Vise and Low angle adapter issues

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Vise and Low angle adapter issues

- This topic has 42 replies, 9 voices, and was last updated 01/04/2021 at 4:25 pm by

TeeK.

-

AuthorPosts

-

11/25/2020 at 7:22 pm #55251

Hello,

I’ve purchased pro pack 3 and faced few surprises that is close to being a show stoppers.

1. Design defect of the main vise. The lips of the main vise are closing at an angle, never flat and clamping properly only thick blades – closer to 3/16”. Anything thinner are touched only by the very top part of vise lips – as this vise is designed to have lips closed at an angle. This causes knives with thin blades to be prone to wiggling with rather small effort. This in turns causes more convex results vs. flat sharpen results. This also causes some knives not to clamp consistently vertically but rather at some small skew angle.

2. Low angle adapter. It doesn’t clamp perfectly upright but rather at an angle. This is likely (but i still not 100% sure) due to the vise design issue described above. I missed that and ended up almost defacing expensive knife. Basically setting equal angle on both sides resulted in one side sharpened almost 2 degrees different than other. So besides low angle adapter clamping at an angle it becomes really easy to wiggle because it also essentially being clamped only by the top part of main vise lips.

3. Low angle adapter design issue #2 – the lips are designed to artifically limit the clamping space no more than 1/4″ depth. Which means that unless you have prefectly straight and flat blade – it will be uphill battle to try to fix it in a proper position within low angle adapter.

So to summarize – it became some sort of secondary problem solving task for me – I had to put some sort of padding on the sides of the knife blade to make vise to clamp it in more or less flat + fixed + stable manner.

Second – i have to measure vertical misalignment against the blade itself (or reset angle measument tool against the blade) and then set angles on each side considering this to ensure the proper result.

Third – wiggliness of low angle adapter as well as it’s limits (see #3) is kind of making it not usable for high quality sharpening work.I attaching pictures. Maybe I missed something .

-

This topic was modified 4 years, 9 months ago by

Precept.

Attachments:

You must be logged in to access attached files.

11/25/2020 at 7:40 pm #55254Please post additional photos of vise jaws from several different angles including top down.

Marc

(MarcH's Rack-Its)11/25/2020 at 7:44 pm #5525611/25/2020 at 9:59 pm #55261The forum was just off-line for a scheduled/announced server maintenance. I was expecting we would get interrupted.

I’m asking for photos that allow me to see the jaw tips and inside faces. Top straight down with vise jaws open and an angled down view like at 45º . Similar photos from the different perspectives would be helpful, like from the rear and from the side, also

Question: when you turn the tensioner lever from the lightest (-) setting, full clockwise to the tightest (+) tension position, while the jaws are open, does the space narrow down with the increase tension setting?

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

11/25/2020 at 10:11 pm #55265Your low angle adapter, (LAA), appears fine. The LAA has limited usefulness and doesn’t work with every knife. It’s generally used for small, thin bladed knives.

The LAA utilizes the “standard vise” design. By the nature and the physics of this adapter’s design, with one side fixed and stationary and the other side floating and movable, it will clamp and hold a knife offset from centered and closer to the fixed side. This offset is compounded when the LAA is clamped in the WE130 vise. Adjustment needs to be made to your guide rod set angles when using the LAA to compensate for the clamping offset.

I use a small dry rectangular patch cut out of a real leather chamois cloth, (like that used to dry a car after handwashing). I wrap the chamois up around the knife’s spine where it’s clamped in the vise and the LAA. The dry chamois is compressible so it helps the jaws hold the knife more securely along with protecting the knife steel from metal on metal contact.

Marc

(MarcH's Rack-Its)11/25/2020 at 10:27 pm #55266Instead of pictures – here’s video of some of the issues:

Tell me I’m doing things wrong and how to do them right.

11/25/2020 at 10:54 pm #55267Your video shows you manipulating the empty vise. From what I see the vise appears fine. You are not really using the vise to clamp anything so it’s hard to say you may be using it wrong.

Please, read the above posts again we are getting crossed in our posts and timing.

A knife is clamped by the two flat pads on the far ends of jaws. You need to find the balance between the proper knife position and the applied tension setting to clamp a knife securely. It does take some practice and experience.

I just clamped up my LAA. It is tight and holds solid with no wobble. With the tensioner on the minimum setting it does require me to apply some good amount of force to lock the lever handle over so the jaws lock on the LAA. This force is when the jaws are locking tight and flexing under the clamping pressure.

It may be helpful for you to post a video of you clamping a knife so I could see how it sits and how tight and solid it clamps.

Marc

(MarcH's Rack-Its)11/25/2020 at 11:06 pm #55268Hi Marc, I agree with you:

>>> Your vise and LAA appear to be fine...

They are fine as there are no manufacture defects. There is a design issue. Main vise grasps the blade (or LAA) with only a top part of the vise clamp, leaving the rest of the blade (or LAA) prone to wiggle.

>>> realize the tall LAA, when clamped is easy to wobble it.

The above wiggle is not a consequence of how tall is it. LAA is a solid alloy all the way. The base vise is super solid. It’s impossible to bend any of it. It is wiggly because main vise by design cannot clamp it solid. It clamps it with only a fraction of it’s top surface. The rest is essentially hanging in the air.

11/25/2020 at 11:20 pm #55269Precept, Read my last post, I edited it. We are both also posting quickly so our response are getting missed.

The vise should clamp tight and require some applied force to lock it over. Even with the minimum tensioner setting and empty jaws.

