Wire Edges

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › Wire Edges

Tagged: knife sharpener, sharpening, wicked edge, wire edge

- This topic has 31 replies, 8 voices, and was last updated 04/24/2016 at 1:50 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

04/22/2016 at 4:11 pm #33625

Basically, I’m putting this post together with your “scratch on a convex” posted here; https://knife.wickededgeusa.com/forums/topic/following-a-single-scratch-on-a-convex-edge/. Could this “gouge” be a result of a larger diamond among the other diamonds? In the paste or the higher grit stone? Is contamination possible and just somehow being overlooked? I’m confused…….about the idea that a carbon steel metal can damage or round off the edges of a diamond? Isn’t it more likely to come loose from the substrate that it is stuck too than for the steel to damage the diamond? See the attachment of missing diamond in the substraight.

In the post you’re referencing, the gouge can be either: from a large particle, either within the compound or on the surface of the leather, and could be either the abrasive being used or some bit of grit that’s contaminated the strop; or it can be a scratch that was present from a previous stone and is the last to be removed. I’ve seen it both ways very often.

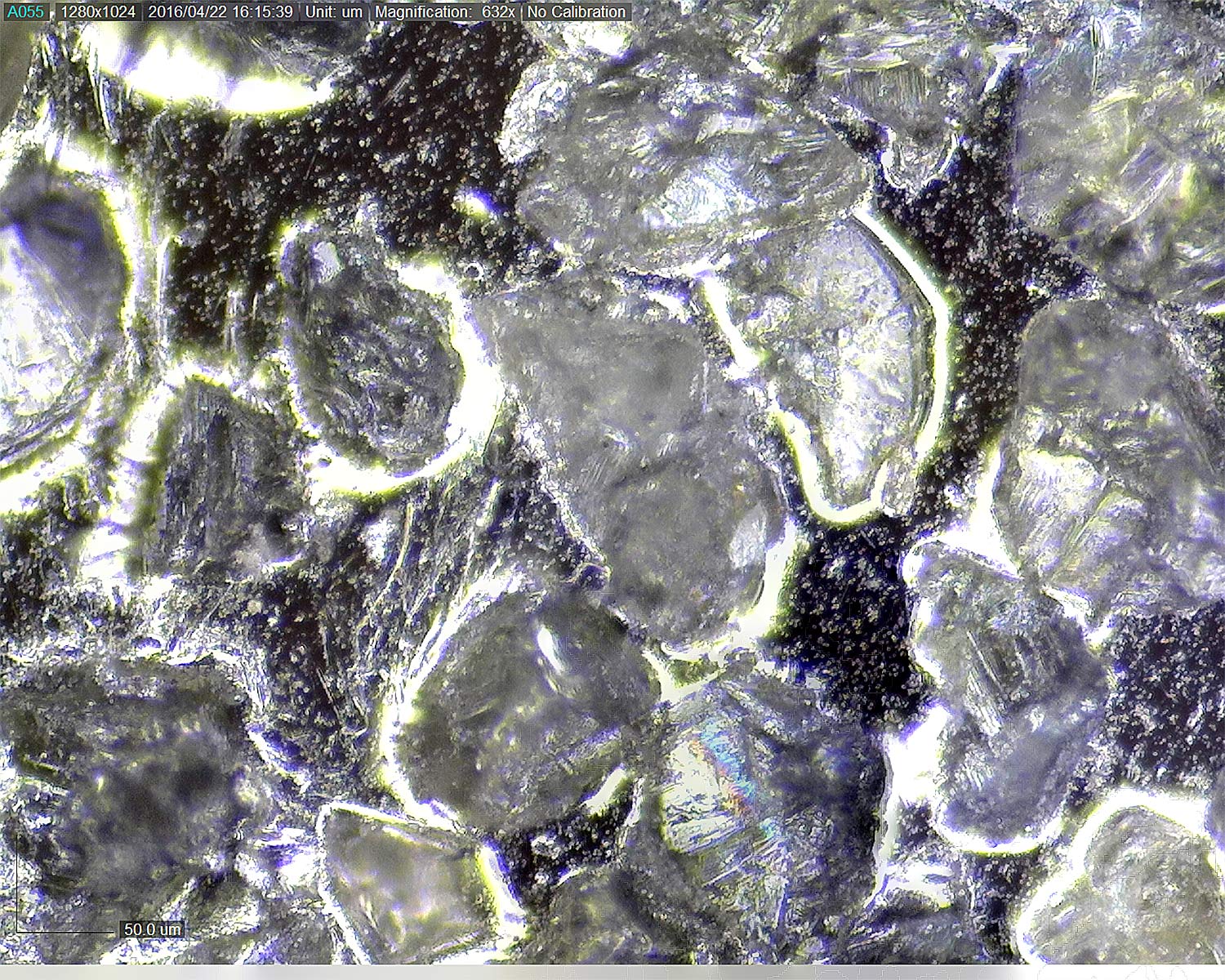

The rounding of the diamonds is pretty well documented. I’ll try to image a new stone and an old one for you so you can see it.

