Bob Harvey

Forum Replies Created

-

AuthorPosts

-

04/24/2021 at 11:47 am #56621

@Bob Harvey The SA is going to add 24° to the angle so I don’t see how it won’t help you to easily get to 45°.

Gotcha, I am new to the Scissor Attachment – but here’s my opinion.

I think if it simply angled over a bit from vertical, while still holding the “goat hoof shears” upright, then it would work. But it also moves the shears 90 degrees from vertical, so it is a very big change from doing simple knives on Wicked Edge.

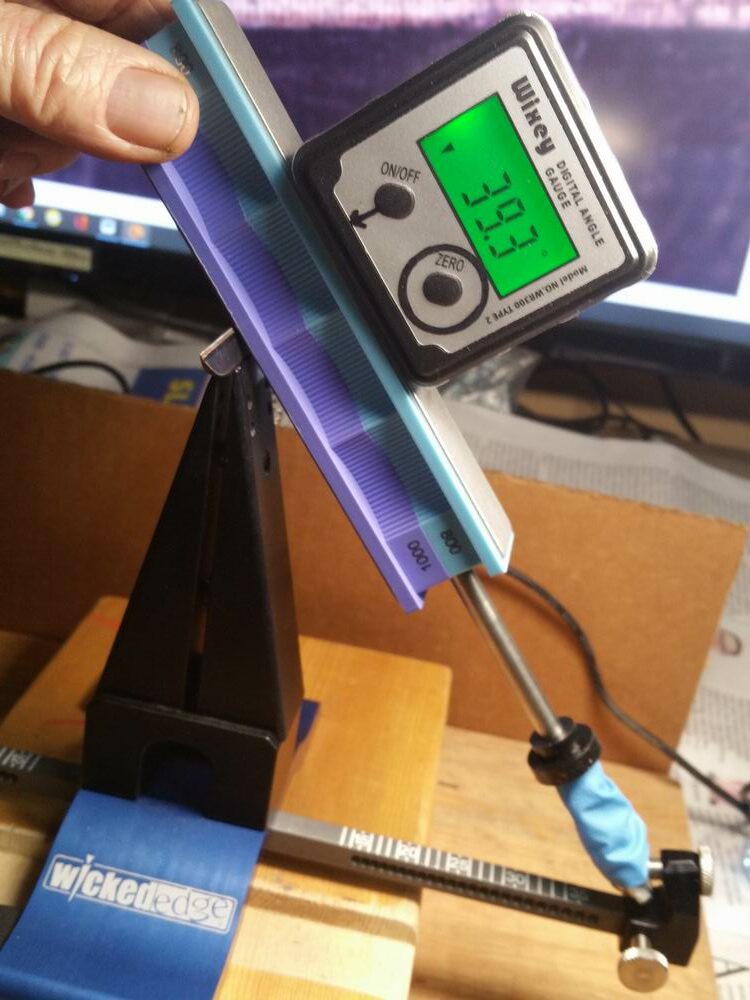

In this photo, I have the rod-arm moved outward as far as it can go on the WE120 and the sharpie is only removed from the apex.

I knew that I was getting the tool for something other than what it was intended for (scissors). The angle of these “goat hoof shears” tends to be about 40 degrees which is just odd. I just did some garden pruners, the factory edge was 36 degrees and I could do them with the Wicked Edge standard out of the box set up. So I realize that I have an odd-ball application.

I am OK on keeping the scissor attachment regardless, I am a tool freak and am sure they will see some use.

-

This reply was modified 4 years ago by

Bob Harvey.

Bob Harvey.

-

This reply was modified 4 years ago by

Bob Harvey.

Bob Harvey.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/24/2021 at 10:42 am #56618But photos always help.

Right – please see the previous page for photos. We have been busy this morning, and it started a new page.

04/24/2021 at 9:43 am #56615The longer bar simply gives you a wider angle capacity you lacked with the regular length bar.

Awesome. That is my next step on the journey.

04/24/2021 at 8:45 am #56613Bob, the Wicked Edge steel square bar is 5/16″. You can replace it with a longer bar.

Wow I never thought of getting a longer bar. People are always giving away junk BBQ’s on Craig’s List, I will have to find one with the rotisserie thing. I could live without the indents.

I already have the longer guide rods and low angle adaptor, so should be able to find combinations that work for all sharpening with the addition of 5/16 longer bar.

You are putting those “pool noodles” to good use on your base. I use them on my ladders to avoid damaging the edge of shingles, I do roof inspections.

1 user thanked author for this post.

