Flexible Kitchen Knives

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Flexible Kitchen Knives

- This topic has 24 replies, 11 voices, and was last updated 11/24/2018 at 3:02 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

05/08/2017 at 9:58 pm #38987

I think coming up with a wide set of jaws with 4 touch pads per side would do the trick. You might have to make them out of steel for stiffness/strength with a slight bias curvature (concave to the blade) to ensure sufficient contact. I saw a Kyle youtube vid showing how easy it is to change out the OEM jaws for the 1/4″ set. It makes sense to be able to do that for special conditions. My sketch below is the best I could come up with. It’s getting late in Jersey.

The other thought I had was a very stiff blade guard used upside down which would fit in and line up with the OEM pads in the 1/4″ jaws. I am not sure it could be made stiff enough without interfering with the paddles.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

05/09/2017 at 12:34 pm #39013Thanks, that helps. We briefly explored using some sort of spring steel like you might find in a binder clip as a spine wrap but didn’t pursue it vigorously. Now that we’ve wrangled some new sourcing agents, I’ll try to that approach again. A second set of jaws, possibly from steel seems like a good thought too though more expensive.

-Clay

05/09/2017 at 7:28 pm #39020Maybe you should continue with the adapters which attach to the standard jaws like you did with the chisels and scissors. This way you increase the accessories available instead of having to change out jaws.

05/10/2017 at 10:15 am #39030A second set of jaws, possibly from steel seems like a good thought too though more expensive.

Clay, Possibly instead of a second set of jaws, two separate wider stiff thin metal adapters, one for either side of the jaw that could insert or lock in with a pin that fits in the “Knife height adjustment key pin holes” Then you could adjust how it clamps by choosing the top or bottom pin holes? I realize the limiting factor would be the adapters thickness, reducing the jaw opening. Due to the nature of the problem of the knife being flexible, I would imagine the flexible knives tend to be on the thinner side.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

05/10/2017 at 11:58 am #39031Here is how I figured it out, works pretty well:

05/11/2017 at 6:14 pm #39062I like the ” stiff thin metal adapters” idea, it’s simple. If you have them “prestressed” in opposite normal directions to the blade face then they may work together to keep the blade stiff while minimizing their own thickness. The only thing that worked for me so far along the blade face was 2 regular files (very stiff metal) which makes the thickness not feasible. You could use a third side (along the spine) as the stiffener though which would then make it one piece.

Hmm, you know, I live right near Aldo the NJSteelBaron guy, he has a new steel called Nitro-V which is an AEB-L with nitrogen added in the melt. He works directly with a foundry in Germany. He has a full shop and is making knives again as well as supplying great quality steel. I am going there over the next week with my field pro WEPS to talk custom kitchen cutlery for my desired 8 inch chef knife. I bet he would have some ideas and has the ability to fab prototypes.

Lets keep this thread alive. Send me some ideas for Aldo fab.

Tom in Jersey

3 users thanked author for this post.

10/10/2018 at 1:51 am #47849Love to see some videos of filleting/fishing knives being sharpened please.

10/10/2018 at 1:02 pm #47853Here’s a YouTube Video I found of a guy sharpening a long flexible filet knife with his home-made Wicked Edge-like sharpener. His video does use some of the techniques I wrote about in this post. Even though the sharpener is not a real Wicked Edge Precision Sharpener it has all the same issues you are experiencing. It is close enough that if you watch his method it should be helpful.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

