New 2200/3000 stone

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › New 2200/3000 stone

- This topic has 5 replies, 4 voices, and was last updated 05/22/2020 at 9:00 pm by

Readheads.

-

AuthorPosts

-

05/18/2020 at 4:02 pm #54257

I have had my stones (100 thru the diamond films) for a few years now. I recently added the 2200/3000 stone which should fit between the 1500 stone and the films. However, when using them I can feel that the scraping is coarser than the 1500. My scope verifies it. I figure its because the 2200/3000 is not broken in and I’ve done ~10+ knives with them. So my problem is how to get the new 2200/3000 stone broken in enough to fit the progression of my used stones ?

Its a major PIA and I just skip them these days. I am not even sure if they are even needed (once broken in) because the diamond films finish the job tremendously after the 1500. We need a breakin procedure.

WDYT ?

1 user thanked author for this post.

05/18/2020 at 5:41 pm #54263Others with more knowledge will chime in I’m sure. I had an older 1500 and the new 2200/3000 stones. Because of the polish I was getting from my 1500 stones, I decided to get the new 1500/2200 stones so that I could do 1500>2200>3000, all new. Turns out, I didn’t have to do that.

The old 1500 stones were giving me a slight polish, because they were worn, however the scratches were the same size as the new 1500 stones, although the new scratches appeared to be much higher in density. Better way to put it might be, there were more scratches per inch with the new, than with the old. The scratches fall right in line with the new 2200/3K stones. Although I could have continued using my older 1500s, I decided to use the new 1500s, just to keep that 1500>2200>3K progression consistent to my eye. Suffice to say, I love the new stones and now, couldn’t do without them. Hope this helps.

05/20/2020 at 10:18 am #54286We need a breakin procedure. WDYT ?

I think you’re right. I wonder if it isn’t useful to temporarily use a new pair of 2200/3000 stones in place of the 800/1000 stones until they’re broken in.

-Clay

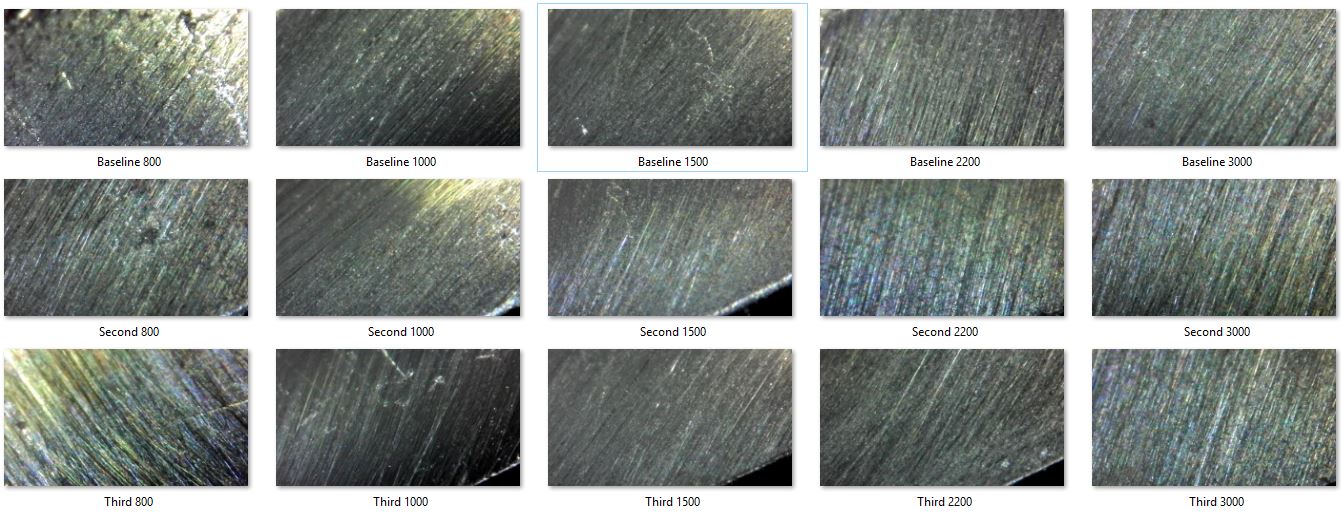

05/20/2020 at 9:53 pm #54291Clay, I think you may have hit the correct “temporarily”. I just spent my corona evening doing my best scope analysis at home on my 6 month old 2200/3000 paddles with my 3+ years old 100-1500 paddles. Nothing too fancy but here is what I did (all numbers are grit):

- Baseline Pass – Took a POS paring knife thru first bevel at 100 to 1500 to establish a nice finish for comparison, then did 2200/3000.

