Micro-Adjust Question

Recent › Forums › Main Forum › Welcome Mat › Micro-Adjust Question

- This topic has 43 replies, 14 voices, and was last updated 01/31/2021 at 7:54 am by

JimR.

-

AuthorPosts

-

07/05/2020 at 12:39 pm #54478

Nah, I used blue loc tite. I can definitely get the screws back out if I want to. Mine is the new gen 3. I love the machine and hope to resolve the issue. From what I can tell, the wicked edge haters on the internet are angry about how other people spend their money. I’m definitely not in that category. The 24 hour cure time is almost over. I’m looking forward to finishing my Hinderer!

1 user thanked author for this post.

07/05/2020 at 2:00 pm #54479Nah, I used blue loc tite. I can definitely get the screws back out if I want to. Mine is the new gen 3. I love the machine and hope to resolve the issue. From what I can tell, the wicked edge haters on the internet are angry about how other people spend their money. I’m definitely not in that category. The 24 hour cure time is almost over. I’m looking forward to finishing my Hinderer!

Well I hope it works well for you.

1 user thanked author for this post.

07/16/2020 at 12:35 pm #54598I do not understand how W.E. could have released the Gen3 with such a glaring problem. All they had to do was try there own prototype once or twice to see it was a design that was not ready for release. Considering the apparent quality of the rest of the product, releasing a knife sharpener that relies on exact angles but which cannot maintain those angles due to the micro-adjusters constantly loosening is baffling to me. And now after spending $900 on the Gen3 I have to order aftermarket parts made in someone’s garage to get my Gen3 to be able to work properly. Ridiculous!

This is a legit criticism and shows that I haven’t been listening enough. I’m working to change that. After hearing some more from some users, we did some prototyping, thought we’d come up with a viable fix, got (kindly) corrected by a couple of our beta testing users and are now reworking the fix. I’ll post again when we finalize the solution.

-Clay

-

This reply was modified 5 years ago by

wickededge.

wickededge.

7 users thanked author for this post.

