Micro-Adjust Question

Recent › Forums › Main Forum › Welcome Mat › Micro-Adjust Question

- This topic has 43 replies, 14 voices, and was last updated 01/31/2021 at 7:54 am by

JimR.

-

AuthorPosts

-

12/23/2020 at 4:00 pm #55511

Yes, got the SS adjusters and handles, the stops and the hand guards. Should be good. Thanks again.

12/23/2020 at 4:28 pm #55512Yes, got the SS adjusters and handles, the stops and the hand guards. Should be good. Thanks again.

That’s great! I’m sure that you’ll love them. What do you mean by, “handles”?

12/23/2020 at 7:14 pm #5551312/23/2020 at 7:23 pm #55518Good idea. My lock great without the washers.

12/24/2020 at 11:29 am #55519Hi rummels, can you please tell me what type of nylon washers you use. As I’m waiting on my SS mod kit to arrive and I may want to use your tip. Thank you

12/24/2020 at 11:34 am #55520Hi 000Robert, by handles I mean the L-screw. I think of them as small handles I use to fasten the mini-L bracket to the angle bar; I guess I should be thinking of it as a screw and not a handle 🙂

12/24/2020 at 12:46 pm #55521Hi 000Robert, by handles I mean the L-screw. I think of them as small handles I use to fasten the mini-L bracket to the angle bar; I guess I should be thinking of it as a screw and not a handle 🙂

I was going to try the L-screws and forgot about them. That’s why I changed my photo and added them. But with my SS Micro-adjusters, they lock very well and I have not had any problems with them loosening. I guess the washers would be a quick fix if you have problems with something loosening. But I would just sand the surfaces myself until they stop loosening.

Usually if something like a knurled lock nut or screw tip is loosening up it means that there is a burr or uneven surface causing it. If I didn’t see a burr or something that may be causing the problem, then I would sand the surface on a flat surface like a piece of steel or thick glass and sand it more flat. But I’m an old school kinda guy.

1 user thanked author for this post.

12/25/2020 at 7:00 am #55524They are just a white nylon washers. They have an ID of 1/4″, an OD of .500″ and are 1/32″ thick. I imagine a 1/16″ thick washer would also work.

I also use them on the guide rods to keep them from loosening.

You should be able to buy them at any hardware store.

1 user thanked author for this post.

01/30/2021 at 3:59 pm #55894I’m new to forum. I must admit that having spent this much for the Gen 3 Pro with lots of extras that I’m now about to call it quits. I can’t get through a single set of stones without having to re-tighten my right sided micro adjustment screw no matter how tight I have it. It’s throwing off the bevel on some knives and they don’t sharpen well if one isn’t extremely diligent and tightening this screw every literally every few passes. Now I’m seeing this is a known issue and discussed quite often online. Given this flaw I may have to seek another sharpening alternative and sell my new sharpener.

01/30/2021 at 4:35 pm #55895I’m new to forum. I must admit that having spent this much for the Gen 3 Pro with lots of extras that I’m now about to call it quits. I can’t get through a single set of stones without having to re-tighten my right sided micro adjustment screw no matter how tight I have it. It’s throwing off the bevel on some knives and they don’t sharpen well if one isn’t extremely diligent and tightening this screw every literally every few passes. Now I’m seeing this is a known issue and discussed quite often online. Given this flaw I may have to seek another sharpening alternative and sell my new sharpener.

Check the ends of the screws and see if they have burrs on them or something, or maybe they are not very round. Take some emery cloth and smooth them up. I don’t know how many times I have had to do that with screw ends on all kinds of stuff. It’s so bad that any time I buy something that uses screws like that, sanding them good is the first thing I do when I open the package. Most of the time I will sand them even if they don’t look like they need it.

All to often it’s the little things that ruin something. Reminds me of a song by the band, Bush – It’s the little things that kill.

1 user thanked author for this post.

01/30/2021 at 6:44 pm #55896Thanks very much! I’ll take your advice and give it a shot.

1 user thanked author for this post.

01/30/2021 at 7:22 pm #55897R Comp, the loosening adjusters as you stated is a known issue. W.E. has been working to resolve it. I don’t know if they’ve come up with a micro-adjuster upgrade for the Gen 3 Pro. They have introduced and include a new adjuster locking mechanism for all the new WE130 models they sell and ship. Maybe call Wicked Edge next week to ask about it.