My LAA clamps solid and holds tight on the miminum tension setting. My LAA does not wobble and locks stationary without any movement.

You may have an issue internal to your WE130 Gen 3 vise. It’s possible you don’t have the full compliment of Belleville washers (6 pairs) in your washer stack. Or possibly there is an internal part missing, miss-positioned, broken or defective. You’ll need to disassemble the vise to determine this.

This post will help…read the last post on the page

The Gen 3 vise clamps just by the very tips of the jaws on the pads at the four corners. The jaws flex as pressure is applied with the locking lever allowing the jaws to tightly and securely clamp, if everything is functioning properly.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

11/26/2020 at 8:22 am #55271Precept, Read my last post, I edited it. We are both also posting quickly so our response are getting missed. The vise should clamp tight and require some applied force to lock it over. Even with the minimum tensioner setting and empty jaws. My LAA clamps solid and holds tight on the miminum tension setting. My LAA does not wobble and locks stationary without any movement. You may have an issue internal to your WE130 Gen 3 vise. It’s possible you don’t have the full compliment of Belleville washers (6 pairs) in your washer stack. Or possibly there is an internal part missing, miss-positioned, broken or defective. You’ll need to disassemble the vise to determine this. This post will help…read the last post on the page The Gen 3 vise clamps just by the very tips of the jaws on the pads at the four corners. The jaws flex as pressure is applied with the locking lever allowing the jaws to tightly and securely clamp, if everything is functioning properly.

That is what I was going to say. It seems like he is missing some Belleville washers. My WE130 locks up tight on my LAA and 1/4″ adapter and they are solid and don’t wiggle, even with the tension adjust all the way to “-“.

1 user thanked author for this post.

11/26/2020 at 8:41 am #55274Towards the end of the video (00:53 secs to 1:16 secs) while you’re wiggling the LAA in the vise jaws I noticed the lever arm does not appear to be all the way locked over, flat and horizontal. My lever arms are positioned flat and horizontal when the vise jaws are locked tight. I feel and hear a clicking sound when the vise locks tight, at the end of the full rotation to the right.

It also require a slight extra push of applied pressure to lock the lever over at the end of the right rotation, while the vise jaws are compressing on whatever is being clamped in the vise jaws.

Marc

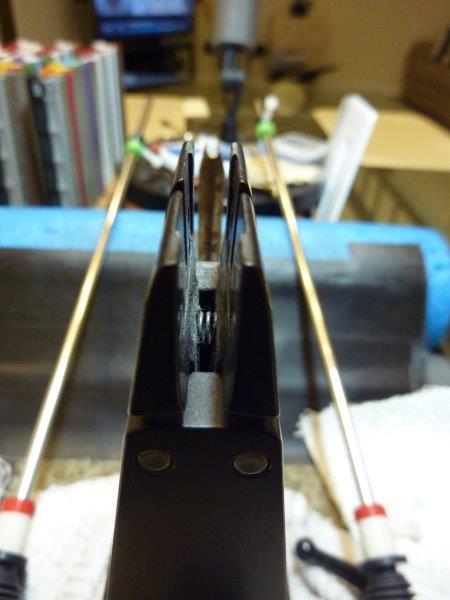

(MarcH's Rack-Its)11/26/2020 at 1:45 pm #55275Ok, i disassembled vise completely. It doesn’t seems any part is missing. I see 6 x 2 = 12 washers that act like a spring sort of. All in place.

The vise does behaves as designed – as Marc described. Tension lever does add tension. The lock lever does requires extra pressure and then it does lock.

And it does locks in horizontal position – on my first video it probably doesn’t show well – but it does work like that.Let me know if anyone see anything missing?

It doesn’t change my point about the deisgn where vise jaws BY DESIGN connot coming together in parallel. They merely secure object (blade) with their upper edges, NOT with all available flat surface, like a normal vise operates.

Attachments:

You must be logged in to access attached files.

11/26/2020 at 2:01 pm #55277Here’s my video explanation of design issue:

11/26/2020 at 2:53 pm #55278Precept, thank you for taking the time to produce the 2nd video. I can tell you from looking at your WE130 that your’s is the most recent version released with all the newest internal parts and upgrades. The vise jaws have not had a design change since first introduced. I don’t know what I can share with you to be helpful. All I can say is I personally own and use four of these Gen 3 vises with this exact same design, (including one with the new upgraded parts, like your’s). All of my vises clamp tightly and securely hold knives and the LAA with out any wobble when clamped by just the jaw tips, as it’s designed.

I hear you’re assertion that the design is faulty. I can share that I do not have, or have I ever had, any problems or issues with the functionality of this vise design. That’s not to say that you are wrong. I cannot say with certainty that there is not something defective, or that might be missing, or that may be effecting your vise and its function.

Hopefully once reassembled it will work better for you. Maybe the parts weren’t seated properly when first assembled and now it’s resolved. I hope so for your sake. Please let us know what you learn.

Marc

(MarcH's Rack-Its)11/27/2020 at 7:36 am #55280Just thought I would suggest my personal guess as to why the vice only has contact at the tip. Most knives are tapered triangles not flat squares. If the WE Clamp closed like a standard wood or metal vise (2 blocks coming together) it would only contact at the fattest part of the knife down at the heal of the blade leaving a large gap at the top and the vise would be in the way of the sharpening stones.

I own an old version of the Gen 3 Vise (coil spring not washers and no adjustment) it does not always hold a knife as tight as I would prefer but the LAA does not move when clamped. I had to add a post after this to add more photos..

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

-

This topic was modified 4 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.