mate utility knife.

3. Could I possibly have worn out the 100 grit diamond stones in this endeavor? the stones don’t really seem worn out, they’re still making dust, but if a stone is expected to last 200-600 sharpening based on some bell curve of user skill/tactic and amount of steel removed, I’m certainly guessing these 100’s are, um, at least well worn in!

4. Lock that micro-adjust jamb nut tight and, realize that with enough steel removal your angle will change and you may want to adjust your angle slightly to stay on 16.00 deg.

Late in my second day of grinding, I broke out the phone, hot Amazon, and ordered some 50/80 stones that I’ve already semi-broken in on my beater cheap steel survival knife. The initial 50 stokes per stone surface were really quite painful to listen to, but eventually that very course/agressive stone set seemed to settle in and with reasonable technique put a quite nice edge on some cheap presumably Chinese steel. I can’t imagine I’d ever hit a quality knife anywhere near the apex with the 50/80, but had I had it while re-profiling the Yanagiba, I probably would have used it in hopes of saving hours and a lot of frustration let alone 100g stone wear trying to restore the original geometry.

So, how would you all go about restoring a VG10 Yanagiba to original geometry? Would you bother?

Do you use microbevels with intentions to making maintenue sharpening easier and not even thinking about any desire to go back to the initial geometry?

– edit was to use forum formatting bold vs. IPad text bold which does not actually bold the text…

Cheers,

Merry Christmas, happy Hanukkah , and / or happy holidays

-

This reply was modified 3 years, 4 months ago by

Henry.

1 user thanked author for this post.

12/11/2021 at 10:04 am #57339All,

Thanks for all the commentary in this topic which has taken a left turn down a rabbit hole of files and determining a steel actual hardness. All the above comments are fabulous!

My biggest takeaway is that I whole heartedly agree with Marc that we really can’t blame the steel so quickly for what’s most likely user-error or let’s rephrase as lack of user deep understanding of proper manipulation of all the variables involved with getting the desired edge.

I continue to break in the diamond stones, improve my strokes, pressure, attention to details while gaining confidence if not small incremental gains in getting desired results. I am still plagued with edge chip / tear-out on some blades, but will continue the learning journey.

As an aside, and I will start another thread on this, I did buy and receive the Shapton stones from eBay that Marc seems to like and must say, although it’s a bit messy, I’m loving the results.

Shapton Pro Kuromaku Stones Pack for Wicked Edge Sharpening Systems 220-30000,

I’ve got lots of good knives to sharpen, and feel confident enough now to start working on all but my exotic powder steel Japanese knives with diamond stones. Based on Marc’s experience ruining Mayobi knives using diamonds, I am not going there!

As the Germans say, “step by step”….

Peace all. Happy holidays, merry Christmas, happy Hanukkah, or joy to you in what ever you bay believe or celebrate.

I look forward posting a new thread that will be titled something like “ A novice step’s up the learning curve and gets better results; here are the lessons learned”.

<b>Let the journey and this discussion continue</b>!

-

This reply was modified 3 years, 4 months ago by

Henry.

2 users thanked author for this post.

12/06/2021 at 1:39 pm #57297Thanks Robert.

It’s funny you mention chasing the simple things firs. My career is precision motion control. Think robotics. I’d say that 85% of all problem we / I’ve seen over the decades is cable related! Chase the simple things first! Yes Sir!

YES to the too much pressure!

Interesting conflict you mention on edge leading vs edge training strokes. In this one post I’m getting conflicts. As Marc has told me before, It’s part science, part are (my words) but this is supporting evidence.

I will learn this voodoo slowly but methodically! Hopefully supported by as much data as feasible / possible.

And, I have no intention of making every blade a showpiece. Most of my case-use will be kitchen knives which I may polish to some extent but keep a 1000 grit or so micro-bevel edge to practical purposes.

We shall see. Perhaps there may be a lot of shiny knives in my arsenal, and friends, just because I can!

Finally, the hardness test file on Amazon is $80/ set. Yikes. It’s not out of control but my budget is blown .. for now. I think I’ll stick with assuming the knife maker has produced a product “close enough” to their target spec.

THANK YOU!!!!

