I measure the blade’s verticality by attaching a 1/8″ x 1″ x 3″ long piece of precision-ground steel to one side of the ‘cube. For those of you thinking “Geez!” I’m sorry, but it’s what I had laying around. I will then hold that steel edge against whatever part of the blade I can see. Often, I have to turn the steel to put it on edge. I take reading from both sides of the blade and move the handle until the blade is as vertical as I can get it. This works well with medium to large knives, but getting a steady hold against a narrow blade is tough. It’s even tougher when the pivot joint is a bit loose, a problem often seen in small knives.

If the blade has a section of flat (non-ground) blade surface, the on-edge method works better.

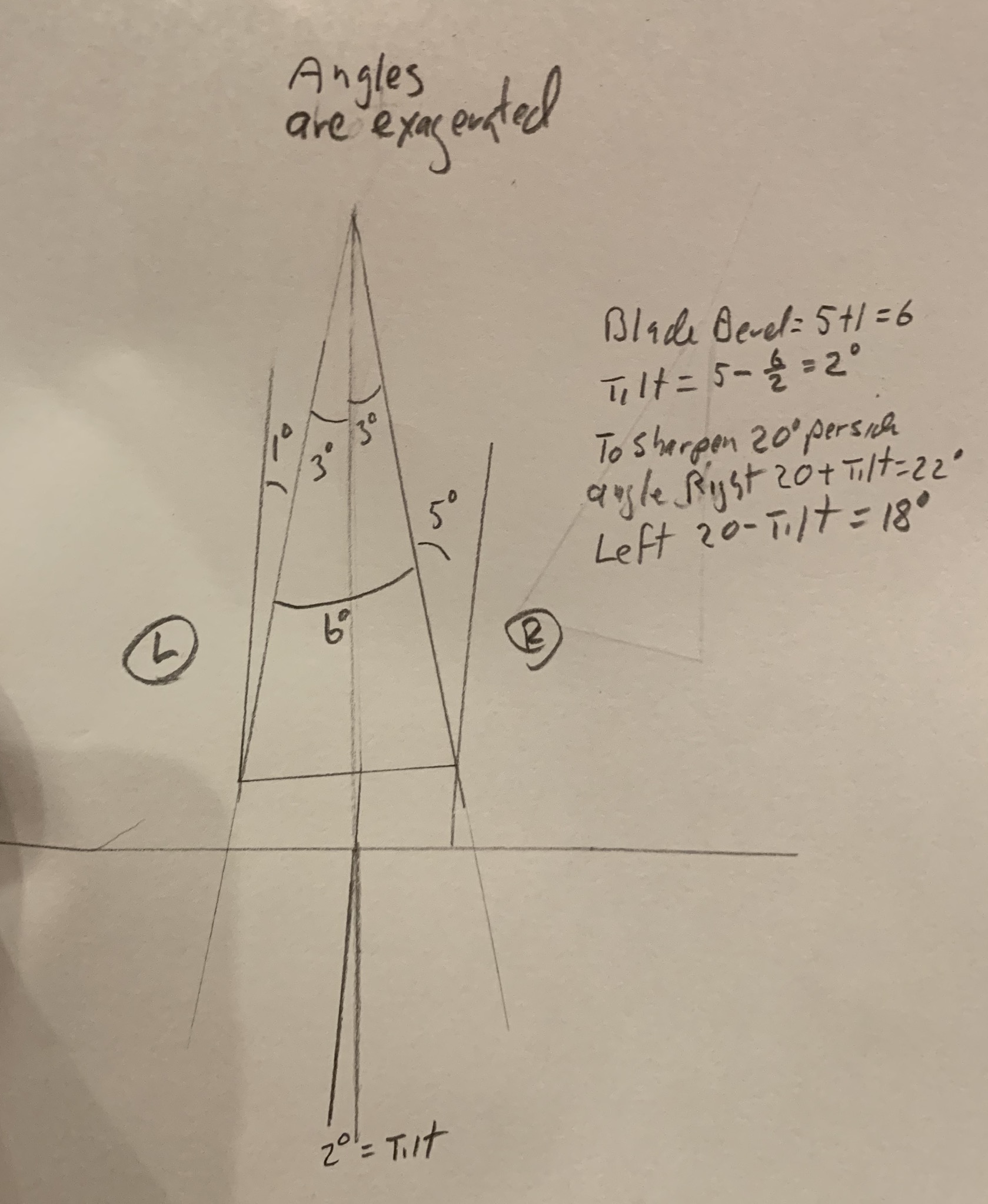

Having said all that, you’re just as well off using the eyeball method as Marc suggests. Our brains are very good at judging vertical or horizontal lines. If you are off by a few degrees one way or the other, the edge will still sharpen just fine. Any nominal error will simply result in a slightly canted edge, but the included angle will be the same and the edge will be just as sharp as if it were held perfectly vertical. Wide bevels may be noticeably different, but narrow bevels will be so similar that detecting the difference will be quite difficult.

4 users thanked author for this post.