-Clay

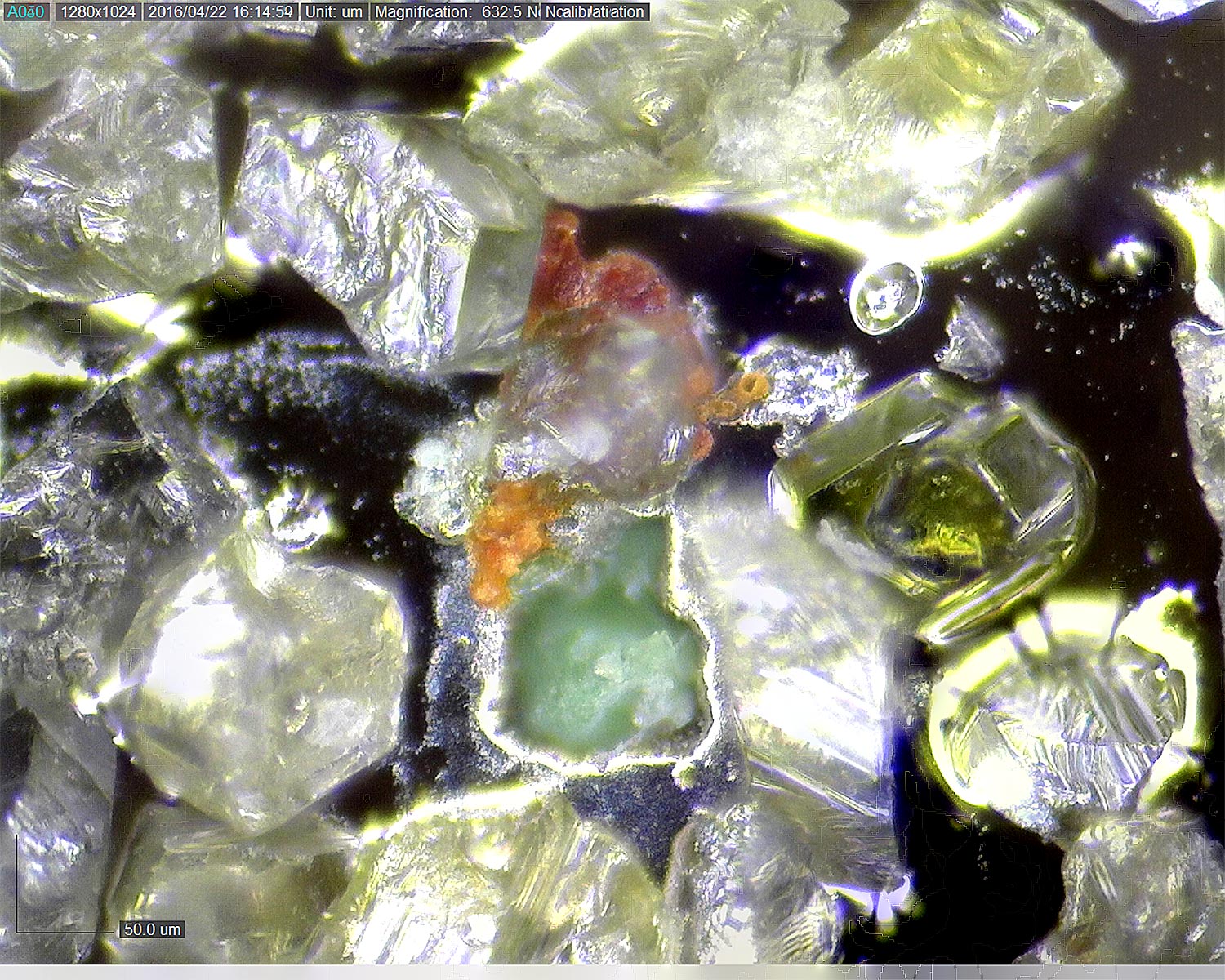

04/22/2016 at 4:34 pm #33629Here are two pictures at 632x of 100# diamonds. One is brand new and the other is somewhat worn though not worn out:

-Clay

Attachments:

You must be logged in to access attached files.

04/22/2016 at 5:10 pm #33633Just so I know what I am looking at. These are images of two different wicked edge paddles. One that has never been used and a 100 grit paddle that is worn but not worn out. The diamonds I am looking at are not the same diamonds in each photo correct? Would you agree that observing the same diamonds on the same paddle (over time) would be more accurate?

I realize the extreme difficulty that trying to perform this comparison would be, however, would you agree that doing so would be the better way to document the rounding off of diamonds with carbon steel?

Check out this video on YouTube:

I am not a geologist in any since of the imagination, however, I always “believed” that diamonds where the hardest Carbon substance in the world and could only be cut with lasers or other cut, broken, or chipped diamonds? Am I wrong? If so please tell me. I admit I could be wrong. It wouldn’t be a first time.

https://en.m.wikipedia.org/wiki/Mohs_scale_of_mineral_hardness

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

04/22/2016 at 5:38 pm #33634FROM BLADE HQ: All that is needed to make basic steel is a combination of iron and carbon. However, over time it was found that adding different elements to this basic steel substance can increase its toughness or hardness. These added elements account for what is the major difference of most types of steel in blades. It was quickly discovered that there are advantages and disadvantages to each added element. For example, a certain alloy might make a blade harder. The more hard the steel, the longer