12/06/2021 at 1:21 pm #57292As I promised, here are a few photos of the edge POST blending the microbevel on a series of strops (down to .5 micron). I did a series of about 4 progressive angle increases stopping 2 deg. above the final microbevel angle.

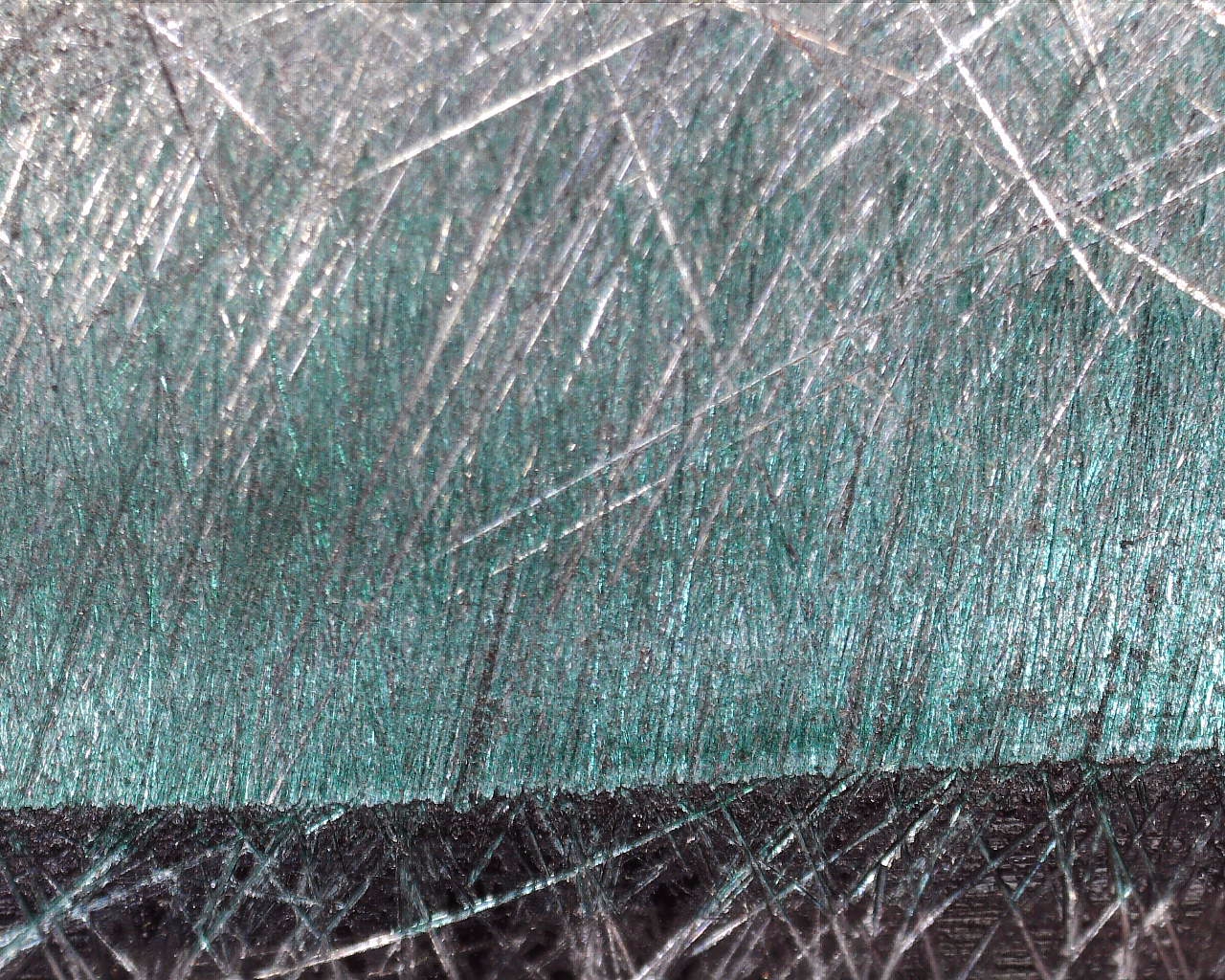

In this one you can see the “rough” scratches that indicate to me anyway a LACK of fully polishing with each and every grit. This clearly is using the USB scope on the “low” power…

Here you can see some of what I am calling tear-out. This is WAY better than initially, cuts like a hot knife through butter, but I am looking for BETTER as my technique (and perhaps the stones break in) improves.

