? counterfeit 12 inch guide rods . . . .

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › ? counterfeit 12 inch guide rods . . . .

- This topic has 25 replies, 8 voices, and was last updated 07/03/2019 at 6:01 am by

Expidia.

Expidia.

-

AuthorPosts

-

06/25/2019 at 8:49 am #5079806/25/2019 at 8:53 am #50799

Rippled is not an accurate description they have more of a texture to them rather than a smooth polished finish like their other sizes.

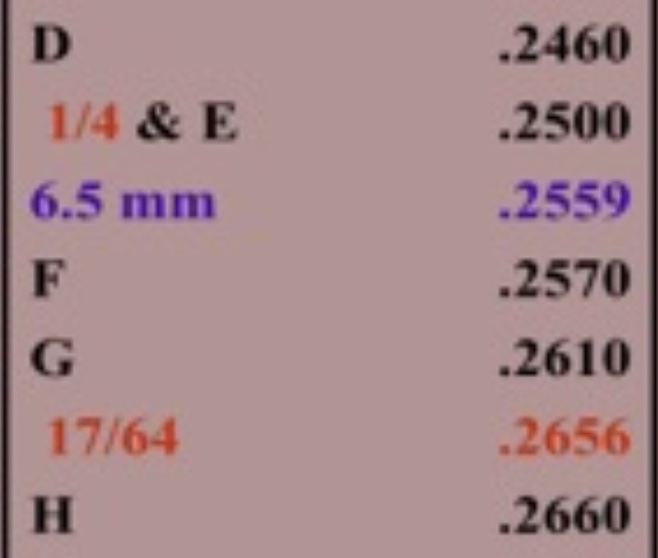

06/25/2019 at 9:15 am #50800Expedia, I haven’t looked but I don’t know if you can find stainless with a diameter of .257″, although I think tcmeyer may have, judging from an earlier post.

As for rusting, if you are not lubricating your stones with water the tool steel probably wouldn’t rust. A coating of paste wax from time to time may help as well.

Depending on how sharp the texture is it might cause wear. The diamond stones are textured.

Maybe someone can post a magnified photo to see how “smooth” the textured finish is.

-

This reply was modified 5 years, 10 months ago by

Bill Kirkley.

06/25/2019 at 6:53 pm #50809I am/was getting that musical sound too but I used a light swipe of Dry Bike Lubricant on the rods and the music has toned down. I believe either MarcH or tcmeyer (thank you gents) suggested it in a different thread dealing with cleaning the WE vise.

3 users thanked author for this post.

06/25/2019 at 8:27 pm #50811Mine sing like a “Canary in heat”….I’ll try lube (but I shouldn’t have to).

check the pics I took of the polished and the new textured 12 inch ones with my digital microscope.

I drive by a custom designs machine shop on my way to my office. I need to note again what TC mentioned about creating a shoulder before they turn the threads. This shop can make me another set in polished. He can also give me an idea why in the world WE would make this change in their stock. When I use the coarse stones its understandable they are noisy until I get to the 800/1000. But these rods “sing” the entire sharpening session with EVERY paddle.

Really, do I need to wear my shooting ear muffs for each sharpening session?

Notice the circles cut into the rods along the entire length of each 12 inch rod under the scope

Under the magnified scope it almost looks like a “threaded” rod! this is why they are singing.

-

This reply was modified 5 years, 10 months ago by

Expidia.

Expidia.

-

This reply was modified 5 years, 10 months ago by

Expidia.

Expidia.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

07/02/2019 at 7:01 am #50854Update: if you want to make your own 12 inch rods that don’t sing to you . . . just stop by a local metal shop and they can cut 0.25 stainless rods while you wait. My shop doesn’t thread them, but I have a die set and I’ll put 3/4 inch of thread on myself leaving that extra 1/4 inch for a jam nut if I find I need one.

$5.12 for “two” 12 inch rods ($2.56 each).

Attachments:

You must be logged in to access attached files.

