Angle Settings from stone to stone

Recent › Forums › Main Forum › Angle Settings from stone to stone

- This topic has 20 replies, 2 voices, and was last updated 12/24/2019 at 3:11 pm by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

AuthorPosts

-

12/02/2019 at 7:46 am #52647

Hello my name is Edward, I recently received a used WE100. I got the full WE120 upgrade for it and have A MicroBeast angle cube from my RC helicopter days. I believe it to be of good quality. My question is about the angle setting from stone to stone. If I start my first stone(usually50/80)at 18.0 on both sides I sometimes find that if I check the same stone before moving to the next one that the angle has slightly changed, say 17.9. When I go to the next stone do I set it to the initial 18 degrees again or should I match the 17.9? I don’t so much care about having a certain degree edge as much as I do getting the edge done as fast and with as little metal lost as possible. Just thought I’d see what you guys had to say about it in case I’m missing something. Sorry if this has been asked a hundred times and thank you!

12/02/2019 at 8:00 am #52648Welcome to the Wicked Edge Forum Edward Riley.

I always check my angle settings with each and every new grit I’m using in my sharpening progressions. If it is not set at the initial setting, 18 degrees in your case, I re-adjust and lock it in at 18 degrees through the entire sharpening process. This insures your final profile is the same angle you initially set it to be.

If you keep readjusting the angle chasing the resulting angle after using each stone you will ultimately create a rough convex bevel. To end up with a sharp and polished “V” bevel edge readjust the angle to match your initial setting.

Marc

(MarcH's Rack-Its)5 users thanked author for this post.

12/02/2019 at 10:32 am #52652The stones do vary ever so slightly (usually less than 0.5 degrees). I check my angle with each grit change and adjust as needed to keep the sharpening angle consistent.

4 users thanked author for this post.

12/02/2019 at 10:53 am #52653So you also set each stone to the original angle? I’m just having trouble getting each stone to cut perfectly across the whole bevel. I thought once I had the ability to adjust the micro angle refining the edge to the new grit would only take a few strokes. Before I got the adjustable arms I would spend an 1-2 hours per stone getting an even bevel across the whole blade. And yes it is faster now that I can adjust the micro angle but not really by that much.

12/02/2019 at 3:24 pm #52654Edward, The Wicked Edge is designed and machine very precisely to maintain the sharpening angle across the blade length when operated correctly. Realize that the individual grinds and the steel thickness on knives may vary across the length of the knife blades. Some knives may be ground thinner towards the knife’s tip to allow for fine and detailed work, whereas other knives may be thicker towards the knife tip to allow for added strength. These differences may give the bevels an uneven appearance along the length of the knife blade, when sharpening. These differences are due to the differences in the steel thickness and the blade grind differences and not due to a change in the sharpening angles. The angles will be correct and uniform although it may appear as though they aren’t. If the appearance differences, that is, the aesthetics, bothers you, then the angle can be adjusted for those areas to sharpen and shape the bevel there, so it appears uniform.

Ed, also, the WE120 with their standard vises have an inherent clamped blade lean, to the left. This is due to the fixed left vise side and floating right vise side, of it’s design. This will also give the visual appearance that the angle is changing during sharpening, because the bevels are inconsistent in their height from side to side. There are angle adjustments that can be made to the sharpening angle settings to compensate for the blade lean.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

12/02/2019 at 5:49 pm #52655Aww man now I’m thinking about the 130 vice upgrade. Any tricks you know to counter the left hand leaning of the blade. The one I’m working on now is a OTF double edge with a groove down the center and now I see exactly what you mean and think I see what my problem is. I keep flipping the blade every stone so I can keep an eye on the point, with 4 grinds coming together this point has been very tricky. So I bet what’s wrong is even though I have been using the alignment gauge it’s been tilting slightly and throwing off my angle. This is my first one with the adjustable arms so I expected it to be more precise but slight tilting would totally explain it. Thanks so much your awesome!

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

12/02/2019 at 6:14 pm #52657Edward, I don’t want to spend your money but, the WE130 Gen 3 vise upgrade is certainly the way to go. This will remove the clamping lean associated with the standard vise used in the WE100 and WE 120. It is easier and faster to use and more consistent. It also includes a tension adjusting feature.

On the double sided knife you’re sharpening, every time you flip it around you introduce another source of inconsistency. The double sided knife you’re sharpening, I’d suggest you leave it clamped and sharpen one edge till it’s complete. Then filp it over and do the opposite side start to finish. Like any knife the two sides of that knife may be inconsistent in their grinds. Treated like separate knives will give you better results.

