What are you sharpening today?

Recent › Forums › Main Forum › Welcome Mat › What are you sharpening today?

- This topic has 126 replies, 18 voices, and was last updated 05/11/2016 at 11:36 am by

Rick.

-

AuthorPosts

-

02/11/2016 at 5:00 am #31104

Took one of my benchmades to 15 and a mirror polish. I think it came out ok.

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

02/11/2016 at 8:04 am #31109Anonymous

Inactive- Topics: 14

- Replies: 427

I do a lot of the cooking around our house… I have two ” go too ” knives, I use in the kitchen. I spent 20 minutes yesterday, touching them up..

One thing <i>I never</i> had to deal with is the knowledge of a truly sharp knife. Now that I know, that truly sharp edge does not last for 5 years… which was my typical experience. My go too knives get touched up every 10 days or so. That’s a Good thing. ( having wicked sharp knives )

LOOKS LIKE ITALIC is not working.

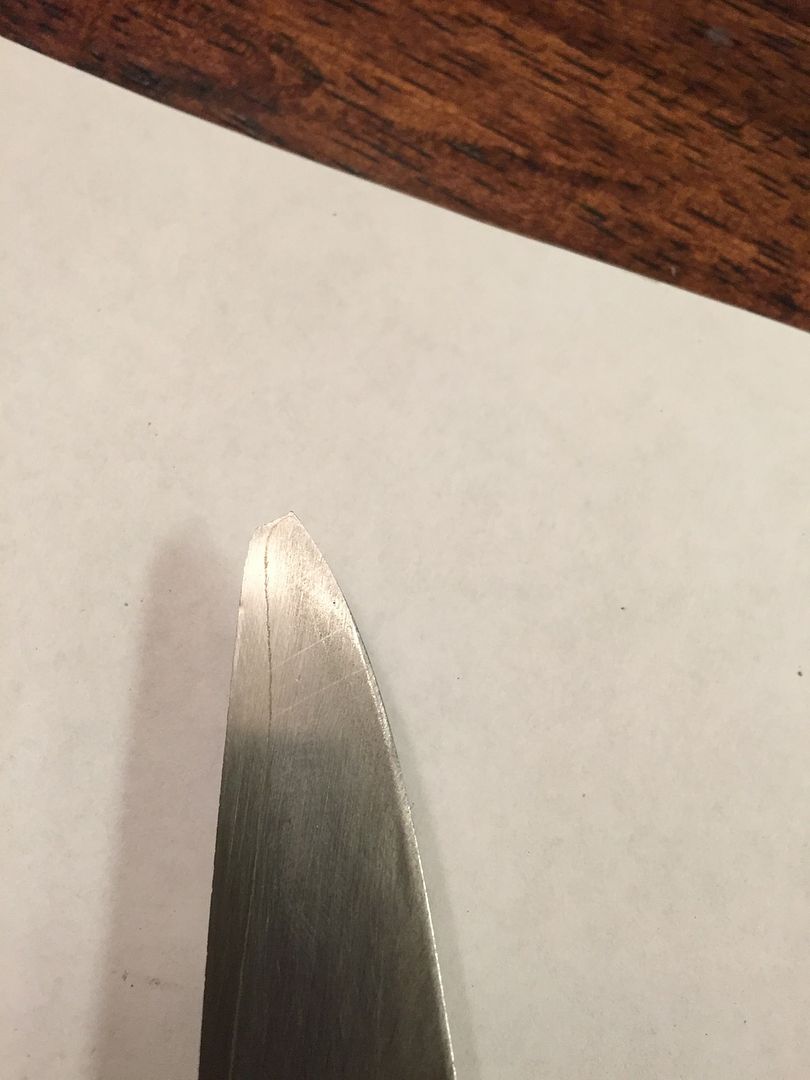

02/11/2016 at 9:07 am #31113Great work Clay! Any idea of the current thickness at the shoulders of the edge? What angle is that sitting at? A large benefit of the regrind is that it cuts your mirror/super polished time into about 1/3rd of what it was before… but you won’t be able to see the “platinum” edge from the moon anymore since it will be pencil line thin from the side view!

