Do new Micro Fine Ceramic Stones (1.4 and .6 micron) need to be lapped?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Abrasives › Do new Micro Fine Ceramic Stones (1.4 and .6 micron) need to be lapped?

- This topic has 17 replies, 8 voices, and was last updated 05/25/2017 at 1:11 pm by

Mark76.

-

AuthorPosts

-

05/19/2017 at 6:55 pm #39262

So the first few times I used the micro fine ceramic stones i did not like the results. I got uneven grinding and some scratches. I did this first after the 1000 grit diamond stone, I tried it again after I got the 1500 diamond stone. And then I tried it after the 1000-10000 chosera stones. Never getting a desired result of improved bevel appearance.

So i stopped using them.

Yesterday I was exploring this forum looking for more info on these ceramic stones and I came across several threads that talked about the need for lapping the ceramics.

I have been lapping the chosera’s but had thought that the ceramics were more perfect surfaced stone.

So I marked up one of the 1.6 micron sides with a pencil grid. And I started to lap it on a 1000 grit diamond stone. I found it was barely touching a few points about the size of dimes. further, the more I rubbed, I got very little progress. So I tried the 800, same, 600, same…. down to 100. Then I finally got some progress but it took about 20min of rubbing before I had not grid lines. So then I worked my way back up to 1000 adn then 1500. All of that took another hour or so. I went to do the .6 micron side and decided to go right to the 100 grit. After 10 min. I had one clean spot the size of a dime. Another 2 hours later the side was clean (that is some hard material).

So Am I screwing up but do this to these stones? Is this typical of the ceramics? I am kind of excited to see what the newly lapped ceramics will do now…. but too tired today to even look at them.

05/19/2017 at 8:29 pm #39263It sure seems like there have been a significant number of forum members who are dissatisfied with the quality control on the ceramic stones as of recent. Ideally, they should be flat from the factory. Obviously, yours were not. In this thread, Clay seems to recommend lapping the ceramics flat as you have done. On Mark’s blog he also reports an improvement when lapping the ceramic stones. Tcmeyer, however, has recommended against this. He says that lapping the ceramic stones destroyed their surface and caused them to behave like the final grit they were lapped with rather than the grit the stones were rated at. I know that this makes things clear as mud, but I don’t have a definitive answer for you.

05/19/2017 at 8:46 pm #39264Thanks for the info. I have a hard time believing that lapping the ceramic changes the grit. Choseras do not change grit if you lap them, The ceramics are much harder but if you sharpen enough hard steel on the ceramics you are going to remove some ceramic material and I do not believe that action would change the grit of the ceramic. I guess I do not know about ceramics either.

05/19/2017 at 9:10 pm #39265This blog post explains some of the differences between the ceramic abrasives and whetstones like the choseras. It is worth the read.

2 users thanked author for this post.

05/19/2017 at 9:47 pm #39266When I got started, I believe there was only one ceramic pair. It was labeled fine/micro-fine; now labeled 1.4micron/0.6micron. The 1.4 side is white and the 0.6 side is a dark grey or dark brown color stone. This pair 1.4/0.6 were supposedly made by the same maker as makes the stones for the Spyderco Tri-Angle Sharpmaker. These stones are super hard and worked very well, if you have experienced a Sharpmaker. I found this pair to work very well, for me, just as they came from WE. There’s some back and forth, on-going opinions, as to where in the sharpening progression they should belong. Apparently there’s more than one grit scales to describe their coarseness and particle size.

The 1200/1600 stones, I believe came along a little later. I believe these are ceramics also. Both stone sides are white. As they came I didn’t care for the feel of these stones or the results I got. I heard they had a sintered coating on the stones; like a powdery film. For me that inhibited the stone from making good flat contact with my knife edge, so I got an uneven scratch pattern. When I looked at the used ceramic stones face, I saw this same uneven skipping looking scratch pattern.

When I lapped them (1200/1600) the first time, I did it, they behaved as TCMeyer describes, as though they were the same grit as what ever was used to lap them. It was thought the lapping material scratched the ceramic’s surface and left a scratch pattern that was in turn transferred to the knife you used the ceramic to sharpen. After some time when the 1200/1600 wore in they improved, marginally.

Recently I lapped the same 1200/1600 set again, this time with a Shapton’s Diamond Glass Lapping Plate. It was a very hard job to do that. The ceramics are very hard. End result was two different grit ceramics stones, that behave as you’d expect they should. One is fine and the other one finer. They now have a narrow regular scratch pattern very similar in size, spacing and depth to what I see from the new 1500 Diamond Stone. The ceramics are not as aggressive as the diamond stone. Now that they’re surface is clean and flat I believe they behave like the grit rating describes and they do fit into the stone grit progression. They’re still different like every different cutting medium is, so they don’t exactly follow a straight line on the grit progression chart.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

05/19/2017 at 10:22 pm #39267Interesting blog article. So it seems that I have probably change my 1.4 and .6 micron ceramics to 1500 grit ceramics? And proably wore down my diamonds some. Oh well.