That’s all for now.

I look forward to further constructive criticism and guidance as I continue down this journey.

I think I’ll try and do a different folder next, although I’m tempted to try and redo this one from the ground up.. uggg, the edge really is wicked sharp now. I can’t wait ’till I know what I’m doing and able to get to the next level!

Attachments:

You must be logged in to access attached files.

12/06/2021 at 11:39 am #57290Robert, Tc, and Mark,

Thanks for the guidance!

I’ll be the first to admit that user error and a learning curve are likely the root cause of the observed symptoms.

I’ll give the stones more time to break in and see how it goes.

Yes Marc, I need to do a better job taking and posting consistent photos. Heck, I’m happy I was even able to get the pix properly inserted!

I will pay more attention to ensuring each progression, beyond the initial reprofiling using low grits, actually apexes the blade.

Being far from new to sharpening, even with DMT diamonds but mostly whetstones, I “think” I have the light pressure down, but will continue to be cognizant of very light -reassure. I’m thinking that perhaps as I scrubbed with the 100 grit, I may have caused 2 issues?

1. Edge trailing strokes could have caused tear out. The “classic” stroke as demonstrated by many including Clay Allison – the “ bicycle stroke” for lack of a better term, seems to usually show edge-leading… but not always. I will keep this edge leading stroke in mind for sure.

2. I may have put too much pressure on stones, even though I “Tried”… I know I got … a bit agressive..

Robert, I like your idea of testing the steel for hardness… hmmm, another tool to buy at some point. But, I know the Spyderco is hard so…. ‘Does it really matter if I know the actual hardness”?

Finger placement on the stones… yea… after looking in the forums and YouTube, I’ve made a point of trying to grasp the stones near the bottom, one “ tick” up “ feels” right to me; but, I’ll make effort to be 100% consistant.

Regarding abrasive grit side, my hypothesis was that yes, the coarser stones would be a potential cause of tear out, and that’s why I started at 1000…but.. the 1k was just taking forever to make progress… so went down step by step looking for any meaningful progress but fell all the way to my lowest grit of 100 before I perceived any noticeable reprofiling. I sure did not want to spend 20 hours polishing the blade sides and never hitting an apex!

“Patience is a virtue“!!!

I really like the idea of hogging out with the coarser stones till BEFORE I hit the apex, then, as TC states, use nothing less than 600 as I approach and hit the apex using edge-leading strokes. Good advice. Actually, all this is great to get from the three of you who seem very knowledgeable and active! Thank you!

Marc, regarding magnified edges showing what appears to be tear out but may in fact be just scratch lines, I get where you’re going, but in my case, there were clearly tear outs of significant size, well above any grit line.. I think…? I sound so confidant but respect your thought and will noodle on that thought…

oh, FYI, I did occasionally recheck the angle with the cube and as far as I could read, given the accuracy and resolution of the 2 cubes I have ( one is the WE – wixley 300, my other is a

<h1 id=”title” class=”a-size-large a-spacing-none”><span id=”productTitle” class=”a-size-large product-title-word-break” style=”font-weight: normal;”>Momenturn Level Box Miter Gauge </span></h1>

has a claimed resolution of .05 deg., and seems to have the same readings as the wixley so I assume similar accuracy only higher resolution ( hope accuracy too), the point being, to the best of my measurements, the angle didn’t change stone to stone, but I’ll pay particular and detailed attention to this next sharpening session.As a final note, after I wrote this post, I decided to blend the bevels with strops / diamond paste and created a very shiny convex bevel. Yes there are still some deeper scratches left indicating to me, I think, that not enough time was spent on one or many of the progressive grits. But, the blade is beyond shaving sharp, it’s shiny, and I’m thrilled with this first experience.

There is still so much to learn! I’m a newbie and hope through practice and guidance of the community I’ll be able to create any edge il looking for within a few bazillion sharpening sessions! Lol, ok, I hope a dozen and I’ll consider myself competent.

I’ll try and post a photo of the latest blended edge for all’s viewing and constructive critical pleasure and feedback.

Thank you,

-Henry

-

AuthorPosts