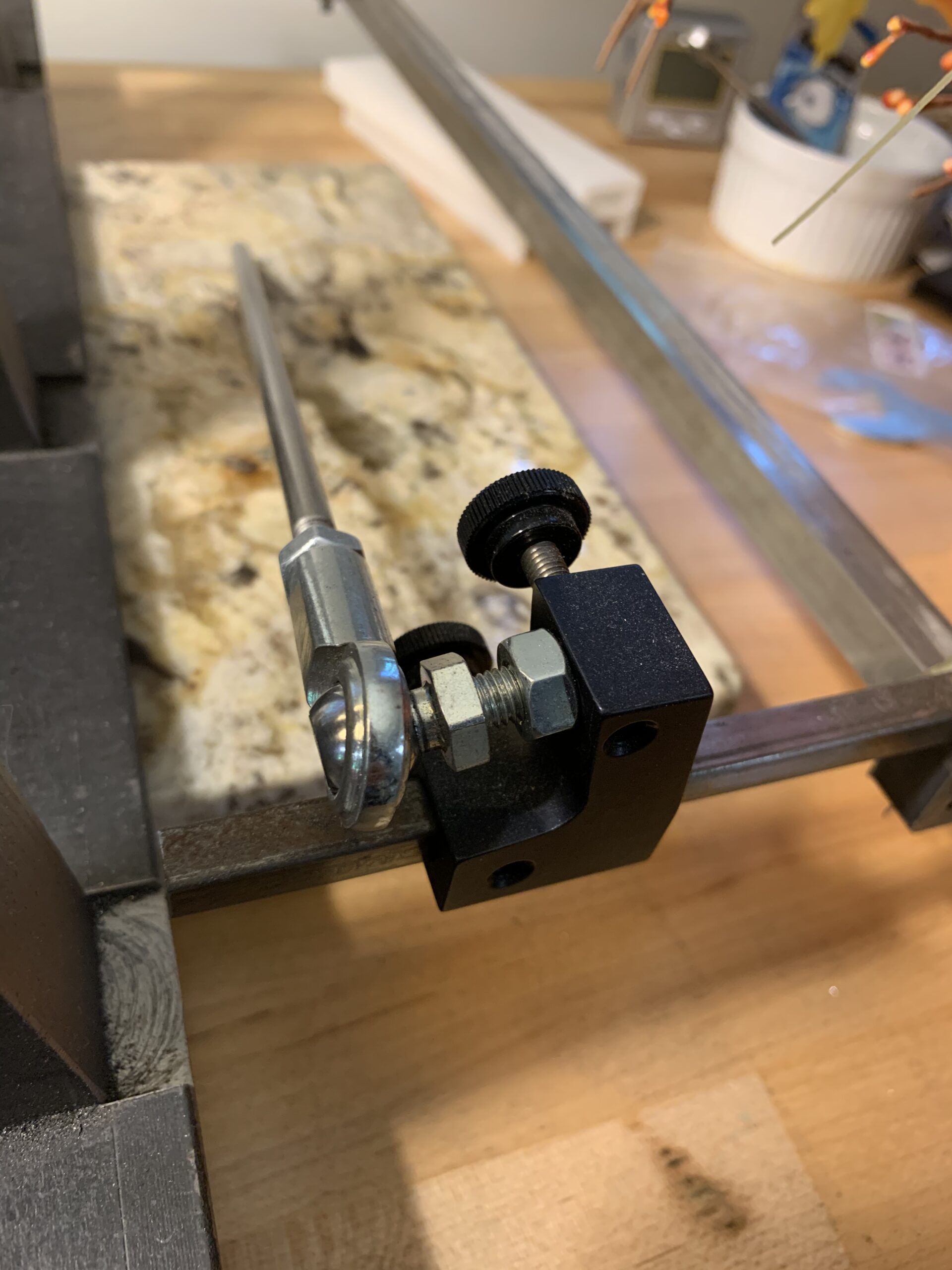

07/21/2020 at 12:25 pm #54644I may be missing something, but a simple solution is to add a nut and tighten it against the hex key.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

12/21/2020 at 11:07 pm #55475Is there a follow up to this post? Thanks

12/22/2020 at 6:40 am #55479Rodger, welcome to the W.E. Forum.

