Vise and Low angle adapter issues

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Vise and Low angle adapter issues

- This topic has 42 replies, 9 voices, and was last updated 01/04/2021 at 4:25 pm by

TeeK.

-

AuthorPosts

-

11/27/2020 at 7:39 am #5528411/27/2020 at 9:44 am #55287

Well said…I share “airscapes” observations and user’s experiences.

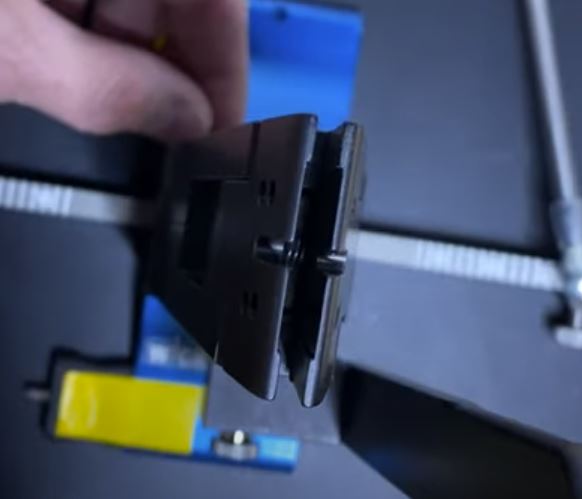

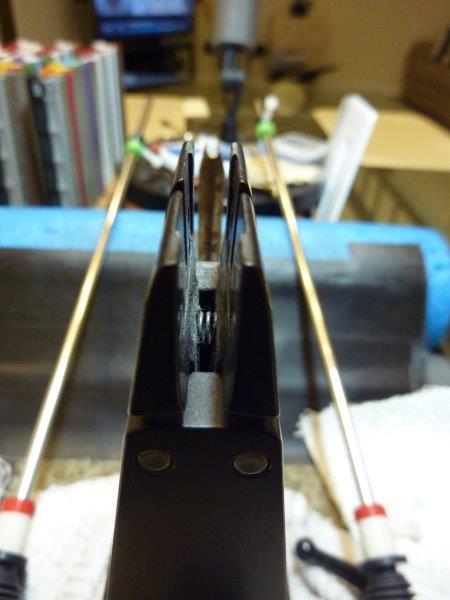

The narrow tip pads on the Gen 3 vise jaws, (like tweezer tips), allow them to clamp knives of a variety of shapes, tapers and profiles by just a small portion of the knife’s steel. The jaw tips small foot print allows them to tightly and securely grasp tapered and uneven shaped knives without gaps. It also greatly limits the amount of steel needed between the vise jaws for secure clamping. This allows knives to be clamped on just the very tip of the knife heel, right at the spine, (or on a small flat spot some knives have), or so the knife can be clamped very high up in the jaws. This allows for narrower bevel angle profiles to be applied. Also, oddly shaped, ground and multi-faceted knives can usually still be clamped. Exercising some ingenuity or previously acquired clamping experiences may be necessary or helpful.

Marc

(MarcH's Rack-Its)11/28/2020 at 10:35 am #55289One last thought on the OPs issue with the LAA being loose.. Could the installed Jaws be the set made to clamp knives that are thicker than 1/4″ ??

Those will not hold anything thinner than 5/32″ and the LAA is only 1/8″ thick.

11/28/2020 at 12:22 pm #55290No, it’s regular jaws.

11/28/2020 at 2:59 pm #55291Well I am out of ideas, call WE customer service on Monday and they will take care of you. Your experience is not normal so hopefully they can get you fixed up.

1 user thanked author for this post.

11/29/2020 at 4:22 am #55292From the photos by the OP, I can’t see any evidence that says the clamping pads are actually there – as though somebody might have screwed up in manufacturing. This would produce results exactly like precept is describing.

