I finally got the mirror edge. Happy WE user

Recent › Forums › Main Forum › Knife Photos › I finally got the mirror edge. Happy WE user

- This topic has 8 replies, 5 voices, and was last updated 11/19/2021 at 9:34 pm by

JWF.

-

AuthorPosts

-

11/05/2021 at 12:06 pm #57156

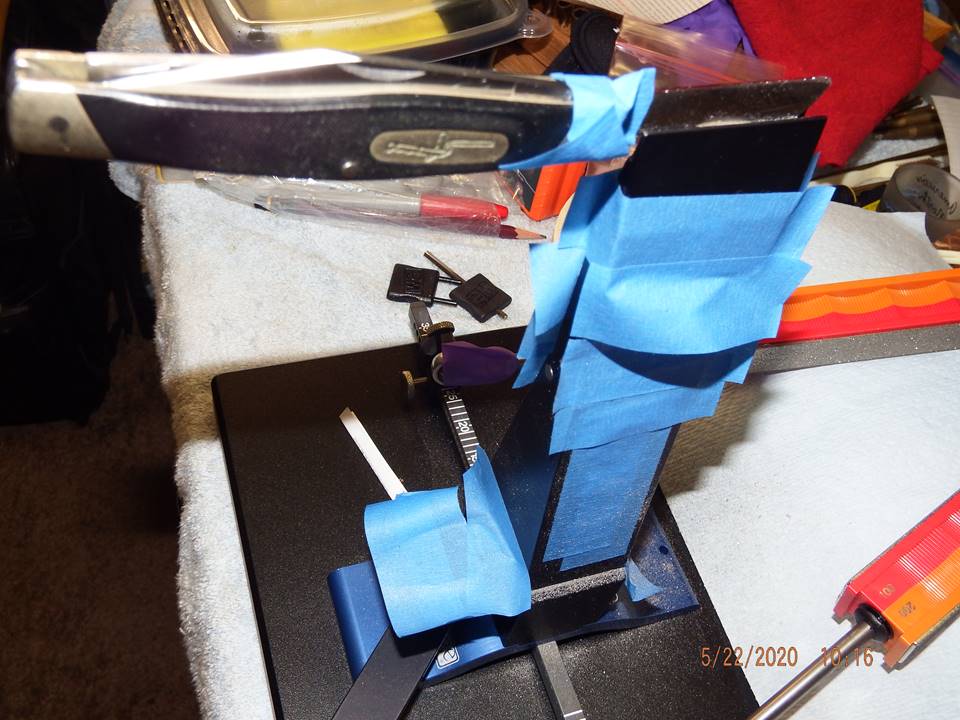

I have been getting nice edges but not like this one. I finally got that wicked edge mirror I was looking for.

Now I don’t feel like using the knife. Not sure after I srtart using it on light duty office work kind of thing how long that edge will last.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

11/05/2021 at 5:05 pm #57158Really nice, Alex. Also, the photo is impressive on its own. Nice work there, too.

The pristine condition of the knife is equally impressive. To keep it that way, use masking tape to cover everything that the stones aren’t supposed to touch. I once scratched one of my sister’s SO’s cheap folders (I don’t think he ever spent more than about $30 on a knife) and I felt terrible about it.

1 user thanked author for this post.

11/05/2021 at 5:58 pm #5715911/05/2021 at 7:51 pm #57160Alex you’re pretty much on track with sharpening results and outcomes many new W.E. users seem to follow if they’re really serious about learning to use their W. E. well.

The process seems to go sort of like this…since, you now have a W.E. knife sharpener you can position and clamp a knife rigidly, stationary and predictably to sharpen both sides of the knife simultaneously. These W.E fixed angle precision knife sharpeners then let us sharpen our knives at an angle of our choosing, repeatedly, predictably and consistently. We no longer have to struggle with always holding knives in a constant particular angled position just in order to sharpen them well. Each side separately.

With all our practice we excitedly strive to achieve the coveted pristine mirror reflective beveled edges as we figure it all out. All the while we’re getting our sharpening stones really well broken in with consistent, predictable abrasive surfaces helping us achieve these results we’ve been working towards. As we really get our sharpening progressions and techniques down, all the while we continue to gain more experiential knowledge. We’re finally exercising just the right amount of effort and pressure for the necessary length of time. We use just the right amount of care and pay the right attention to details and everything has come together.

The proof is in the pictures. You’ve arrived! A “learning curve” graduate. Your officially an experienced W.E.P.S. user. Now you get to figure out what your looking for. What kind of knife edges you want to have. What edges you want on which knives. Do you want a show piece or a work horse. A knife edge to use or one to look at. Now that we know exactly how to use our systems well, the real learning began for me.

This is when I got to learn, or really, teach myself about the kinds and purpose for different knife edges and grinds and how best to apply these and use them. I really began to learn the different tools of the trade for making my W.E. setup(s) do what I want using the intricacies of specific sharpening techniques, knife edges, and bevel angles while employing the various grits and mediums. I’m too much a thinker, writer and theorists for some W.E users. I’m OK with that. I enjoy what I do, and what I have as I continue to learn while sharpening knives I use.

Nice job Alex. Enjoy using your W.E. Now you get to buy more accessories and knives that you’re certainly going to need to have. Not to forget all the different steels you could own, sharpen and use or show off.