it will hold its edge (and that means less frequent sharpening), which is great! However, if you harden the blade, you also make the blade less tough, which means the blade is less resistant to shock and impact (not such a good thing). Unfortunately, a blade cannot be both harder, and tougher; as you add toughness, you make the blade less hard and vice versa. Since not all of us have the basic training of a materials scientist, here are a few key differences in steel types that will help you decide what type of blade is best for you.

Ingredients of Steel

First, I will introduce you to the basic ingredients of steel and their uses.

Carbon – This ingredient is essential to steel’s creation; all steel will have some amount of carbon. It is the most important hardening element, but as it is added it can reduce the toughness of the material. Carbon reduces the amount that the knife will wear over time. So, the amount of carbon in the blade tells you a lot about the quality of the steel. Low carbon means there is (.3% or less), medium has between (.4-.7%), and high is (.8% and above).

Chromium – Combats corrosion. Stainless steel knives will have chromium as a major ingredient, typically at a minimum of 12%. Chromium will also increase the strength of a knife, but adding chromium in large amounts decreases toughness.

Cobalt – Strengthens the blade.

Copper – Combats corrosion.

Manganese – Hardens the blade. If added in high quantities it can increase brittleness.

Molybdenum – Maintains the steel’s strength at high temperatures.

Nickel – Adds toughness.

Nitrogen – This element is sometimes used as a replacement for carbon in steel.

Phosphorus – Improves strength.

Silicon – Increases strength. Also, removes oxygen from the metal while it is being formed.

Sulfur – Increases machinability but decreases toughness.

