1500/2200 Diamong Worth It?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › 1500/2200 Diamong Worth It?

- This topic has 16 replies, 8 voices, and was last updated 08/14/2019 at 4:28 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

08/06/2019 at 11:10 am #51383

I purchased a GO a while ago and added in the 1000G diamond stone set. I sharpen mostly kitchen knifes and very few folders. I am currently getting what I think are great results but wonder if they be be made better.

My question is if it would be worthwhile going up to the 1500/2200G diamond stones? I am not really interested in polished finish more slicing and chopping usage.

1 user thanked author for this post.

08/06/2019 at 12:42 pm #51398Hi Saskboy,

The truth is, for kitchen knives you can actually stop with the 800 or even 600 stones. This leaves very small jagged or serrated edge which is great for kitchen knives.

I just purchased the 1500/2200 stones and like them a lot! But I don’t use them on kitchen knives, instead I use them on knives that I intend to have a finely polished edge.

In your case, I would not think you would need them.

Hope this helps.

Alan

4 users thanked author for this post.

08/06/2019 at 1:29 pm #51399I agree with Alan 100% if your only looking at the edge from a utility or practical point of view. Yes 600 grit or 800 grit will yield all that is needed for a basically sharp cutting toothy edge when applied properly.

An edge sharpened to a finer grit will have a more precise and thinner apex and will be measurably sharper. A simple analogy is a newly sharpened pencil and a pencil you’ve been using a bit. They’ll both write but the newly sharpened pencil writes a thinner line.

The knife edge from a 1500/2200 grit sharpening will be thinner and sharper and shinier if done correctly. IMO, it will cut and slice noticeably better. A day to night improvement. It may be more brittle and wear easier due to it’s thinness. It’s a trade off. Everything is. For me the improved cutting and slicing edge from the finer grit stones make them well worth the investment and their use. The finer grit sharpened, better cutting knife requires less effort and work for the same cutting chore then the practically sharpened knife with the 600 or 800 grit edge. That’s just my opinion.

Just to add, even with the 2200 grit very fine diamond stone, an edge leading stroke applied as a finishing stroke in your sharpening progression will apply a noticeably toothy finishing edge, all though very tiny, it does help.

Marc

(MarcH's Rack-Its)3 users thanked author for this post.

08/06/2019 at 4:26 pm #51408Thanks guys. Figured it would come down to yes worth it but not needed. That said have got the sharpness bug and most likely will end up with them. And then strops etc. I know that you’ll understand the addiction

1 user thanked author for this post.

08/06/2019 at 4:46 pm #51409Strops IMO will enhance any edge sharpness as a final step in your sharpening progression, for whatever stone grit you choose to end your sharpening with. I’d get and use the strops first. I’d start with the 4µ/2µ strop pair. You’ll see a real enhancement to your sharpened edges with the strops. Be aware the strops have a learning curve unto themselves, like all of the sharpening techniques. Even with the 1500/2200 stones I’d finish off with the 4µ/2µ strops.

Marc

(MarcH's Rack-Its)4 users thanked author for this post.

08/06/2019 at 5:23 pm #51411I know that you’ll understand the addiction

Oh ya! We understand..

Alan

1 user thanked author for this post.

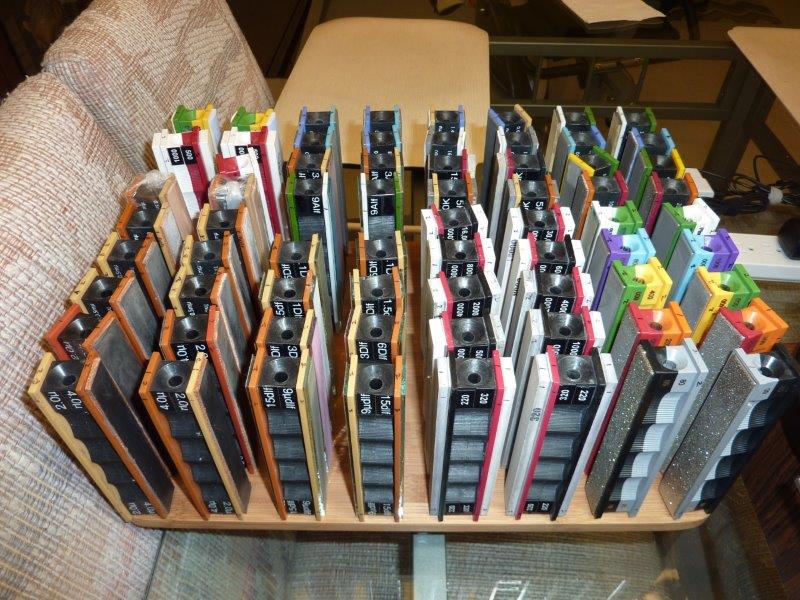

08/06/2019 at 5:47 pm #51414Do you think that? This pictures before I got the 1500/ 2200/ and 3000 grit diamond stones!

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

7 users thanked author for this post.

08/06/2019 at 6:16 pm #51419When it comes to sharpening more is more. You won’t always use the fine grit stones, but they are fun to have when you want to see a nice looking edge or get a super sharp edge for detail work. We all understand the sickness. That’s why we’re here.

6 users thanked author for this post.

08/06/2019 at 6:20 pm #51420Do you think that? This pictures before I got the 1500/ 2200/ and 3000 grit diamond stones!

MarcH that’s a good one! I think you might need some help.

Alan

2 users thanked author for this post.

