Using 50/80 stones

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Using 50/80 stones

- This topic has 36 replies, 17 voices, and was last updated 10/16/2019 at 6:29 pm by

Pat.

-

AuthorPosts

-

08/21/2019 at 10:47 am #51544

My feeling is that at this price point, the diamond paddles should be broken in at the factory. How hard can it be under a controlled rubbing machine. Why should we have to do it ? I am thinking of replacing my 100 grit paddles (most aggressive use) and to tell you the truth it pisses me off that I would have to “break them in”, us amateurs do NOT have time for that. Give me a broken in 100 grit plate that I can stick on and move on. I would pay the same price, it’s just a value prop. Do my diamond films need to be broken in ? I would hope not. Clay, what say you?

We go round and round here about whether to break the stones in before shipping. Here are some of the pros/cons we’ve come up with:

Pros:

- New users will have more refined edges more quickly

- Experienced users won’t have to take the time to break the new stones in

Cons:

- New users will not have the extra coarseness of the stones to help remove material on their (probably) very dull knives

- The break-in period can be used to re-profile the majority of their knives while they build their technique

- Breaking the stones in before shipping will shorten the lifespan of the stones

- The process of using a rubbing machine will add cost to all the diamond stones which might not be value added for a lot of people

We’re still undecided about it and I’m especially leary of doing it because it’s very easy to go too far and ruin the stones.

-Clay

4 users thanked author for this post.

08/21/2019 at 1:18 pm #51545Clay, would it be possible to have it as an “add on” service? That way people could choose whether or not they want it done to their stones and you also don’t have to mark up the prices on the stones as they currently are sold. I can understand if this would not be economically viable considering the investment into developing the break in tool.

08/21/2019 at 2:28 pm #51547Clay, would it be possible to have it as an “add on” service? That way people could choose whether or not they want it done to their stones and you also don’t have to mark up the prices on the stones as they currently are sold. I can understand if this would not be economically viable considering the investment into developing the break in tool.

That’s a good thought. I’ll look into the equipment and processing time for this and see if it makes sense.

-Clay

08/23/2019 at 1:14 pm #51563Clay, not sure about the cons, most of my understanding from our core forum guys is:

1. During breaking, do NOT use them on a good knife, you can put deep gauges into the edge which you may never get out (they show up later for strange metallurgical reasons).

2. I have never heard anyone suggest to do some major reprofiling on all your good knives. It is always do it on a junk knife. One of us suggested on a piece of glass but you only know it’s done by feel and sound.

3. Shorter life span ? — Giving up the break in part of life span would be a benefit to the overall value proposition.

It would seem that eliminating the whole conversation about break in (although I dont think there is a repeatable, documented process) would go a long way toward matching your excellent jig/angle consistency design.

Just thinking out load while drinking IPA’s on a New Jersey beach. I love my WEPS.

1 user thanked author for this post.

08/30/2019 at 6:09 am #51732Just going through the threads. Just got my WEPS yesterday and bought the 50/80 stones because i have some older dull thick knives. Had to put in the 1/4 in. attachment right off the bat. Put in the old buck knife and started with the 50 to re_profile the knife. Took almost 30 minutes to get to the apex. When I started this knife might as well been an axe. Will have pic. later. Got to the 80 and got all the pin mark off from heel to tip. Then i put it up to start tonight with 100 and start the sharpening process. This knife has never been sharp and I dont know where it came from. I know I’ve had it over 20yrs. Love those course stones. If i would of started with the 100 i would still be working it. I also figures this knife would be good to start breaking in my stones.

4 users thanked author for this post.