04/24/2021 at 7:56 am #56603

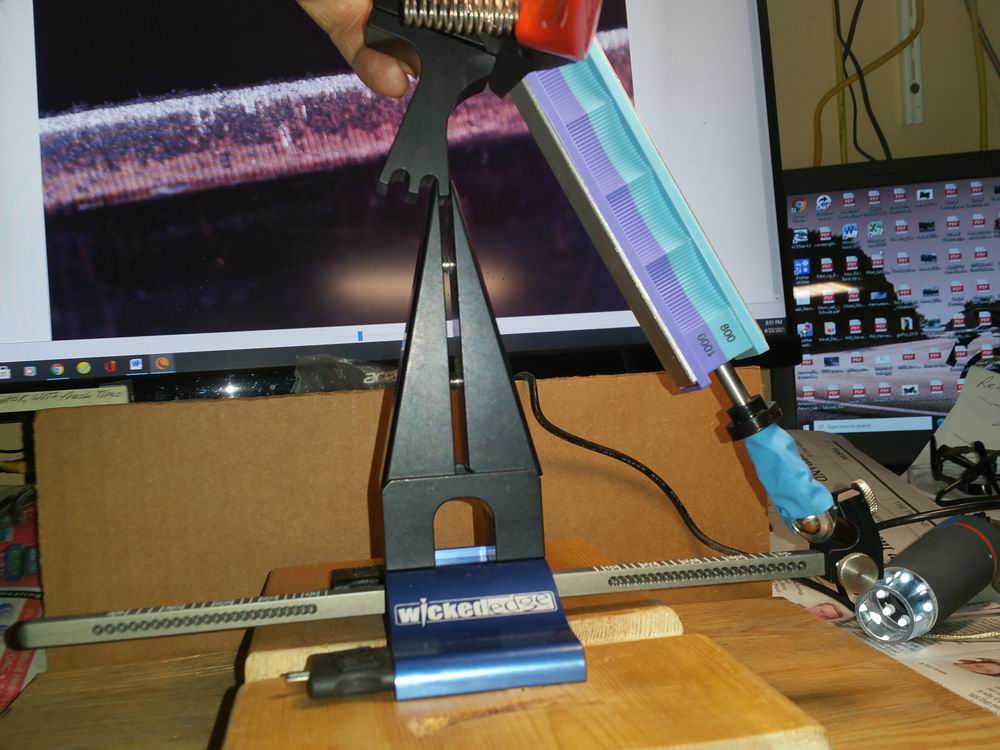

Here the scissor attachment is on. Of the 3 positions this is closest I can get to factory angle but can’t clear the sharpie off anything but the apex.

Celestron USB close up. Best I could do with scissor attachment on this particular hoof shear.

WE120 with arm moved outward as far as it can go.At this point, I think I am going to do all my long kitchen knives while the riser block is in place. Then remove it so I can do the constant supply of dull goat hoof shears, and still do the average length knives, my Paramilitary 2’s etc. without riser block.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/24/2021 at 7:48 am #56599

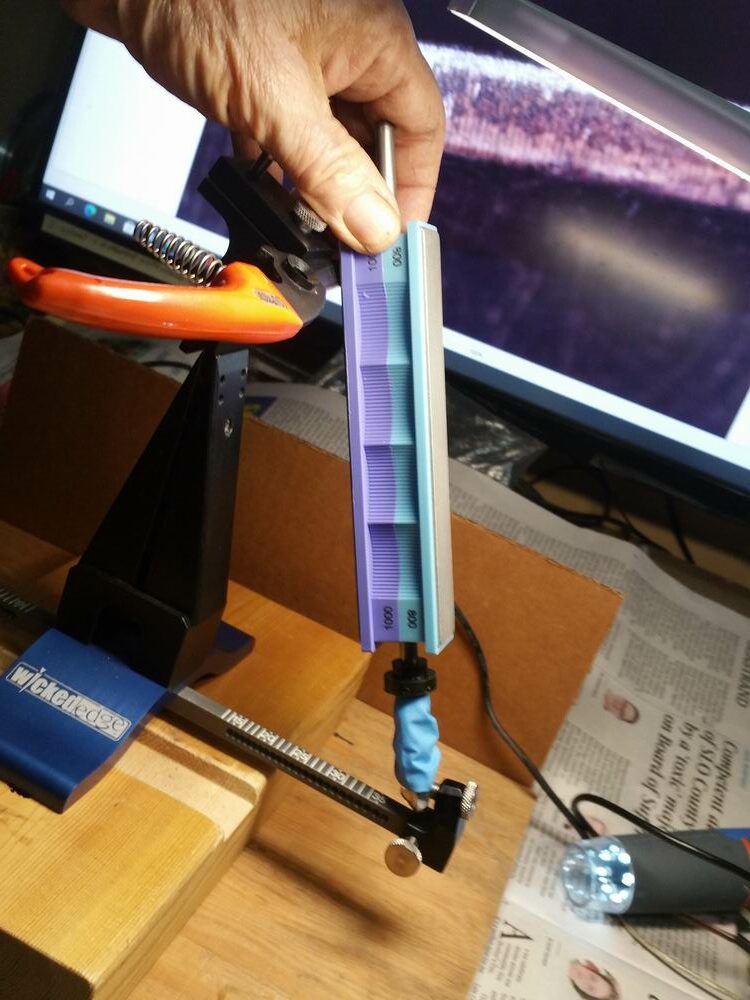

While waiting for scissor attachment to arrive, I took the riser block off.