Here is another solution for your issue if you want to make the investment in an aftermarket micro-angle adjuster upgrade.

This is the link to various after market accessories made by experienced W.E. users. These are available for W.E. sharpeners including micro-angle adjusters that lock positively and enhance your angle range for your Gen 3 Pro model.

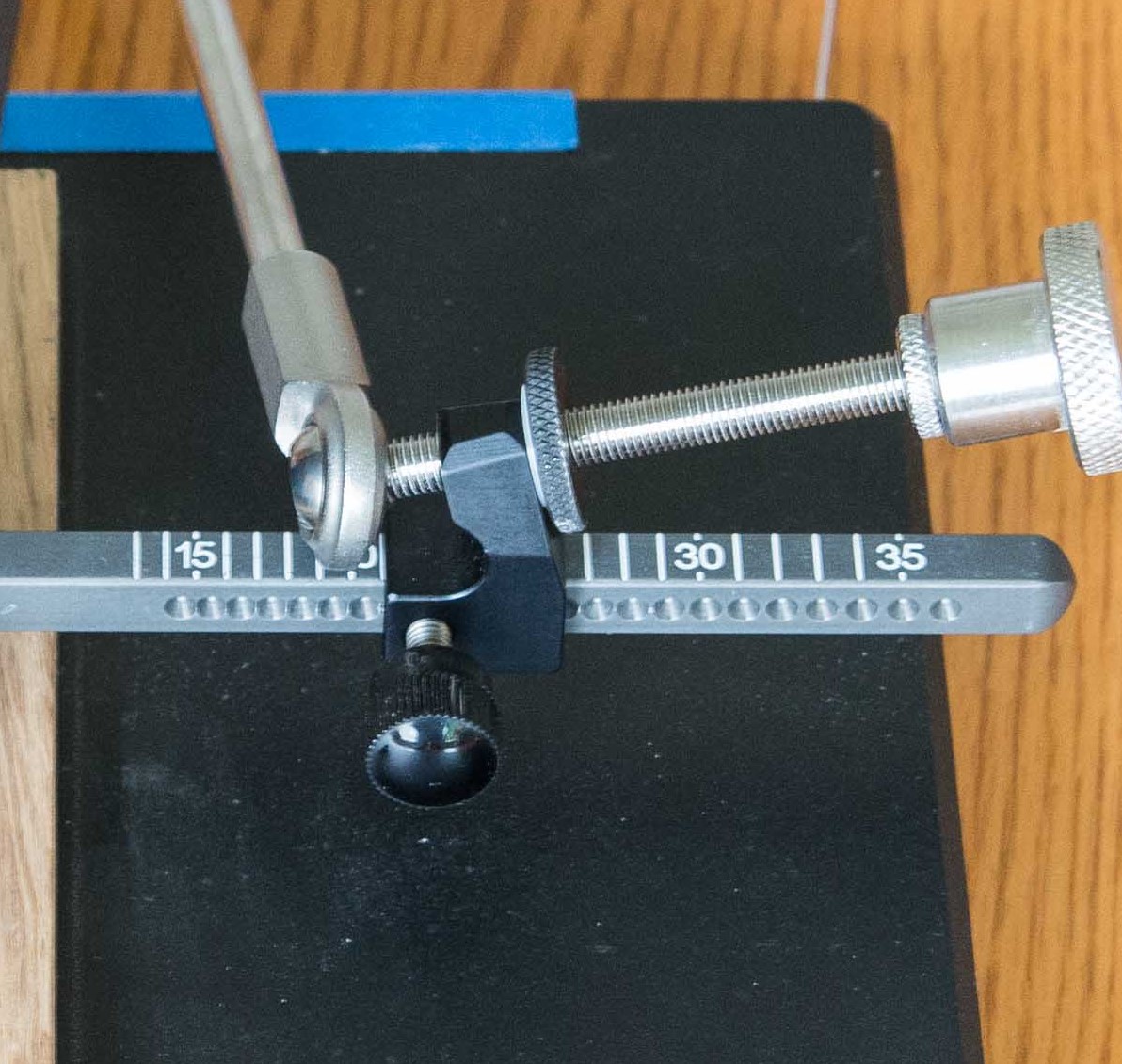

I have an older model Gen 3 Pro from 2017. Here’s a photo of the micro-angle adjusters on my setup.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

01/31/2021 at 3:26 am #55902Thanks very much! I’ll take your advice and give it a shot.