08/06/2019 at 7:05 pm #51422Do you think that? This pictures before I got the 1500/ 2200/ and 3000 grit diamond stones!

MarcH that’s a good one! I think you might need some help.

He might need some help moving them from place to place! Personally, I’m getting a bit green with envy!

1 user thanked author for this post.

08/09/2019 at 3:31 am #51465I agree with the idea of kitchen knives only needing 800 grit, but I can’t help myself. The 1000s, 2200s and 3000s are calling to me. they’re calling … and… I … can’t … resist. Oh, poop, there I did it again. Well, at least it’s gonna be a sharp knife.

Funnin’ aside, I really do do this every time. I did four kitchen knives today, and every one got 17 dps convex edges to 3000 grit and 6 micron film.

7 users thanked author for this post.

08/09/2019 at 1:10 pm #51476Cutting and slicing are totally different animals.

For cutting the finer is better. Cutting is shaving, chopping, and when edge cuts perpendicular to the material.

Slicing is when edge is moving against material like a saw. The toothed edge is much better for slicing. Even surgical scalpels are very toothy. Toothy edge is better for most of the kitchen tasks (not all though), for cutting rope, for meat processing.

So the final stone grit depends on the material and how you approach it. There is not absolute sharpness. For different tasks you may need a different edge.

7 users thanked author for this post.

08/09/2019 at 1:46 pm #51478I agree with dulledge. You can, though, have a combination of a very fine sharp cutting edge with some very fine toothiness for slicing. A balance.

Even 3000 grit stones used edge leading can leave a micro toothy edge.

Marc

(MarcH's Rack-Its)6 users thanked author for this post.

08/13/2019 at 10:47 am #51520Probably due to my inexperience, I have been unable to find any discernible difference between two identical kitchen knives that were finished with either 1000 grit or 3000 grit diamond stones. Both will easily slice through newspaper (thanks in large part to a recent suggestion from MarcH to remove any wire edges by finishing each and every grit stone with a few alternating side, edge-leading strokes).

I am just curious as to what practical applications folks have encountered that required knives that needed to be sharpened beyond 3000 grit diamond stones, and into the realm of micron-sized diamond lapping foils, micro fine ceramics, or sub-micron lapping compounds?

I have read discussions of cutting tests that will tell a person approximately where a knife falls on the BESS scale (such as slicing a sales docket/receipt, filleting printer paper, or slicing cigarette rolling paper), but nothing that I have ever used in my day to day experiences.

Thanks!

rummels

-

This reply was modified 6 years, 1 month ago by

rummels.

1 user thanked author for this post.

08/13/2019 at 12:51 pm #51522rummels, sharpening is a repetitive process fo me. Grit after grit I repeat the same routine with the same technique again and again. The culmination of the repeated steps yields my sharpened edge. This you know.

I test the knife edge with each grit for sharpness. First, as I believe I’m making progress I test the edge for sharpness with a simple finger feel. When I think I’m making good progress working with that grit, I’m working with, I’ll pull a piece of newspaper, about 3″ tall down, over the sharpened edge to get a starting place feel, for sharpness. As I continue to exercise my sharpening technique, still with the same grit, I’ll paper test again and again to feel the improvement in sharpness.

With the coarser grits the paper cuts requiring more applied force and with a more ragged cut. With each finer grit there is a discernable improvement with how well and more easily the newspaper will pull cut down over the clamped knife edge. By the second or third grits in my sharpening progression I can feel a marked improvement between my first paper cut test with that grit and subsequent paper cut tests as I continue to sharpen the knife with continue effort with that same grit. At some point when I no longer feel any improvement, I step up to the next finer grit and repeat.

This method insures that I do more work then less, with each grit because I continue sharpening with each grit long enough to see if I can improve the edge further while still using the same grit. Each finer grit the paper cuts easier and easier. Cleaner and cleaner. The improvement in how easily the paper cuts becomes quicker and more discernable till the edge is truly sharp. At this point the paper cuts easily with each grit but the starting point and after spending time and effort with the finer grits there is a smaller perceivable difference in how easily the paper cuts. At this point I am comparing how easily and smoothly the paper cuts at different positions along the knife edge. Now I applying my efforts with the finer grits to refine the entire length of the knife edge so it’s the same every place I paper cut test.

With the finest grits the edge difference I see is strictly visual using the USB scope to inspect the polish.

I can feel a distinct difference in how well a knife performs between a 1000 grit properly finished edge and a 2200 grit finished edge when proper, time effort and technique has been applied to both. The difference in feel and the performance between a 2200 grit edge and a 3000 grit edge will probably only be detectable with a BESS Tester.

Does that mean it’s unnecessary? That’s up to you. The extra effort to use the very fine grits beyond 1500 grit is negligible. It takes me just about the same time to swap out the grits, set my stone stops then double check and make micro-angle adjustments if needed, then it may take to use these very fine grit stones. The biggest improvement I see is edge refinement along the knife’s length and visual appearance. For me if I spent the effort to get to that point a few more minutes is no big deal and worth the personal satisfaction. At this point it’s that long asked old forum question, how sharp is sharp.

As a final thought I’d like to add, I think one of the single best changes a W.E. sharpener can make to their sharpening technique is to spend more time and attention to detail with each and every grit in their progression, before moving on. I think we tend to move on too quick to the next grit before we get the most out of the grit we are using now. That few minutes, extra time and effort, grit after grit, will make a world of improvement to your final results.

Marc

(MarcH's Rack-Its)5 users thanked author for this post.

-

This reply was modified 6 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.