Now it goes to 45 degrees easily, so I have freedom to easily move around that 40 degree range to clear the sharpie and approximate factory angle (which is usually around 40 degrees)Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/24/2021 at 7:45 am #56595

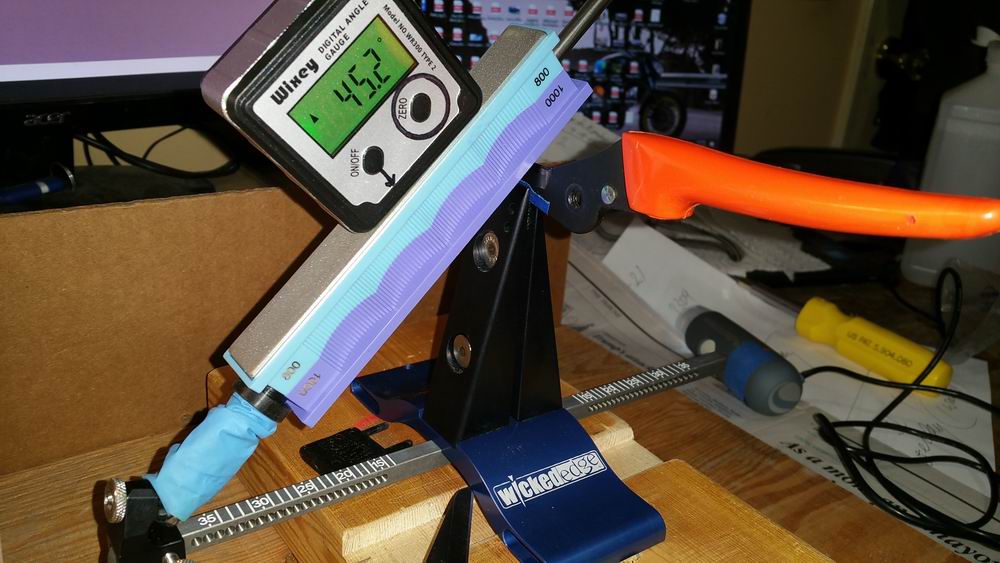

Factory profile on this hoof shear is about 40 degrees. With the WE120 set as far wide as it can go, it barely clears the sharpie off the factory bevel. She has several different manufacturers of these shears, some factory edges are a bit over 40 degrees and I have to reprofile.

Here we are getting a proper angle – just barely.Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/23/2021 at 10:37 pm #56593It works great for me on my scissors.

…But the easiest way to sharpen them is with the sharpie method anyway.

OK, got the scissor attachment in today – and it is the opposite problem. The angle is too wide, the sharpie gets hit along the apex. Previously it was hitting along the base of the bevel.

I tried the 3 mounting points on the attachment, the one that angles “down” more rather than level is approximating what I need on this odd 40 to 45 degree angle on the wife’s hoof shears. But it’s not angled down enough, and it is like the sliding arm needs to be a couple inches longer for that to work (I have the WE 120 that is numbered out to 35).

I removed the “riser block” on the WE 120 which fixed everything for this odd application – but it is a pain to go back and forth.

She has a bunch of goats, and needs these things sharpened all the time. Has several sets of these shears, and I have been reprofiling them to about the 38 degree max that is mentioned on the first post of this thread.

04/19/2021 at 10:44 pm #56572The scissor attachment won’t work for the goat hoof shears?

I thought they would have a much more blunt angle – but I can’t seem to find any numbers on that from Wicked Edge…

But maybe you are right – I found a scissor site that said 40-45 degrees which is what I need. I will have to pick up that attachment. I think it would clamp the disassembled shears well. Yeah I will give that a try.

04/19/2021 at 9:59 pm #56570…planer blades that require a 45 degree angle. …I have the WE130 and the largest angle is approximately 38 degrees.

I have the WE120 and wonder if there is some way to LOWER the clamp that holds the blade in order to achieve a wider angle.

The WE scale goes out to 35, I can use the angle cube and get it out to 38-40 but that is it. I am sharpening “goat hoof shears” which look just like the small pruners that gardeners use. At my max angle I have to reprofile all her shears, that are likely around 42 degrees from the factory.