I enjoy seeing your photos. Do you spend a lot of time working at it till you get just the right photo you’re proud to post. Or does that come easy to you.

Check out this guy’s pics. (Looks as though he’s switched his gallery host. There’s some old dead links). Josh is a very experienced professional knife sharpener and now a knife maker. He’s a long-time W.E. user. He has a gift for knife photography, also.

Congratulations Alex!

Marc

(MarcH's Rack-Its)11/11/2021 at 12:08 am #57193Thanks a lot for your feedback and suggestions. I guess you’re right, I sharpened that at 20deg and I’m happy with the look and the way it cuts but if I get to do the same finish at 19 or 18 I’m not sure I could tell the difference all that much. Also, with this knife (not sure if it’s the positioning) but at best I might be able to go down to 19deg but the stone might be touching the jaws of the jig. I don’t think I can do a more acute angle without the W.E Low angle adaptor.

As far as the pictures, thank you for the compliment. I happen to be into photography and own a pretty decent system and lighting gear. It makes it to much simpler to get decent results (kind of like the W.E system in a way) you get wha you pay for

Best wishes.

11/11/2021 at 12:11 am #57194TC MEYER. I appreciate you comment and suggestions. I did tape the handle, not the blade. I should do that as well. I have already put a scratch line on a blade that happened to be coated, just so it makes it more visible.

-

This reply was modified 3 years, 5 months ago by

Alex.

Alex.

11/11/2021 at 9:07 am #57196Alex, I believe about a 3° to 5° bevel profile difference is where a discernable cutting difference is recognizable. I suggest a noticeable improvement in the cutting quality indicates there’s been quite a change, made.

Questioning your results, wondering if a slight change in your clamping position may improve your sharpening results is logical reasoning. That’s good to always strive towards better results. It’s hard to qualify an improvement unless it’s drastic and quite obvious. Another issue, to do this, we tend to resharpen an already sharp knife over and over again, looking to improve the outcomes. That may indicate or suggest we could have done a better job by spending more time and effort on the knife from the start.

Expecting you can improve the sharpness of your results is not always necessarily the case. IMO, there are limits to sharpness and performance for each knife. Some knives perform better then others even though both knives may be so similar that they are almost indistinguishable. There are lots of factors involved. Some knives at their best are just fair and unimpressive, while others even though they may look like twins are eyebrow-raising impressive. This can be the case even when made with the same steel. Some knife enthusiasts will say the difference is due to poorer quality, poorer workmanship or bad hardening on the steel for the poorer performer. Maybe, but really it just is what it is. Unless maybe the poor performing knife is high-end, high dollar with buyer’s support. Otherwise we just relegate it to a drawer or gift it away. In reality, we tend to choose to use the ones we like better.

An objective accurate sharpness tester may be needed to quantify an edge’s sharpness. Testing an edge before and after sharpening gives you that needed quantifying basis for comparison to truly recognize the quality of your cutting edge and your sharpening process. This is another separate process and an additional investment.

The issue then becomes learning good, effective and consistent sharpness testing technique to get repeatable test results you can be confident in. It’s time consuming and complicates the knife sharpening process. We have to decide where to draw-the-line on where we want to take this knife sharpening hobby? What’s needed for function and for utility or just for pleasurable use, or what’s done just for bragging rights.

You’ve reached another plateau in equipment operation. The LAA works very well and does what it’s designed to do. Needing to use it seemed to me to defeat the simplicity of the WE130. I thought with the LAA I lost the convenience of simple clamping control. Instead, I choose to modify my setup(s) by using aftermarket 1″ riser block adapters between the vises and the vise mounts. This elevation changes the basic set-up’s geometry to allow less obstructive clamping/sharpening using lower bevel angle settings. (The riser block, at the same time, limits the widest angle settings that can be achieved). It’s a balancing act…the W.E. is a simple precision tool, a table-top bench vise. The W.E. works well most of the time but has limits, too. It doesn’t do anything and everything you may want to with it. When you look to take your results to the next level, set-up enhancements may be a helpful method.

By simply positioning and clamping knives higher in the jaw set(s) helps to avoid some stone/jaw conflicts when looking to lower the angle profiles. The knife does not need to be always positioned so it rests directly on the depth key pins for proper clamping. Tight, stable and secure is all that’s needed. If you can stably clamp the knife just by the jaw tips, go for it.

It’s endless where we can take this.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

11/11/2021 at 3:13 pm #57197I agree with what Marc said. I have noticed that the biggest problem that I have had with my WE130 is sharpening tiny blades. On pocketknife blades like the wharncliffe blade on my Buck 301, I can clamp it closer to the spine at the nail-nick. On smaller blades like the tiny sheepsfoot, I use the Tormek SVM-00 small knife holder. I had to reposition the blade in the holder because the stones were hitting the Tormek bar. But I forget to take a photo of it. I also use the Tormek holder when sharpening my leather knife.

-

This reply was modified 3 years, 5 months ago by

000Robert.

000Robert.

-

This reply was modified 3 years, 5 months ago by

000Robert.

000Robert.

Attachments:

You must be logged in to access attached files.

11/19/2021 at 9:34 pm #57218Verry Nice!!

-

This reply was modified 3 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.