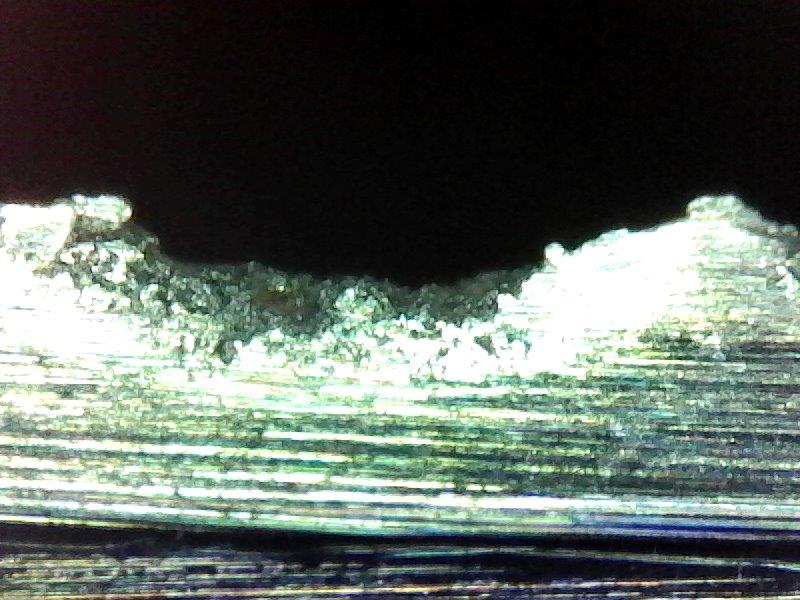

09/01/2019 at 1:08 pm #51762I’ve been sharpening four fish cleaning knives this guy has been using a “V” style pull through sharpener, with. The sharpener destroyed the edges on these knives I have previously sharpened, well. Here is some damage it had incurred. You can see the horizontal scratches and the steel tear out, from the carbide pull through sharpener:

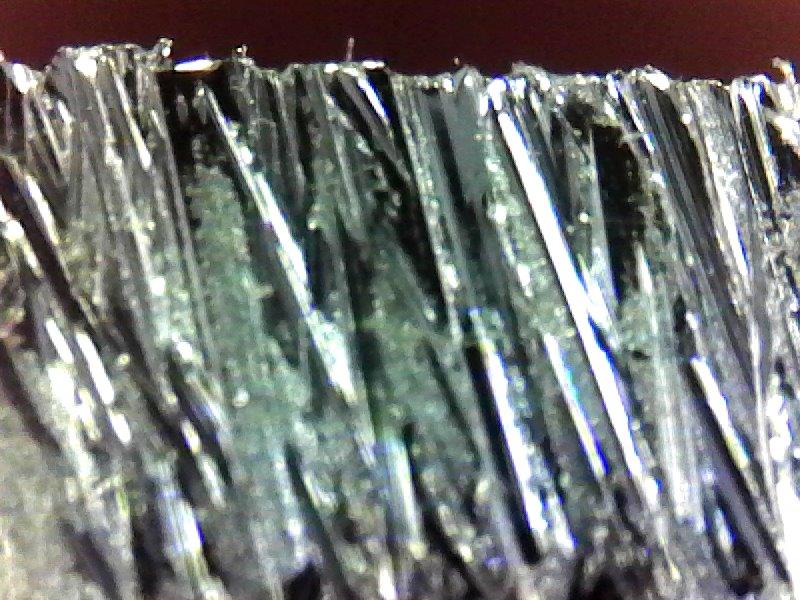

I started with using the 50 grit diamond stone horizontally, working with a scrubbing stroke along the edge length heel to tip to heel. This photo shows the flattened edge still existing after I changed to using up-down scrubbing strokes to re-profile the damaged bevel back to 18º. Even after scrubbing with some pretty good applied force, for some time, the vertically flattened edge from my horizontal scrubbing that I had used to remove the deep damage, still is present. The point I’m making is as aggressive as we think or know this 50/80 stone pair is, it still requires some time and effort to remove and profile the edge on a knife that requires this grit for it’s repair and restoration.

