Micro Fine ceramic stones: my first impressions

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Basic Techniques and Sharpening Strategies › Micro Fine ceramic stones: my first impressions

- This topic has 33 replies, 12 voices, and was last updated 02/21/2015 at 3:55 pm by

Pat.

-

AuthorPosts

-

08/01/2012 at 10:59 pm #4429

I don’t have the Spyderco stones for comparison and the manufacturer doesn’t kiss and tell

It’s a good question though and maybe I’ll order up a set so I can compare.

With all of this info on the Spyderco stones, I wonder whether the Micro Fine ceramics are the same material as the Spyderco fine/ultra fine stones? Or are they different stones that happen to be made by the same manufacturer?

-Clay

08/02/2012 at 12:12 am #4430My perception is they are not the same. The Spyderco stones feel a bit harder and just feel different. I have all the Spyderco bench and Sharpmaker stones as well as a 701 profile set. They are all the same as each other (by grit) and different from the WEPS ceramics. JMO

Ken

08/08/2012 at 6:02 pm #4522I happen to have a Spyderco Sharpmaker, my favourite sharpening system until I got the Wicked Edge. My Sharpmaker came with two stones, which Spyderco calls “medium” and “fine”. As cbwx34 wrote, Spyderco hasn’t published any grit/ratings or micron sizes of these stones.

Here are the Spyderco stones next to the Micro Fine ceramics.

As you can see, the color of the coarse micro fine ceramics is exactly the same as that of the Spyderco medium stones and the color of the fine micro fine ceramics is the same as that of the Spyderco fine stones. Coorstek has probably used the same pigments to color the Spyderco stones as the Wicked Edge stones. To me the stones also feel very similar (smoothness, hardness).

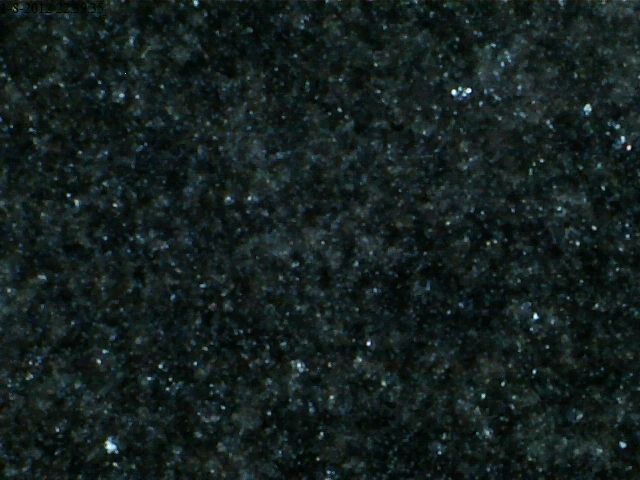

I took a few pictures of each of these stones under my microscope. This is the Spyderco medium stone:

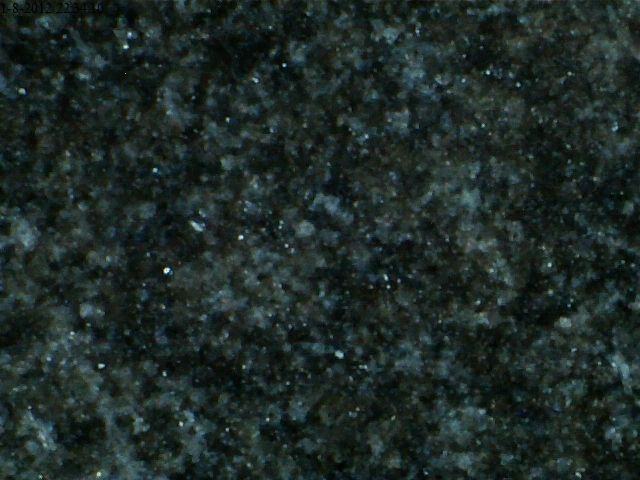

And this is the coarse Micro Fine ceramic:

Although they look similar, the difference between these pictures seems significant: also if I take pictures on different spots on the stones, the Micro Fine ceramics have more and larger grey areas.

