graphite

Forum Replies Created

-

AuthorPosts

-

01/20/2018 at 8:06 pm #44729

On using the microscope with every sharpening, do you guys with significant WE experience feel that if your microscope broke, you’d probably get mediocre (or at least, less consistently excellent) results without it? In other words, do you consider the microscope a truly essential part of your process toward getting excellent not just OK results?

1 user thanked author for this post.

01/20/2018 at 7:30 pm #44727Thanks Marc. When you say “edge leading strokes” does that mean up-strokes (spine to edge direction) or down-strokes (edge to spine direction). That terminology just seems more intuitive to me. “edge leading” seems better suited terminology to sharpening where you move the knife against stationary stones.

When you do initial scrubbing strokes, are you scrubbing with a good bit of diagonal motion so you aren’t really hitting the same point on the knife with more than about 2 scrubs as you move down the knife with the scrubbing motion. Or are you doing a lot more scrub strokes than that, where you dwell at one point on the knife for several strokes and then moving down maybe half the width of the stone (so there’s overlap) and repeat over the length.

PS, when I say the edge is OK, I mean acceptable; better than awful. I’m expecting to get way better than OK/acceptable edges.

01/20/2018 at 5:40 pm #44723Marc, the advice earlier in the thread, ignoring the trizact and angle cube sidebars, was start with my finest and work backward to coarser only if needed. Recall the edge on this knife is very thin, with such a small bevel (a few thousandths) it needs a microscope to see it. Using a microscope along with the 1000 grit looked to be removing sufficient metal (very little to remove) so I didn’t back up to coarser grits. Just guessing, I did about 40-50 strokes per side, in groups of about 5-10 per side then switching sides. The edge cuts paper cleanly once it’s started, and cuts food (just used it for very thin slices off an onion half) so it’s close, but not quite there yet.

I know the paper swipe cut test isn’t really a practical test, but it seems to correlate well with good performance cutting food, and you don’t waste food in the process.

One of my questions, given 1000 grit is the finest stone I have (and I don’t have strops or pastes) is whether there is a particular finishing sequence to follow if 1000 grit is as fine as you’re going. Like 2 light passes heel to tip each side, or whatever?

My other question is about my left to right bevel imbalance, which I’ve seen on several knives.

PS just got a 2-axis cube (the DXL360s) but that’s a discussion for a different thread.

01/20/2018 at 9:44 am #44710Variable speed is going to run up the price significantly, I’m afraid. I have a 1×42 Delta SA180 (no longer made) and I consider it too fast for knives (1725 RPM fixed). There are pulley mods to slow it down but I haven’t bothered and I use it mainly for wood sanding. A few other manufacturers you might look into (I’m not sure if they have variable speed) are Kalamazoo industries, Grizzly, Harbor Freight has a cheap one, Lee Valley sells a model where you provide the motor so you could pick a slow speed motor, Wilton, Baileigh (has a $2200 variable speed model with 1″ wide belts), probably a few others I’m not recalling .

1 user thanked author for this post.

01/20/2018 at 9:15 am #44706Checking back in after an impossibly busy post-holiday catch-up period. Where I left off with this MAC knife is I sharpened it at about 16 degrees (or at least that’s what my angle cube showed) with just the 1000 grit, and using my circle contour jig for blade positioning (left to right, and tilt).

The bevels within each side were reasonably uniform, but I still have a problem with uneven bevels from side to side. This is even with concentrating on trying to do the same number of strokes and the same pressure with each hand. But I guess it’s hard to know if I’m *really* applying the same pressure give that one hand is dominant. Have any of you heard of anyone needing to make a permanent adjustment where, for example, you always do only 80% (or whatever) of the strokes with your dominant hand and 100% on the non-dominant hand?

Anyway, the resulting edge was, let’s call it pretty sharp. But certainly not “oh, wow” sharp. I can cleanly slice-cut paper if I move the knife through fairly slowly, but with quicker swipe cuts of the paper (more of a wrist-flicking motion) it hangs up. To explain that further, if I make a slow starter cut into the edge of the paper, once the cut has started I can then do a clean slice. But banging the knife edge into the paper’s edge (as with the wrist flick motion), the paper just curls over most of the time. Is this something that has an easy cure?

Maybe something with the direction of the last couple finishing strokes with the 1000 grit? Do you guys have a standard process you’d follow for the last couple/few strokes if 1000 grit were the max grit you’d use? I suppose it becomes less important to follow some final process of swipes if you’re taking the edge several finer grits beyond 1000?

01/12/2018 at 8:57 pm #44552Very sad news. Even in my very short time here, Mark stood out as always ready and willing to share his extensive experience, and his blog was a wealth of information and obviously a labor of love. He will be missed.

7 users thanked author for this post.

01/11/2018 at 12:42 pm #44514I’ll try to build a sturdier model to test after the Christmas break and see what comes up. Then I guess I’d try it out on some knives to see what it does to bevel widths.

Clay, have you had a chance to do further tests?

I have not . it’s been crazy busy around here and will probably be so until after Shot Show in a couple of weeks.

I know what you mean re: crazy busy. It seems like we take “vacation” only to be behind by as many days as we took vacation, when we get back.

