2200/3000 Diamond stones

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Abrasives › 2200/3000 Diamond stones

- This topic has 40 replies, 15 voices, and was last updated 03/02/2022 at 12:02 pm by

Mr.Wizard.

-

AuthorPosts

-

11/13/2019 at 10:57 am #52543

From what I have observed, the 2200 / 3000 fits really well after the 1500 grit diamond stone and before the 1.4 / 0.6 micron ceramics. If you dig back in the forum archive you will find a thread around the time that the 1500 stone was introduced where Clay shared several microscope images of scratch patterns left by the 1500 stone as well as the various lapping films. In this thread Clay stated in relation to the scratches left by the 1500 grit stone that, “Most of the widest scratches measured between 2.5µ and 3.5µ from ridge to ridge.”

In another old thread Clay shared some microscope images of the scratch patterns left by the ceramic stones. The 1600 ceramic yielded scratches that were slightly finer than those of the 1500 stone. See post 31960 on page 3 of the thread below where Clay shows that the 1600 grit ceramic scratches range between 2.6 micron and 3.3 micron in width.

Based on this evidence, I suspect that the 2200 / 3000 will fit very well after your 1200 / 1600 stones. I cannot say for certain whether or not you will need the 5 micron or 3 micron lapping film in your progression. I like to overlap my grit ratings when changing from one type of sharpening medium to another.

11/13/2019 at 12:23 pm #5254411/13/2019 at 1:43 pm #52546Bandaid’s question/assertion may have been direct, gruff and undiplomatic but I don’t think it’s unreasonable to expect the specifications (i.e., grit particle size) of a product being marketed and sold is a known commodity, that can be shared. Afterall how to you rate the grits in order to name them without this information. Obviously W.E. and Clay had this information to make naming these new diamond stones possible. This information was asked for in this thread, by several posters.

Many of us prefer to determine our own sharpening, polishing and stropping progressions on our own basis on published specifications. For these newly marketed grits their were none. All we were provided with was a name without the basis for the naming. The stones seem to work well used in this order they were named. I can’t disagree with this.

I can state that I owned two sets of the originally introduced 1500 grit stones, from 2016, that were documented as Organic referenced above. My experience using my two sets of the newly released stone this past year, 2019, that they don’t behave similarly. I cannot state unequivocally that these newly released 1500 grit stones differ from the originally released 1500 stones from 2016. I have no specifications for documentation.

I can say based on my experience that the two era or version 1500 grit stones behave differently and for me yield different results. I use a USB microscope to visually inspect and photograph my sharpening sessions for all knives. The scratch patterns appear to me to differ. The new stones do work well. I cannot complain. They are not as fine as the first set of 1500 grit stones I still have and use. The new 1500 grit stones, after being well broken in, still do not yield anywhere near the polished effect I saw with my first 1500 grit set. I can simply state they appear to be different stones although named, similarly.

I’m concerned what will be the results if after the Los Alamos testing that the grit naming procedure is needed to be changed to a new separate chart. What if it determines that the 1500, 2200, and 3000 grit nomenclature are all wrong based on the particle size studies, investigation and determination. This certainly would reflect, in my mind that the however, roughly stated assertion by bandaid, is possibly indeed correct. It certainly would suggest as asserted that the products as marketed and sold are an unknown commodity.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

11/13/2019 at 2:00 pm #52547I want to add, to make it very clear, I do not assert that these products or any products introduced, marketed and sold by Wicked Edge, Clay and his company are not top quality and fully functional products. I enjoy using them all. I just suggest the documentation as requested could be more forthcoming.

Marc

(MarcH's Rack-Its)11/13/2019 at 5:35 pm #52549Doesn’t look like we are relaxing much…

I don’t think it wise to make enemies here.

I’ll rephrase since there are so many snowflakes here…

11/14/2019 at 1:17 am #5255311/14/2019 at 8:52 am #52554Hi all,

I’m away at a conference today. When I’m back in the office I’ll pay the specs with some pictures and explain the logic of switching to a new system. The current progression is rational and each of the diamond stones progress from one to the next as pretty much you’d as you’d expect them to.

-Clay

11/15/2019 at 2:01 pm #52559First I’ll address the elephant in the room:

I am perplexed by the decision to release the new stones without also releasing the same information you’ve released with every other stone in the Wicked Edge lineup.

We removed our old grit chart well before the release of the new stones. We did it for a variety of reasons, the foremost of which is that we are in the process of switching to a new grit system. I will elaborate on why we are doing this and exactly what the plan is in my next post.

This in my mind means either you released the stones without knowing the micron rating or you knew and didn’t want to release the information.

Of course the other option, which is the real reason, is stated above though bears repeating: We didn’t post particle sizes with these stones because we’re moving to a new system that makes more sense to us.

If you didn’t know, then you released a product without knowing what it was.

We do and did know the particle sizes but considered them irrelevant because of the new system we’re developing.

If you did know, you chose to hide requested information from your customers.

