It's a long wait

Recent › Forums › Main Forum › Product Announcements › It's a long wait

- This topic has 17 replies, 7 voices, and was last updated 06/26/2019 at 2:52 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

06/01/2019 at 9:06 pm #50576

Serrated sharpener

No offense intended but I have been waiting 2 years for a serrated accessory. I know it is challenging from a $ perspective. So I am throwing this out there.

Serrations are basically a series of individual “edges” over a long distance. I am talking kitchen knives. True razor & mirror serrations are nonexistant, exotic (makes me smile) and most likely only achievable with $$ CNC.

Let’s crowd source it. I think there are 2 basic challenges.

1. A linear indexer (fixed to the clamp) which will advance the bread knife to the exact next serration. The advantage here is that each serration is basically the same.

2. Circular diamond rod attachments to the WEPS paddles. Challenge is multiple dimensional & grits; possibly solved with cones yet limited stroke distance.

I invite comments as I am not interested in patenting anything. I have rigged up some stuff and think off the self ceramic rods (then sticky diamond film) work well to get close. The real challenge is a cheap linear indexer.

Comments ?

1 user thanked author for this post.

06/02/2019 at 7:31 am #50577I don’t think it is doable because of the basic design of the Wickededge. The paddles pivot at a point. For serrations you grind vertical concavities in the blade.

Attachments:

You must be logged in to access attached files.

06/02/2019 at 7:46 am #50580If you really want to do it I think you could mount your vise on an x-y table and mount your rod on the work table. You would have your rod pivot in one plane only.

Next, as you pointed out, you would need cylindrical stones to slide on the rods.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

06/02/2019 at 8:27 am #50583Another advantage of mounting the vise on an x-y table is that it would make sharpening long blades easier. You can move the blade/vise to get to the part of the blade that is out of reach.

Although mounting your back rod would be a bit tricky.

-

This reply was modified 6 years, 2 months ago by

Bill Kirkley.

06/02/2019 at 8:48 am #5058506/02/2019 at 5:45 pm #50587Challenges for sure, but all you need is a simple (cheap) adjustable step linear indexer which holds the knife and mounts in the clamp. For the rods — yeah there are many but most are arcs or flat angles and off the shelf ceramics cover maybe 80% of them. Diamond rods are probably out of the question. Diamond film on the other hand can be stuck to the ceramic rod. We basically reprofile straight edges with WEPS the first time thru anyway.

Mirrored serrations do not exist in the world today. Even Jay Fisher would be impressed.

06/03/2019 at 10:47 am #50593I’ve solved a couple of the problems. One of them was finding a small-diameter diamond sharpening rod. I found that in the CRKT VEFF Sharp tool. Unfortunately, they don’t sell it anymore. You can occasionally find one on Ebay, like this: https://www.recreationid.com/crkt/veff-sharp-knife-sharpener-mpn-veff1.html?gclid=EAIaIQobChMIu4ue19_N4gIVoCCtBh0RxANgEAEYBSAAEgKtsvD_BwE

I solved the moving pivot point pretty easily by putting a linear bearing/bushing on a rod that runs parallel to the blade, mounted with its axis roughly thru the WE pivot point. I also made a simple fixture to hold a SharpMaker rod. I made a mock-up of it once, but failed to take a photo when my interest flagged. I don’t know if I still have the parts. I’ll look around.

1 user thanked author for this post.

06/07/2019 at 9:12 pm #50619I tracked down Tom Veff, Edgeologist from Oregon City, Oregon a while back and he told me he still had some in his personal stock. Unfortunately, I did not pull the trigger, I will retry.

Putting a putting a “linear bearing/bushing on a rod that runs parallel to the blade” was also a thought of mine as it would be much cheaper and simpler than a linear indexer. You would only need it for one side. I think the parallel mounting/fixturing would be tricky though as well as the location to slide the pivot to for the next serration.

Anything you could find would be appreciated.

1 user thanked author for this post.

06/08/2019 at 2:42 am #50620I’ve been putting my mockup together and have made it work with the Spyderco triangle stones. I’m not all that happy with the performance so far, so I want to rebuild a section before I share it. Should go pretty fast and I should have something by Monday. Had to order some parts from McMaster.

1 user thanked author for this post.

