Stone Sequence

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Stone Sequence

- This topic has 27 replies, 12 voices, and was last updated 03/19/2017 at 7:29 pm by

Marc H.

Marc H.

-

AuthorPosts

-

03/15/2017 at 2:16 pm #37770

I think that the WE chart was made before the diamond film came into use here, so I’d be interested to hear if Clay has subsequently re-evaluated the comparison.

Part of the new website roll-out will be a makeover of the grit chart. Our plan is to unify everything by scratch size. We’ll still post the stated grit and particle size listed by the manufacturer but we’re also planning on sending sample scratch patterns from each grit to the lab to image and measure in an SEM. That will provide the best, results oriented, progression recommendations.

-Clay

1 user thanked author for this post.

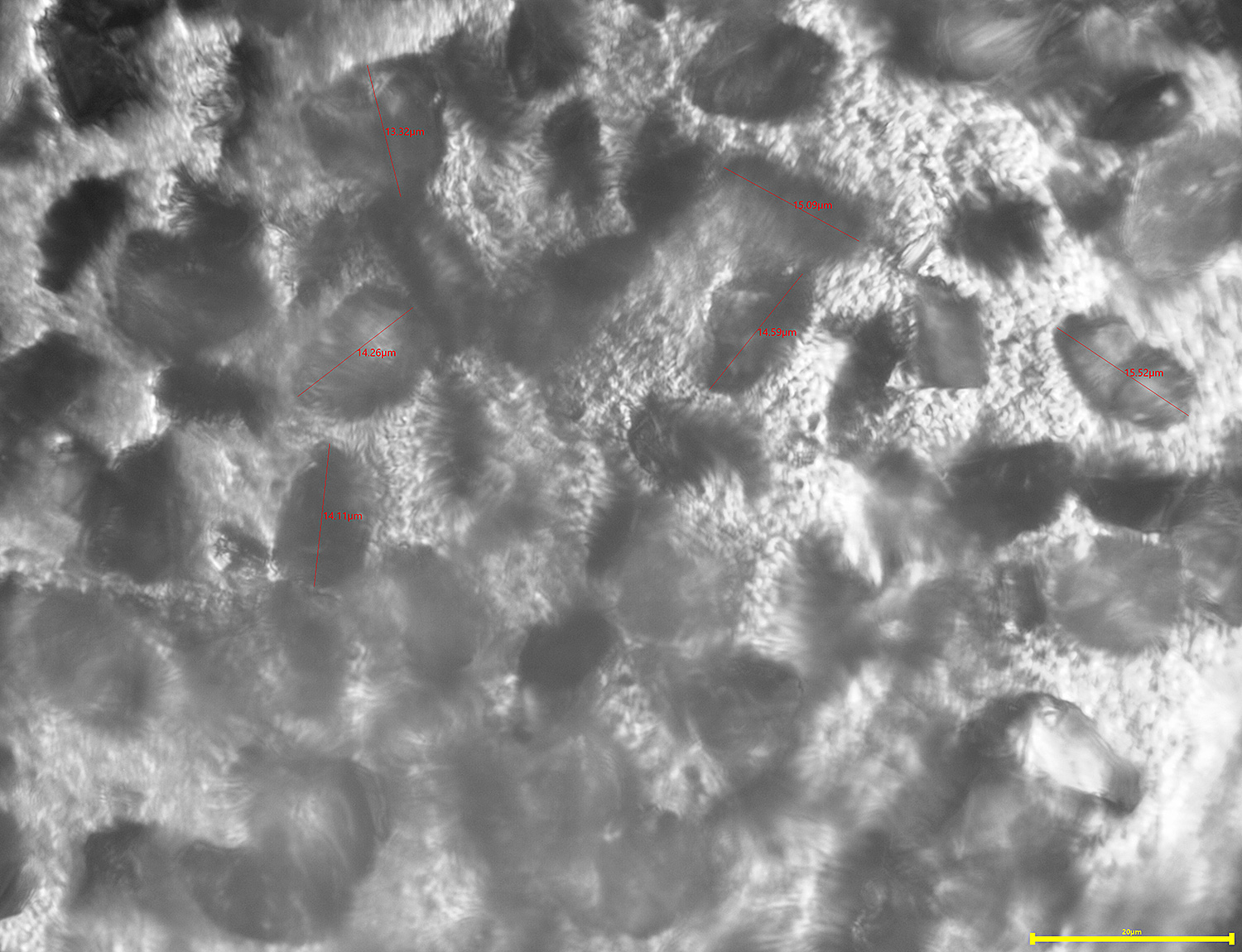

03/15/2017 at 2:28 pm #37771Here’s a photo of a new 1500# stone at 2000x:

It shows individual stones in the 14µ-15µ range so following with a 9µ or 6µ film makes sense. Of course the scratch size from the 1500# stones is much smaller than the diameter of the individual stones.