When you hit the limit on how far out you can move the arm, you just have to wonder if it’s possible to put a smaller riser / spacer that sits below the clamp. That would achieve the same result of a bigger angle…

03/17/2019 at 6:07 pm #49738Thanks – that all makes sense. I know i will get better. I am following the advice to work on inexpensive knives first, before working on me EDC’s.

Hoping to confirm my understanding that a kitchen steel WILL NOT STRAIGHTEN the edge, but simply starts to remove some metal (as per the science of sharp article). I would love to learn that I could simply use a steel and push the little rolled edges back in place – but I don’t think it is that simple.

2 users thanked author for this post.

03/17/2019 at 5:01 pm #49735I’m pretty new – 7 knives with my model 120.

I have suffered through a Lansky and Sharpmaker, gladly spent the money for a WE and some extra stones.

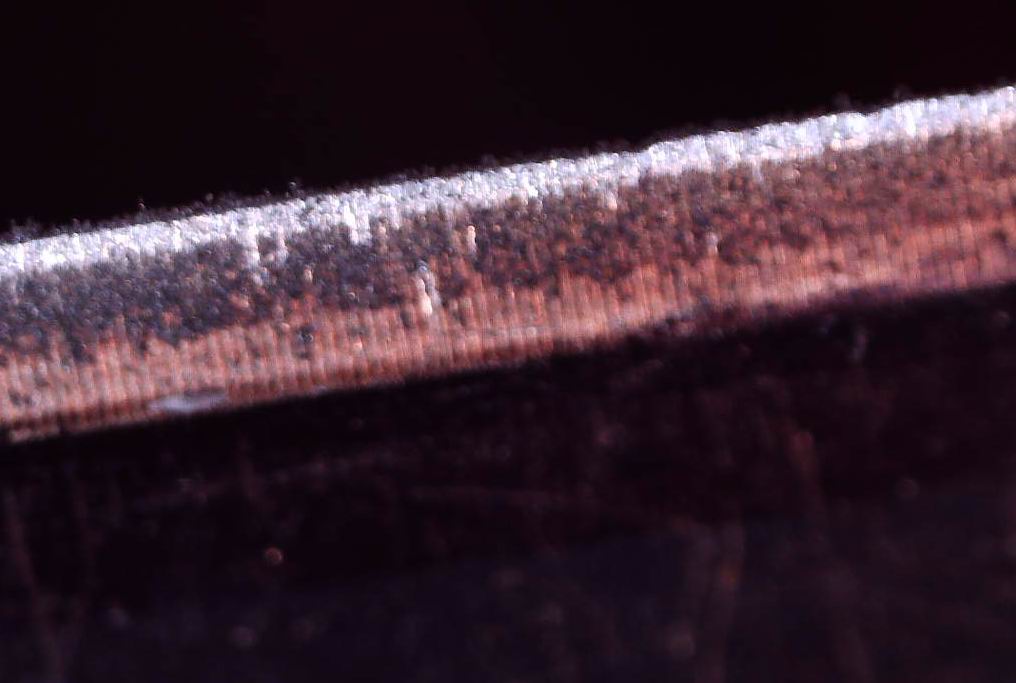

I got that Victorinox 8″ chef knife “serviceable” (not pretty) but getting the flaws out with 200, then 400, 600, 800, 1000. This photo was at 400 grit

I did not take the time to fully remove all prior grit scratches because I suspect I will be going to 20 degrees soon on this soft steel

Attachments:

You must be logged in to access attached files.

03/17/2019 at 4:28 pm #49731…Whustof knives with the X50CrMOV15 are relatively soft (Rockwell 58 or so) and are designed to roll fairly easily. This allows the edge to respond well to a honing steel and to be resistant to chipping even with hard use. Knives that are harder will be prone to chipping if you accidentally hit bone or knock them on the edge of a glass bowl.

I understand the the Victorinox kitchen knives are made of same steel – and I got a set last month.

Yeah the steel is really soft. Wife used the 8″ chef knife 4 times and it got pretty dull, won’t cut paper…

I looked at it with the Celestron scope (thank you tcmeyer) and see “waves” in the edge where it has deformed, not chipped.

I put the factory 15 degree angle back, and as you can imagine when the deformations were removed, there were small “missing areas” (look like small chips) which required more metal removal.

I am fairly new to this – and hope to confirm my understanding that a kitchen steel WILL NOT STRAIGHTEN the edge, but simply starts to remove some metal (as per the science of sharp article). I would love to learn that I could simply use a steel and push the little rolled edges back in place – but I don’t think it is that simple.

Next time this knife gets dull I will put a 20 degree micro-bevel on it.

Attachments:

You must be logged in to access attached files.

-

This reply was modified 4 years ago by

-

AuthorPosts