Not posting information that we feel will no longer fit into the new grit system is not the same as deliberately hiding information. Anyone with a microscope can look at and measure the stones. Suggesting that we would deliberately hide information when we’ve always been so transparent is silly.

So did you hide information or did you release a product without knowing what it was?

Neither, please see above.

-Clay

-

This reply was modified 4 years, 8 months ago by

wickededge.

wickededge.

-

This reply was modified 4 years, 8 months ago by

wickededge.

wickededge.

6 users thanked author for this post.

11/15/2019 at 2:23 pm #52562If you are moving towards a new system, what is it and why move away from an industry standard, and will all your diamond stones be rated on the new system so we can compare in an apples to apples manner? Thank You

Yes, our plan is to include all the abrasives we off in the new system.

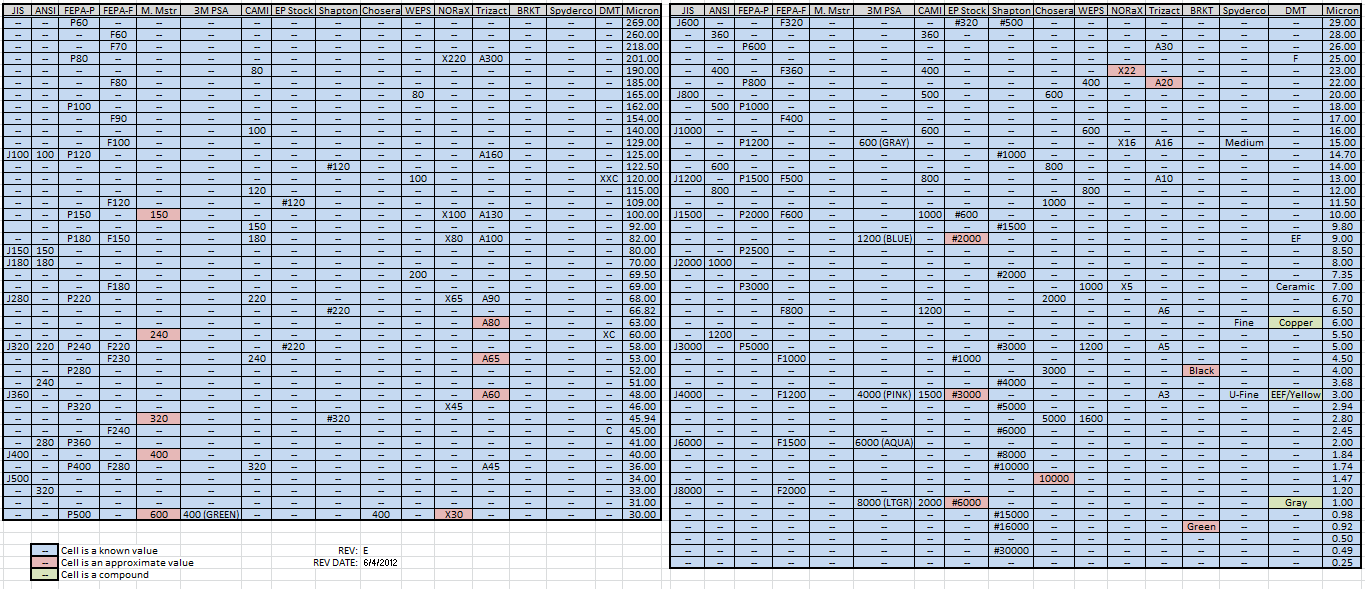

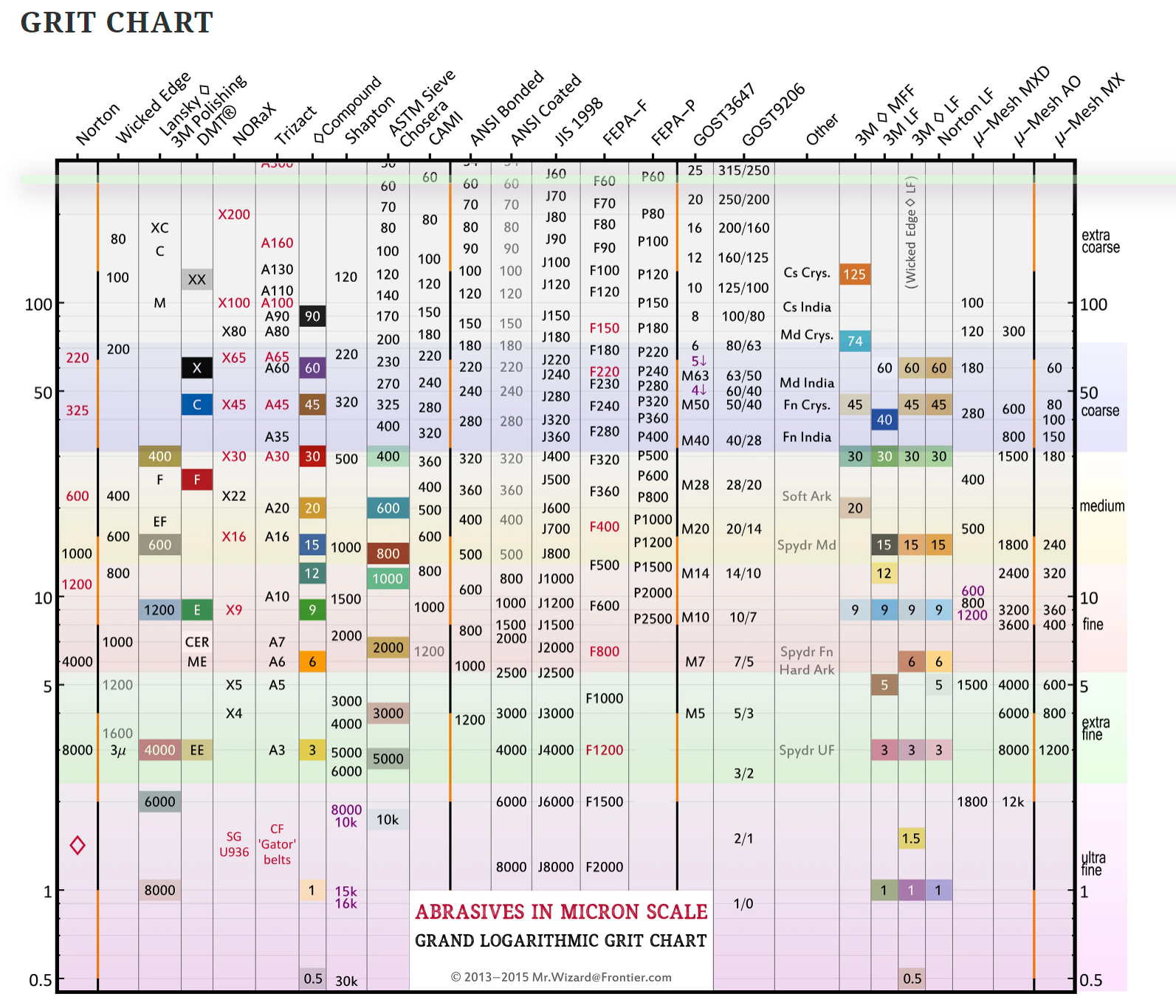

The charts below represent the efforts of some very smart, dedicated people to make some sense out of all the different grit systems on the market today. In addition to the clear confusion represented in these charts, there are concerns about the way different abrasives behave when used to grind metal e.g. 14 micron diamonds plated to a steel substrate produce very different results from diamonds of the same size in an emulsion or paste and applied to a leather strop and ceramic stones with original constituent particles of the same size can no longer be characterized by their particle size once they undergo the sintering or vitrification processes.

