Small chip near tip . . . Best plan of attack?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Basic Techniques and Sharpening Strategies › Small chip near tip . . . Best plan of attack?

- This topic has 24 replies, 6 voices, and was last updated 12/31/2018 at 11:05 am by

Expidia.

Expidia.

-

AuthorPosts

-

12/25/2018 at 6:40 pm #48709

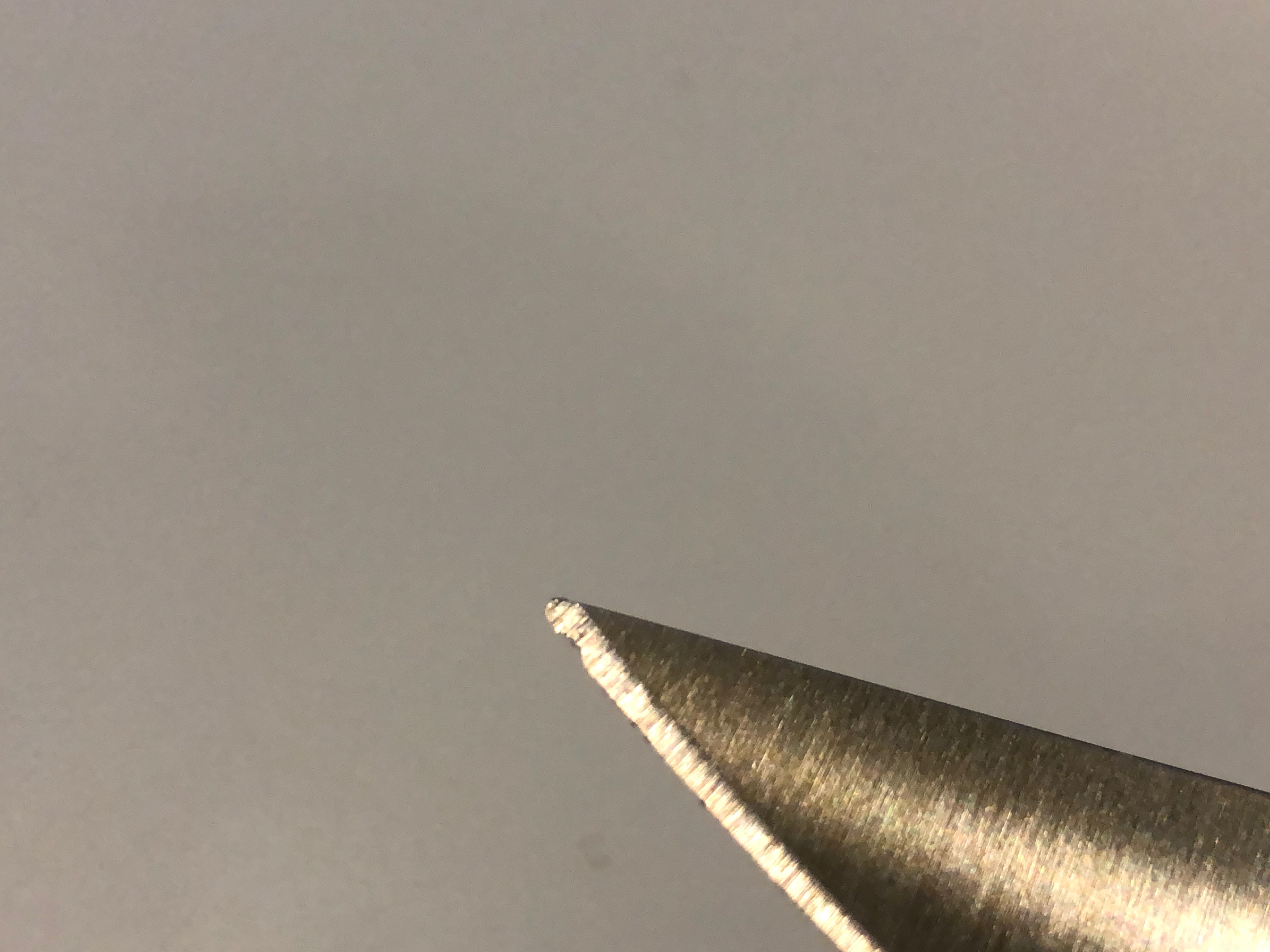

Just picked up this used Spyderco Para Millitary 2 that came with a small chip near tip. It’s CPM S110V steel and my office mate tried sharpening his on his WE. Ruined his blade and sent it back to Spyderco for a new blade.

Seems factory angle is 15 degrees per side. I’ve read others have had a tough time with CPM S110V steel from other forums.

Since I have to first re-profile it anyway to 15 per side do you think that chip would come out just in the normal reprofiling? I was going to start with the 80 grit as I find the 100 grit takes a long time to raise that first burr and i already know this is a hard steel.

I see there is no sharpening choil so I know this might make it even more difficult for the heel strokes.

Thanks

Attachments:

You must be logged in to access attached files.

12/26/2018 at 4:15 pm #48737Anyone. Anyone. How would you start removing this chip?

12/26/2018 at 7:37 pm #48743IMO you are going to have to redo the tip. The chip goes ~1/3 into the bevel. I would reprofile the tip until the chip is “gone”, plus a little. Bad chips can have damaged subsurface steel. I have used the diamond paddles for this using the surface area not normally used in sharpening (near the top/bottom). It is going to take quite a while though (hours) and may wear out a paddle & make a set inconsistent.

You should prob reprofile with a power 1×30 variable speed. Some of our super users do that.

If you do decide to go standard WEPS and keep grinding the bevel until it’s gone, I think it will take a very long time to get your perfect burr. You should also not rush the removal of metal as it can cause metal fatigue.

Hope that all helps.