Save the standard vise to use when you need to sharpen something too thick to fit in the gen 3 vise setup. With longer screws the standard vise can clamp any thickness.

It is not supposed to be this difficult to sharpen a knife with the Wicked Edge. True, the less expensive models are more manual to operate and adjust and require more skill, practice and understanding to use these well. Even those of us who have mastered sharpening with the standard vises prefer the new gen 3 vise with self centering floating jaws and tension adjustment. It makes the,whole process simpler, easier, faster and more consistent. For me it removed the difficulty involved in sharpening and made it easy and pleasurable.

Marc

(MarcH's Rack-Its)4 users thanked author for this post.

12/07/2019 at 4:03 am #52674I suggest measuring each stone on a flat, solid surface. Measure the angles on both faces, and also turn the stone end-for-end and check them again. The angle differences should measure close to 0.1 degree or less. If your measuring cube has a readout of 0.1, +/- 0.2 degrees, you’re SOL.

Keep in mind that any error you find could be caused by either platen on that handle. The same thing applies to measurement taken against the blade/vise. If you have a stone (platen) that’s mounted a little deeper on one end of the handle than the other, you’ll get a changing angle, varying with the height of the stone where it touches the blade. 0.010″ of error in the stone thickness, will cause about one tenth of a degree error in angle.

I have one stone that has about 0.2 degrees of error in it, and I know which handle it is and can make the appropriate micro-adjustments. It doesn’t matter which platen it is, as the error shows up on both sides. One side reads an error because the bad platen is against the blade and when I flip the handle, the measuring cube will be on the bad platen. Either way, bad reading, so I had to run the test above to know which platen was off. I make a 0.2 degree correction, then go back when the bad platen is done. Next time I change stones, I’ll figure out why the error.

The concept to keep in mind is that the face of the platen should be parallel to the bore. I set the handle, face down on a granite plate (any flat, solid surface will work. I set a straight steel rod through the bore, then measure the height of the rod off of the surface. I use a bridge-type digital height gauge. If the platen is not parallel to the bore, the rod will be higher on one end than the other. I hold the rod down so that it stays parallel to the bore.

One tenth of a degree is pretty much negligible. You need to put another level of precision in to see changes of 0.15 degrees in the scratch pattern, unless your technique is pretty highly refined. For lots of years, guy made a hell of a lot of knives really sharp with the WEPS when plus or minus a half degree was considered OK.

4 users thanked author for this post.

12/07/2019 at 1:43 pm #52675Edward, even if you undertake an engineer’s based study to determine your sharpening stone paddle inconsistencies, stone mounting inconsistencies and parallel bore hole inconsistencies, or, you simply apply your magnetic digital cube to measure the set angles each time. The bottom line is small or micro-adjustments made with each and every grit will insure consistency in your sharpening results and make it easier to achieve the results you’re seeking.

Marc

(MarcH's Rack-Its)6 users thanked author for this post.

12/09/2019 at 2:04 pm #52684As tcmeyer pointed out, in the past people have had a variant of 1/2 degree and ended up with a good result.