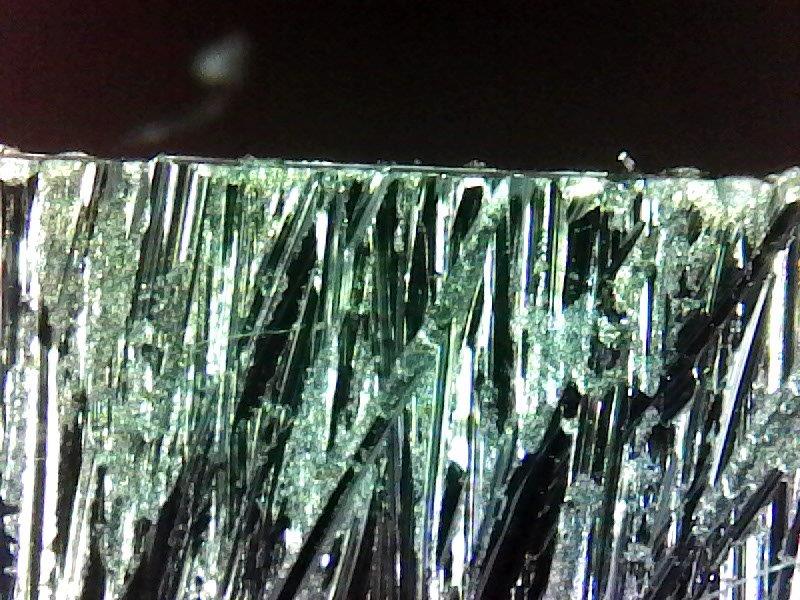

With continued up-down scrubbing, alternating back and forth, side to side, I was eventually able to apex the edge as shown in the last photo.

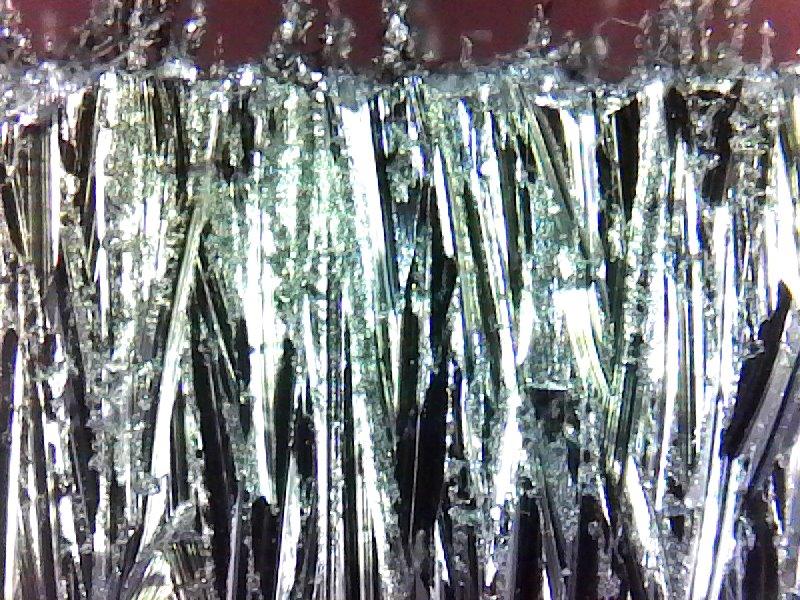

The 50/80 diamond stone does definitely have a place in a sharpeners arsenal. This is 4 knives in a row I’m using it. I believe the 50/80 is broken in, now. I have been using it for a while now, months, regularly. From looking at the ragged scratch pattern, you wouldn’t think that is broken it. The aggressive scratches are scary. Don’t let that fool you. These stones have there place. I wouldn’t want to try to sharpen a knife with this damage without it. The only other recourse is a belt grinder.Last is the end results of the 50 grit. An 18 dps profiled bevel. Now to move on.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

10/16/2019 at 6:29 pm #52391Same reason not to hit two hammers together to test hardness.

Just so you know rubbing diamond stones together, especially the very coarse diamond stones is strictly <b>not recommended.</b>

-

AuthorPosts

- You must be logged in to reply to this topic.