12/26/2018 at 8:37 pm #48744Thats great info Readheads. Marc had emailed me some tips also. One point he made due to the hardness of this steel is to take my time as you said above as a micro chip can get worse too. I actually have a set of WE knock off 200/800 stones that came with my Gen III Pro unit that Clay’s former machinist was selling on Ebay awhile back. I bought all my stones through WE and upgraded the vice to the 3001 from WE too.

Good point on wearing down my stones. I was worried that if I started with the WE 50/80 stones I might cause further chipping since they are so coarse and this steel is so hard.

These 200/800 stones are probably a good place to start using the 200’s and just take my time or as Marc noted re-profile it over a few sharpening sessions so as not to rush the edge into a burr to quickly just to make that chip disappear. I bought it as a user for cheap, so if I mess it up I can send it back to Spyderco for a new blade to be put on. Or maybe they will just sell me a blade and I won’t have to send it in.

I’ll check back into this thread and note my progress. Marc also suggested I add a sharpening choil which I had already figured I’d need one since the edge runs right up to the heel or whatever that area is called near the handle. So I’ll have to youtube to see how the best way to do this is.

12/27/2018 at 12:29 am #48746My suggestion is to stone the tip as if you were sharpening it. When you get to the point (!) where the chip is gone, you’ll have lost the least amount of blade length.

1 user thanked author for this post.

12/28/2018 at 7:51 pm #48788I love this system. Clay is a sharpening “genius”! So I first took Marc’s suggestion to put in a sharpening choil. I found a round diamond blade that is held in a hacksaw. Did the job in no time. Then I used TC’s suggestion to just sharpen it as normal until the chip is gone. I used the Tormek adapter as 15 degrees is such a low angle with a small blade.

I had it to the point where the chip was almost gone and I figured next I was re-profiling anyway . . . so I took the 100 stone off the rod and freehanded the chip area by holding the stone perpendicular to the blade and lightly rubbing until it was gone. Then I re-checked the angles for 15 degrees again and started raising a burr with the 100’s. Took about 45 min to an hour to get that first burr as I went slowly so as not to fatigue this hard steel.