07/02/2019 at 7:49 am #50857Unfortunately the current rods are larger that .250″

The current rods measure (in mm) 6.43mm

The old .250 in rods measure (in mm)6.33mm

It is not a huge difference but it makes for a more accurate fit with the handles.

This is not new news, it has been documented more than a few times in other thread.

-

This reply was modified 5 years, 10 months ago by

airscapes.

3 users thanked author for this post.

07/02/2019 at 8:02 am #50859Unfortunately the current rods are larger that .250″ The current rods measure (in mm) 6.43mm The old .250 in rods measure (in mm)6.33mm It is not a huge difference but it makes for a more accurate fit with the handles. This is not new news, it has been documented more than a few times in other thread.

You can’t tell the difference when the paddles are on the rods! Their paddles are already proprietary. Why not just make the new paddles to fit point 0.25? Because using 0.257 keeps that size proprietary to WE.

$5.12 for two 0.25 rods which my other rods are is a hell of a lot cheaper than $38 with shipping. For +642% more for 0.02 …. Im happy with non singing rods now!

07/02/2019 at 10:58 am #50860I’m the guy who uses 0.257″ rods. They are slightly bigger than the new WE rods and may not fit over every handle without some “tuning.” I simply spun a 0.243 (6mm) bronze rifle bore brush in the tight spots until they worked. You can buy 0.257″ rods from McMaster, but probably not in stainless. It’s a drill rod size for size “F” drills.

Running a 0.250 diameter die over 0.257″ rod is a real PIA. Even 0.250″ rod is really tight, and the .257″ rod stock is a tough tool steel (HSS) On the larger rod, the die wants to drift out of alignment, which will result in a rod that will not maintain the angle unless you lock it down with a jam nut. One solution is to make several attempts until you get one that goes on straight before you cut the rod to length.

When Clay came out with the new Gen3 Pro in 2017, he increased the diameter of the rods slightly. I don’t know for sure, but he may also have decreased the bore size of the new handles slightly. The result would be a significant improvement for the new rods/handles fit and still work with the older handles. I don’t think this was some scheme to make the WE more “proprietary” – just an incremental improvement.

2 users thanked author for this post.

07/02/2019 at 11:30 am #50861You can’t tell the difference when the paddles are on the rods! Their paddles are already proprietary. Why not just make the new paddles to fit point 0.25? Because using 0.257 keeps that size proprietary to WE.

The size of the rods is due to the more complicated evolution of the paddles. As we began experiencing problems with the older design of paddles, which specified a 0.250″ but were consistently larger and creating too much slop, we increased the rod size. When we switched to the new paddle design, we had to make the bore match the majority of rods already on the market. It would be much cheaper for us to use stock 0.250″ rod but instead we have to start with larger diameter material and turn it down on the Swiss machines.

The singing noise is common now with the new paddle design, but what you’re experiencing sounds excessive. We can take a look at them if you’d like to see if there was a bad batch from a worn cutter or some other cause that left an overly rough finish.

-Clay

-

This reply was modified 5 years, 10 months ago by

wickededge.

wickededge.

5 users thanked author for this post.

07/03/2019 at 6:01 am #50869OK thanks for that explanation Clay. I have a short vid of it and I was going to post it on Youtube but I didn’t because I did not want to deter anyone who saw it on Youtube from buying this accessory from you.

After the holidays, I’ll send the vid to Kyle to get his opinion on how loud mine are. Now I can see why the circles are there taken with my digital microscope and from your explanation and what is causing the singing. They are from turning in a lath to reduce the stock. IMO they should take it one step further and polish that texture off while they are still in the lath.

I just attributed the texture to a bad batch of rods. Similar to that bad batch of paddles where all my numbers quickly wore off. I know Kyle would have replaced them but I did not want to go through the entire break in process again with an entire set of paddles. I dremeled the numbers back on and filled the etchings in with a black sharpie.

Do you have any “old stock” of 12 inch rods left which are probably 0.25? If so could you put a set aside for me and I’ll send you back the singing set. I find my 8 inch or 10 inch set work fine for my needs.

I can give the set I just made up to my office mate who also has a WE system.

-

This reply was modified 5 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.