1 user thanked author for this post.

01/11/2018 at 12:01 pm #44511I’ll try to build a sturdier model to test after the Christmas break and see what comes up. Then I guess I’d try it out on some knives to see what it does to bevel widths.

Clay, have you had a chance to do further tests?

01/02/2018 at 7:03 pm #44378Hi Marc, not to worry. I’ve thought the very same thing in some of our exchanges, and just as you said, our brains are just wired very differently. I still value your inputs, whether you like it or not ;o) Yes I think it’s just terminology, since I don’t fundamentally disagree with what you described. I think it’s a case where if you were sitting right here next to me, by showing you the process I was attempting to describe (obviously not very well) it would all click. But as a written description it’s a challenge since the English language lacks enough word diversity on some topics. Sorry for furthering not lessening the confusion, and that was certainly not my intent.

3 users thanked author for this post.

01/02/2018 at 4:39 pm #44374Marc, on my angle logging comment, what I’ve been doing is logging both the coarse angle setting (i.e. the setting on the angle rod) and the fine angle (using the height gauge on calipers, measure the height of the fine adjuster screw above its holder). That way I can replicate the whole coarse plus fine position for the next time I do the same knife (assuming I position the knife itself the same). Or in theory, that’s how it would work.

From the stone compensator videos I’ve seen, I seem to recall some stones varied enough to need to move the coarse adjuster +/- 1 degree notch, not just the fine adjuster. My trizact holders measure 1.15″ thick (across both faces) while the diamonds measure 1.18″ so they’re pretty close to start with (and the actual difference in-use is half that, so call it about .015″).

But your question gets me thinking, while that coarse/fine logging will work when I’m trying to replicate the exact angle for using same stones I used before, I’ll really need to use an angle cube if I change to stones of a different thickness from one sharpening to another. In that case I’d need an absolute angle reference, not just a relative one. So a properly functioning angle cube would be the tool for the job.

BTW, I previously mentioned my angle cube repeatability issues and that I haven’t been relying on it. My Wixey cube uses what they call “Dead Level” and they claim it is “permanently calibrated at the factory and should never need re-set.” They do offer up a way to override it, but I hesitate to do that since I’m not sure my issue is a calibration problem. The readings are accurate, just not to the .1 degree accuracy due to the lack of repeatable measurements. tcmeyer mentioned something interesting in that other thread (extraneous vibrations e.g. due to music playing in the background) that I had not thought about before but it does sound plausible. I’ll have to mess with it some more.

Also, the Wixey model I have only has magnets in the base. So I’d either zero it then put the base on the stone for a hands-off approach (and subtract 90* from the result) or I manually hold the Wixey on the stone on one of its sides, but any vibrations in my hand will translate, even if I think I’m being steady. I tried both, and both had repeatability issues, but I’ll look at it again later. Using just the base has the advantage that it doesn’t include any error in the sides of the cube not being 90.00 degrees, but the disadvantage is to get a direct angle reading I’d have to hold it manually on a side face. Also, I may consider getting one of the dual-axis Floureon models since it sounds like you guys have been pretty happy with those.

1 user thanked author for this post.

01/01/2018 at 8:39 pm #44352Marc, this particular set of photos is single images only (no stacked) since they were mostly straight-on, and 220x is the maximum claimed magnification but tic marks go to 230x and it seems to work there.

Depending on which end cap (it came with 7 different ones), some were in contact, and some were with the endcap spaced above the knife, held by a clamp. I had to do some tilting and propping of the handle and edge of the knife to get a good angle for a few of them, so in those cases I had to hold still while I snapped the photo or it would have blurred. At 220x the focus is at .46″ from the main rim of the scope with no cap, and the smaller end caps are about .35″ thick so it ends up just a hair above the surface. Oddly, all the end caps they included are too long to focus in the 70x-180x range so in that range you have to go without the cap, or cut one down. On the polarization control, I find that for knives I can just leave it on full +, without having to mess with the setting, but it’s pretty challenging to avoid oversaturated areas due to metal reflections without it so I’m glad it has it.

1 user thanked author for this post.

01/01/2018 at 8:21 pm #44351Justin and Marc, thanks for explaining your perspective. Trizact isn’t new to me (I’ve used it more than I’ve used diamonds, but never by hand). I used Trizact for years on powered sharpeners for woodworking tools back when I was doing that a lot. There are 4 different lines of Trizact and this particular line is designed specifically for tool blade finishing, cutlery, etc. It’s not a foreign abrasive for this application (I’ve seen several youtube videos where knifemakers use Trizact, albeit in a powered system).

The finish, longevity, consistency, and price are all great in my past experience. So I think you probably have some mistaken impressions in equating it to sandpaper. The only reason I can think of that it might not work here would be if it doesn’t work for hand sharpening (i.e. maybe it cuts too slow compared to powered applications, and that’s just a time issue, not a complexity issue).

I only have diamond stones 100-1000, and not planning to buy more. I bought the aluminum blanks specifically for using Trizact in cases where I want a finer finish. But I’m not interested in mirror edges on my knives, so I’ll take what these give me.