Now I know why people like Spyderco so much. This CPM S110V is damn hard to work with but the diamond stones worked very well. This steel started mirroring when I was working the 800’s. I don’t see that with the Chris Reeve’s CPM S35VN softer steel until I’m on the 1,500’s.

I say Clay’s a genius because the systems desigh locks everything tightly into place where I don’t think I could make the mistake of rolling a bevel unless I switched the angle. It just makes such flat and repeatable bevels its amazing. I was worried I was going to mess up this blade, but the system worked so smooth. This edge is one of my best yet and I’ve probably done 75 edges so far.

sharpening choil added

The finished WE edge. And it’s a beauty!Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

12/28/2018 at 8:11 pm #48794Looks good!

4 users thanked author for this post.

12/28/2018 at 9:23 pm #48795Nice job.

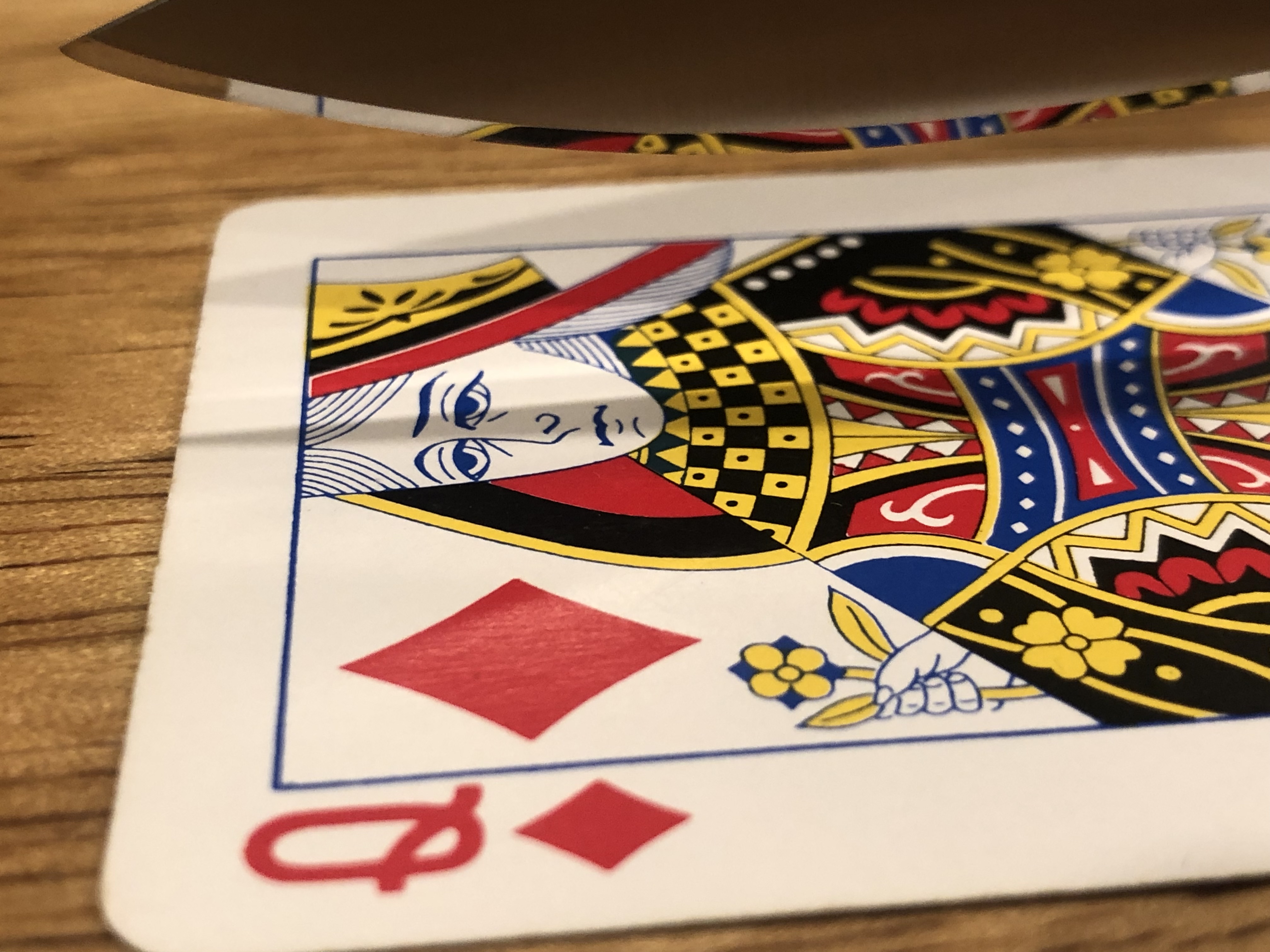

As an aside, and along the line of visionary “beer talk” might we start a discussion of the ultimate tip. This is prob most appropriate for kitchen knife honsuki types which I use to skin out full beef tenderloins into filet mignoins. To me, the ability of a perfect (impossible) needle point to surgically slice is in the same family as our hands putting mirrors on a knife edge. Craftsmanship at it’s best.

I propose that the method you used (although very prudent) did not enable you to define the tip dimensions as much as you could have. Defining your ultimate tip (with perpendicular soft grinding) and then raising the burr (keeping in mind the WEPS geometry drivers) is an interesting endeavor to me. I think there are techniques which may allow the human hand to do things a CNC macine cannot do.

As reference, you tip IMO is slightly rounded and could be “tighter”. I would have prob done the same. Since we spend so much typing about mirrors could we spend some on tips. They are fragile but the sharpest of all the knife parts. I attached a pic of my newest knife, Roland Lanier’s Gentlemans Steak Knife meant to take to a restaurant. The tip is one of my favorites and my future challenge is to maintain it.