The above examples are just two of the charts put together to try to make sense of the various abrasives on the market. They do not take into account:

- Substrate

- Friability of the abrasive

- Fusion/transformation of particles during production of some types of ceramic stones

- Sintered ceramics

- Vitrified ceramics

Our new system attempts to solve these issues and provide our customers with information that clearly relates one abrasive to the next in an “apples to apples manner”.

Here is the approach we’ve taken:

- Polish to all samples to 0.1 microns

- Electro-polish the samples

- Continue polishing with 3M diamond lapping films

- Alternate with each grit and image at each stage to ensure all previous scratches are removed

- Apply the grit to be studied to the polished surface

- Send the samples to LANL to be analysed

- LANL will report on:

- # of scratches per distance (density)

- Scratch profile

- Avg width of scratches

- Height of ridges

- Depth of valleys

- RA (roughness average of the surface)

- Cross-section profile image of the sample showing scratch width, depth and height

- LANL will report on:

Our thought process is that what matters at the end of the day is what each abrasive does to the knife. Once that is quantified, we should be able to state something like the following: Abrasive X has n effect on the metal. With each grit having a quantified effect, it should be easy to see where each fits within a progression.

-Clay

-

This reply was modified 4 years, 8 months ago by

wickededge.

wickededge.

-

This reply was modified 4 years, 8 months ago by

wickededge.

wickededge.

Attachments:

You must be logged in to access attached files.