It’s done at 20° per side and the thickness at the shoulder averages 0.04″.

-Clay

02/23/2016 at 9:28 pm #3154202/23/2016 at 10:18 pm #31543Sweet job Rick! How did you choose to refinish the flats and how long you think on the project? Looks like new… 🙂

1 user thanked author for this post.

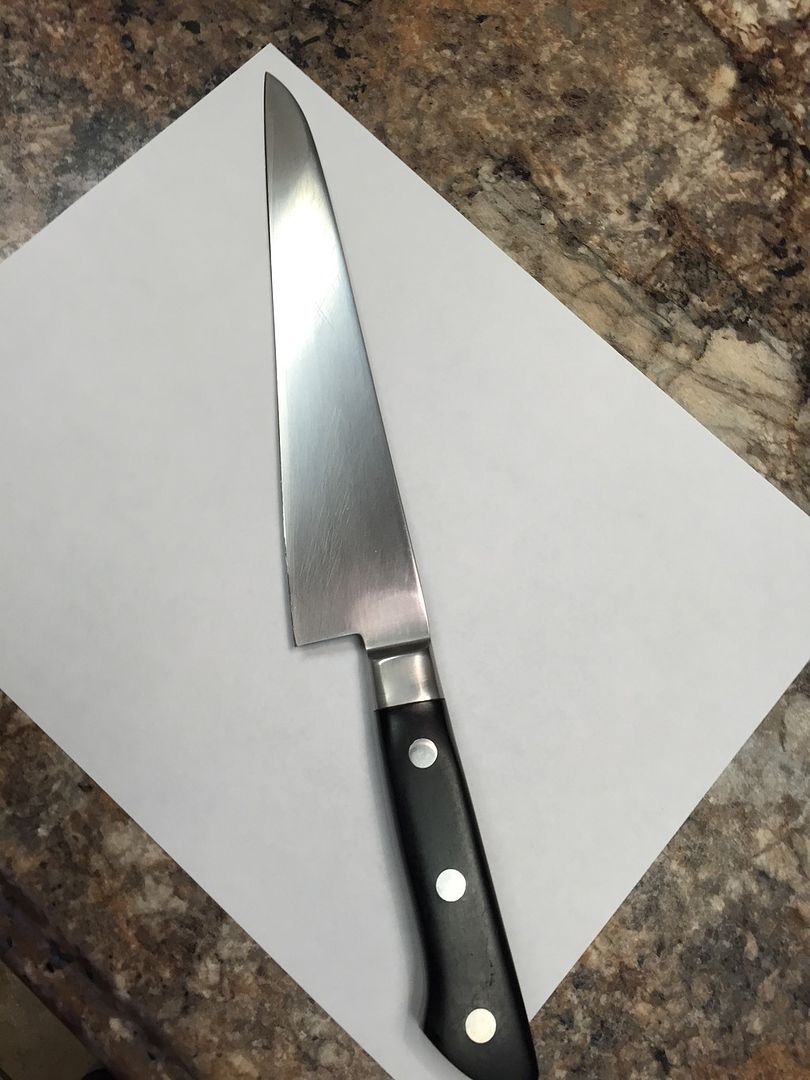

02/23/2016 at 11:49 pm #3154502/24/2016 at 10:25 am #31553Thanks! Thats quite the compliment from you guys. That is an older Tojiro DP that belongs to a local guy runing a great little hibachi place near me. Great food. Curry Custom; I did it by hand, no grinder, or belt sander. A couple of different hand files, then on to the diamond stones to finish shaping the tip and thinning it out. I used wet sanding up to 3K to blend it all. Some of the deeper gouges I wasnt willing to try and take out due to how deep they were, so I just tried to smooth them out some. Then sharpened up to 5K with the Chosera on the wicked edge. I have to admit I was suprised they wanted a 50/50 split for the edge, but thats what it came to me with and what he wanted. I have a Misono 440 petty from him that Im about to start working on for him. I have to retip this one as well, though its not as bad as the last one. This one will be sharpened at a 70/30 split.