Each of these Trizact strips cost under a buck, even considering tax, shipping, and waste when cut to size. I doubt I’ll spend more on Trizact in my lifetime than one set of fine-grit diamonds cost (let alone dozens of them), so it is actually significantly cheaper than an elaborate collection of fine diamond stuff.

I don’t have the giant collection of WE stones you guys have, so my situation is different from yours. It seems that maybe you are assessing whether it would be complicated for you, given all you already have, but I wasn’t trying to ‘sell’ it. For me, it’s all I have for finer grits. I truly didn’t expect it to be controversial.

Having said all that, I’ll just stick to the diamond stones thru 1000 on this particular knife for now, in case I run into any issue and have further questions. Then if all goes well I’ll try the Trizact on it next time (the angle settings I log will probably be different so I’ll need thickness compensation). I’ll use the Trizact initially for knives where I don’t have any questions, or that are expendable. But since I already have it, have used it before, and have already cut strips (paper cutter) and have the aluminum blanks there’s no extra cost or other complication for me.

3 users thanked author for this post.

01/01/2018 at 4:40 pm #44333Justin, I’m not sure what you’re reference to complexity is about. I asked a question about whether 600 grit would be coarse enough to start sharpening a knife with an edge I’ve not encountered before, which is the purpose of this forum. If you’re referring to all the microscope photos as implying I’m adding complexity, I posted those only because Marc and you asked for them, and I spent a fair amount of my time trying to get photos to show you the varying results using different end caps and settings. The photos did turn out to have value in getting guidance, but I certainly didn’t need to take that many.

01/01/2018 at 12:35 pm #44314I have never sharpened this blade, but I do run it across a fine ceramic rod now and then. As you will see in the photos, there are a number of tiny chips in the edge (mostly less than a thousandth of an inch deep) visible under magnification, but in spite of that, this blade still swipe-cuts paper easily with no snagging. I’ve had the knife about 5 years I think, so all things considered, it has held up well with just using the ceramic rod to maintain it.

My microscope has 3 choices of image size to save to (640×512, 1280×1024, 2560×2048). I saved these all at 1280×1024 (the native sensor size), but the forum software might reduce that.

I used different end caps (clear, translucent, white, black etc), different magnification, and different exposure settings just to see what differences they can make in the photos.

