What are you sharpening today?

Recent › Forums › Main Forum › Welcome Mat › What are you sharpening today?

- This topic has 126 replies, 18 voices, and was last updated 05/11/2016 at 11:36 am by

Rick.

-

AuthorPosts

-

02/03/2016 at 9:20 am #30901

That looks like a big adventure Cliff. I can’t wait to see the after pics!

-Clay

02/03/2016 at 10:33 am #30902Anonymous

Inactive- Topics: 14

- Replies: 427

That is a diamond in the rough… If you can pull it off, it will be a significant achievement. Looking forward to the end product.,

Bill aka ET

1 user thanked author for this post.

02/03/2016 at 1:51 pm #30903Really interesting cleaver. I wondered at first if the holes were left over from when the steel was part of something totally different. Looks like this thing has never seen a hand-operated sharpening stone. I suspect that when it was new, the edge was quite a bit further from the holes. If it was always a cleaver, there must have been a purpose for the holes; maybe bending and/or nail-pulling?? For hanging the beast on a nail or peg, the round hole would have been near the upper front corner.

That deep pit behind the edge and near the tear-drop shaped hole might have been a repair job with a welder. When you grind off the patina, it’ll probably show.

The “patina” is really deeply pitted rust. I suspect Cliff will be removing a lot of steel. Maybe just take off the surface crap and then treat it chemically to (A) stop further rusting, and (B) replace some of the colorful patina.

One of the woodworking magazines I get has a monthly puzzle. Guess what this rusty old tool was used for. Cliff’s got a good candidate.

1 user thanked author for this post.

02/03/2016 at 2:20 pm #30904I think this paper might shed some light on Cliff’s mystery cleaver: Knife World – WHUT IZZIT Number 377. A very similar cleaver is described. You can also look at the patent US535839. The image isn’t identical, but that’s common between patent drawings and production models.

-Clay

2 users thanked author for this post.

02/03/2016 at 11:01 pm #30921Thanks guys for the support, it sure makes it fun when you can share with other enthusiasts as you learn.

Unfortunately I have “learned” that this beast may be beyond repair due to the odd placement of those darn holes so close to the secondary bevel and the extensive edge damage I discovered running the entire length of the blade.

I had planned to do similar to what Tom had mentioned above, sand off the surface gunk and apply citric acid or something to clean the pits but leave some character marks, then re-handle in nice wood and give it a full restoration deserving of its heritage etc…

As it sits that’s not gonna happen…gonna lay an edge of it and wrap in para-cord. Its being used primarily for backyard processing of locally hunted pig. They loved its action and they will love it being sharp and new(er) looking for as long as it lasts but its just not worth it to place any additional time into it with the condition the material IMHO.

At least that’s my rookie assessment…any second opinions of course are welcomed. Its kinda sad but that’s why its a learning experience. Sometimes ya gotta know when to say yuck!

02/04/2016 at 6:22 pm #30963

02/04/2016 at 6:22 pm #30963Pics from previous 2 posts that didnt show…

And rough idea of finished look…

Again if someone has feedback…am I crazy or is this just kicking a dead horse as far as blades go?

Aloha, Cliff

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

02/04/2016 at 10:21 pm #30976I think you already did great work on that. But you’re right, it is beyond much further repair. One hole is too close to the edge and the pit/other hole/edge are too close together as well.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

02/05/2016 at 12:50 am #30978I agree with Mark. If the owner is strictly interested in usability, you might try having a good welder close up the forward hole to strengthen the edge. As it is, a good blow to a section of hard bone will collapse the edge at that point. Any kind of back-up will help there. I think the deep pit next to the key-hole won’t be an issue for some time, but any repair is more likely to help than hurt..

1 user thanked author for this post.

02/05/2016 at 10:28 am #30980I got inspired by Josh to rework my ZT 0560 yesterday. It came out looking pretty good though I can’t shake the idea that I’d like to send it to Josh for a re-grind to check how it performs afterward. I have a feeling that I’m going to like it a lot.

-Clay

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

02/05/2016 at 1:02 pm #30984That ZT definitely needs thinning

. And a very nice mirror edge!

. And a very nice mirror edge!Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

02/07/2016 at 2:55 am #31003Final results before I return to customer. Spent about 1hr on the blade and 1/2hr on the cord wrap. For what it is, damaged and all, Im happy with the results. Sure the owner will be too.

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

02/07/2016 at 4:36 am #31005Really nice work!