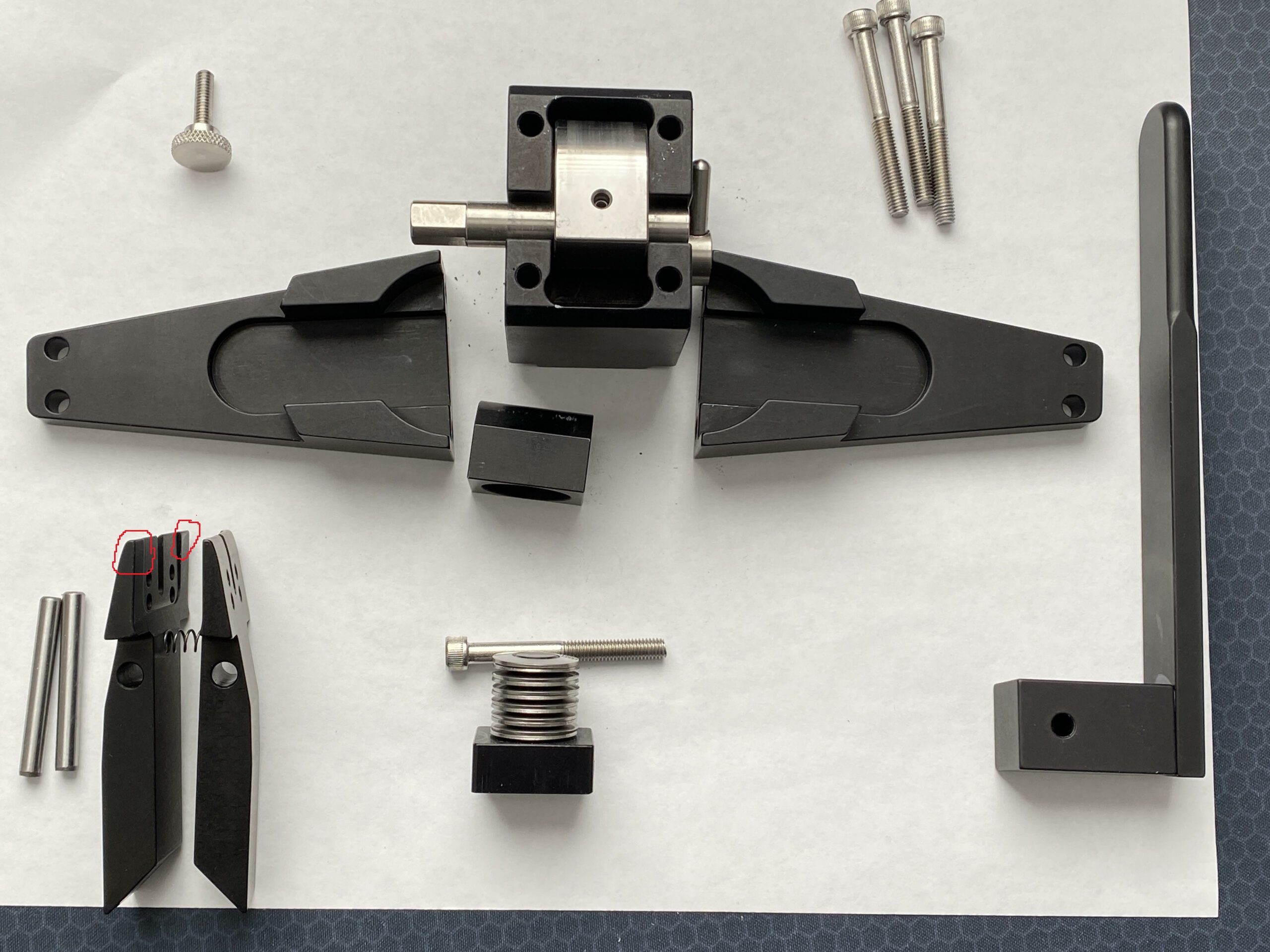

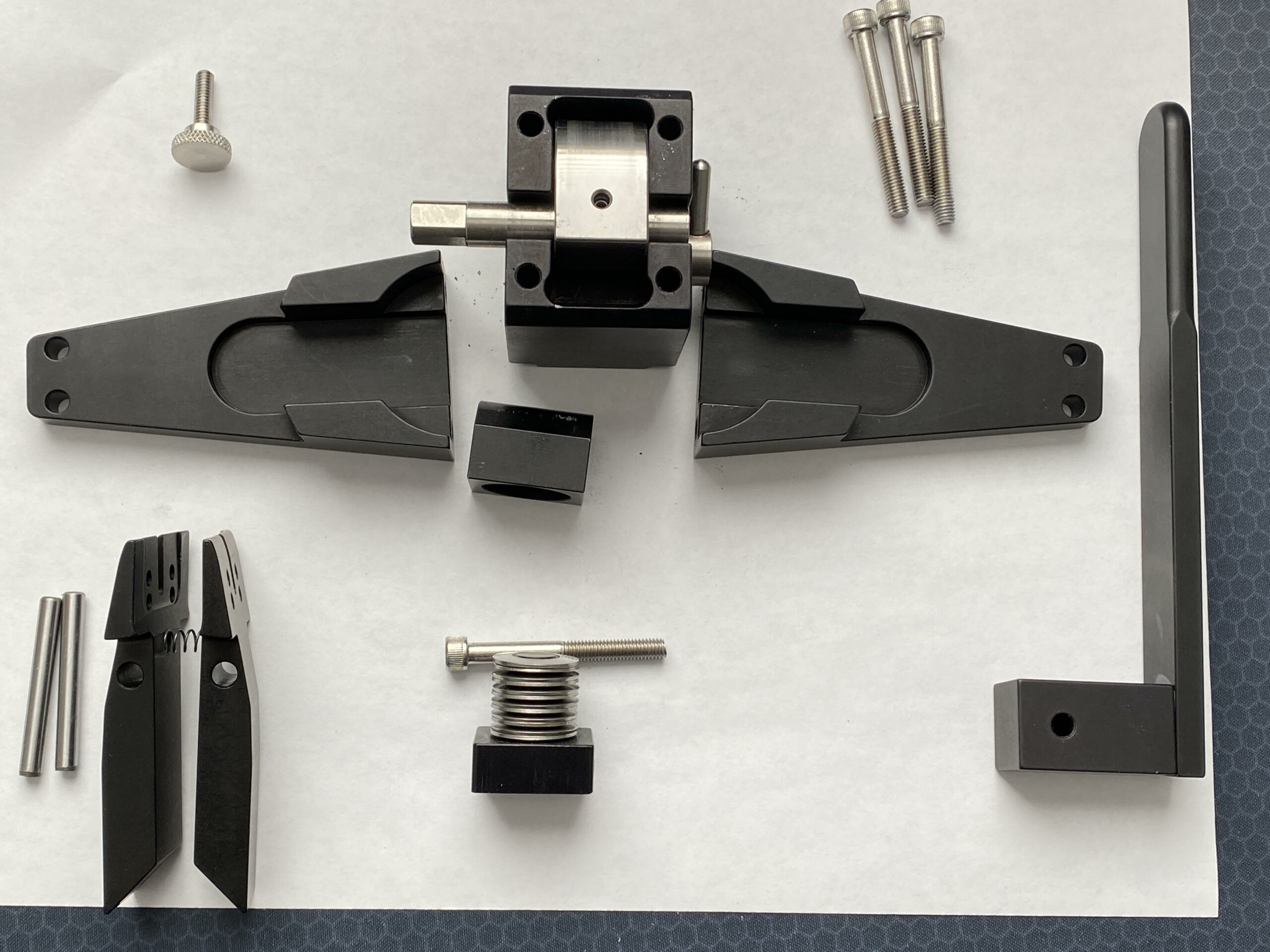

The pads are rather small sections of the vise which are the parts that are supposed to actually touch the faces of the knife. They are flat surfaces which apply very high clamping forces. In mechanical design speak, they are called “bosses,” which are raised sections which extend above the surface they are attached to. The design of the vise is such that the pads clamp the faces of the blade and align themselves to slight differences in parallelism, both vertical and horizontal. The jaws are forced together by a cam which symmetrically applies a spreading force at the bottom of the jaws, thereby producing the clamping force at the top. The stack of Belleville washers converts the vertical displacement of the cam (located on the crank shaft) to vertical force. The configuration of the stack of washers and the number of washers included is such that the force is relatively constant throughout a relatively large displacement. This means that the clamping force is relatively constant for a variation in blade thickness.

The Gen 3 jaws I own all have a vertical slot cut at the top edge, on center and extending down about 4 or 5mm (that’s a guess from my memory). This slot is designed to allow the jaws to flex, from one side to the other, thereby complying to any differences in blade thickness from the front pad to the rear pad, as well as some small variations in vertical blade shapes. This compliance helps to keep the pads flat against the faces of a wide variation in possible blade shapes and thickness.

If precept’s jaw pads are indeed missing, I think it’s important to recognize that this is not a design flaw, but rather a manufacturing flaw. If I am correct, then Clay must confirm quickly if this is a one-time problem or a problem that extends throughout a batch of vises which may already have been shipped to a number of customers.