- Mounted a flat file handle into the WEPS and took 40 passes each on the 4 faces of the 2200/3000 paddles with firm (not heavy) pressure. As I was doing it I became afraid that I was going too hard and maybe destroying the paddles due to the amount of steel dust (turns out I was mistaken).

- Second Pass – After doing step 2, I went back to 800 thru 3000 expecting to see a discernible difference to the baseline – wrong again

- Third Pass – Repeated Step 2 thinking that maybe I messed up – wrong again

A few thoughts:

- When looking at the scratch marks (~200x cheapo USB scope, lousy lighting, no fixture, still reasonable IMO), it seems like my 2200/3000 handles belong as a “sister” to the 800/1000. BTW, the feel and sound feedback I get when I work the bevel tells me the same thing. I attempt to keep confirmational bias in mind when doing this. Also, when I first got the 1500/glass from you a couple of years ago there were none of these complications. Your 1500 is world class but I am still not sure what to do with the 2200/3000.

- I would love the 2200/3000 to be next in line to the 1500 before the films (I have no use for ceramics) but I have no idea how to get them there or more importantly how to know that they are ready to go there.

- Maybe I need to use a light file and check scratch patterns every 5 strokes but when doing step 2 above I was really worried and then amazed that it basically made no difference in second and third passes vs. the baseline.

- Is it possible that current batches coming out of your supplier are now closer to where they should be ?

Not sure what to do.

-

This reply was modified 4 years, 11 months ago by

Readheads.

-

This reply was modified 4 years, 11 months ago by

Readheads.

-

This reply was modified 4 years, 11 months ago by

Readheads.

-

This reply was modified 4 years, 11 months ago by

Readheads.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

05/21/2020 at 3:51 am #54298A few years back, I had a new 800 grit stones which was taking big chunks out of the edge of my ZDP189 Delica. On close inspection, I found a couple of clusters of diamonds which were elongated and oriented parallel to the long axis of the stone. The particular orientation was such that it resisted all normal efforts to break the cluster free. I had a piece of 1/4″ plate glass which I mounted in the vise as I would a blade, then worked the stone over the edge of the glass for what I seem to recall was about a half-dozen strokes. Magically, (well, not really magically) the clusters were gone, taking the problem with them.

Not suggesting that your problem has anything to do with aberrant clusters, but perhaps a short session over a piece of glass might hasten the break-in period. Steel is soft when compared to diamonds. Glass, not so much. Keep the pressure light, as excessive pressure would tend to dull the sharp edges of the diamonds

2 users thanked author for this post.

05/22/2020 at 9:00 pm #54324TC, I took your advice and about the glass although I could not find a good piece so I use my white ceramic Messermeister rod (supposedly around 1200 grit but I feel that ceramics don’t follow the scratch grit thing well at all). Anyway, I did another composite below showing 2 rows of Baseline scratch patterns on a cheap knife (800 thru 3000), then I did 10 strokes on the ceramic rod for the 2200 and 20 strokes for the 3000. I did both paddles for consistency. Used medium pressure. I could definitely feel the difference with my finger as well as while sharpening. I did more strokes on the 3000 because my pics at 10 strokes looked and felt like the 3000 needed more (I took over 50 pics). I was also worried about damaging the diamond paddles on the ceramic rod so I started slow but I think I found my sweet spot.

Pictures can be deceiving with lighting and focus challenges under ~200x mag and I tried to use the most typical of my pics without backing into a decision. To me, it seems like both of the Baseline 2200 & 3000 patterns look more like Baseline 800/1000, definitely not 1500. After ceramic rod strokes they are much closer to 1500 but not quite there yet. I am hesitant to do more ceramic rod strokes though so I am just going to use them now after 1000 and before 1500. Maybe after a bunch more knives I will do a scope analysis to see if its time to move them to where they belong. A real PIA BTW.

To me, this shows that break-in is important, complicated when replacing or adding specific grits, not desirable from a marketing standpoint, very inconvenient cause some need more some less, and I still don’t think I am exactly done. Even though I think I have shifted the 2200/3000 grits from around 800/1000 (per Clay) to around 1500, I still use the 1500 after the 2200/3000 for now. I will occasionally do a scope check but it complicates things. I guess I have no choice.

I still wonder 2 things:

- The OEM must do some kind of quality check and you would think they could do something like your glass rub to get them closer to “true”

- If the OEM won’t do it, it would seem prudent for WEPS to offer some nominal service to do it and verify it so I don’t have to deal with it.

-

This reply was modified 4 years, 11 months ago by

Readheads.

-

This reply was modified 4 years, 11 months ago by

Readheads.

Attachments:

You must be logged in to access attached files.

-

AuthorPosts

- You must be logged in to reply to this topic.