Tungsten – Increases wear resistance.

Vanadium – Increases wear resistance and makes the blade harder.Isn’t it true that any alloy of metal is only as stong as it’s weakest part ingredient (mineral)? As far as I can tell, their isn’t any substance or mineral in this list that is more “scratch resistant” than the diamonds we are sharpening with.

I must be obsessed, sorry everyone. If you can help answer some of these questions for me, please do. I actually want to know what is going on.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

04/22/2016 at 9:24 pm #33639Probably true however… If I’m reading you correct (may not be) you are using the same sort of argument I’ve heard others make. For instance, if hardened steel is harder than paper, why will paper dull steel after a while?

04/22/2016 at 9:55 pm #33640I believe synthetic diamonds made for cutting and grinding, are designed to be friable.

1 user thanked author for this post.

04/22/2016 at 10:21 pm #33641Watch the video at minute marker 0:47 through 1:18 (and then do it again) What’s “shocked” and “floored” me, is the fact that the bronze blade is coated with fine diamond and “to cut a average rough diamond in half, could take up to four hours”.

WHAAAAT?..What has got my attention on this point is the forces at work are substantially higher than the force we are applying and are capable of generating on our wickededge sharpeners. This is evident to me because of how soft bronze is in my understanding.

Which indicates something in our understanding of this process isn’t accurate.

Please understand…. I am not a geologist or metallurgist. I’m just making a observation and asking a tough question.

I respectfully appreciate all comments even if you don’t agree with my observations.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/22/2016 at 10:38 pm #33642Natural diamonds (as in your linked video), and synthetic or industrial diamonds, are two different things. Try this link… see if it helps…

http://industrialdiamonddirect.blogspot.com/2006/02/industrial-diamond-properties-and.html

1 user thanked author for this post.

04/22/2016 at 11:16 pm #33643Razoredgeknives–Similar yes, the same observation conclusion oh no! The paper in your example isn’t altering the elemental structure of the metal as being described by Clay on the diamonds. In your observation and my understanding, the soft paper is just rolling over the edge or if you will….just, “pushing the metal around” which results in loss of edge “keenness”. Normally, and through personal observation . Stropping on a leather strop or a butchers steel or ceramic rod will bring back a usable edge ( effectively pushing the metal back).

What is being discussed above is the destruction of one of the hardest natural or synthetic minerals on earth with forces I am not convincd we can generate on the wicked edge. Kind of like rocks on the bottom of a river bed that are smooth like glass but in that case the water is smoothing the surface with very different forces. From the documentary video on the discovery channel, it could take up to four hours to cut an average size diamond with other diamonds.

Japanese water stones are said to be friable which causes the swarf to build up visibly with the naked eye. With diamond stones we are seeing metal loading up or abrading from the surface, not diamonds.

My hypothesis is that the diamonds are falling off the substrate with time as a failure of the substrate not deformation of the diamonds. Check out this page from the blog. Diamond plate shows missing diamond after five minutes of sharpening. Very curious would you not say?

https://scienceofsharp.wordpress.com/2015/09/10/diamond-plate-break-in/ ( Josh didn’t you comment on this page in the blog in Sep 2015 (just curious)?)

It is these broken diamonds that could be causing some of these deep scratches and maybe the Higher diamond grits are more complicated than we once thought.

We are discussing the work of Todds blog the scienceofsharp.wordpress.com . Todd did a wonderful job describing and documenting his observations. He also tried hard not to make any conclusions, which is why I am interested in discussion of the images and observing this for myself with the help of like minded folks like you guys. Take a few days and read it slowly. I realize we are all busy, I am too. This article may generate addional observations not yet realized.

Great article cbwx34. It shows the forces required to create these diamonds are tremendous. Elemental particles like diamonds are not created or destroyed they just move from one state to another. And from bigger to smaller. Can you imagine the energy required to create these elementary particles of matter? Mind boggling.