Just food (drink) for thought to generate conversation on ultimate tip techniques while we wait for linear indexes to handle serrated knives from clay.

Happy new year to all, I will be in New Orleans for a wedding.

2 users thanked author for this post.

12/28/2018 at 9:37 pm #48796My steak knife

12/28/2018 at 9:38 pm #48797

The mobile version of the WEPS site leaves a lot to be desired. Just saying.Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

12/29/2018 at 7:50 am #48805Thanks Readheads. Good info. As an aside my father-in-laws girlfriend used to bring her own silverware to restaurants with her. But she was a germ-o-phobe. And she’s also DEAD now, so I guess that didn’t help her much.

I had to look up what a 1 x 30 was and I see Harbor Freight has one of those for $52. That’s a sweet belt sander and I would love one of those. But I rent and my work shop was fashioned from a spare closet, but hey, I have my own window! So I tend to try and get rid off stuff, rather than accumulate more but that would sure make fast work re-profiling the tip.

I store my stone’s and accessories in a drawer of my Craftsman tool box that is under the WE. Each stone in its own compartment to avoid grit contamination using Dick’s field and Stream $5 tackle or lure boxes (the ones with the vertical slots) if I didn’t have that option I’d be a buyer of “MarcH’s Rack-It” stone storage rack system.

As you can see from the pic of the chip, the tip too came damaged from the former owner who probably used it to open paint can lids or beer bottle caps. I was more conerned with getting the chip out and to see if I could actually sharpen CPM S110V steel without ruining the blade like my WE experienced office mate did when he attempted his Para 2 knife with the 110 steel (he was the reason I bought my WE).