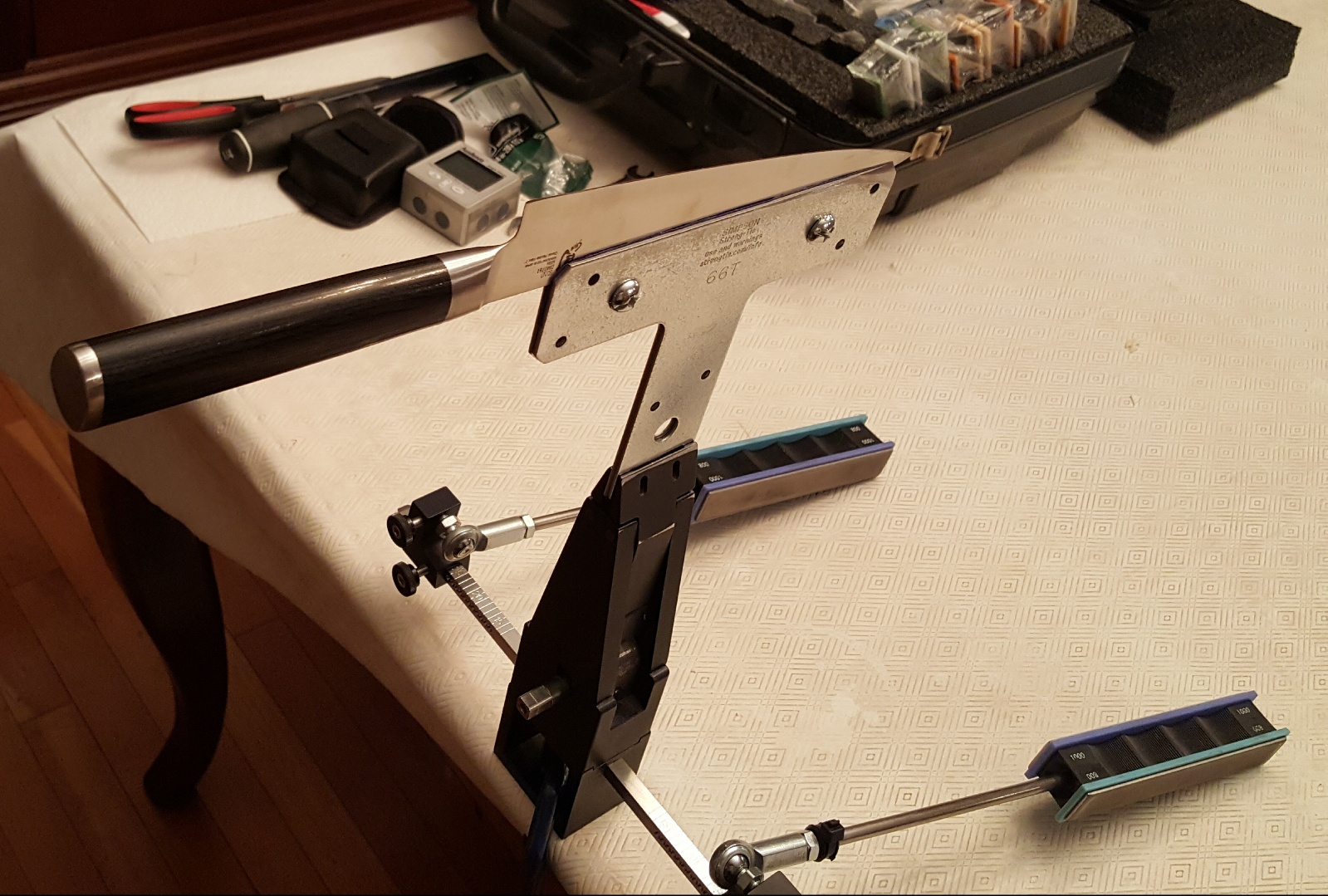

10/10/2018 at 1:58 pm #4785411/24/2018 at 3:02 am #48188I picked up a new RAM mount – suction cup mounted to the table/desk top just in front of the Gen 3 Pro. It works really well, although I’ve only done one knife so far. It clamps on the knife’s handle and lets you move the blade back to a minimum amount of blade tip extending out of the vise. No more using my fingers to support a flexy knife.

The arm is actually extra long, and I moved the mount to the side to show how adaptable it is.

For those interested in the parts:

RAM Twist-lock Suction Cup Mount RAP-B-224-1U For $16 on Amazon Prime

There’s a slightly cheaper version: RAP-B-224-2U For $12.50 on Amazon Prime

RAM Double Socket Arm RAM-B-201U-C For $18.50 on Amazon Prime

RAM Small Tough-Claw RAP-B-400U For $31 on Amazon Prime

My Twist-Lock Mount came without the Diamond Ball Base, but I had one in stock RAM-B-238U For $7.50 on Amazon Prime

Edit note: I’ve removed the links because they weren’t working correctly – probably because the items were linked to my past orders. Please copy and paste the part numbers in Amazon’s search box.

One additional comment. The first knife I sharpened this way wasn’t particularly long, so tonight (11/24) I sharpened the knife as shown in the photo and couldn’t believe how solidly it was clamped. Works great!

-

This reply was modified 6 years, 4 months ago by

tcmeyer.

tcmeyer.

4 users thanked author for this post.

-

This reply was modified 6 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.