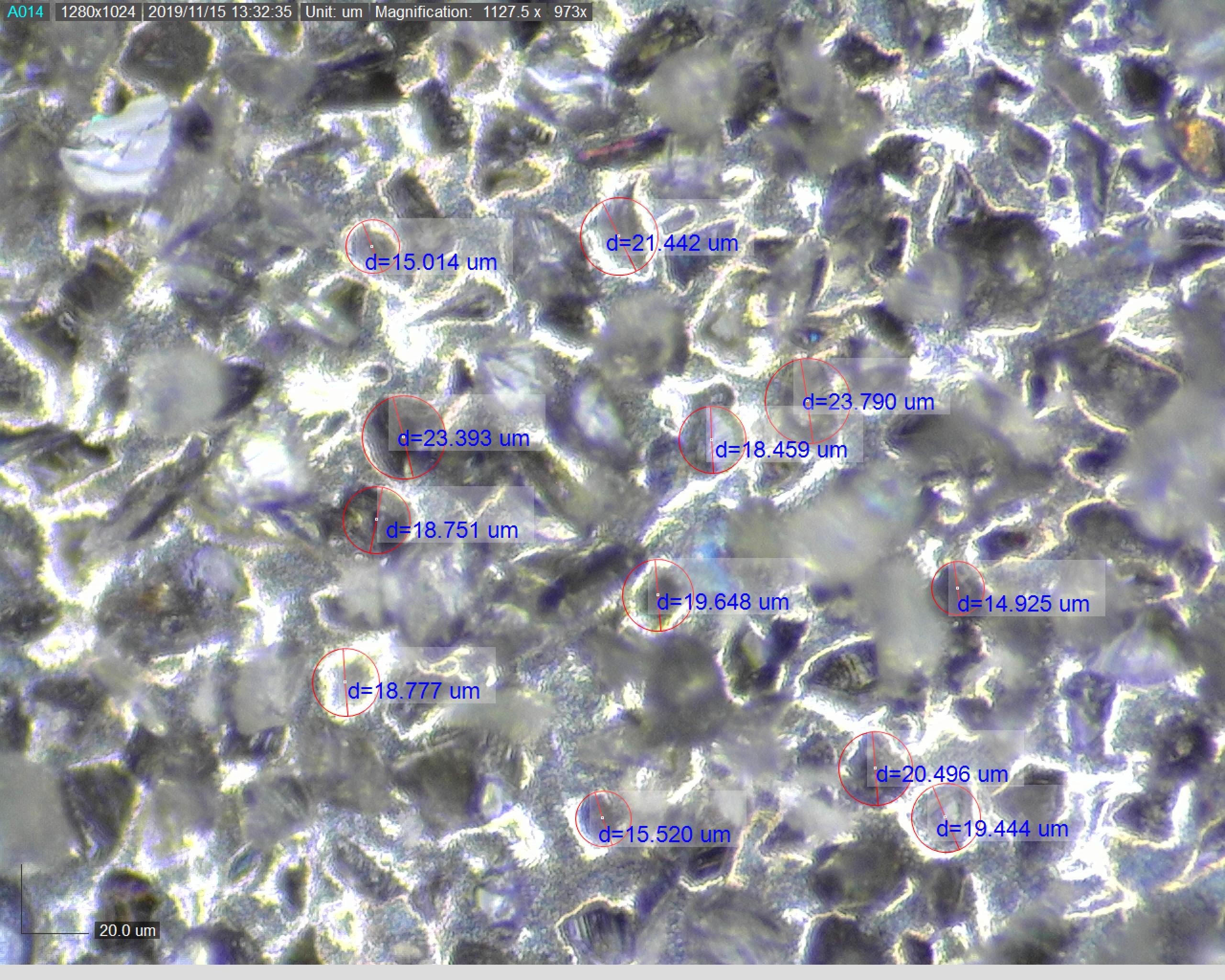

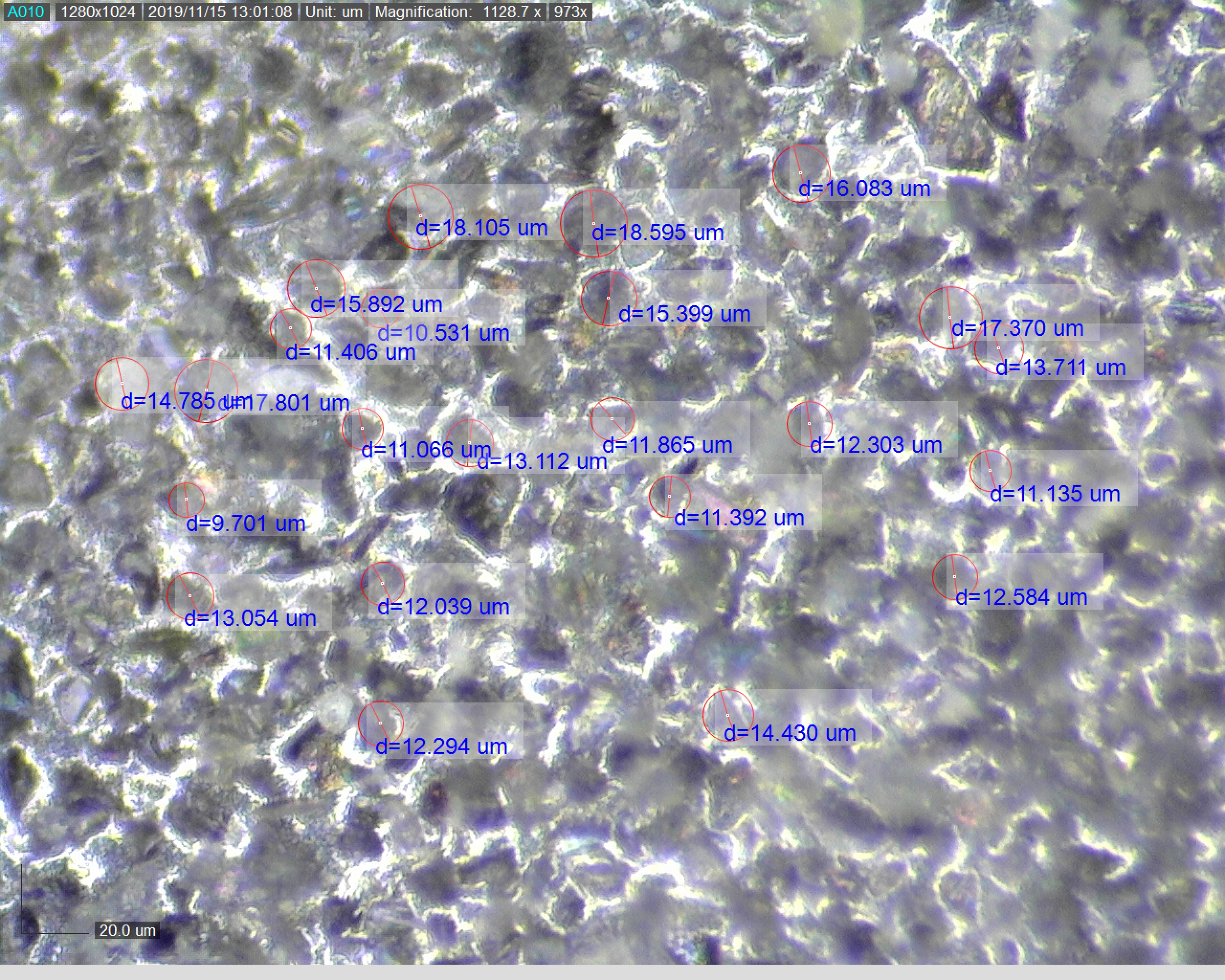

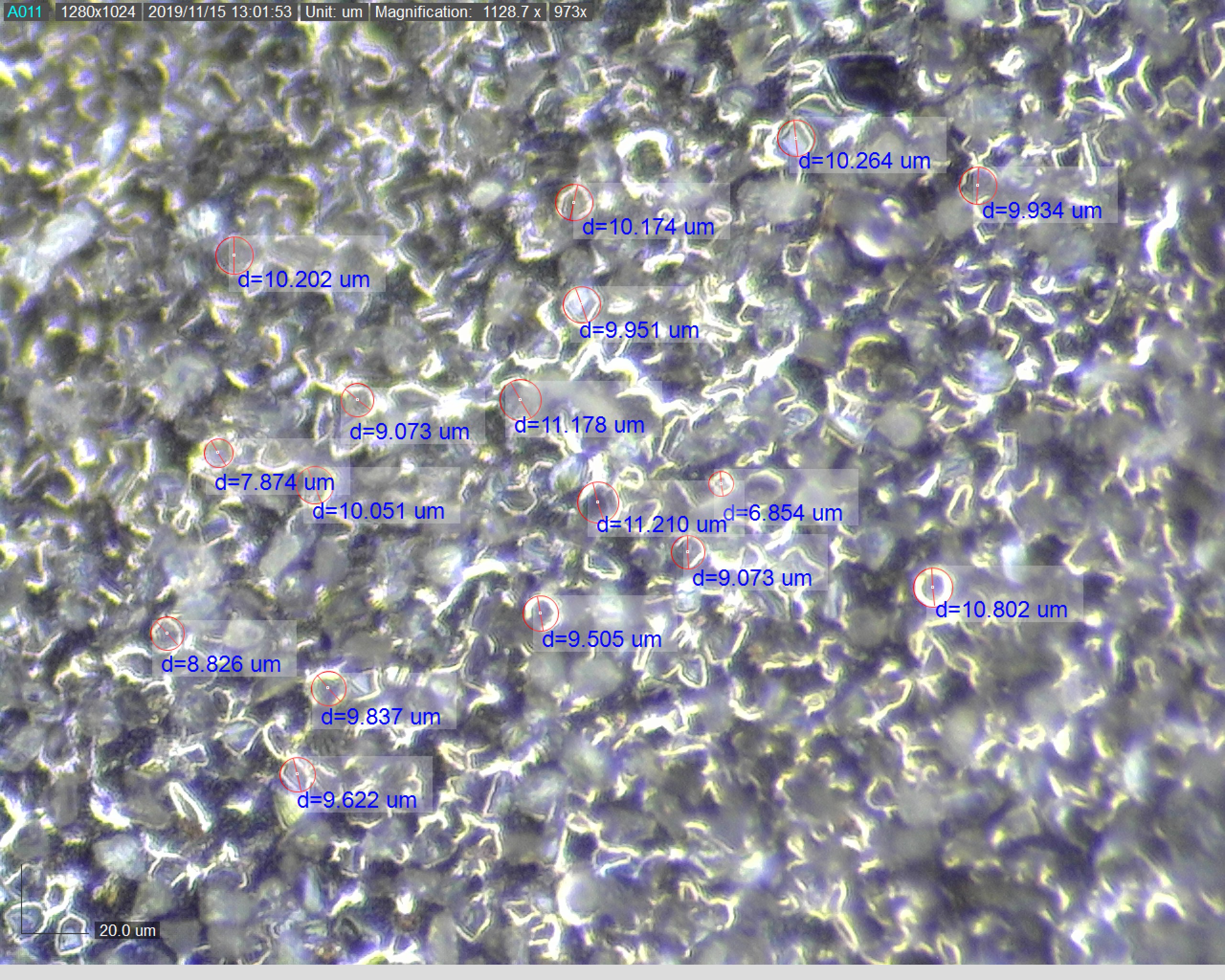

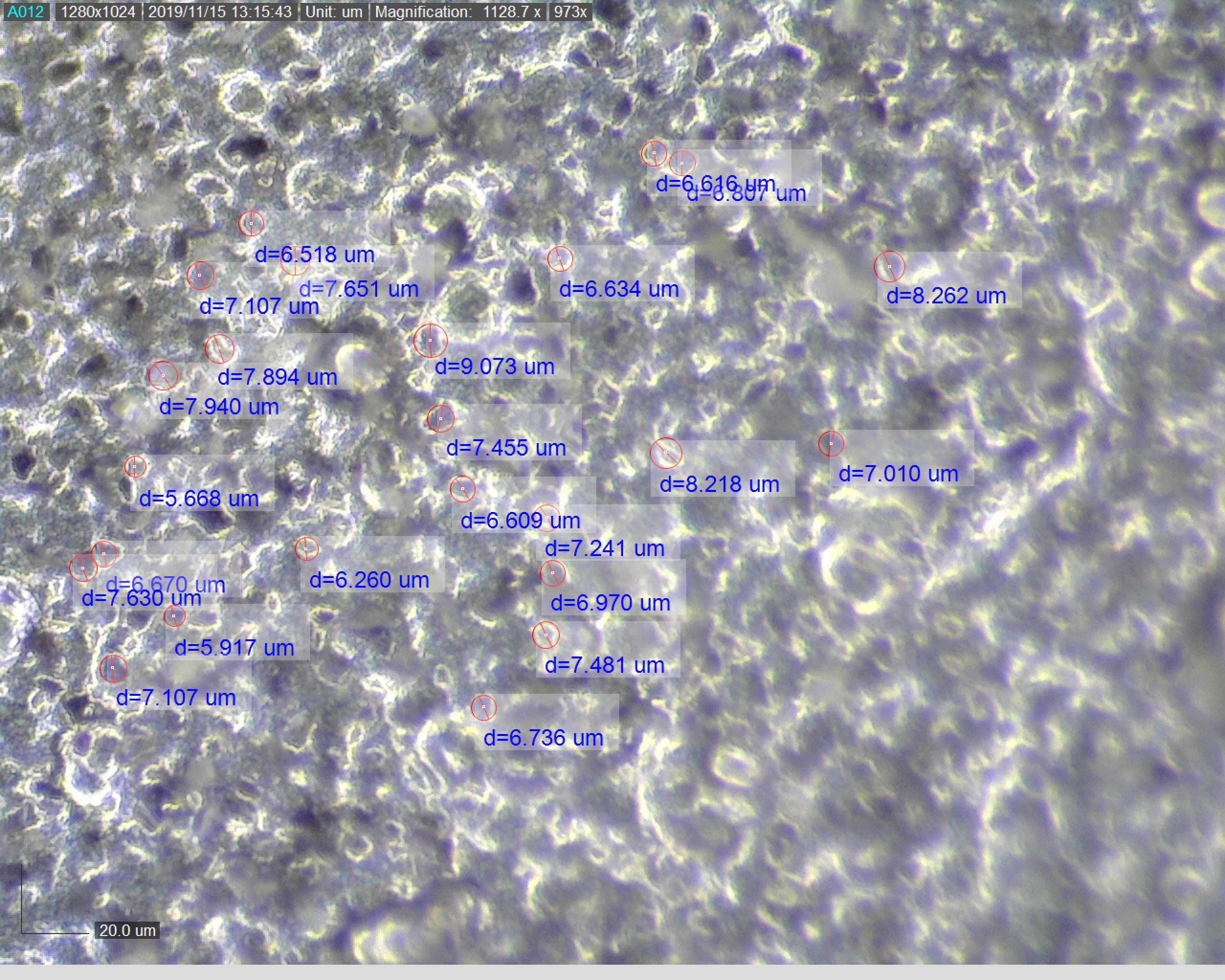

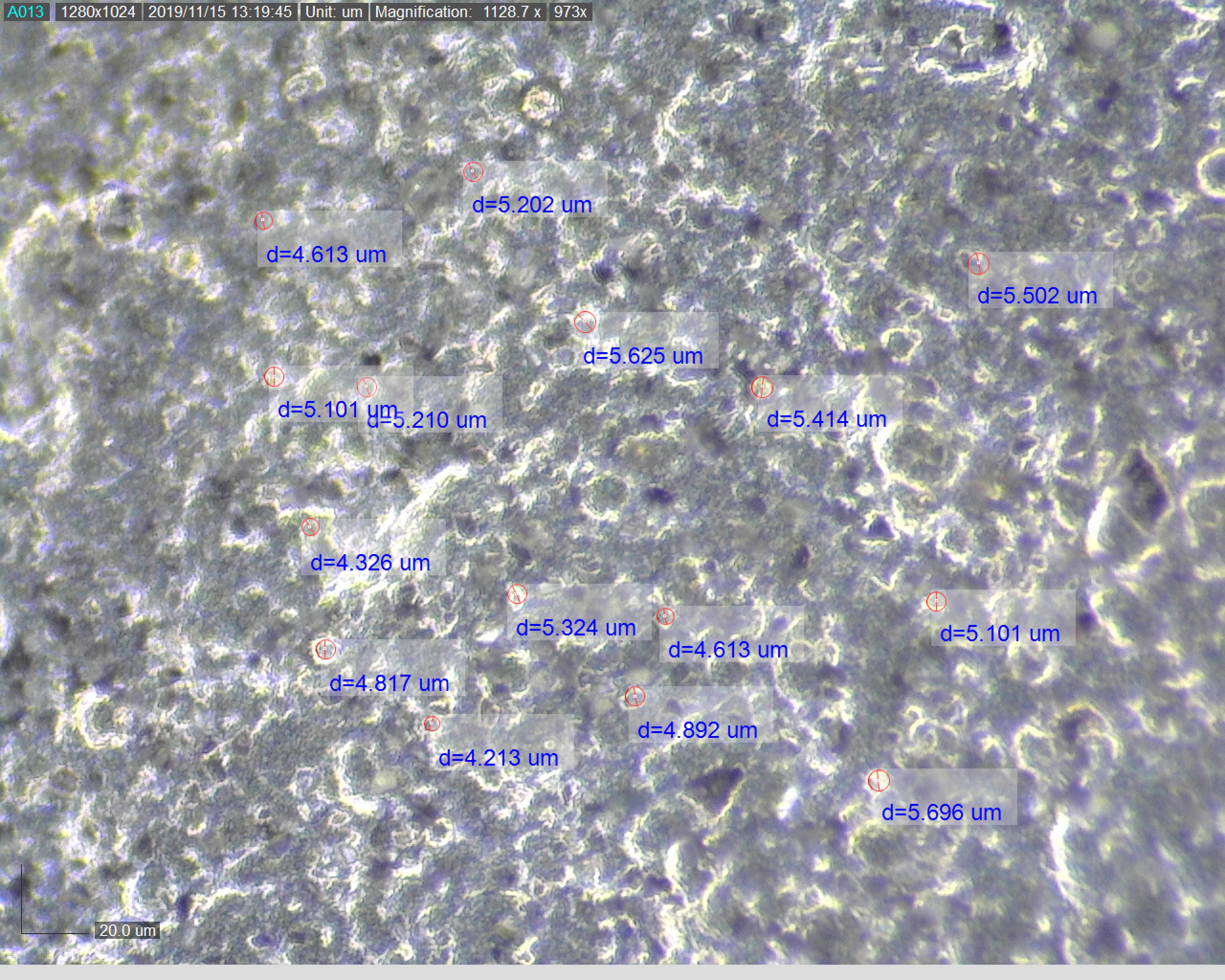

11/15/2019 at 2:56 pm #52567I just completed imaging diamond stones from 800# – 3000# and measuring a sample of the individual diamonds on each stone which I then average:

800# – 19.13um

1000# – 13.68um

1500# – 9.67um

2200# – 7.14um

3000# – 5.04um

*It’s worth noting that there is some variation between sizes depending on how well we can determine the edges of the stones, especially since they are irregularly shaped and it’s not always clear with the diamonds which planes or edges we should referencing.

-Clay

Attachments:

You must be logged in to access attached files.

8 users thanked author for this post.

11/15/2019 at 4:21 pm #52574Clay, I believe those of use with some sharpening experience recognize that the same grit particle size when adhered to a steel plate as with a diamond sharpening stone and applied to a stropping medium through a paste, suspension or an emulsion, or adhered to a plastic film do behave (possibly very) differently. I believe if the grits you list on the grand-unified chart or the gritomatic chart are simply identified to what they are, sharpening stone VS stropping abrasive VS etc., etc., it will be very clear to us what they are.