-Clay

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

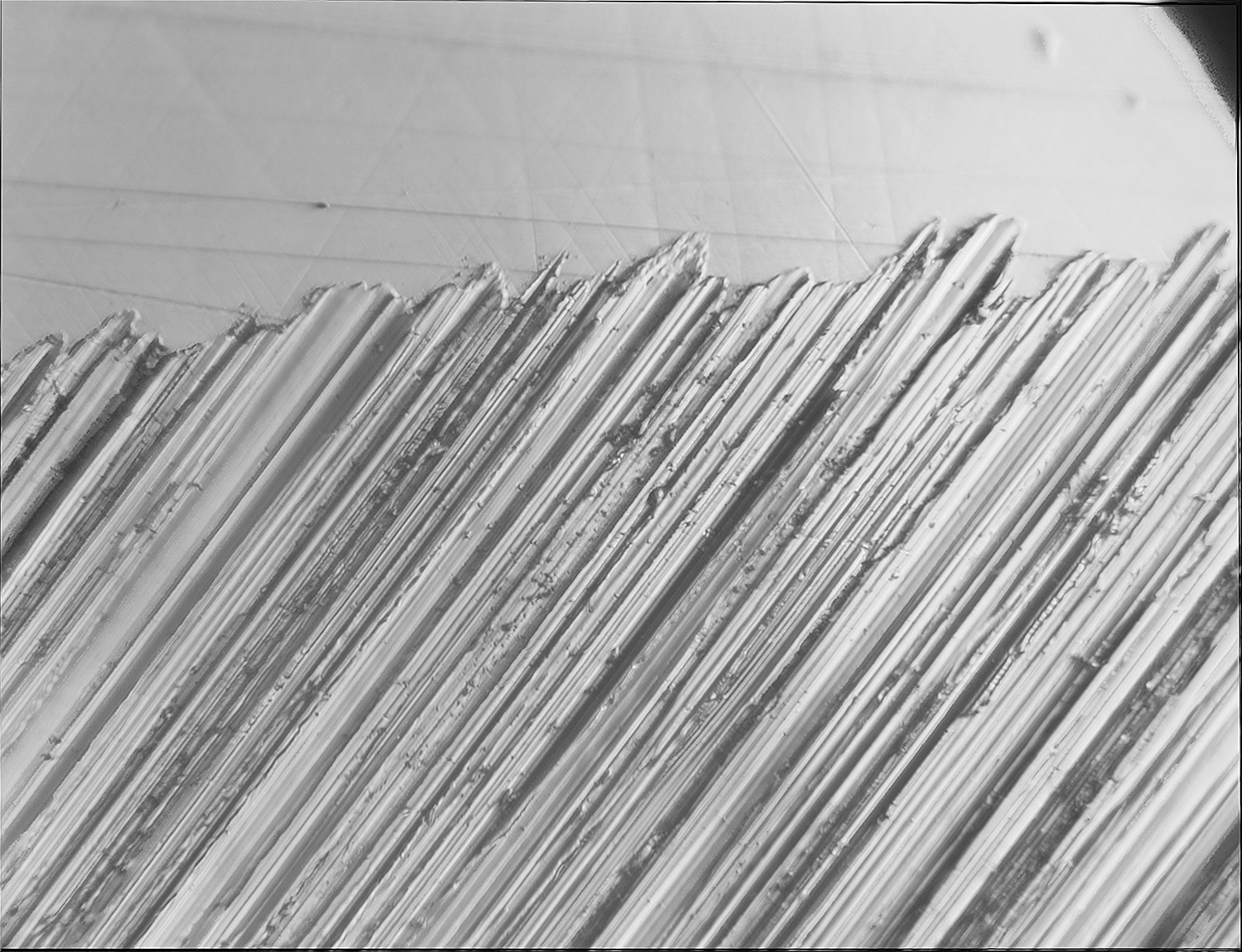

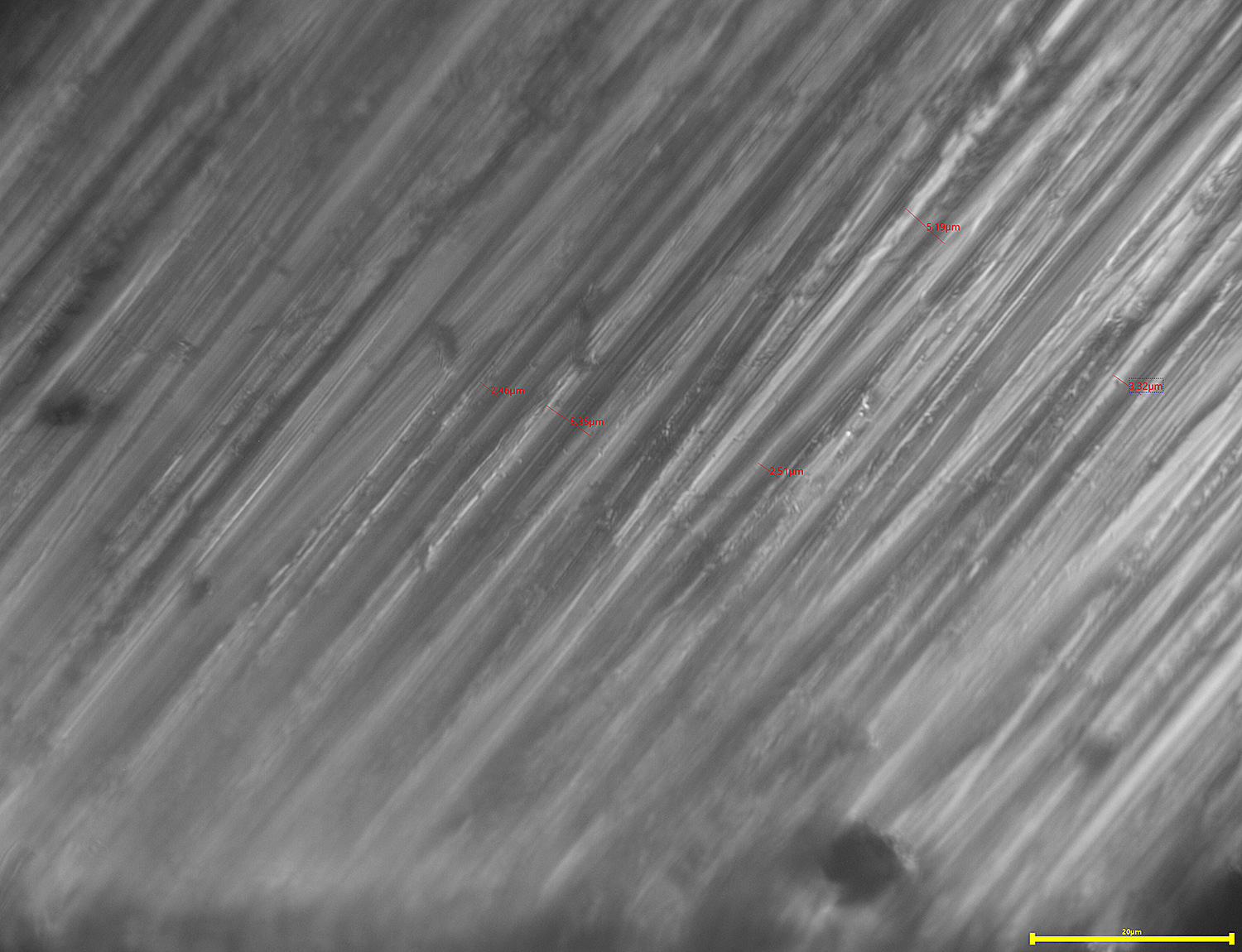

03/15/2017 at 2:47 pm #37773Here are a couple of shots of the sample scratch pattern created by the 1500# stones:

You can see that I started with a relatively pristine sample and then added the 1500# scratches. The second image isn’t super clean, but it shows that the scratch sizes are small compared with the individual stones, measuring 2.5µ and 5.5µ.

So the reason for a newly evaluated chart should be pretty clear – individual particles can be graded by size, usually by the mesh through which they fit, but also by microscope. How they act against metal varies greatly depending on their shape, friability and substrate. The same size diamond, say 15µ on a leather strop will cut very differently from one plated onto steel. Another issue arises from ceramics that have been sintered because their particules melt and fuse together creating amorphous shapes with wildly varying sizes. Those ceramics are usually graded by Roughness Average (RA) which seemingly bears no relation to mesh or particle graded abrasives. By focusing on the results the different abrasives create, we can have a much better apple-to-apples comparison. Rambling away here now, thinking out loud…

-Clay

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

03/15/2017 at 3:09 pm #37776I measured the diamonds on my 9µ films and they were all very close to 9µ in size. The density was somewhat less but I was looking at a fairly used sheet. I’ll dig up a new sheet this afternoon and look at it as well.