This Para Millitary 2 sells for $165 at the online dealers with this grade of steel and I only paid $80 for it. So bringing it back to life is a work in progress. As MarcH had said I’m better off working it over several sessions. I don’t know if that chip did more damage deeper into the metal than was showing. My next session since its already profiled I’ll start repairing the tip. I wasn’t going for sharpness on this session. The edge still has a tiny burr that I can feel on one side. It’s extremely time consuming to flip CPM S110V at least for me, it was very hard to flip that first burr to the other side with a 100 stone. I did not want to start with a coarser grit for fear of micro chipping this hard steel. Its a user for me as I’ll carry it when I’m in cities that frown on knives that can be flicked open with one hand. Especially the type that uses a thumb stud or a flipper lever as these are illegal to carry in cities like NYC or Montreal by their knife carry laws. I don’t know how they view a knife with a Spydie hole opener since this knife can be viewed as a two hand opener. But I’d have rather have an $80 knife confiscated than a more expensive one from my collection.

Your steak knife is really sharp looking. I looked up their cost . . . probably best not to forget and leave it on the table after you finish dinner! Drill a hole in the end of the handle and attach a lanyard to your belt :O)

Check out the hardness scale in pic. Only two steels above CPM S110V in hardness on this chart. Check out where the new kitchen knife I bought falls VG-10. MarcH and Organic recommended I start with a softer steel like the VG-10 because its easier to re-sharpen and micro chips less.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