Molecule Polishing: my blog about sharpening with the Wicked Edge

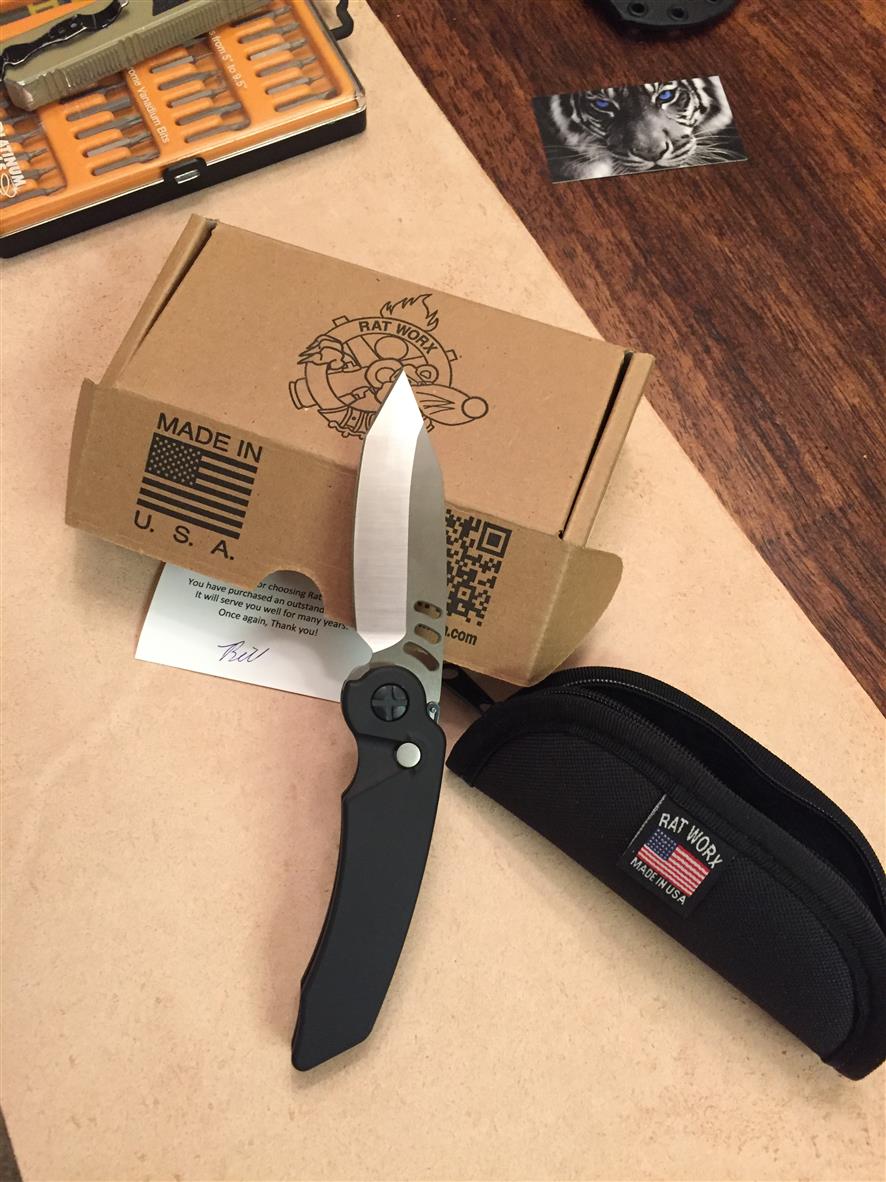

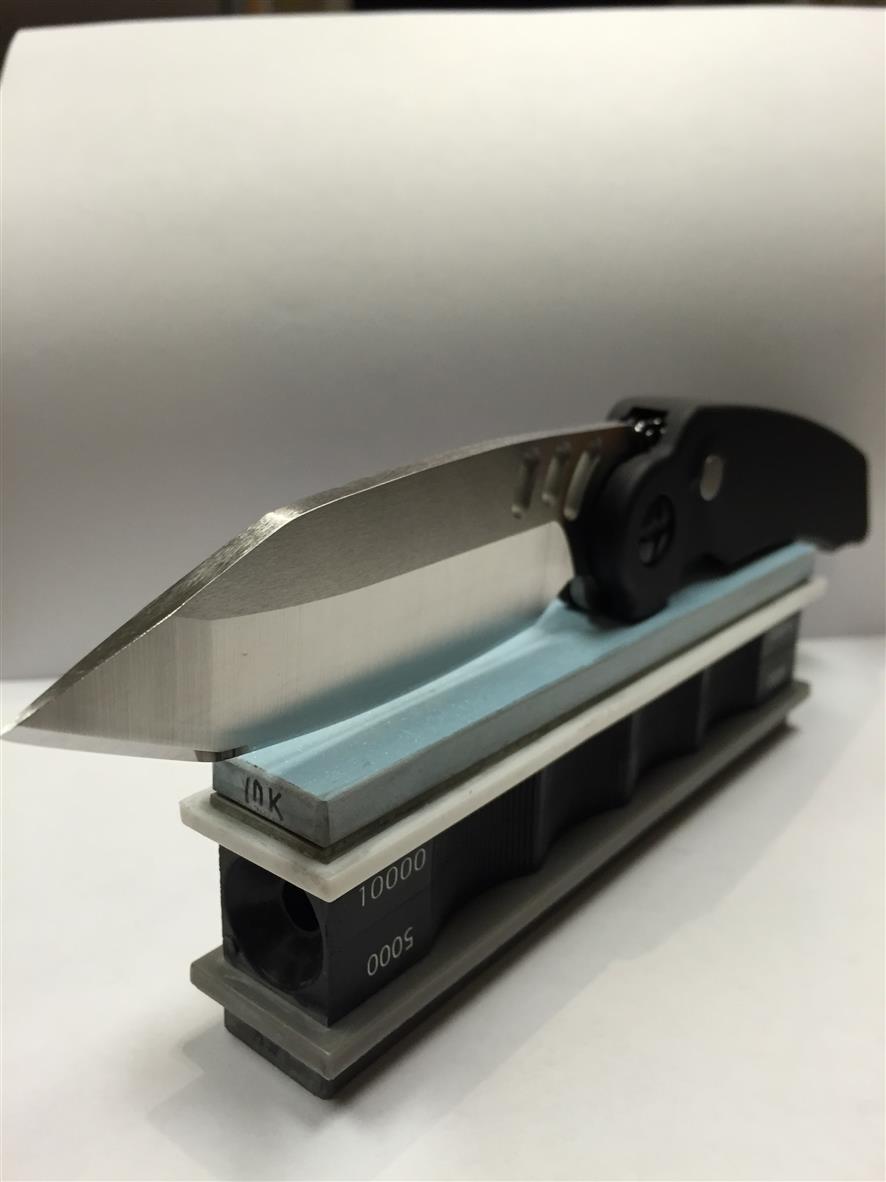

02/09/2016 at 11:25 am #31043Curry; Nice work! Great work on the wrap as well. I havent really done anything all that intresting as of late, just run of the mill sharpening, except for one. I recently did a review and write up of the RatWrox MRX, spent two weeks beating the crap outta the knife. I was so impressed this one is now my EDC.

So, spent some time to polish up the edge a bit.

So, spent some time to polish up the edge a bit.Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

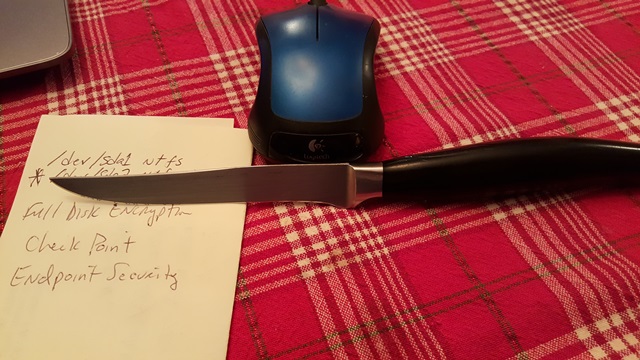

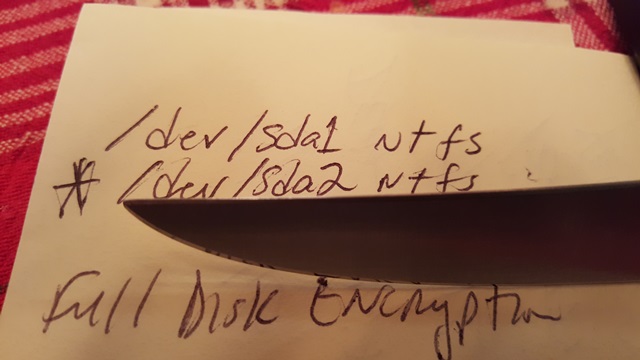

02/10/2016 at 7:51 pm #31096Wow, you guys got some big ones – LOL, I am new to Wicked Edge and think I finally have my diamonds & ceramics worked in. My only knives are for the kitchen (Henckel and Shun). I just did a 40 min touch up of my 4.5 inch Henckel steak knife at 17 DPS in a horizontal position with the spherical joint approximated to just outside the curve using my written log from last time (tip was at B on the steel ruler). The angle cube says I have a 4 deg total delta along the total edge (this was tricky and somewhat inaccurate though because the angle cube needs to be kept in the same vertical position as you traverse the edge – which I did by eye). I say this in reference to some back and forth with Clay, Mark76 about Anthony Yan’s paper on the geometry and math toward optimum setups. My Result: 400 grit thru strop green and I can read the newsprint, shave my arm and fast cut bent newspaper. I am sure it will cut my steak and hopefully my kids will keep their hands off it.

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

02/10/2016 at 10:17 pm #31100I got inspired by Josh to rework my ZT 0560 yesterday. It came out looking pretty good though I can’t shake the idea that I’d like to send it to Josh for a re-grind to check how it performs afterward. I have a feeling that I’m going to like it a lot.

Great work Clay! Any idea of the current thickness at the shoulders of the edge? What angle is that sitting at?

A large benefit of the regrind is that it cuts your mirror/super polished time into about 1/3rd of what it was before… but you won’t be able to see the “platinum” edge from the moon anymore since it will be pencil line thin from the side view! 😉

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.