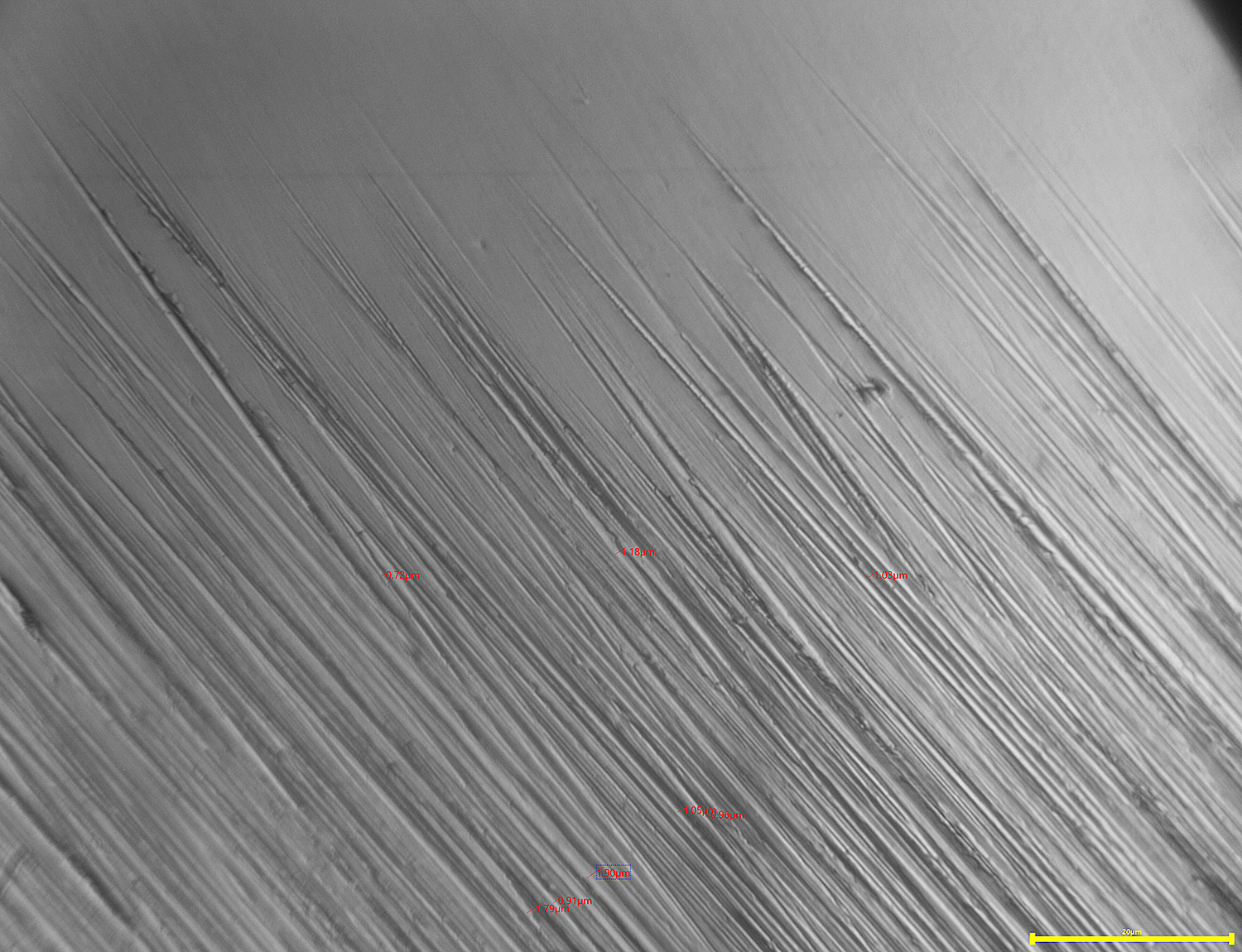

In the photo below, I used the same sample I’d used for the 1500# stone and I did 20 strokes per side with a fairly used set of 9µ films. They quickly erased the scratches from the 1500# stones and created a scratch pattern with individual scratches between 1µ-2µ. So the scratch size is a fraction of the particle size.

The 1500# stones have particles around 14µ-15µ and leave scratches of 3.5µ-5.5µ and the 9µ films have particles that are 9µ and leave scratches that are 1µ-2µ.