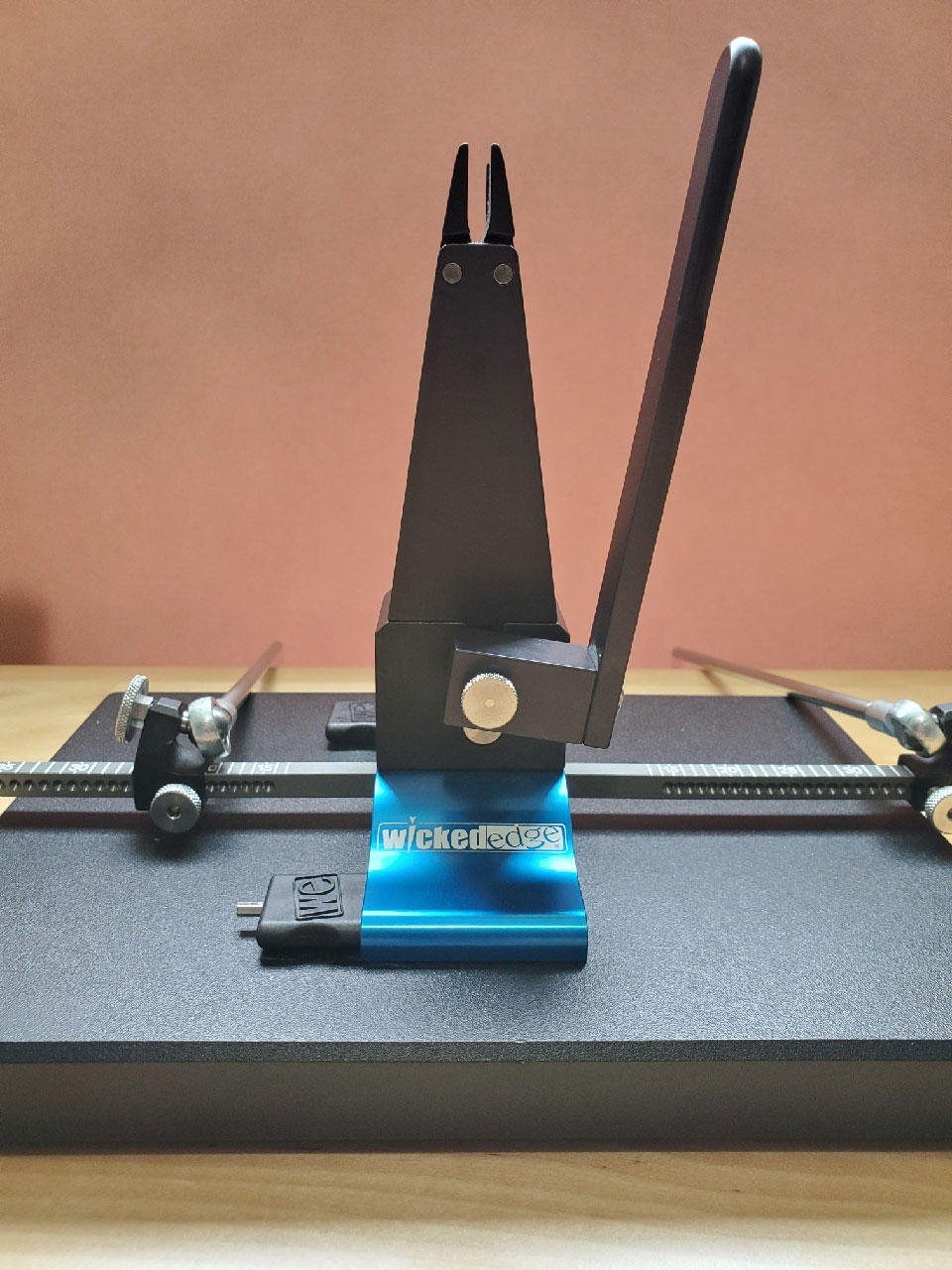

The W.E. micro-angle adjusters have recently, (in the past few months), been upgraded to include the hex thumb wheel on the outside. This serves as a jam nut to lock the micro-angle adjusters positioning. It can be either finger tightened or tightened with an appropriate sized wrench.

The thumb screw that positions the black mini “L” brackets positioning on the square bar, for gross angle adjustments, has been upgraded with the hex tool insert thumbscrew. This facilitates more positive tightening using the included hex tool.

Other W.E. users choose to customize, modify or accessorize our setups with handy items available here. There is a micro-angle adjuster available.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

12/22/2020 at 9:32 am #55482Thanks very much MarcH. My WE130, which I received only last week, looks exactly like the picture you’re showing. I’m still interested in the mods and will contact NotSharpEnuff, who I believe sells some. He recently PM’d me.

I’m looking forward to increasingly become more skillful at using the WE130. What a beautifully machined piece of equipment that is; wow. This forum appears to be full of great tips and advice so seems like a great resource. Speaking of, do you have any recommendations on a good angle cube that is accurate. WE sells the Wixey but I don’t know about its accuracy.

Thanks again

12/22/2020 at 10:11 am #55487Repeatability and consistency is more important then absolute accuracy. Realize the angles we’re working with are relative angles. That is we’re setting a bevel to an angle relative to the position of the WE130 and the knife’s position in the vise jaws. We’re using a properly zeroed angle cube to make these settings.

As long as the knife’s position while being sharpened can be recorded to use for future touchups and the zeroed cube can be positioned the same again, then everything should be consistent and match right up. Your 15° bevel won’t necessarily be my 15° I set on my WE130. But they’ll be pretty close. What’s more important is that you can count on your readings if you do everything consistently.

I used to use the Wixey Guage type 2. I liked the Wixey because it was fast to lock in readings. I could take the readings 2 or 3 times to be sure and I got good stable readings quickly. I didn’t like it because it only has a magnet on the bottom. Since we’re always using it on a vertically positioned sharpening stone it mean you had to add or subtract the reading from 90° to determine the angle.

To be honest, I too sought the best most accurate and precise digital angle cube. I tried several settling on the Flureon DXL360S. (I believe they’re all Chinese so you’ll find there are lots of different brand names for this model #). The red one is the more accurate model to the yellow model. I also like that it is dual axis. It does have a bit of a tedious calibrating procedure. The good thing is it is both precise and accurate. The bad thing is it’s both precise and accurate. This level of accuracy requires much more time for the cube to settle down and give a reading. It’s much slower then working with the Wixey cube. It does have magnets on all the sides so that is handy, too. Direct readings, no more math.

When you start working with +/-0.01° resolution it makes you really have to pay attention to the details. It slows everything down to work at this level of precision. Do you want to drive at the 35 mph speed limit, or at the 35.00 mph speed limit? When you’re looking to know the value of the extra digits are you just going to ignore them??

Of course then you’re going to want a USB microscope so you can see where you’re applying these super precise bevel angles. This is a good inexpensive model to use with a laptop.

Have fun going down this near endless rabbit hole.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

12/22/2020 at 11:51 am #55489Thanks very much MarcH. My WE130, which I received only last week, looks exactly like the picture you’re showing. I’m still interested in the mods and will contact NotSharpEnuff, who I believe sells some. He recently PM’d me. I’m looking forward to increasingly become more skillful at using the WE130. What a beautifully machined piece of equipment that is; wow. This forum appears to be full of great tips and advice so seems like a great resource. Speaking of, do you have any recommendations on a good angle cube that is accurate. WE sells the Wixey but I don’t know about its accuracy. Thanks again