The esoteric nature of this “sacred” geometry is coming to light…. Did you know that 42° is the position we must be in to see the colors of the rainbow and gemologist cut diamonds to 42° to also show the colors of the rainbow in the reflection of the crystal diamond. This was also in the video and interesting but off topic.

I am enjoying the discussion, thanks for contributing guys!

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/23/2016 at 4:20 am #33650It is my experience that if, with the finder grits, I finish an edge with soft sweeps alternately on both sides I hardly/do not get a wire edge.

I’m going to have to try this. I find that at 800 grit (last grit I use for kitchen knives), I have a wire edge that is hard to eliminate. I’ve tried running a piece of wood down each side and also a cork. They help I think, but do not eliminate it, as the knife will feel sharp with my finders dragged across the edge from one side of the edge, but not from the other side.

Alan

04/23/2016 at 7:45 am #33657I’m going to have to try this. I find that at 800 grit (last grit I use for kitchen knives), I have a wire edge that is hard to eliminate. I’ve tried running a piece of wood down each side and also a cork. They help I think, but do not eliminate it, as the knife will feel sharp with my finders dragged across the edge from one side of the edge, but not from the other side.

Try making 1-2 very light edge leading passes, at a 4-5 deg. higher angle with your final stone (800g in this case). You’re not creating a microbevel (shouldn’t even see it under magnification)… this is done just enough to eliminate the burr… especially on knives where, as you stated, the burr is hard to eliminate.

2 users thanked author for this post.

04/23/2016 at 5:14 pm #33669I believe synthetic diamonds made for cutting and grinding, are designed to be friable.

I found this article this morning interesting:

http://www.metallographic.com/pdf/Data-friable.pdfAnd this quick inforgraphic as well discussing “cleaving”:

http://science.howstuffworks.com/environmental/earth/geology/diamond3.htmI have some extremely worn out stones and some brand new ones I hope to do a comparison on very soon….when the new scope gets here!

04/23/2016 at 8:00 pm #33671

04/23/2016 at 8:00 pm #33671Since Clay’s observation a few weeks ago, I’ve tried to stick with edge-leading strokes to minimize burr build-up. Because of a neurological deficit, to stay safe, I prefer to work one side at a time – perhaps 20 strokes on the left, then 20 on the right. Regardless of how I’ve been proceeding, my last 10-20 strokes are very light and always alternating. This seems to take care of any burrs.

Very interesting video about cutting diamonds. About Christmas of 1965, when I was getting ready to be discharged from the Navy, I visited an Uncle who lived in Bellingham, WA. He had a hobby of gem-cutting, or lapidary. He had the same equipment shown in the video and let me cut up and polish an amethyst for a girlfriend. My recollection of the forces applied is that they were extremely light. The glob of adhesive that the stones are held on is just a hard, sticky form of wax. The gem is attached while the wax is melted. Any excess pressure would knock the gem off of the dop (the wax and its holder). If you were cutting a diamond with a diamond wheel, too much pressure would also tear the diamond dust particles off of the wheel.

On further thought, it makes sense that the bronze diamond wheel has the diamond dust cast into it with the bronze. Since the cut happens at the periphery, there has to be diamond media along that edge. High pressure would still eat up the wheel at a prodigious rate.

1 user thanked author for this post.

04/24/2016 at 12:36 am #33673tcmeyer- Thanks for your response. Based on your experience with your uncle which could help this discussion tremendously, do you happen to know the speed of the diamond coated cutting disk and the polishing disk? I believe that the reason the pressure on the wheels was so light, is that the speed/ velocity, angle of attack (With the grain) and the remarkably hard stones of two different sizes made the cutting effortless. It doesn’t mean that the frictional forces between the two were not tremendous at the apex of the cutting disk.

Could you imagine for just one second if you cut the amethyst, just one facet, with a hand saw? How long do you think that would take and could you imagine the energy that would be required to do so? The cut would probably not be straight enough to reflect any light. I would suggest that this effort with a hand saw would be relatively equivalent to the forces we are capable of applying with a WickedEdge sharpener?