My understanding of the grand-unified chart is the placement of all those different grits used by all the different companies and sources is how they relate and compare to one another. As a user of mixed sharpening mediums the placement in this relationship is most helpful. I don’t really care how large or small the grit particle is, measured, or named, but more so how it relates to another grit particle called that same size by another source or producer.

A chart that objectively visually measures, grades or rates, and compares all the different grits made by all the different companies by the appearance of the scratch patterns that those grit particles produce, by width, depth and distance between the scratches would be wonderful. It seems dauntingly impossiple to produce such a chart and tremendously expensive for that long tedious process. A chart that only places W.E. grits together, how they relate to one another, would be nice, but not nearly as helpful, to me.

Simply how the new grits fit into this existing grand-unified chart compared to the other Wicked Edge sharpening stones is really what I’m wanting. My concern was, were these grits withheld or not included with the chart because they didn’t fit in with the flow and placement that would be expected or interpolated as suggested by how they were named, in relation to previously marketed and sold sharpening stone grits.

This could certainly be problematic for you Clay, if the sharpening stone manufacturer you are using, or the manufacturing process has changed. If, or when, the new stones are found inconsistent in their behavior, effect, quality and appearance of their scratch patterns produced, compared with older stones from the previous manufacturer but called or named similary, because they’re supposed to be the same grit, could be a difficult situation. Many products change with out renaming them. This happens.

It’s all the more reason to place them in the chart how they compare to the other stones and grits we may be using. Even if they don’t fit as expected or predicted. I’m left wondering are you finding yourself forced find a new way to compare them and label them so they fit together in a flow that better matches the naming system now being used.

As I wrote at the onset of this post, those of us with some sharpening experiences have come to learn that different mediums behave and work differently even when they share a grit (size) name. That just “is how it is”. That may become the same case, for same mediums stones named by grit number, in this situation diamond sharpening stones. Even though they’re all branded Wicked Edge, they are different and don’t fit together neatly the way the once did. Maybe just call them new stone and old stones.

I don’t know this is the case, but I’m guessing it is the case. My very first 1500 grit diamond stone from 2016 was exactly like the second 1500 grit stone I bought some time later as the first one showed signs of wear. The 2019 1500 grit stone released, was somewhat different from the earlier sold 1500 grit diamond stones. Though equally effective, they were still differences in the scratch patterns the two era 1500 grit diamond stones produce.

The new 1500 grit, 2200 grit and the 3000 grit diamond stones all fit together nicely and produce similar progressively finer, shallower and closer together appearing scratch patterns. As would be expected. Whereas, by my personal experiences and observations the earlier version 1500 grit diamond continues to produce finer and more polished appearing bevels then even my well broken in 3000 grit diamond stones. I am aware of this situation I have with my 1500 grit sharpening stones. So I simply use the stones accordingly for the sharpening effect and results I’m looking for.

I’m not concerned but I do wonder if this is what I should expect down the road from the other grits when it’s time to replace them again.

Reading your preceding post made as I’m typing this appears your making a lot of effort to test study and relate the grits one to the next and I thank you and commend you for the effort and your expenditures. We’ll see what it looks like when completed. The size of the particles as observed and measured is nice to know. But moe important to as a sharpener is exactly what you stated in your conclusion on the last post, I really don’t care the particle size but what the grits will do to my knife edges as I am using them. And are they named or labeled so I can place them in an order to follow in my sharpening progressions.

Will the results force you and us stone owners/users to rename our previously bought manufactured and named grit stones so that the name reflects how the relate one to the next, like your new chart is supposed to do?

Marc

(MarcH's Rack-Its)-

This reply was modified 4 years, 8 months ago by

Marc H.

Marc H.

3 users thanked author for this post.

11/15/2019 at 6:01 pm #52576I’m looking forward to seeing the results of these measurements. One thing that I would love to see (in addition) is the material removal rate.

-

This reply was modified 4 years, 8 months ago by

Todd Simpson.

1 user thanked author for this post.

11/18/2019 at 4:15 am #52581Thanks Clay: The particle sizes you’ve measured and the assigned grit ratings fall very close to the numbers I’ve been using. I am really curious though, as to how they will be rated now. Seems to me it ought to be something like “scratches per inch,” but I’m guessing it will be straight micron particle size, to stay in the “apples for apples” format with 3M’s diamond lapping film. For sure, they’re not likely to change. But who knows? With the Vikings winning yesterday, they might be in a good mood.

2 users thanked author for this post.

12/20/2019 at 7:05 pm #52756I know this may be too early to ask, but does anyone have an idea as to these stone’s longevity? Will the 2200/3000 stones last at least as long as the 1500?

01/15/2020 at 11:36 am #53093I just completed imaging diamond stones from 800# – 3000# and measuring a sample of the individual diamonds on each stone which I then average:

Are you planning a similar analysis for the 80 through 600 grit stones? If not I humbly request it.

Also is there a time frame for the LANL results?

1 user thanked author for this post.

-

This reply was modified 4 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.