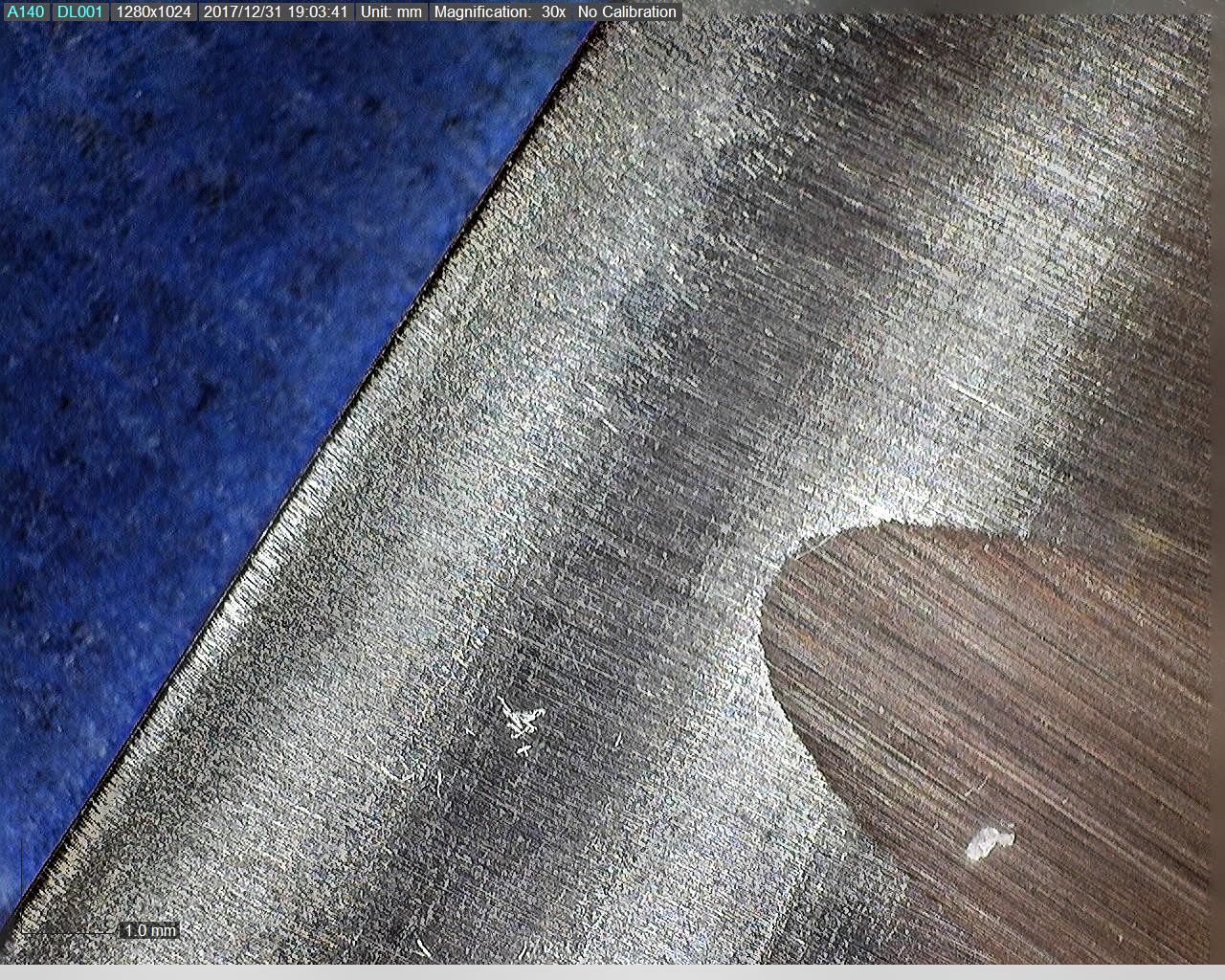

The first two photos are 30x magnification but using different end caps.

Compare those to this one at 40x and using the EDR (extended dymanic range), and the convex grind is more visible in this one. The bevel here is about .05 mm (about 2 thousandths of an inch).

