Calculating the Sharpening Angles for Blade Positioning

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › Calculating the Sharpening Angles for Blade Positioning

Tagged: t

- This topic has 12 replies, 5 voices, and was last updated 07/23/2022 at 2:58 pm by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

AuthorPosts

-

07/16/2022 at 12:35 pm #57985

I have a knife that is mangled a bit, so is unlikely to yield a good answer using the sharpie marker approach. So I have been thinking about a computational method for optimizing blade position.

I have determined that the sharpening angle can be determined analytically from the blade profile, where X and Y are the mounted horizontal and vertical displacements from the pivot point and Theta is the blade angle at that position.

Forgive me if this is available elsewhere, I have scoured the board looking for related items, discovering for example the excellent discussions of Anthony Yan, who presented both results and analysis. I could not find in his discussions any formulas that could be used for calculating. I have also been helped by the discussion of graphite, whose circular template approach was insightful and instructive. But I wanted to be able to get a formula for the sharpening angle at any position on any blade. That analysis is in the attachment below (fingers crossed that its readable, — this is my first post…)

I have developed a spreadsheet to explore this computational approach for real knife geometries. As a check I made sure the results for the three known consistent sharpening angle geometries are in fact consistent. And I have tried it out for that mangled knife I mentioned at the start. I am just beginning to explore its functionality.

I would very much appreciate knowing if

A) this is old hat and I am late to the party.

B) If you find some error in my approach (or something is not clear).

C) Whether it might be worth sharing the spreadsheet I am developing.Sorry for the long post and the pedantic style, kind of hard to help that…

Looking forward to knowing your thoughts…..-

This topic was modified 2 years, 9 months ago by

Tom_G.

-

This topic was modified 2 years, 9 months ago by

Tom_G.

Attachments:

You must be logged in to access attached files.

07/16/2022 at 2:50 pm #57990Welcome Tom, there a few engineers here who may have enough math skills to discuss with you but by far most of us are just normal joes who want a sharp knife to cut whatever that particular knife would be used to cut. If one does not know what the angle is, nor the make and model to look it up, then 20 degrees works well for most knives I own.. Doing high math really isn’t in the cards for me and I know the knife doesn’t do math

If the steel is of the hard variety and the knife is thin then 17 or 18 would also work, depending on the use case. Use case has more to do with what angle and final grit to use then the shape and size of the knife in my opinion.

07/16/2022 at 5:00 pm #57991airscapes — thanks for touching base, and for the info and guidance about sharpening angles. I am thinking that I did not introduce that first post very well. Rather than determining an angle to use for a blade, the calculation is aimed at finding the variation of the sharpening angle for each portion of the blade. My understanding is that setting the knives mounting position is key in getting the sharpening angle uniform across the blade. The recommended approach, if I understand things correctly, is to use a sharpie marker and a fine grit to see what the sharpening angle had been, and then to see how uniform the angle is across the blade. And then repeat at another mounting place to try to make improvements in that uniformity if need be. My discussion above is essentially a beginning of a computational substitute for the variation part of that process — knowing the knife geometry (just from a picture) its possible to get the variation in the sharpening angle across the blade. If put in a spreadsheet, you can get numbers for the angle at positions along the blade, and then change mount values and calculate again. Not sure it’ll be easier than the sharpie approach to mounting, but it will accurately yield the sharpening angle variation. Cheers!!

07/16/2022 at 5:49 pm #57993Tim, we try to find a single “best” clamping position at the start, the “Sweet Spot” that allows us to sharpen the whole blade efficiently and effectively. It usually is a slight compromise for the full length of a knife edge to find a position that yields a good balance in sharpening effectiveness and aesthetics along the knife edge. Since the W.E. is a fixed angle guided sharpening system we usually work with this balance or compromise and use the angle setting made once, at the beginning, for the entire knife. Any changes in the edge steel thickness along the knife’s length,and/or the height of the knife edge of the mounted knife relative to the ball ends height will affect the applied set sharpening angle and possibly the appearance of the applied bevel’s heights.

Those W. E. users who prefer to fine-tune their sharpening results such that the results appear more uniform and consistent, aesthetically, may choose to make slight angle variations for that portion of the knife edge and work it separately. For instance, at the knife tip.