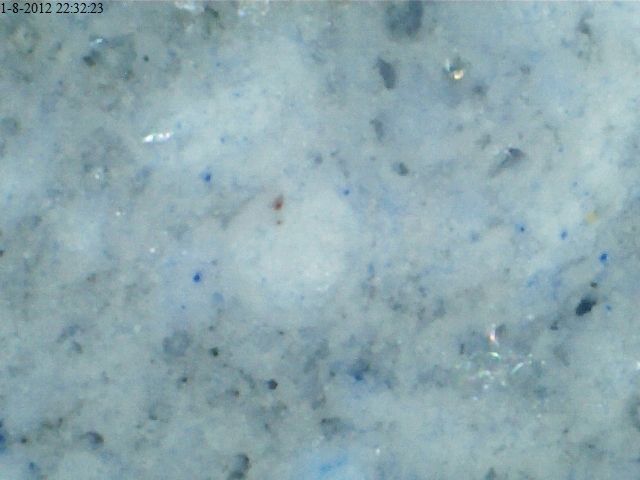

This is the Spyderco fine stone:

And this is the fine Micro Fine ceramic:

Again, the difference between the pictures seems significant: the Spyderco stones have more white spots, all over the stones.

I don’t know what to conclude from these pictures, other than that both the Spyderco and the Wicked Edge stones have similar structures, probably because they have been manufactured using similar processes. Which is not too surprising, since they were both manufactured by the same manufacturer

.

But it would be interesting if somebody could take a microscope picture of the Spyderco ultra fine ceramics.

To show that not all ceramic stones have the same structure, here are microscope pictures of the 1200/1600 ceramic stones. These were made by a different manufacturer.

The 1200 stone:

The 1600 stone:

Molecule Polishing: my blog about sharpening with the Wicked Edge

08/08/2012 at 11:55 pm #4523To me the stones also feel very similar (smoothness, hardness).

I agree… they seem more similar than different. I guess you could do a comparison picture of what type of finish they leave on a knife… although the fact that the stones’ finish can be altered by lapping, this probably isn’t necessary… or wouldn’t really tell that much anyway.

Nice pics!!

08/13/2012 at 6:16 am #4566I have experimented a bit more with these stones and I took some additional microscope pictures. I think these stones are a bit coarser than I initially thought. See my blog update[/url].

Molecule Polishing: my blog about sharpening with the Wicked Edge

08/13/2012 at 7:34 am #4568I agree with your updated blog… Micro Fine coarse –> 1200 –> 1600 –> Micro Fine fine. Alternatively, I’ve skipped the 1200 & 1600, and just used the Micro Fine stones, then onto the leather if I wanted. Seems to be about as effective to me, maybe not quite as polished, but I’m not as concerned about that as I used to be.

02/19/2015 at 6:58 pm #23623I have experimented a bit more with these stones and I took some additional microscope pictures. I think these stones are a bit coarser than I initially thought. See my blog update[/url].

(Blog post) So my current preferred progression is 1.4 micron stones, 1200 grit stones, 1600 grit stones, 0.6 micron stones.

I agree with your updated blog… Micro Fine coarse –> 1200 –> 1600 –> Micro Fine fine. Alternatively, I’ve skipped the 1200 & 1600, and just used the Micro Fine stones, then onto the leather if I wanted. Seems to be about as effective to me, maybe not quite as polished, but I’m not as concerned about that as I used to be.

Clay, given the findings of Mark and Curtis quoted above would it not be prudent to relabel these ceramic stones? Specifically the 1.4 micron rating seems quite incorrect.

02/19/2015 at 8:35 pm #23633You mentioned lapping the micro fines on the diamond stone. Can you explain your process there, or link me to something explaining it?

Thanks and I enjoyed your writeup.

02/19/2015 at 9:13 pm #23635You mentioned lapping the micro fines on the diamond stone. Can you explain your process there, or link me to something explaining it?

Thanks and I enjoyed your writeup.

Watch this video . It will explain fully. He is lapping choseras but it will be the same doing the ceramics.

02/19/2015 at 11:12 pm #23643Got it! Thanks.

02/20/2015 at 4:41 am #23651Do you wet down these types of ceramic stones and do you scrub them up and down like a chosera stone. I am getting quite a few micro chips when I use these.

02/20/2015 at 4:51 am #23652No point in wetting down the micro fines. They re so fine they will not even hold any water. Just scrub up and down with light pressure, then make alternating strokes. Lightly.