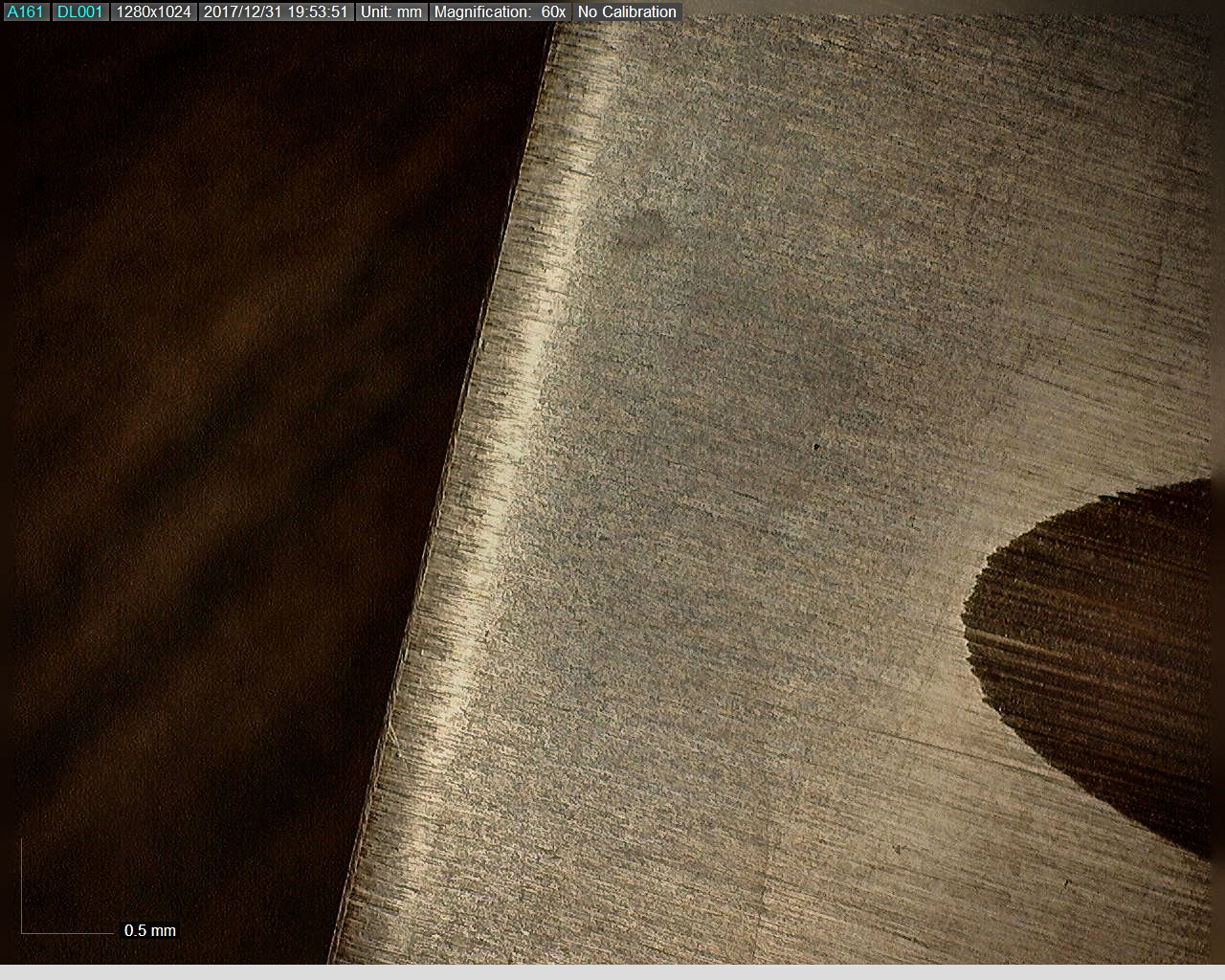

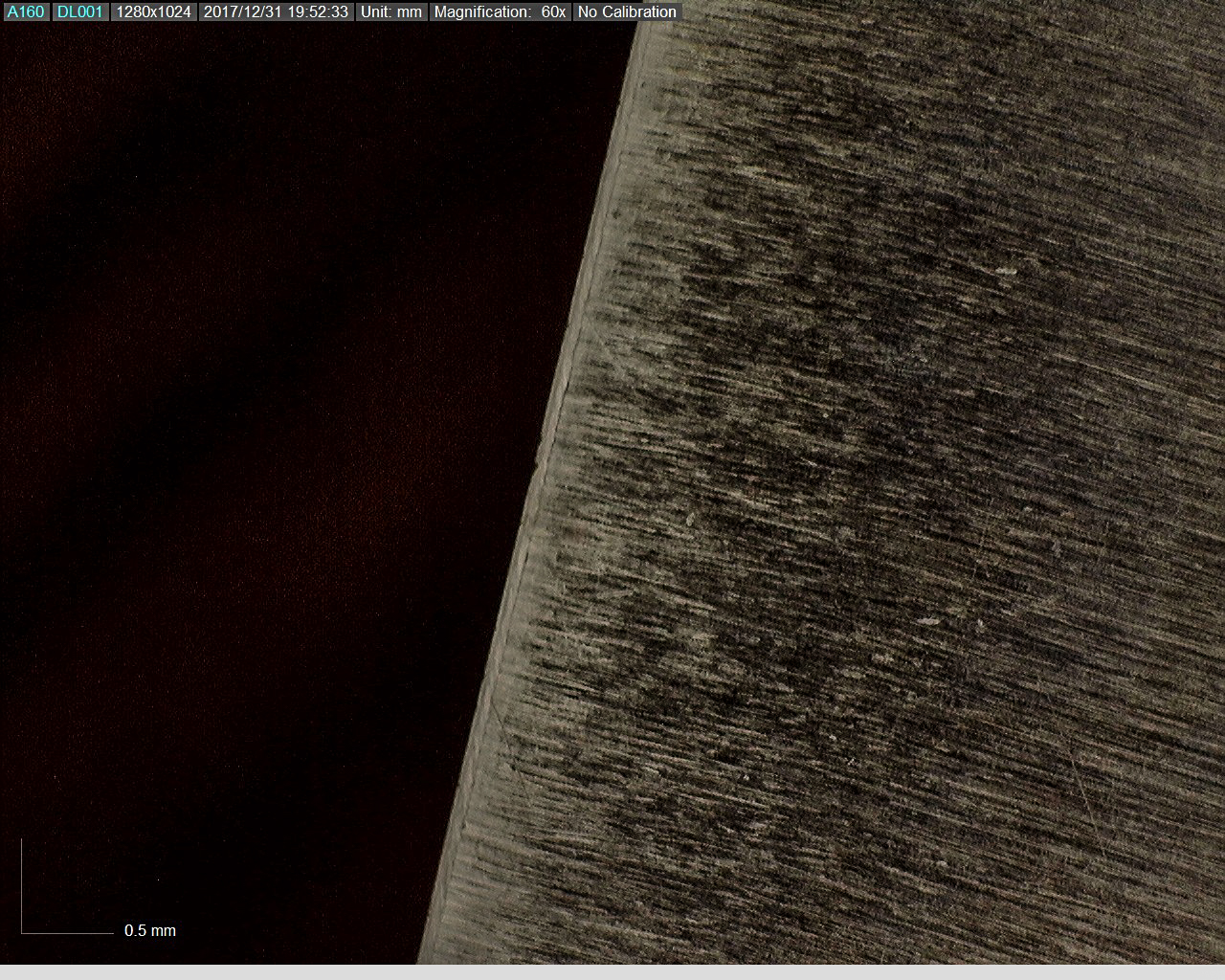

This next one is at 60x and a different end cap. Either I slightly moved the knife or I missed the focus slightly since they edge focus isn’t super crisp.