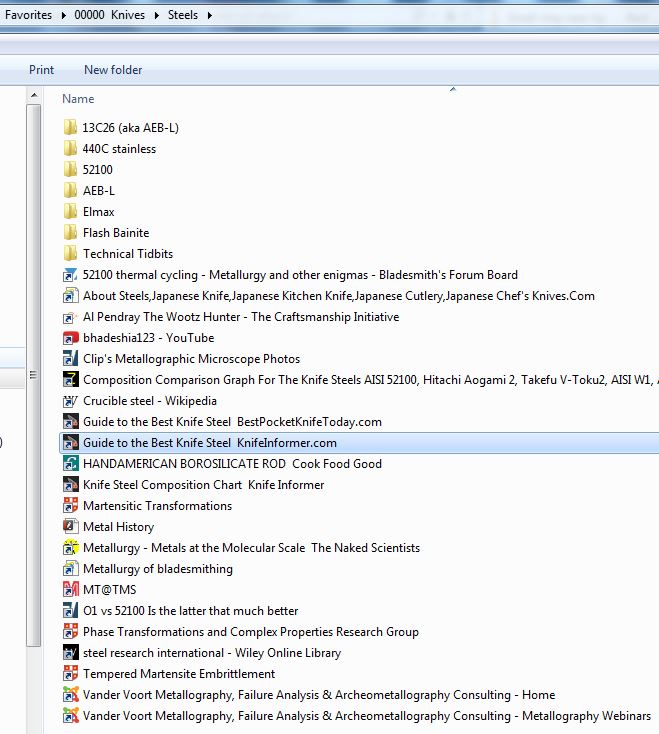

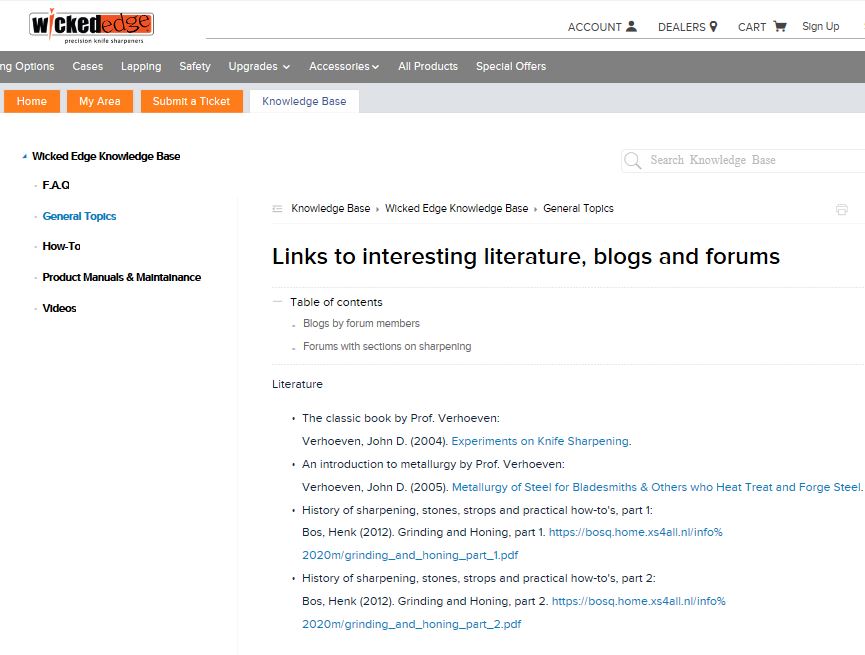

12/29/2018 at 10:19 am #48812Nice setup. I dabble in material science as a hobby. Attached are a couple of pics (one of my Favorites and the other from the WEPS Knowledge Base).

I recommend the Verhoeven works greatly as they have a lot of well written technical info.

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

12/29/2018 at 12:14 pm #48816Expedia,

I also have a PM2 with S110V as my EDC. I’ve profiled it once at 17DPS to a mirror polish and have been touching it up at 18 DPS. I have found that it doesn’t take as keen an edge as my Kershaw 1812 in M390. Both knives have excellent edge retention and are close to the same in difficulty to sharpen.

The link below from Blade HQ gave me the impetus to find an M390 knife to sharpen.

https://www.bladehq.com/cat–Best-Knife-Steel-Guide–3368

Your shop picture shows a BESS tester. I also have one, and the PM2 gets down to 110-130gf. The 1812 out of the box was 123gf but the WE treatment got it to 71gf. Both the PM2 and 1812 edges are razor sharp but the S110V just doesn’t seem to want to get the apex as thin.

Just FYI, when I got my PM2 I emailed Spyderco tech support asking what edge angle they used on the PM2 S110V and the Manix 2 in Maxamet steel. Their response was that all knives leaving the factory outlet in Golden CO. are sharpened to 20DPS.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

12/29/2018 at 12:22 pm #48821Adding the fifth pic of the WE laser edge.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

12/29/2018 at 8:47 pm #48827Thanks for all that info Notsharpenuf. Those are some smoking sharp numbers on your edges. I thought I was hitting a few numbers like that when I initally got the unit, but even though I was using the fulcrum to support the tip I found I was ever so slightly “slicing” into the testing medium instead of “pressing” straight down! Below 100 is double edge razor blade sharp. For me, I know that edge won’t last me very long. I was pondering picking up your digital edge finder but it turned out to be pretty pricey for an average hobbiest. I Googled for the factory angle and thought I landed on a Spyderco.com link but now I think I landed on a thread which was probably on a Bladeforums chat room suggesting 15 degrees. When I start my 2nd sharpening session to apex the PM 2’s edge and sharpen out the tip . . . I’ll probably re-profile to 18 which is where I angle most of my folders. I like the trade off of maybe a little less sturdy edge, but a wider showier mirrored Wicked Edge! My user habits might be as severe as opening an envelope. I do like getting the edge as sharp as I can and that’s why I picked up the Bess (great tool). I love the way a razor sharp knife edge “melts” through an envelope. I even hate using my knives to cut open say an Amazon box because I hate getting the glue from the tape all over the mirrored edge. So I usually use a single edge razor blade to open cardboard boxes. But I did read a good tip on one of the forums. Flip the box on it’s long side and cut a 3 sided flap with your knife, take your goods out and . . . Wallah, no tape glue residual on your blade. And if you have to return the item the box is still intact all you need to do is close the flap and put some packing tape over your 3 cuts. Those round laser digital angle finders I think were made in England were running like $230 plus shipping from England. Do you know of another cheaper source?

Thanks, Paul

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.