Sent from my iPhone using Tapatalk

02/20/2015 at 3:26 pm #23670I have experimented a bit more with these stones and I took some additional microscope pictures. I think these stones are a bit coarser than I initially thought. See my blog update[/url].

(Blog post) So my current preferred progression is 1.4 micron stones, 1200 grit stones, 1600 grit stones, 0.6 micron stones.

I agree with your updated blog… Micro Fine coarse –> 1200 –> 1600 –> Micro Fine fine. Alternatively, I’ve skipped the 1200 & 1600, and just used the Micro Fine stones, then onto the leather if I wanted. Seems to be about as effective to me, maybe not quite as polished, but I’m not as concerned about that as I used to be.

Clay, given the findings of Mark and Curtis quoted above would it not be prudent to relabel these ceramic stones? Specifically the 1.4 micron rating seems quite incorrect.[/quote]

I think you have a point, Mr Wizard, but you’ve also touched on a very difficult area.

If you’ve read my blog Post on the Spyderco/WE ceramic stones, you know that grit size (in microns or mesh factor) is rather inappropriate for ceramic stones. And it tells only half the story (there’s friability of the abrasive parts, the compound holding the abrasive parts, …). Ideally, we’d like a way to rate stones (and stropping compounds) on the basis of their abrasiveness. (And I don’t even know whether that is possible… what is abrasiveness?) Over the years I’ve posted this issue several times on different forums, but I don’t think anybody came with an answer.

Molecule Polishing: my blog about sharpening with the Wicked Edge

02/20/2015 at 3:58 pm #23671Ideally, we’d like a way to rate stones (and stropping compounds) on the basis of their abrasiveness. (And I don’t even know whether that is possible… what is abrasiveness?) Over the years I’ve posted this issue several times on different forums, but I don’t think anybody came with an answer.

I agree with you, Mark. I think there is no true rating possible as there are too many variables in play. To arrive at anything resembling accurate relative comparison, you would need to hold all those variables constant and that wouldn’t apply to anyone not holding the same parameters.

Just one example, take pressure. You can use two stones with vastly different grit ratings. Apply diffenert pressures to each and achieve very similar scratch patterns (ie results) Does that mean these two stones are the same “grit”? Clearly not. But they can acchieve the same result.

Taking this further, you can take two stones with very similar “grit size” but very different substructure. At one presure they may achieve similar results, but increase the pressure (on both) and they do not change equally. So a person using 1/2 pound of pressure may think these stones are identical but someone using 1 pound of pressure will think they are completely different. (Just an example, not a recommendation of pressure to actually use.

)

IMO the best you can do is rank stones within their family (say Atoma plates for example) but trying to compare an Atoma plate of one grit rating to a ceramic stone of equal grit rating is an exercise in frustration.

Hopefully, as you learn your gear (and read the experiences of others) you can devise a progression that suites your needs.

This is not the linear comparison most people think they have by using grit ratings to compare various stones.

Just my thoughts,

Ken

02/20/2015 at 9:38 pm #23683If you’ve read my blog Post on the Spyderco/WE ceramic stones, you know that grit size (in microns or mesh factor) is rather inappropriate for ceramic stones. And it tells only half the story (there’s friability of the abrasive parts, the compound holding the abrasive parts, …). Ideally, we’d like a way to rate stones (and stropping compounds) on the basis of their abrasiveness. (And I don’t even know whether that is possible… what is abrasiveness?)

Your blog has been a great resource and it is cited in the README for my grit chart. I am well aware that absolute grading or even ranking is not possible without restriction to a specific test where material, pressure, etc. are controlled. Abrasive performance is not described by particle size but rather rate of material removal and resulting surface roughness. (This is all acknowledged in the README.)

However within a family of products exhibiting fairly similar properties a ranking should be possible. Are any of the ceramics being used with enough pressure in the WEPS to cause actual grain tear-out from the fused structure? If not their behavior (and ranking) should not radically change with different amounts of pressure. Giving these a micron rating is possibly a mistake. By your results, which Curtis confirmed, perhaps the Micro Fine stones should be renamed 1100 and 2000 for example.

Incidentally have you directly compared the result of the 1000 diamond plate and the “1.4 micron” ceramic?

-

AuthorPosts

- You must be logged in to reply to this topic.