Sorry, in my rush this morning I forgot answer about how long it took me. Start to finish about 5 hours, though to be honest there were several coffee breaks, and distractions that I had to stop and take care of, then come back and work on it.

1 user thanked author for this post.

03/06/2016 at 5:23 am #31809Kiyoshi Kato 24 cm gyuto. The beast in my kitchen

.

.Molecule Polishing: my blog about sharpening with the Wicked Edge

03/06/2016 at 11:17 am #31810Hey Mark, nice photo of your setup. Large chef knives are among my favorite to sharpen. If mine weren’t already sharp, I get `em back out today and work on them.

Looks like you’re all set up for a great sharpening session.

Looks like you’re all set up for a great sharpening session.I notice you are set up to sharpen from the backside of the WE. Never seen that before….

Alan

03/07/2016 at 12:25 am #31811Alan: Judging by the locking levers, it looks to me that Mark is using his rig in the normal manner. He sits on the right-hand side of the photo, so the handle of the chef’s knife is mounted towards him.

03/07/2016 at 12:44 am #31812You’re correct, Tom. This way I also have direct access to the adjustment knobs.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/07/2016 at 10:36 am #31813What Alan sees in the photo that confused him is that the base is clearly reversed from standard (no logo showing, the clamping screws are on the right and the hole for the blade support pin is showing opposite the blade tip). I assumed that the locking levers would only be on the front, but I could have been wrong.

I once wondered why the key holes on my Gen 3 vise were on the right, then remembered that I had once disassembled it for cleaning and must have reassembled it wrong. The next time I disassembled it for cleaning, I put it back together correctly.

03/07/2016 at 3:54 pm #31815I’ve thought about setting up with the handle of the knife on the far side, but decided that it would make it harder to see what’s happening at the tip. The tip has always been my greatest source of danger. Maybe it’s a bifocal thing, as my 71 year old eyes don’t easily switch their focal distance back and forth. I’ve eventually settled on a technique where my head leans to the left or to the right quite a bit depending on which side I’m stoning (I normally stone 10 to 20 strokes on one side at a time).

On a somewhat related note:

One of my bases has a Ram ball mount installed next to the near end of the WE base. I have two different length Ram arms and a Ram clamp. This lets me mount long and/or flexible blades with the tips closer to the vise. I then clamp the handle with the proper length Ram arm to steady it. With the newly-learned fact that straight edges needn’t be horizontal, I can be even more versatile in my mounting strategies.