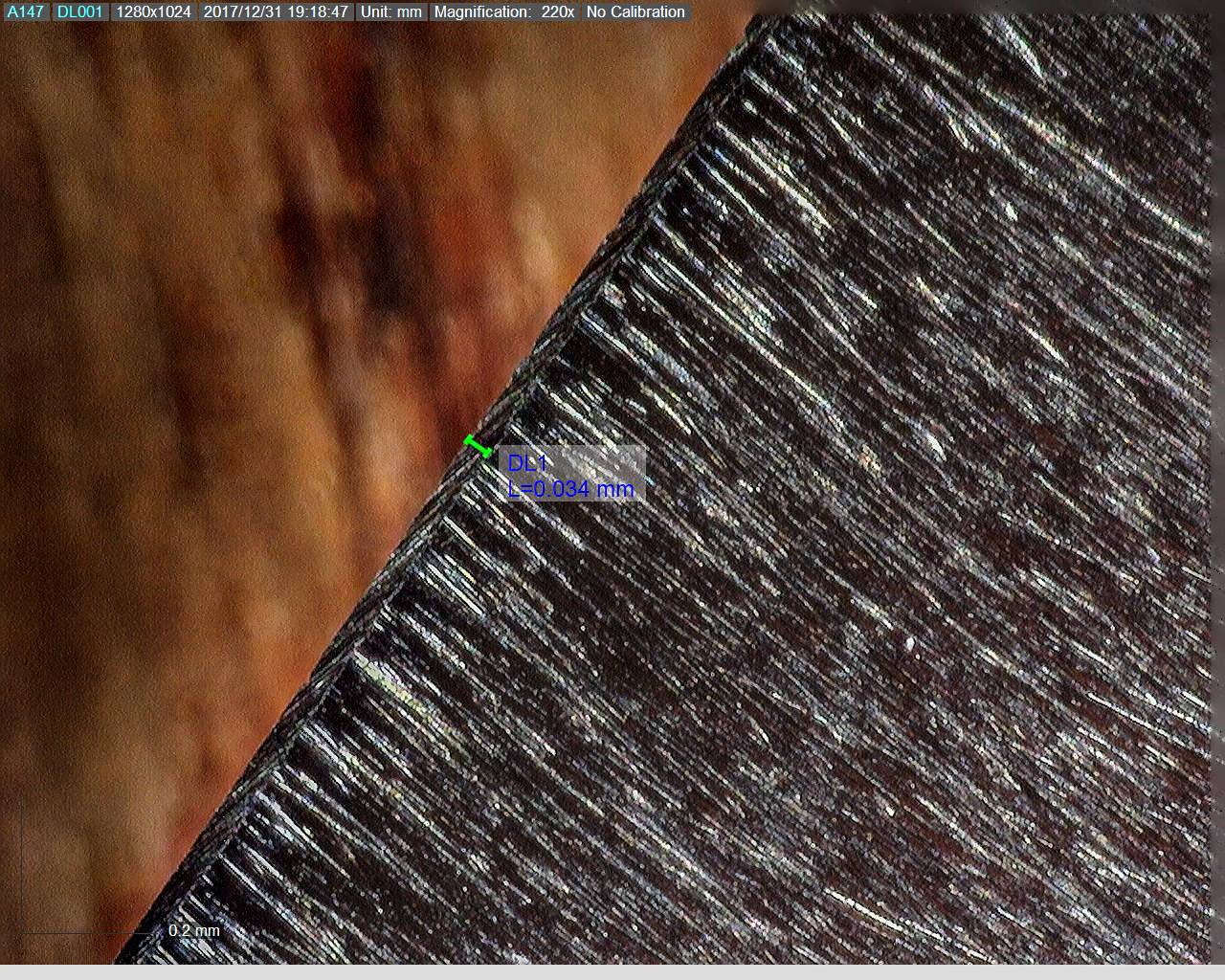

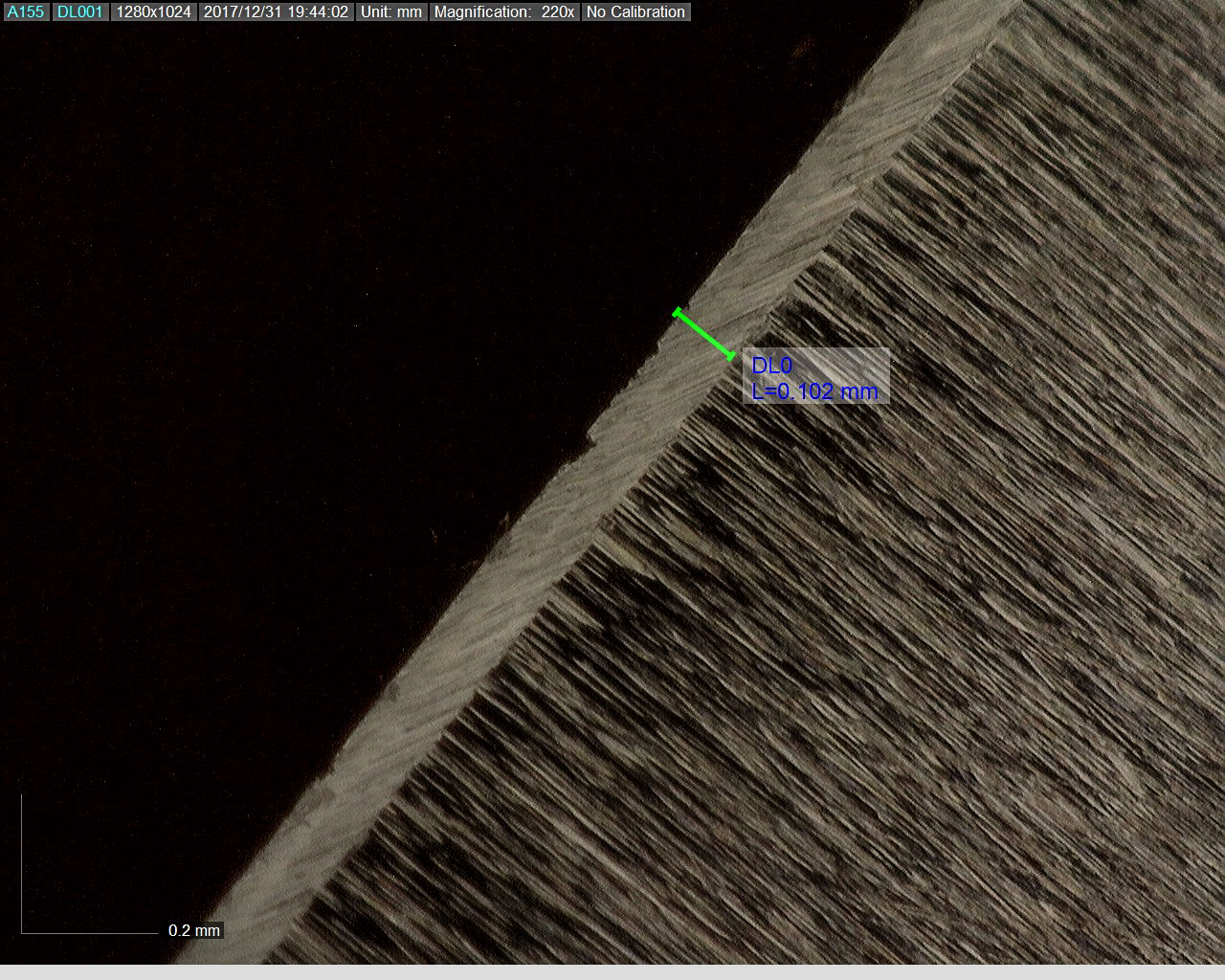

The next one is at 220x using the black cap. Here the bevel is about .03mm. The bevel on this knife varies quite a bit over the length (.102mm is the largest, in a later photo). That might be partly due to my use of the ceramic rod manually.