Based on knife sharpening methods for all the W.E. setups, to achieve uniform consistent scratch patterns across the full kn8fe edge, I would find micro-adjusting the sharpening angles along the entire length of the knife not conducive to this style sharpening. Where the freedom to make those angle changes freely is important a fixed angle sharpener is probably not the best choice.

Marc

(MarcH's Rack-Its)07/16/2022 at 9:05 pm #57994Welcome Tom G And thank you for the thought provoking question.

You want to be able to get a formula for the sharpening angle at any position on any blade.

I like the idea

A) You are right on time. you are not late for the Party, we are trying to get this right or make it better.

B) I am not looking for wrong in your approach (the “Attachment” had a lot of thought put in it)

C) I do not Call the shots hear

With 10″ Chef Knives I put the Center of the blade at the edge of the vice that is near me when I sharpen.

I am thinking the easiest way to check out the “Spreadsheet” accuracy is to use those formulas on a “Wicked Edge” knife sharpener.

07/16/2022 at 10:12 pm #57995I have this from several years ago. It’s a chart or graph from a spread sheet that was put together by an engineer who is a Wicked Edge user. Is this what you’re talking about? It’ll let you set the bevel angle by edge height and ball end distance from the knife’s centerline. This is to determine a single set angle for the whole knife. The guy that made the chart did all the computations for it. Probably using a mathematical equation similar to Tom_G’s.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

07/21/2022 at 12:09 am #58042So I have some preliminary results. These are for the following (inexpensive) knife.

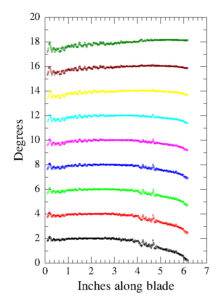

I have calculated the real sharpening angle for the various positions across that blade for a number of different mounting spots. The mounting spots are 2″, 2.25″ 2.5″ ….. up to 4″ from the blade start (right side of the image). The sharpening angle is adjusted to be 18 degrees at the mount location and the blade is pushed down so the both mounting pins are in contact. The variation in the sharpening angle across the blade is shown as calculated for each mount position in the figure below. for readability, the 2″ mount has 16 degrees subtracted from the calculated angles (so its on the bottom and is black). The 2.25″ mount position has 14 degrees subtracted so its just above the 2″ data set (it is red and its target angle looks like its 4 degreees). The data is a bit noisy, which is from the conversion of the picture to top and bottom of blade XY positions. (this can be improved).

This is just my first computation, so I expect accuracy and noise to improve. Hopefully this makes more clear what I was after….

Tom

-

This reply was modified 2 years, 8 months ago by

Tom_G.

07/21/2022 at 9:22 pm #58047Looks like you are trying to find the sweet spot.. where to clamp the knife so the angle changes the least.. It is sometimes more work than needed .. if the knife is not relatively straight, I just do it in sections an change the where and how it is mounted to make the section level.. This type of math exercise is neat, but really not helpful when it comes to making your knife sharp to cut whatever it is you desire it to cut.. Have fun!

07/23/2022 at 4:19 am #58048My method is a form of “finding the sweet spot” except that I don’t try to match any existing bevel – which is what the sweet spot is originally intended for. I pick a mounting position which matches the sweep of the stone to the belly of the knife. Another way of looking at it is to imagine a line forming the radius of the edge’s belly and position the knife so that the line passes through the pivot point of the rod bearing. Then adjust the angle with the stone positioned at the tangent point where the belly meets the straight part of the edge. The position you find need not have the blade’s spine flat on the key pins. No matter what the angle of the blade, relative to horizontal, the bevel angle will be constant throughout the length of that straight section, even if it extends well away from the vise. This is a key factoid that we use to give us flexibility in positioning blades in our vise.

Yes, the deeper the belly, the more variability in angle you’ll see along that belly, but for most knives, it’s simply not a problem to wring our hands over.

Upshot: Position the belly to match the sweep of the stone and trust that the straight section will follow uniformly. No belly? Whoohoo!