Yeah, just check the surfaces for burrs and stuff and sand them smooth using a hard flat surface. That might take care of the problem. Like I said, I’m so used to doing it that I don’t give it a second thought. I sanded the surfaces of the screw tips, tightener wheels, and L-brackets as soon as I opened the box and didn’t think twice about it.

Maybe that’s why I never had any problem with any of mine loosening up on me? I also did the same with the SS micro-adjusters that I bought from the guys here on the forum. And when I talked about mine working good in other posts, I forgot about the fact that I sanded mine up before I started sharpening knives because I am so used to it that I forget about doing it.

1 user thanked author for this post.

01/31/2021 at 7:54 am #55903snip

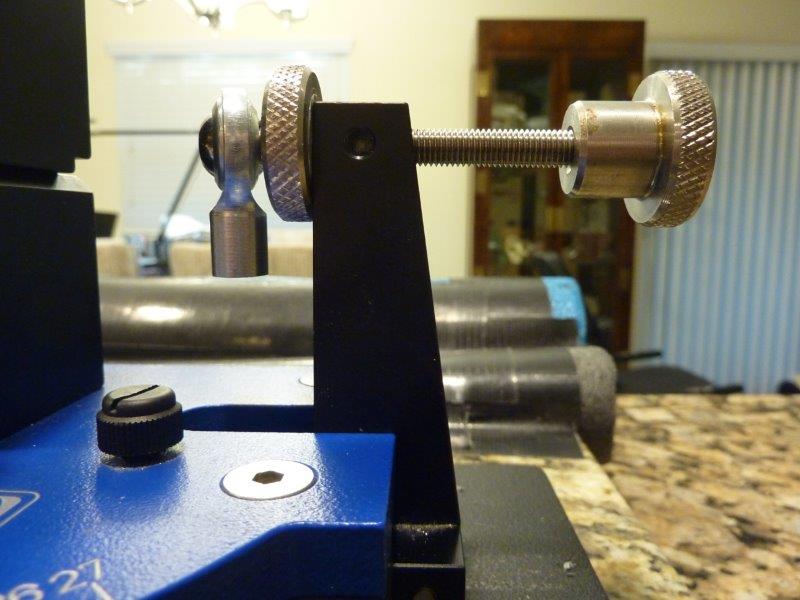

The W.E. micro-angle adjusters have recently, (in the past few months), been upgraded to include the hex thumb wheel on the outside. This serves as a jam nut to lock the micro-angle adjusters positioning. It can be either finger tightened or tightened with an appropriate sized wrench.

snip

Marc thanks for pointing out about the hex on the new production. I got a 120 before I discovered this forum and was perplexed what it was for (in part because my 120 (subsequently upgraded to a 130) came assembled as shown in your picture – with the hex towards the spherical joint – and it didn’t make sense to me. That was before I did some sharpening trials to break in my technique and my stones – and pretty quickly learned that the knurled lock doesn’t stay locked and the micro adjusters move. I reversed my lock so that the hex is on the side away from the spherical joint which allows you easy access to the hex to tighten with a wrench. I have a full set of inch and metric wrenches and found an 8mm metric is the best fit – and the wrench I dedicated to the Wicked Edge is shown in my pic. It’s a ratcheting 6 point box end / open end combination but with the knurled lock facing “hex out” you could use any regular 8mm wrench or even a socket wrench.

The pic also shows the latest sharpening project using the Tormek Small Knife jig – this job happened to end up with a 19 degree bevel. The jig worked well enough – I don’t believe I could have sharpened this knife without it (originally this knife was made by me and sharpened in a Lansky). ETA – that funny looking black knob you see in the hole for the long blade support is a 1/8″ hex driver (that fits the micro adjusters) press fit in a knob (intended for a Fender guitar) that makes it easier to adjust the micro adjusters to get exactly the angle you want.

-

This reply was modified 3 years, 2 months ago by

JimR.

-

This reply was modified 3 years, 2 months ago by

JimR.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

-

This reply was modified 3 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.