Here the bevel is .012mm with a couple chips visible and using either the translucent or the white end cap (I forget).

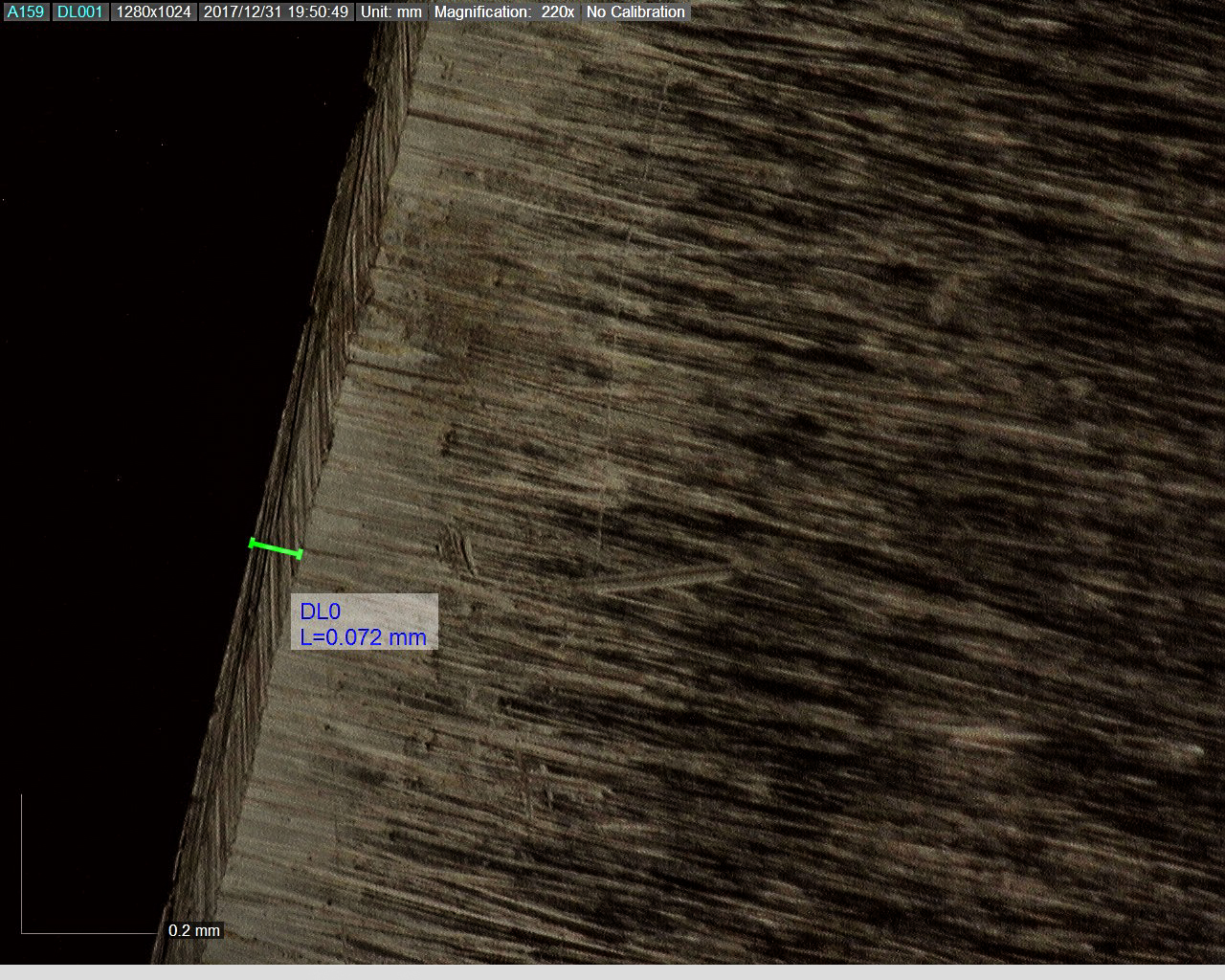

This next one is also 220x but here the bevel is .07mm, and you can see a couple different levels of bevel, with the one closest to the edge having scratch marks that run along the blade (the ceramic rod I presume).