If it takes a diamond to cut a diamond with these considerations, how can a steel blade do it? I concede that we could break or fracture weak or damaged diamond crystals but not significantly alter the structure of the diamond like we see on rocks at the bottom of an old river bed. Has anyone ever seen a round diamond like a river stone in nature?

However, A better hypotheses is that the “weakest link” (in this case the bond between the dissimilar substances) would fail long before the diamonds where altered.

I think everyone on this forum understands this isn’t a failure of the product in anyway. It is a limitation of our ability to stick two dissimilar substances together. Just like sandpaper, diamond plates of all types eventually get abraded away and then need to be replaced even though it takes much longer (This is why we like using them).

I have been reading everyone’s observations and studying photos both new and old (Scratch Patterns). And it seems to me that the only thing that could be causing these errand scratches are loose diamonds. So everyone understands (in the past, present, or future), I am not singling out any one product or manufacturer, this is all only a result of manufacturing limitations and I reserve the right to be wrong completely.

The best visual way to describe what I am suggesting is to visualize a bed of nails with one nail sticking up higher than the others. If a diamond is sticking up among a bed of diamonds (A diamond plate) the weaker or softer of the three substances the diamond, the steel blade, or the bond between the diamond and the diamond plate, will give.

This, I would suggest, will result in a loose diamond. This diamond will end up wedging between two other diamonds on the plate and create a diamond knife that cuts deeper than the diamonds around it. This is exactly what makes this so elusive to observers. It’s the randomness of the pattern. With each pass, the loose diamond moves until it is washed away or re embedded back into the bed of diamonds. This is why it is so hard to duplicate. It may cause a problem now and not on the next blade edge pass.

Diamond embedded in the plate.

https://scienceofsharp.files.wordpress.com/2015/09/dmtc_new_09.jpg

Diamond missing after five minutes of sharpening

https://scienceofsharp.files.wordpress.com/2015/09/dmtc_broken_in_09.jpg

The only variable that can be controlled in this whole process is the manufacture process of the diamond coated plates, however, I can’t see this eliminating the problem completely as we are working with microscopic diamond dust either artificial or natural.

Example of a new plate with a big (microscopic) boulder among the other smaller diamond crystals (Elephant among monkeys).

https://scienceofsharp.files.wordpress.com/2015/09/dmt1200_new_08.jpg

Up Close;

https://scienceofsharp.files.wordpress.com/2015/09/dmt_1200_new_3_04.jpg

Look a whole herd;

https://scienceofsharp.files.wordpress.com/2015/09/dmt1200_new_02.jpg

If the questions is asked, “What is causing these errand scratches”? I think it prudent to make good observations, come up with a hypothesis and then test it. I keep seeing these photos and I am interested in collaborating on the tests. I love problem solving and at least on this forum, we all get these occasional scratches that just frustrate us. Maybe there is something we can do about it and maybe not. Kind Regards – MirrorEdge

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

04/24/2016 at 1:27 am #33677I like the scope Cliffcurry. Thanks for the great articles too. 15,000 revolutions per minute (RPM). I didn’t think it would be that fast, Wow! Could you image trying to do that on a WickedEdge? I also just took the plunge on a new microscope, but I am cheap, and already spent my allowance for the year on a new Gen 3 WickedEdge sharpener (That was more important).

Here is my new metallurgy scope from Radical India (Here). I am hoping that next month, I will get a Dino-Lite eyepiece (Here) USB camera for it, however, I need to measure the eye piece diameter first. It wasn’t indicated on the website for some reason. My wife is going to want something in exchange I’m sure… I love the dino lite capture 2.0 software. I think the two in concert will be outstanding.

In fact, I recently discovered that the software has a cool Advance image transparency function which will allow me to compare two images. This is on the par with this subjects post, align one image taken with a image from a previous capture session. Basically, it will allow me to align the diamonds on the plate after sharpening for comparison. It will also allow me to track individual scratches observed on the bevel. I use similar software at work to compare finger prints. I am looking forward to it. Any one interested in the Dino Lite transparency function can learn about it here. (HERE Transparency).

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.