-Clay

Attachments:

You must be logged in to access attached files.

03/15/2017 at 5:47 pm #37779So to make it absolutely clear, in one post, after the thousand you would recommend the 1500 diamond? On average, TC said about 5 strokes per inch, and then what Exact stones, and what exact sharpening pattern at each level? all leading edge? all trailing edge? I’ve never used the diamond films before. Some of us are not as SHARP as others, ya need to fill in the gaps for us 🙂 I’ve been dabbling at this for a few months, and still have not used anything over 1000 yet

03/15/2017 at 9:01 pm #37789Going from the 1000 grit stones to the 6 micron films works fine. But the 1500 grit stone is of very high quality, too, and I can heartily recommend it to you.

Where is your chart that lists the 6 micron film at 3000 grit? I’m interested.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/16/2017 at 1:03 am #37791Mark: I’ve sent an e-mail to you with the excel chart(s) I use.

03/16/2017 at 7:27 am #37796Found it. Thanks! Sent you an email back already.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/18/2017 at 1:22 pm #37832Hello everyone, Can someone share the basic sequence/order of stone grit to follow. I understand it all depends on the condition of the blade and whether a polished/mirror edge is desired. But what would be a general sequence/order say after a 1000 grit stone? I have seen some videos of guys saying that you can’t/shouldn’t ‘skip’ any one grit. Just trying to learn the craft and get words of wisdom. Thanks…

Usually after 1000 grit diamonds, I go through sandpaper starting at 1000 then go 1200, 1500, 2000, 2500, 3000, 4000, 5000, 7000, 12000 and ill throw in my lapping films in between the sandpaper depending on the micron of my lapping film and then end with 1/0.5 leather strops with diamond emulsion. Yes, thats a lot of steps and it’s probably not necessary, but thats just how I do it.

03/18/2017 at 9:59 pm #37840Of the ceramic stones the preferred order after the 1000 grit diamond is probably SFC→SFF→MFC→MFF. I wrote a blog post on this: blog post. Where exactly the 1500 stones fit in I don’t know, but I suspect before or even after the MFC . The MFC are close to the 1500 grit diamonds, anyway.

If you spend some time you could probably skip the SFC and SFF (and maybe the MFC) and go straight from the 1000 grit to the 1500 grit diamonds.

But I use the ceramic stones not so much nowadays anymore, since the diamond films are very good, fast and consistent.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/19/2017 at 11:37 am #37845Just to throw a wrench in the discussion, even though grit numbers are assigned to a strata’s coarseness to define how it should compare with other strata of a equal, greater or lesser coarseness, not all grits are equivalent. A 1000 grit WE Diamond stone has a different depth and width to the scratch pattern than does a 1000 grit Shapton Pro Stones scratches or 1000 grit sandpaper scratches. Also the stratas wear differently so as the strata is used the scratches of what you’re using may change also. I suggest you find the scratch pattern of a given strata, (i.e.: diamond stones, lapping film, wetstones, ceramics or sandpaper) and work within the progression of those grits because as you mix the strata up you may get deeper or wider scratches for a similar grit number than expected. Using a USB Microscope allows you to visually observe the scratch pattern being layed down. If you do switch from one type of strata to another then it’s often a good idea to step down a grit size or two and work your way back up with the next strata.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

03/19/2017 at 1:28 pm #37849Just to throw a wrench in the discussion, even though grit numbers are assigned to a strata’s coarseness to define how it should compare with other strata of a equal, greater or lesser coarseness, not all grits are equivalent. A 1000 grit WE Diamond stone has a different depth and width to the scratch pattern than does a 1000 grit Shapton Pro Stones scratches or 1000 grit sandpaper scratches. Also the stratas wear differently so as the strata is used the scratches of what you’re using may change also. I suggest you find the scratch pattern of a given strata, (i.e.: diamond stones, lapping film, wetstones, ceramics or sandpaper) and work within the progression of those grits because as you mix the strata up you may get deeper or wider scratches for a similar grit number than expected. Using a USB Microscope allows you to visually observe the scratch pattern being layed down. If you do switch from one type of strata to another then it’s often a good idea to step down a grit size or two and work your way back up with the next strata.

Kinda like, with a tank or big truck off-road, you don’t want to go out on the same tracks you went in on? Or you will sink deeper

03/19/2017 at 7:29 pm #37851The contrary, the total opposite

Marc

(MarcH's Rack-Its) -

AuthorPosts

- You must be logged in to reply to this topic.