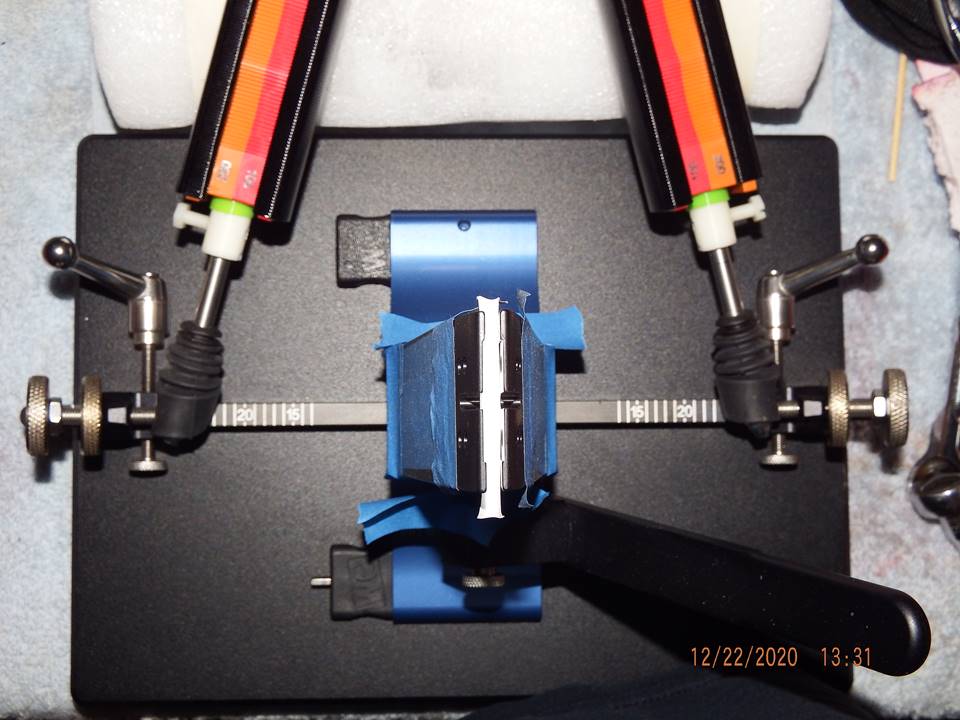

Welcome to the WE family, Rodger. I have my WE130 set up with the accessories that you can see in the photo. I have the Stainless Steel Micro-Adjusters, the ball joint boots, stone stops, and you can see the stone covers on my stones. I love the accessories and highly recommend them. I keep my vise taped up to try to keep out as much shavings and trash as I can.

Attachments:

You must be logged in to access attached files.

12/22/2020 at 12:55 pm #55492Hi 000Robert,

That looks like a great setup. I’m looking at buying those mods and was wondering if the steel adjusters are that much better than the plastic ones. Do you happen to know? Aesthetically the steel wins, hands down, but is quite a bit more expensive so if reliability and strength is not a huge delta I’d probably opt for the plastic and buy another set of stones instead (or maybe the lapping film)

Thank you

-

This reply was modified 4 years, 7 months ago by

Rodger.

Rodger.

12/23/2020 at 2:48 am #55499Hi 000Robert, That looks like a great setup. I’m looking at buying those mods and was wondering if the steel adjusters are that much better than the plastic ones. Do you happen to know? Aesthetically the steel wins, hands down, but is quite a bit more expensive so if reliability and strength is not a huge delta I’d probably opt for the plastic and buy another set of stones instead (or maybe the lapping film)

Thank you

Thanks, Rodger. I am not sure about the plastic ones because I have never tried them. I’m not even sure what kind of plastic that they are made of, or if they are really polymer or whatever. But I really don’t trust plastic. So I saved my money and waited till I could afford the stainless steel kit. I love them! They look nice and work very well. And they give you more range to set/adjust your angles with. Plus the knurled wheels are easy to tighten/loosen.

Now I need to expand my collection of stones.

1 user thanked author for this post.

12/23/2020 at 10:29 am #55506Hi again 000Robert, I just bought the mods from NotSharpEnough. Can’t wait to install and use them.

12/23/2020 at 10:33 am #5550712/23/2020 at 11:14 am #55508Hi again 000Robert, I just bought the mods from NotSharpEnough. Can’t wait to install and use them.

Sounds great! I know that you will love them. What all did you get? Did you get the SS Micro-Adjusters?

12/23/2020 at 11:16 am #55509Hi again MarcH. I think I might go for the Klein. It’s around $30, is (at least) a U.S. brand and probably is “good enough.” The DXL360 looks like it has too many bells and whistles. Plus, you’re right, I’m OK with driving 35 vs 35.00

I love my Klein Tools Angle Cube. I use it all the time. I wish it had magnets on the sides, but I can hold it. It isn’t that big of a deal.

-

This reply was modified 5 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.