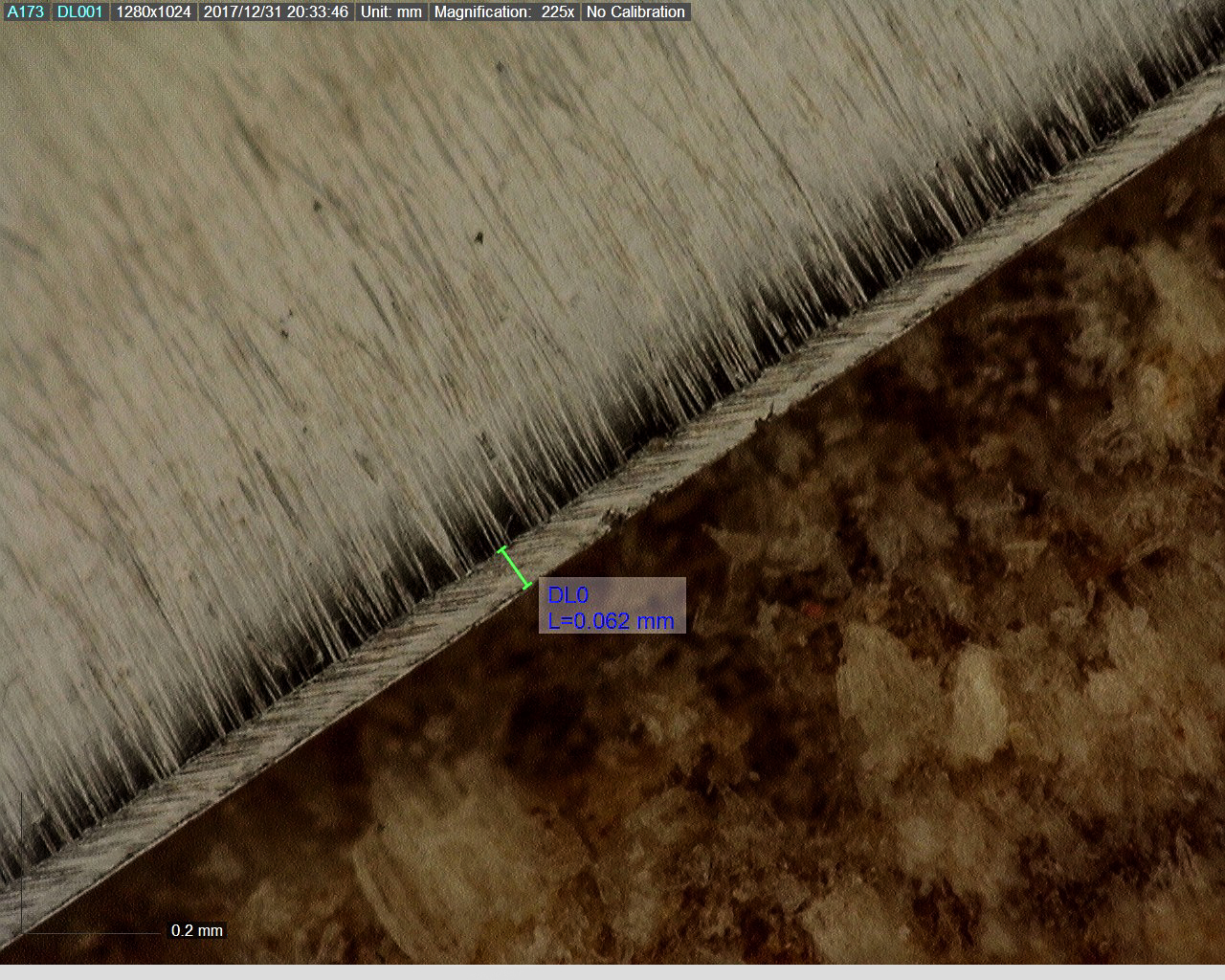

This one is 225x (no particular reason I used 225 instead of 220) and a different end cap, with a .06mm bevel (about 2 thousandths of an inch).

Any advice for going about sharpening it appreciated. I think I’ll use Trizact instead of diamonds, unless you guys think I need to start coarser than that. I have Trizact A35 green (approx. equivalent to P550), A20 red (approx. P1000), A10 blue (approx. P1500) and A5 (slightly finer than P2500). Here’s a photo of the Trizact PSA abrasive on the WE aluminum blanks:

2 users thanked author for this post.

12/30/2017 at 6:43 pm #44276Redheads: question about the angle measurements you are doing. If you had a knife with a long straight edge that was also wide enough to clamp it at a steep tilt (let’s say tilting downward, heel to tip), wouldn’t you measure a smaller angle at the heel than at the tip (the rod would hit the edge higher up at the heel). But if you sharpened that knife, wouldn’t it be a constant angle because the edge is straight?

-

AuthorPosts