Flexible Kitchen Knives

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Flexible Kitchen Knives

- This topic has 24 replies, 11 voices, and was last updated 11/24/2018 at 3:02 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

04/26/2017 at 2:29 pm #38676

Does anyone have a simple jig to keep flexible blades from flexing during sharpening process ? I have the latest generation 3 field version. It gets pretty annoying and difficult to get perfect tips when the blade flexes. The angle changes and you defeat the purpose of holding things stiffly.

It would seem to me that a double extra wide jaws replacement would work.

1 user thanked author for this post.

04/26/2017 at 5:21 pm #38678Great question! I sharpened a couple flexible fillet knives, my work around was I used one hand at a time, with my thumb and index finger on the other hand I pushed against the blade to hold it straight and stop any flex, not ideal but was a quick work around! Keen to hear what people say on this.

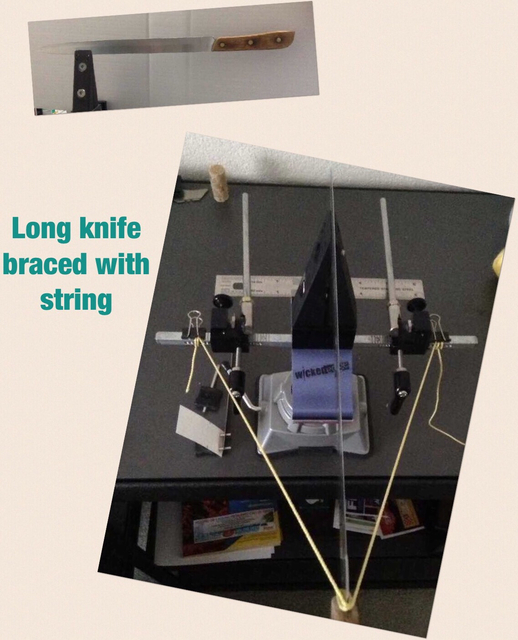

04/26/2017 at 5:47 pm #38679This is what I and another user have done to stabilize a knife

http://13119-presscdn-0-67.pagely.netdna-cdn.com/wp-content/uploads/2015/03/MOD.jpg

http://13119-presscdn-0-67.pagely.netdna-cdn.com/wp-content/uploads/2016/11/flexible.jpg

2 users thanked author for this post.

04/26/2017 at 7:16 pm #38680Great pictures but what it the attachment called, how is it attached to the jaws and do you have a link to order one?

04/26/2017 at 9:11 pm #38681Great pictures but what it the attachment called, how is it attached to the jaws and do you have a link to order one?

They are called RAM Mounts. A large variety of parts are available at Amazon.com

Marc

(MarcH's Rack-Its)04/27/2017 at 7:50 am #38687Marc, that wouldn’t work with the gen 3 vise I don’t believe, due to the lever being right in the way of where you mounted that… but that’s a super awesome mod

04/27/2017 at 8:04 am #38688

04/27/2017 at 8:04 am #38688Marc, that wouldn’t work with the gen 3 vise I don’t believe, due to the lever being right in the way of where you mounted that… but that’s a super awesome mod

They have all sorts of parts. http://www.rammount.com/part/RAM-B-201U#description I remember aways back on this Forum someone installed the “Ram Ball” drilled and secured to the paper/granite base on the back side of the clamp that held the knife stable by clamping the knife between the WE clamp and the knife tip as the knife extended forward. Google “RAM Parts”, there’s a tremendous variety of parts. I’m sure anyone who is intuitive, creative and mechanically inclined, (like many of the WE users seem to be), then you can find some RAM parts to adapt to you needs.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

04/27/2017 at 8:35 am #38690I was thinking of something a bit more simple like a mod to the Tormek jig below which would adapt it to the current WEPS Gen 3 jaws or as a replacement

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

04/27/2017 at 10:08 am #38693I’ve done the “finger support” method a lot and it works pretty well. When I’ve done filet knives, I’d mount them with the tip very close to the vise, then I use my off hand to support the handle – a little steadier and a little safer. Or I could switch bases. I also have the RAM ball mount on my base which has a Gen 2 vise for the same purposes, but mine is actually mounted to the paper stone base, not to the WE blue base. This means I could still use a Gen 3 vise with it.

1 user thanked author for this post.

04/27/2017 at 10:48 am #3869404/27/2017 at 7:05 pm #38704DeeR,

They are Ram Mounts. Attached is what I ordered for my mod. Go to the Ram Mount website to search for what you need. Amazon has the parts also. If you have a Gen 3 Pro vise the Ram kit could be setup on a stationary base(the ball screwed onto the surface that the vise sets on) and the Ram Arm attached and used to steady knife.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

05/08/2017 at 11:43 am #38971I was thinking about something more like the pic below. To prototype it, I used a knife edge protector (with felt inside) but it is not stiff enough so I jammed a very stiff file inside. It also needs to into the jaws but it is too thick. It might fit using the accessory jaws for 1/4 inch knives (the jaw opening is 5/16″). However, I do not have that accessory as I never use knives that thick.

It would seem that if we have an accessory jaw for thick knives that we should have an accessory jaw for long flexible knives (it should be around 6+ inches long). Looking for elegant solutions.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

05/08/2017 at 1:25 pm #38974Redhead, I sharpen almost exclusively kitchen/Chef’s Knives. I suggest you try to clamp the knife more to the center, or at least with the handle further behind the clamp. I’m still able to find the “sweet spot’ that way, and keep an even bevel. (I have found if I tilt or rotate the handle down just a little and the point or tip up, using the clamp as a sort of central axis, to be helpful, but I have read where others tilt the point down and handle up similarly.) This more central clamping holds the thinner forward portion of the knife more rigid to take a lot of the flex out without needing any additional stiffening aids.

Marc

(MarcH's Rack-Its)05/08/2017 at 1:40 pm #38976I have done that and find that the flex is then distributed a bit to the front and a bit to the back. Any flex at all will not only change the angle but will vary the change based on how much the blade flexed during a specific “pass”. The will yield “sloppy” tips. I have also done multiple knife positions but that goes against my beliefs in optimal feasible solutions. I feel this is not difficult to fix using simple fixturing.

1 user thanked author for this post.

05/08/2017 at 8:20 pm #38986I have done that and find that the flex is then distributed a bit to the front and a bit to the back. Any flex at all will not only change the angle but will vary the change based on how much the blade flexed during a specific “pass”. The will yield “sloppy” tips. I have also done multiple knife positions but that goes against my beliefs in optimal feasible solutions. I feel this is not difficult to fix using simple fixturing.

I’d love to hear your ideas on fixturing. We’re always looking to improve things

-Clay

-

AuthorPosts

- You must be logged in to reply to this topic.