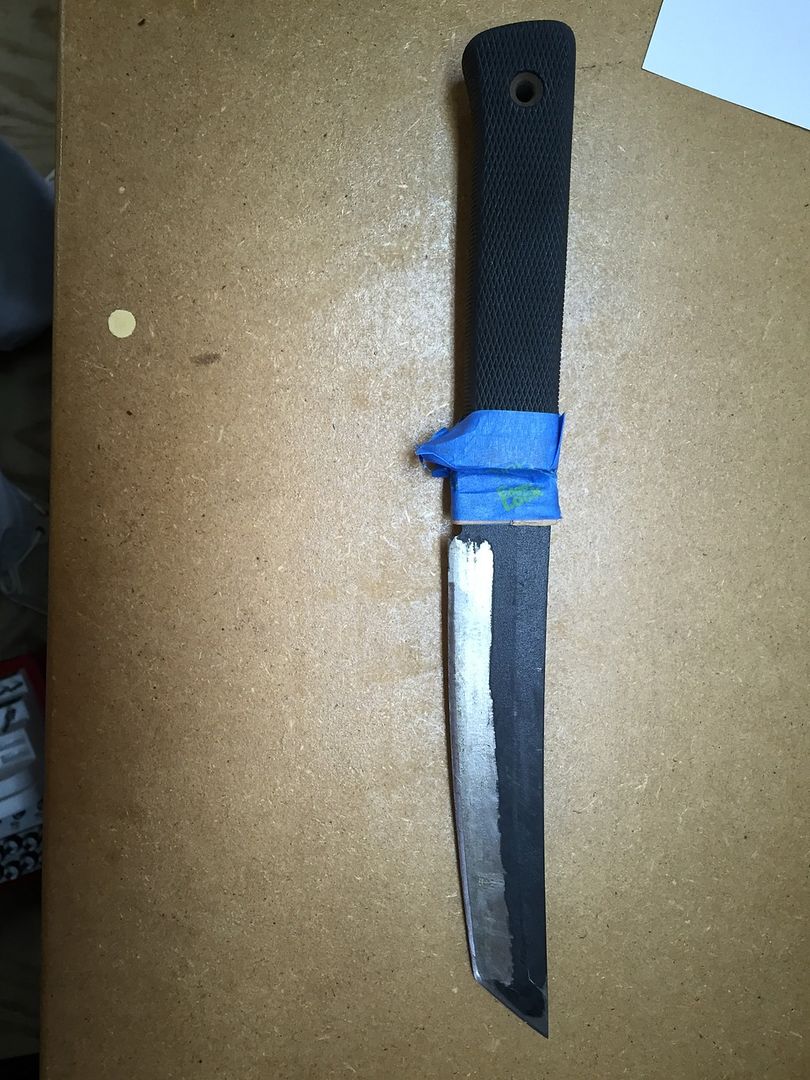

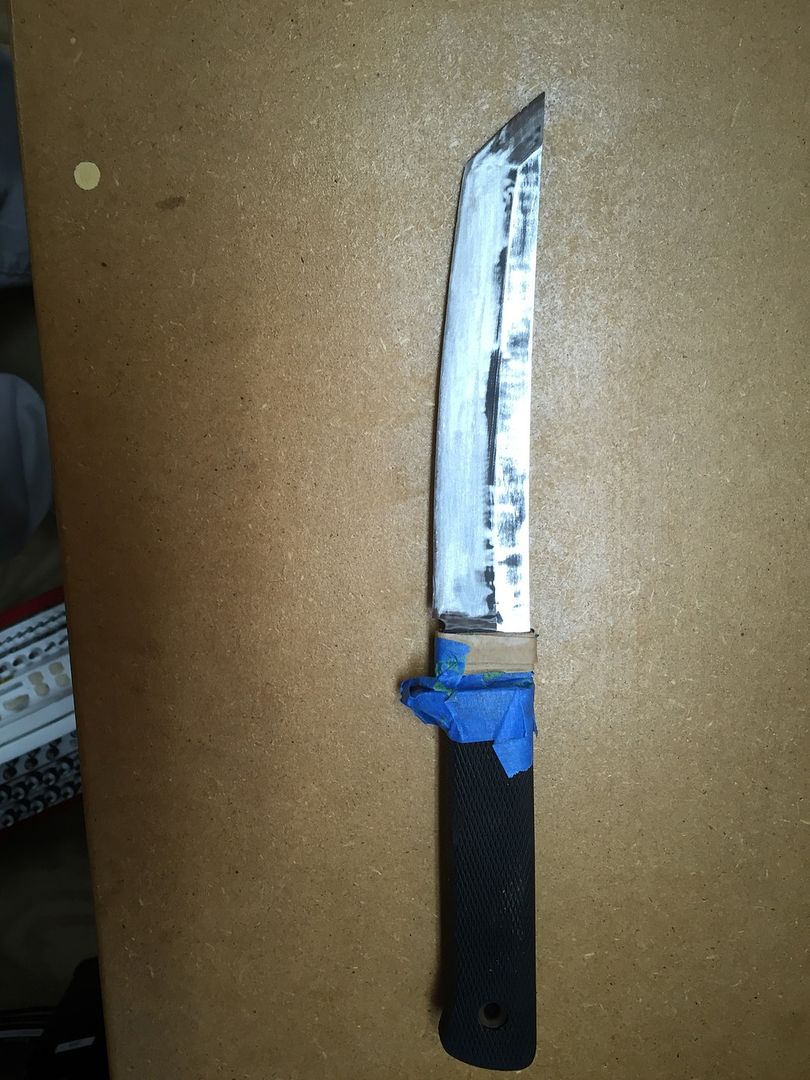

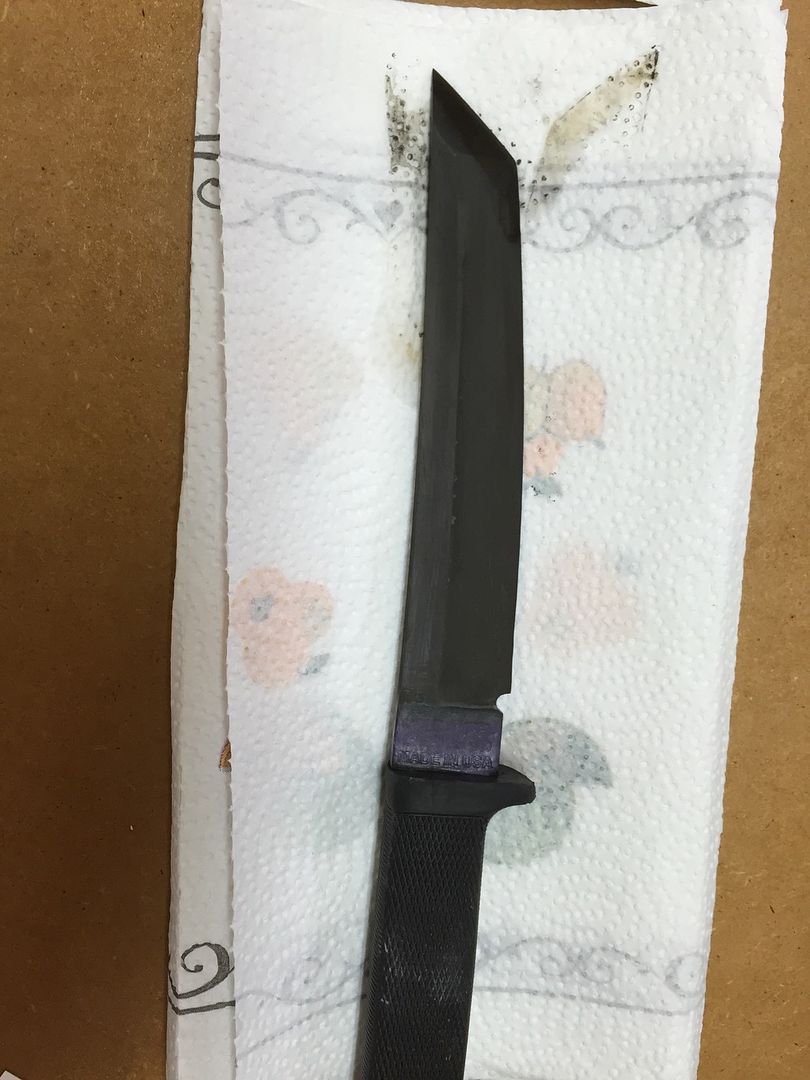

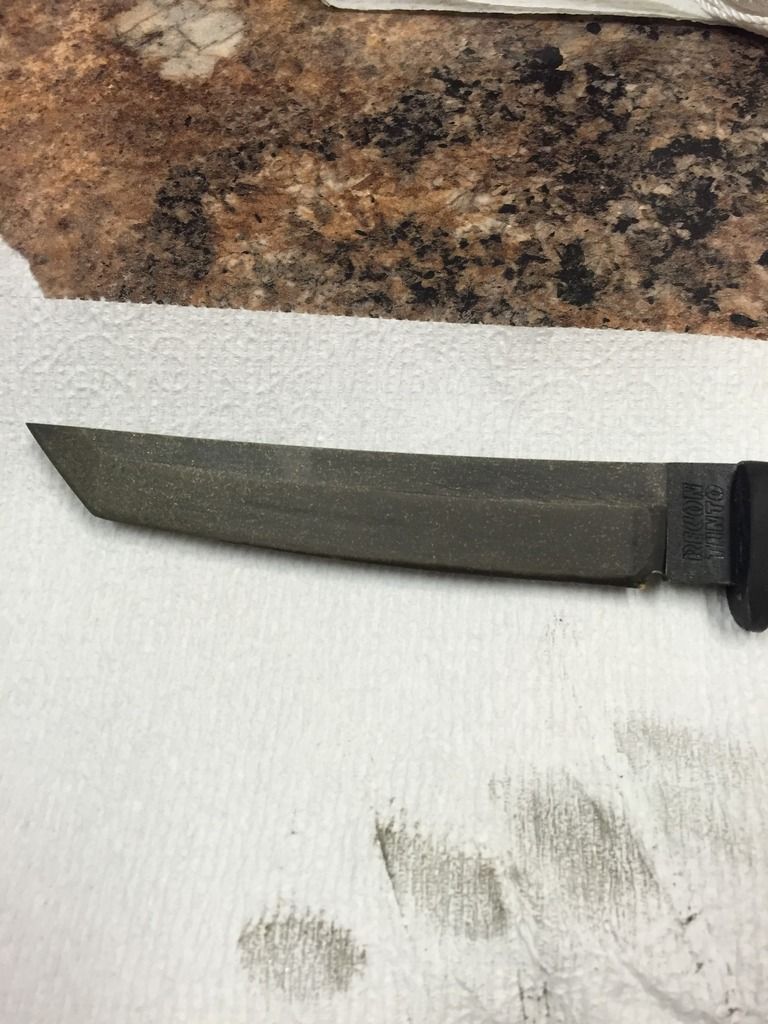

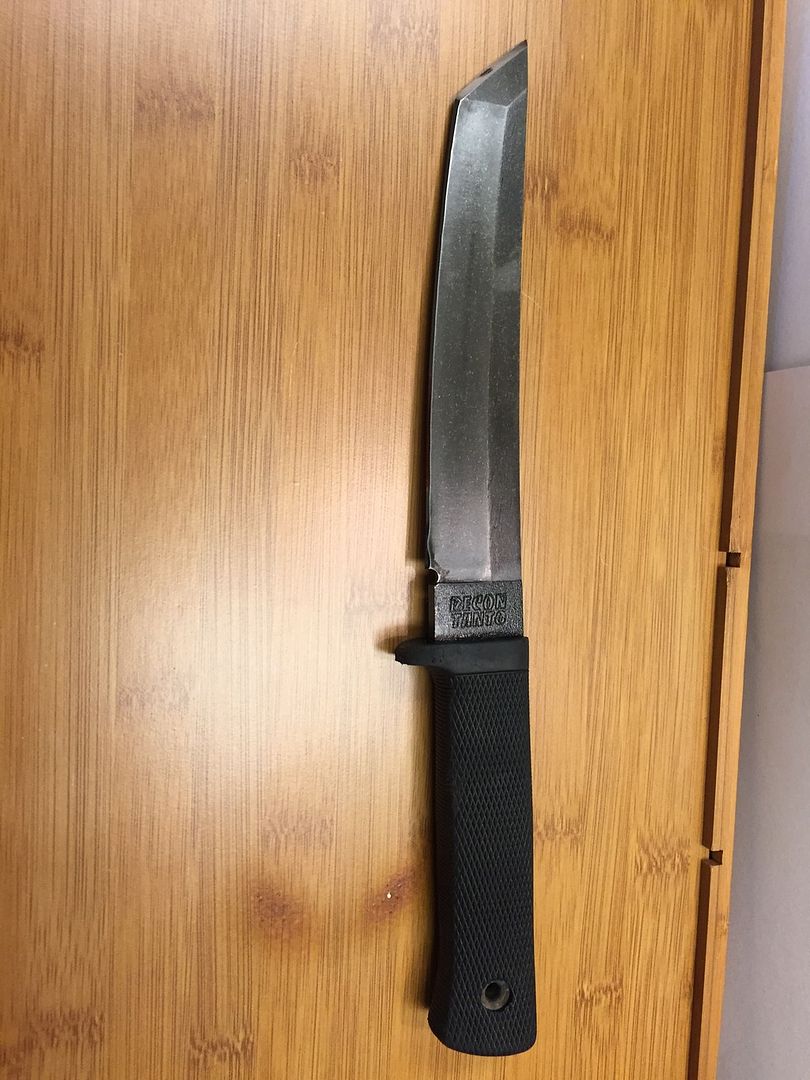

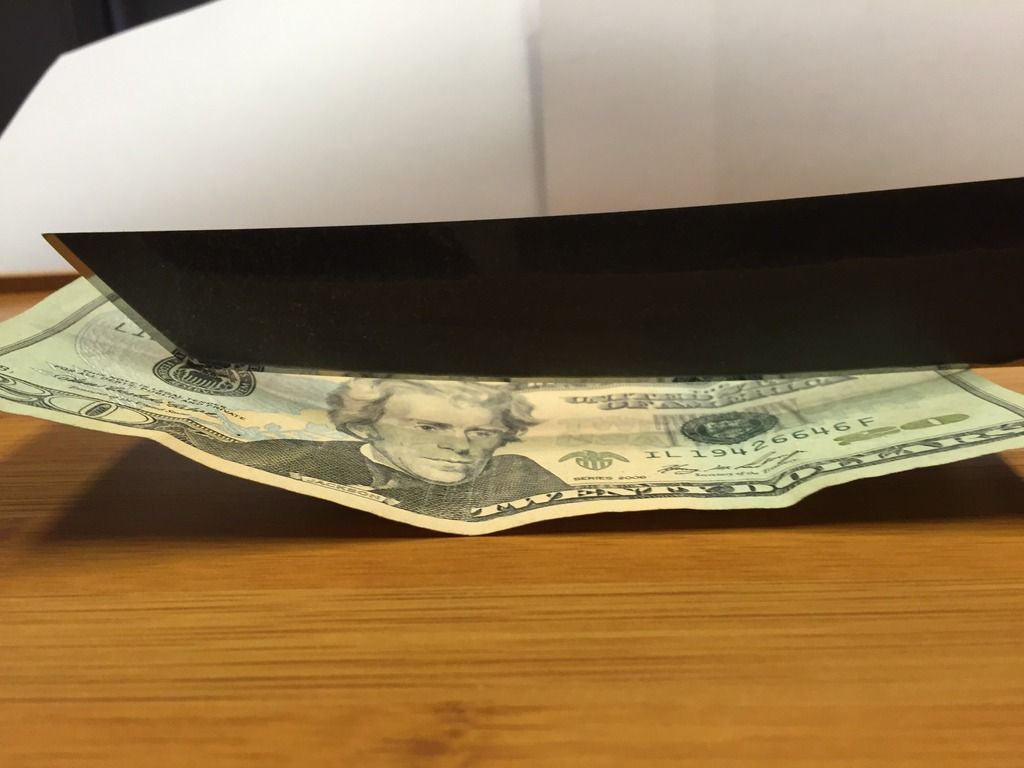

03/11/2016 at 10:49 am #31875OK, so a couple of days worth of work. lol. Cold Steel tanto that looked to have had a bad time with a belt sander. Was told I could do whatever I wanted, just try and make it look decent. Stripped the remaining coating off the blade, took out what I could of the rough spots with sanding though some were so bad I just didnt want to remove that much metal which lead to an idea. Acid bath, and brass wash. Then sharpened at 25dps. In the end, happy customer. lol. Sorry very pic heavy.

2 users thanked author for this post.

03/11/2016 at 5:43 pm #31894Great job! Really like the full body makeover with the brass wash effect. What did you use for the brass?

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.