07/23/2022 at 1:47 pm #58049I have this from several years ago. It’s a chart or graph from a spread sheet that was put together by an engineer who is a Wicked Edge user. Is this what you’re talking about? It’ll let you set the bevel angle by edge height and ball end distance from the knife’s centerline. This is to determine a single set angle for the whole knife. The guy that made the chart did all the computations for it. Probably using a mathematical equation similar to Tom_G’s. offset-of-ball-vs-angle

Marc,

Thanks for digging up the info! The features of that curve is part of the calculation above. I am pretty sure the graph is of the formula Offset = Height * atan(a fixed angle) + (1/2 of the width of the diamond block). It incorporates the width of the block as part of the analysis to gives you how far off the center the ball should be to get a particular sharpening angle for a given blade height. It assumes, though, that the blade is flat and horizontal at the height point, which can generate corrections. Pretty glad to see that this piece of things makes sense — Thanks!!

07/23/2022 at 1:51 pm #58050Looks like you are trying to find the sweet spot.. where to clamp the knife so the angle changes the least.. It is sometimes more work than needed .. if the knife is not relatively straight, I just do it in sections an change the where and how it is mounted to make the section level.. This type of math exercise is neat, but really not helpful when it comes to making your knife sharp to cut whatever it is you desire it to cut.. Have fun!

Got it — thanks and understood. I am just a newbie with a computational/design bent for whom you have correctly identified a big part of my justification for doing this — its fun!

07/23/2022 at 2:17 pm #58051My method is a form of “finding the sweet spot” except that I don’t try to match any existing bevel – which is what the sweet spot is originally intended for. I pick a mounting position which matches the sweep of the stone to the belly of the knife. Another way of looking at it is to imagine a line forming the radius of the edge’s belly and position the knife so that the line passes through the pivot point of the rod bearing. Then adjust the angle with the stone positioned at the tangent point where the belly meets the straight part of the edge. The position you find need not have the blade’s spine flat on the key pins. No matter what the angle of the blade, relative to horizontal, the bevel angle will be constant throughout the length of that straight section, even if it extends well away from the vise. This is a key factoid that we use to give us flexibility in positioning blades in our vise. Yes, the deeper the belly, the more variability in angle you’ll see along that belly, but for most knives, it’s simply not a problem to wring our hands over. Upshot: Position the belly to match the sweep of the stone and trust that the straight section will follow uniformly. No belly? Whoohoo!

Ahh, so your method seems pretty quick as a way to get a near optimally uniform sharpening angle, since, as you point out that angle is uniform if the edge of the knife traces out part of a circle about the pivot point -and- that the sharpening angle is uniform along a flat edge even if its tilted. I came across a discussion, in my explorations of the forum before I dove in and purchased the sharpener, that described a template for locating where the belly should be https://knife.wickededgeusa.com/forums/topic/blade-alignment-in-the-clamp-sweet-spot-constant-bevel-angle-width/

Your approach, I think, matches what you would get using graphite’s template, but — if I understand you correctly, is quick because you just use a point on the pivot arm to make the belly match the circle the point sweeps out. Wow.

The part of this that I was never able to locate information on was how far off the sharpening angle would be if a blade was not a straight section connected to a belly that could map onto a circle. I think your approach may be optimal as well for such blades, but my curiosity got the better of me, so I am calculating away….

Thanks — Tom

07/23/2022 at 2:58 pm #58052Tom_G,

I believe tcmeyer, airscapes and me are putting to practice a method based on graphite’s illustrated technique. For me, at first the clamping positions were intuitive. Like tcmeyer, I just looked at the knife’s shape and clamped it how it looked like it would work well. Later it became experienced based. Now I can look at a blade shape and I intuitively know how I would clamp it up knowing that it’s good and I can work with that position.

More important than the edge angle, and the angle consistency across the blade length, is the edge’s keenness. That is how closely the two planes of the opposite side bevels intersect at the apex of the knife edge. It won’t matter how perfect your angles are if your edge is not keen and your sharpening technique is half-fast. Without a keen edge and good sharpening technique you’ll never be able to discern how the bevel angle contributes to the knives sharp feel. Even a knife sharpened with a less than optimal edge angle will still cut well when sharpened with good proper technique.

Marc

(MarcH's Rack-Its) -

This topic was modified 2 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.