Edit: I’ve sent an e-mail to Clay to draw his attention to this matter. If I’m wrong about the pads missing, he still needs to address this problem for precept.

-

This reply was modified 3 years, 4 months ago by

tcmeyer.

tcmeyer.

11/29/2020 at 7:07 am #55294TC, I think the boss is there, it just extends all the way to the base of the jaw, as if a machining process had been skipped.. or is this part of the “new” design.. To your point this needs WE attention quickly.

-

This reply was modified 3 years, 4 months ago by

airscapes.

-

This reply was modified 3 years, 4 months ago by

airscapes.

Attachments:

You must be logged in to access attached files.

11/29/2020 at 8:31 am #55298Precept’s vise jaws with BOSS are shown in this photo, he posted on the lower left.

My Boss on all my Gen 3 vises have that same square “U” shape like in Precept’s photo. Without having his jaw sets in hand, side by side, with mine and measuring each of them with a calipers I can’t speak to the exact dimensions.

Here are my vise photos:

The jaw set appears to be the same to me. Either way he’s unsatisfied and W.E. is the only one that can give him resolution.

Marc

(MarcH's Rack-Its)11/29/2020 at 8:56 am #55299Here’s another photo posted by a different forum member, that looks just the same:

Here is the maintenance PDF that clearly shows a jaw set:

https://knife.wickededgeusa.com/app/uploads/2020/10/WEClampCleaning-1-1.pdf

To be clear, this maintenance instructional PDF is from the earlier, original, Gen 3 version, when the tensioner function option was first released. That original version has a different cam follower and less Belleville washer pairs in the assembly then the newer version Precept is using. There are other slight differences in the Cam Assembly parts. The functionality is still the same.

Marc

(MarcH's Rack-Its)11/29/2020 at 9:34 am #55300Well I guess that was a one of the many changes over the years.. My old version has on obvious pad

Attachments:

You must be logged in to access attached files.

11/29/2020 at 9:39 am #55303Yes and no split down the center. This split down the jaw tips at the center was added to enhance it’s ability to flex and conform better to tapered grinds. This split came with the tensioner assembly’s introduction.

Marc

(MarcH's Rack-Its)11/29/2020 at 9:44 am #55304Well, like I said, he needs to call and get WE customer support involved. Hopefully he will let us know what the outcome is.

1 user thanked author for this post.

11/29/2020 at 9:44 am #55305From tcmeyer post:

>> From the photos by the OP, I can’t see any evidence that says the clamping pads are actually there – as though somebody might have screwed up in manufacturing. This would produce results exactly like precept is describing.

So I definitely do not have any pads on my version. If any of you have some sort of pads improving clamping within vise – you’re lucky I guess.

11/29/2020 at 10:41 am #55306So I definitely do not have any pads on my version. If any of you have some sort of pads improving clamping within vise – you’re lucky I guess.

Your pads I have circled in red:

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

11/29/2020 at 12:23 pm #55313@Precept thank you for your excellent explanation of the problem along with the clear photos and videos. It’s very helpful to get such high quality information to help troubleshoot.

Thanks to everyone on this thread for the their input, it makes it much easier to track down the issue.

When we redesigned the jaws and added the center split and the tension adjust, we redesigned the pads so that they now slope continuously as seen in Precept’s photos. We performed a lot of prototyping iterations to try and get a “one size fits most” design since it’s pretty much impossible to get a “one size fits all” solution. I can agree that thin blades are what create the challenge here. We’re currently working on a new design for the jaws to solve the issue and one concept we’re playing with are some high durometer pads to go into some recesses pockets to create fill any excess space left with thin, parallel sided blades. We’re also prototyping new pads with different dimensions.

For those in this thread with the more noticeable pads from the earlier design – can you confirm that you are able to get a better grip on thin blades with parallel sides and with the Low Angle Adapter?

@Precept – as we work on this solution, the best workaround is to add some thickness to your blades, either by adding some painters tape, or a thin rectangle of leather or chamois wrapped around the spine of your thin blades. It will also work with the Low Angle Adapter.

Once we are ready to release the new design, we’ll notify everyone on the forum when it’s ready.

-Clay

5 users thanked author for this post.

-

This reply was modified 3 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.