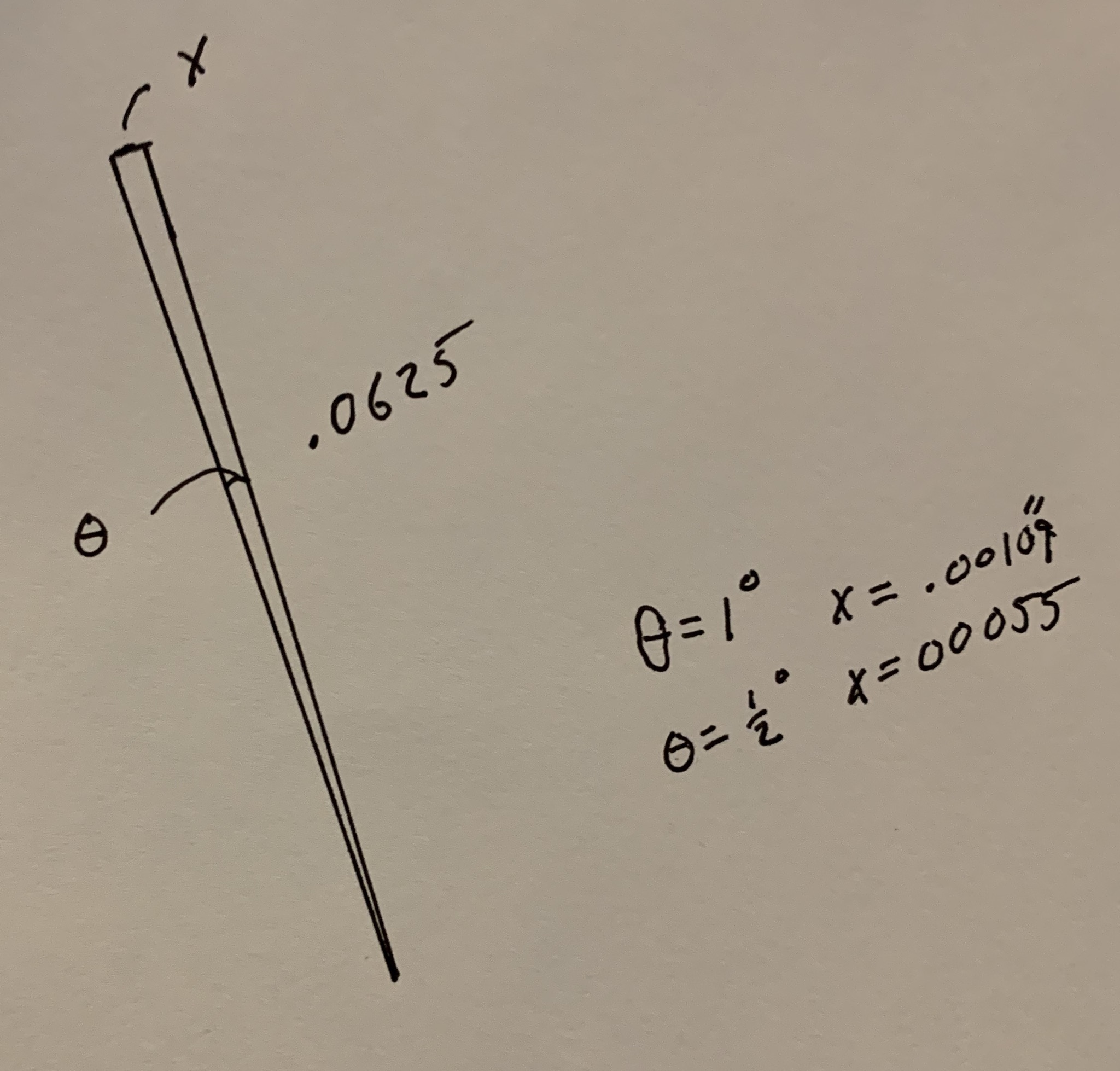

As the attached photo illustrates if your secondary bevel is 1/16″ and you are off one degree between stones you only have to remove .001″ material to creat a burr if you are off – 1 degree. If you are off + 1 degree you would get a burr right off.

Being off one degree might mean some extra strokes to remove the material, but weigh that against the time it takes to check and reposition your stones.

In the end, as long as you creat a burr between stones you should be good to go.

-

This reply was modified 5 years, 8 months ago by

Bill Kirkley.

-

This reply was modified 5 years, 8 months ago by

Bill Kirkley.

-

This reply was modified 5 years, 8 months ago by

Bill Kirkley.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

12/09/2019 at 3:08 pm #52690Thank you all for the great information! I like the idea of checking the angle of the stones themselves. I did another knife yesterday and spent about 7 hours on it. Again getting each grit to remove all the marks of the grit before it is taking a really long time and the lapping films did not really get me the results I was expecting. I think maybe my issue is my angle cube. It was expensive 7 years ago when I bought it for measuring RC helicopter rotor pitch(BeastX) but I feel like it’s not as accurate as I need. Can you guys recommend me a new one? Can you get one that does hundredths of a degree? I don’t want to spend hundreds but don’t want to wish I had gotten a better one what do you guys think is the best that you’ve used? Thanks again your all great!

Edward

12/09/2019 at 4:49 pm #5269112/09/2019 at 5:22 pm #52692Ooh that one looks very nice! Anybody think there’s a better one? I’d hate to order it to find out I should have gotten a different one. Thanks!

12/09/2019 at 5:24 pm #52693Also does anybody make a adapter to put on non magnetic blocks?

12/09/2019 at 5:38 pm #52694https://knife.wickededgeusa.com/forums/topic/adapter-caps-for-non-magnetic-stones/

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

-

This reply was modified 5 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.