06/08/2019 at 4:15 am #50621I tracked down Tom Veff, Edgeologist from Oregon City, Oregon a while back and he told me he still had some in his personal stock. Unfortunately, I did not pull the trigger, I will retry. Putting a putting a “linear bearing/bushing on a rod that runs parallel to the blade” was also a thought of mine as it would be much cheaper and simpler than a linear indexer. You would only need it for one side. I think the parallel mounting/fixturing would be tricky though as well as the location to slide the pivot to for the next serration. Anything you could find would be appreciated.

I would definitely be interested in one of the Veff sharpeners if he still has a spare or two. As far as your guy’s ideas, they are way above my technical understanding but I’m damn glad you are doing something. All of you . keep up the good work.

06/09/2019 at 9:15 am #50622I looked at Tom Veff’s video on his serrated edge sharpening rods. His diamond coated rods are a single grit. The WE system goes through a series of grits. Why the difference?

06/09/2019 at 11:55 am #50623You technically only need one grit to get your edge sharp. However, refining the edge with progressively finer grits will give you a sharper edge. Compare the edge you get off of the 100 grit stones to the edge after a progression to 1000.

There are other tools for serration sharpening (such as the DMT rat tail rods) which are available with several grits.

3 users thanked author for this post.

06/09/2019 at 2:08 pm #50624Thanks Organic!

06/10/2019 at 12:45 pm #50626My current thoughts:

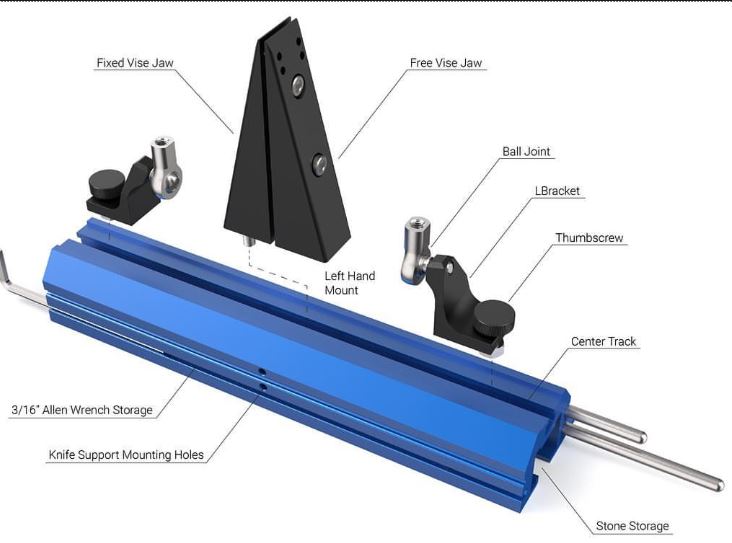

- A version of the WEPS GO could function as the linear bearing (only needed for one side)

- Mount it to the same base plate as the WE130, parallel to the knife, with slots to allow for different angles and fine tuning parallelism

- Use a precision hinge instead of a ball to keep the rod at a fixed location

- Use ceramic rods in lieu of diamonds and I suspect diamond films could be adhered to the rods for mirror finishes

- Incorporate up/down motion as well as twisting of the rods

- You would move the WEPS GO LBracket to the next serration which would be visually aligned to the serration and then fixed by the precision hinge (this would not be fast because each serration is separate)

-

This reply was modified 6 years, 2 months ago by

Readheads.

-

This reply was modified 6 years, 2 months ago by

Readheads.

-

This reply was modified 6 years, 2 months ago by

Readheads.

-

This reply was modified 6 years, 2 months ago by

Readheads.

Attachments:

You must be logged in to access attached files.

06/10/2019 at 7:58 pm #50633Readheads here’s a forum thread from a while back where Bill devised a rack system to allow him to sharpen large and long knives while achieving lower rod angles then were possible at that time. A rack system similar to this supporting adjustable square bars mounted perpendicular to the normal vise setup’s square bar would allow you to make the linear movement along your knives lengths while maintaining the rod angle. The rod angle would be determined by how close or far away the side mounted linear square bars were positioned from the vise’s center-line. As long as everything is square and the knife edge is level as the rod end bracket is moved forward or aft along the linear square the sharpening angle will remain the same. Depending on whether the serrations are on one knife side or both, you may need one or two side linear square bars.

In Bill’s design he has the square bar designed to move along a stationary linear square bar rack system. In your case you want a movable linear side square bar to move along a stationary perpendicular square frame work. It’s the opposite sides of the rack moving but the same principle applies.

Marc

(MarcH's Rack-Its)3 users thanked author for this post.

-

This reply was modified 6 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.