Base Material?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Base Material?

- This topic has 18 replies, 6 voices, and was last updated 04/03/2019 at 9:45 am by

NorCalQ.

-

AuthorPosts

-

03/29/2019 at 1:45 pm #49879

I have a Pro Pack 2 that has a black base that is about 1 1/4″ thick and very heavy. I’m wondering what the base material is, as I would like to machine out a small portion of the underside, in order to accommodate some lites? I’m suspecting it’s quartz. If it is, can the quartz be machined with carbide wood working router bits?

03/29/2019 at 2:32 pm #49880Marc

(MarcH's Rack-Its)03/29/2019 at 2:40 pm #49881Marc, I don’t think it is aluminum or granite. It is charcoal in color, with color thru and thru. I believe it seems softer than granite.

03/29/2019 at 2:43 pm #49882Just found out, even if it’s quartz, I’ll need diamond bits.

1 user thanked author for this post.

03/29/2019 at 11:39 pm #49887Perhaps you have the Paperstone base? https://www.gpknives.com/wicked-edge-paperstone-base-we022.html

If so I believe you are in luck as carbide bits should work.

1 user thanked author for this post.

03/30/2019 at 1:13 am #49888I’ve tried driving drywall screws into my paper stone base. No such luck – they snap off after about three turns, even with pilot holes, which are an S. O. B. to drill. Tuff stuff. Not sure how it’d machine with a router.

03/31/2019 at 12:21 pm #49931Paperstone is just a paper-resin composite, and should machine like Micarta. From https://paperstoneproducts.net/wordpress/installing/

PaperStone® lessens the load because it is easily worked using traditional high-quality carbide-tipped woodworking tools. No special fabrication equipment is necessary as is the case with quartz or granite. And a wide variety of edge profiles can be achieved with a router.

1 user thanked author for this post.

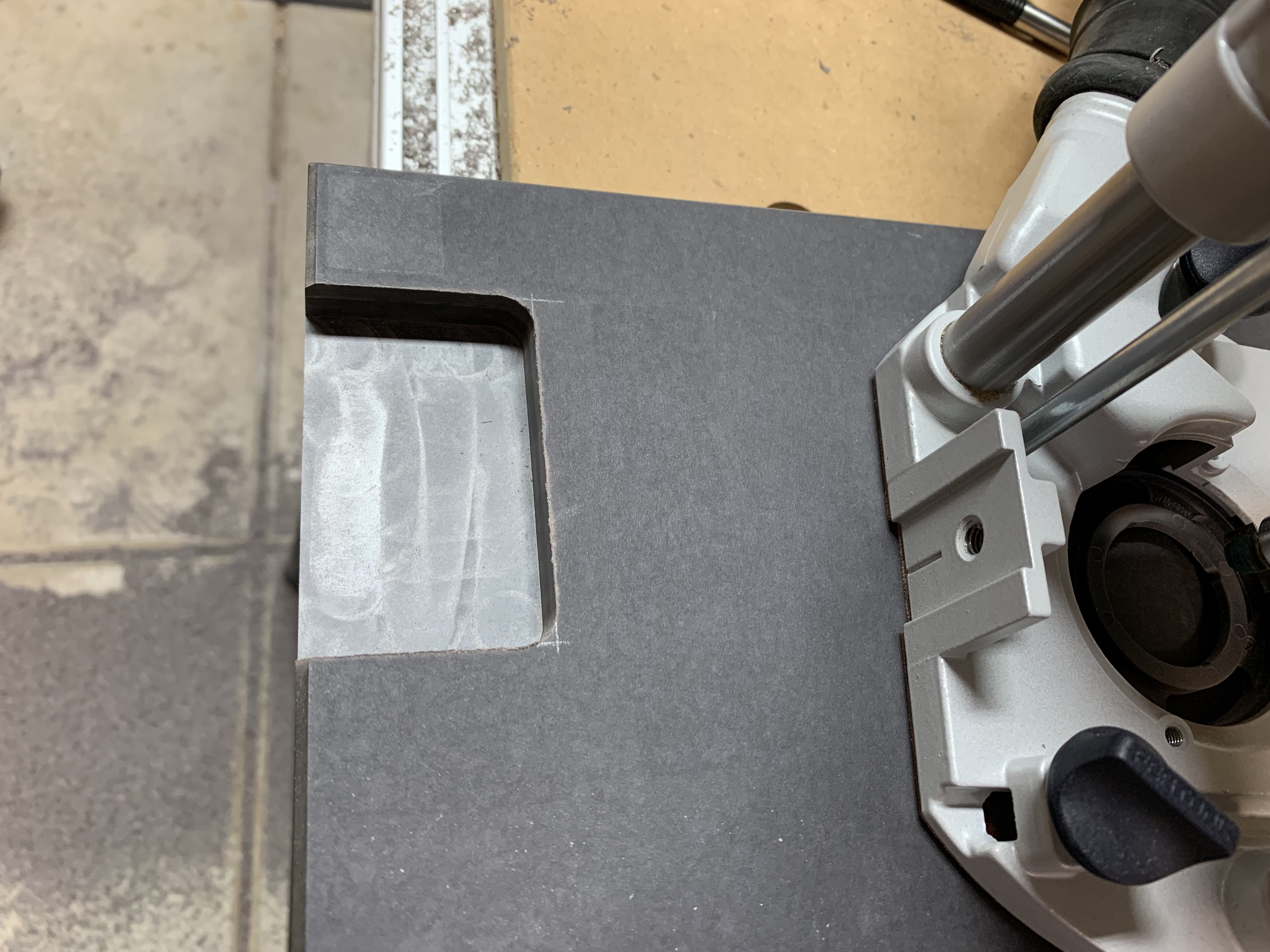

04/01/2019 at 9:29 am #49946Here’s a pic of the base. I scratched it and the color is thru and thru.

04/01/2019 at 9:32 am #4994704/01/2019 at 10:11 pm #49959That looks like Paperstone to me.

1 user thanked author for this post.

04/02/2019 at 1:21 pm #49961Well, thanks for all the help with the base. I was confused, as WE was saying that it had to be either aluminum or quartz. I finally emailed a pic of my base and they confirmed it was in fact, paper stone.

Woodworking bits worked perfectly on it with no issues. I’ve include a pic of the cuts on the underside and the lites clipped onto the recesses.

-

This reply was modified 6 years ago by

NorCalQ.

-

This reply was modified 6 years ago by

NorCalQ.

-

This reply was modified 6 years ago by

NorCalQ.

-

This reply was modified 6 years ago by

NorCalQ.

-

This reply was modified 6 years ago by

NorCalQ.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

04/02/2019 at 1:39 pm #49970Link to where you got those lights please! I want!! My base is a 2×12 will be a cake walk to install!

04/02/2019 at 2:00 pm #49971https://www.amazon.com/gp/product/B00INK4GRC/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

I got similar lights first that were 3W, but found they weren’t bright enough. I also tried some that were adjustable warm, medium and daylight, but again, not quite bright enough. These lights are daylight color temp and plenty bright enough. Once positioned, they really highlight the scratch pattern.

1 user thanked author for this post.

04/02/2019 at 2:03 pm #49972Thanks!

04/02/2019 at 2:46 pm #49973That’s a nice modification.

-

This reply was modified 6 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.