05/20/2017 at 1:40 am #39268Interesting blog article. So it seems that I have probably change my 1.4 and .6 micron ceramics to 1500 grit ceramics? And probably wore down my diamonds some. Oh well.

As in you may have done more damage to your diamond stones than you helped your ceramics.

I’m actually a little surprised by Clay’s experiences lapping a 0.6 micron ceramic. I had a completely different experience, but I don’t have a 3 micron lapping stone. I have to use sheets of diamond film and never got my ceramics back to where they were. But from what I’ve seen, yes, you can restore to their original approximate grits.

I would like to make a comment here that I think you guys are way overestimating the importance of the flatness of the stones. As they come from Wicked Edge, they are capable of producing very high quality edges. You can do much more damage by way of poor technique. Stick the best AngleCube you can find on the back of your “suspect” stone and watch it as you move the stone up or down the rod as it lies on the edge of a blade. Keep your finger pressure constant and at the bottom of the stone and you won’t see any angular change that would merit a lapping job intended only to flatten the face.

This is not to say that there aren’t stones out there that are bad enough to need repair or that ceramics are in the same class as film in terms of uniform scratch patterns. Ceramic stones are apparently cast and therefor have some surface texture variability. They serve a purpose.

2 users thanked author for this post.

05/20/2017 at 6:14 am #39271That was a VERY interesting blog article! Thanks for the link organic!

05/20/2017 at 7:12 am #39273My experience with the 1200/1600 and the 1.4/.6 ceramics have been quite good for me. The stones seem to get better with use, after 30-35 knives with them I think they are still getting better. When I do use them I have to do 2,3 or 4 times the passes that I do with diamond stones. I personally would not lap mine, but there are a lot of more experienced artisans out there.

The 1200/1600’s are still getting better with use, and the same, all though not to the same degree, with the micro’s. The micro’s give me a very good cutting edge, very refined, but I sharpen more for function than for mirrored bevels for the most part. I use them for my final stones and don’t strop that edge very often.

I have noticed that it is very difficult to remove the scratches from any previous stones. They don’t cut nearly as fast, and don’t remove much metal at all, thus the extra strokes. They do require me to take more time when I use them but for certain knives they work very well as they came, for me at least. I do have to clean the ceramics with a super eraser every time I use them and sometime during use. Whatever metal does come off seems to stay with the stone for the most part I believe thus the cleaning.

Also the ceramics being as hard and fine as they are, are much more susceptible to foreign material trapped between the stone and the blade. If not strictly controlled this will drive you nuts and make you think there is something wrong with them.

These are some of my experience with these stones.

2 users thanked author for this post.

05/20/2017 at 11:22 am #39274Thanks for your compliments on my blog article, Rich. Yet I would not recommend lapping ceramic stones, unless it is really necessary (because they are uneven or have clusters of ceramic material that cause scratches). In that respect I agree with Tom (Tcmeyer). I also wrote a blog about how ceramic stones work, which is quite different from whetstones or diamond stones: https://moleculepolishing.wordpress.com/2013/08/08/the-mystery-of-the-spyderco-and-the-wicked-edge-ceramic-stones/ and what lapping them with a diamond stone may do to them.

The conclusion is that lapping ceramic stones with a diamond stone may change their “grit” rating, so be warned.

My experience is the same as that of sksharp: after a couple of knives (sometimes quite a few) the stones get more even and clusters of ceramic material that cause scratches disappear. The stones get better with use.

Molecule Polishing: my blog about sharpening with the Wicked Edge

2 users thanked author for this post.

05/20/2017 at 5:24 pm #39275I didn’t realize you were the author of that blog Marc76, nice work!! Thank you for your effort!

05/21/2017 at 10:45 pm #39285Just a follow up. All my ceramics are flat….. they did have several high spots. But…. you guys are right. The ceramics are now behaving like the last stone I lapped with. So now I have a 1.4 and a .6 micron ceramic stones that behave like 1500 grit.

05/22/2017 at 1:09 am #39286I wonder how the ceramic guys get the sticks to behave like specific grits, if they do in fact use the same material. Do they process it at different temps? Do they form it under different pressures? I had a Sharpmaker for about forty years before I gave it to my brother. I don’t think I ever wore the surface down enough to change the grit. Maybe a little on the corners of the 600’s (brown sticks). Tuff stuff. Does this mean that the surface texture is all that defines the grit? Remove it (as in lapping) and they’re all the same?

05/22/2017 at 8:56 am #39294Good questions. I also wonder how the ceramic guys do this. Perhaps send a mail to Spyderco? Sal Glesser is always pretty open.

But as an answer to your last question: yes, I do think so. Or at least, I wouldn’t be surprised if that were the case.

Molecule Polishing: my blog about sharpening with the Wicked Edge

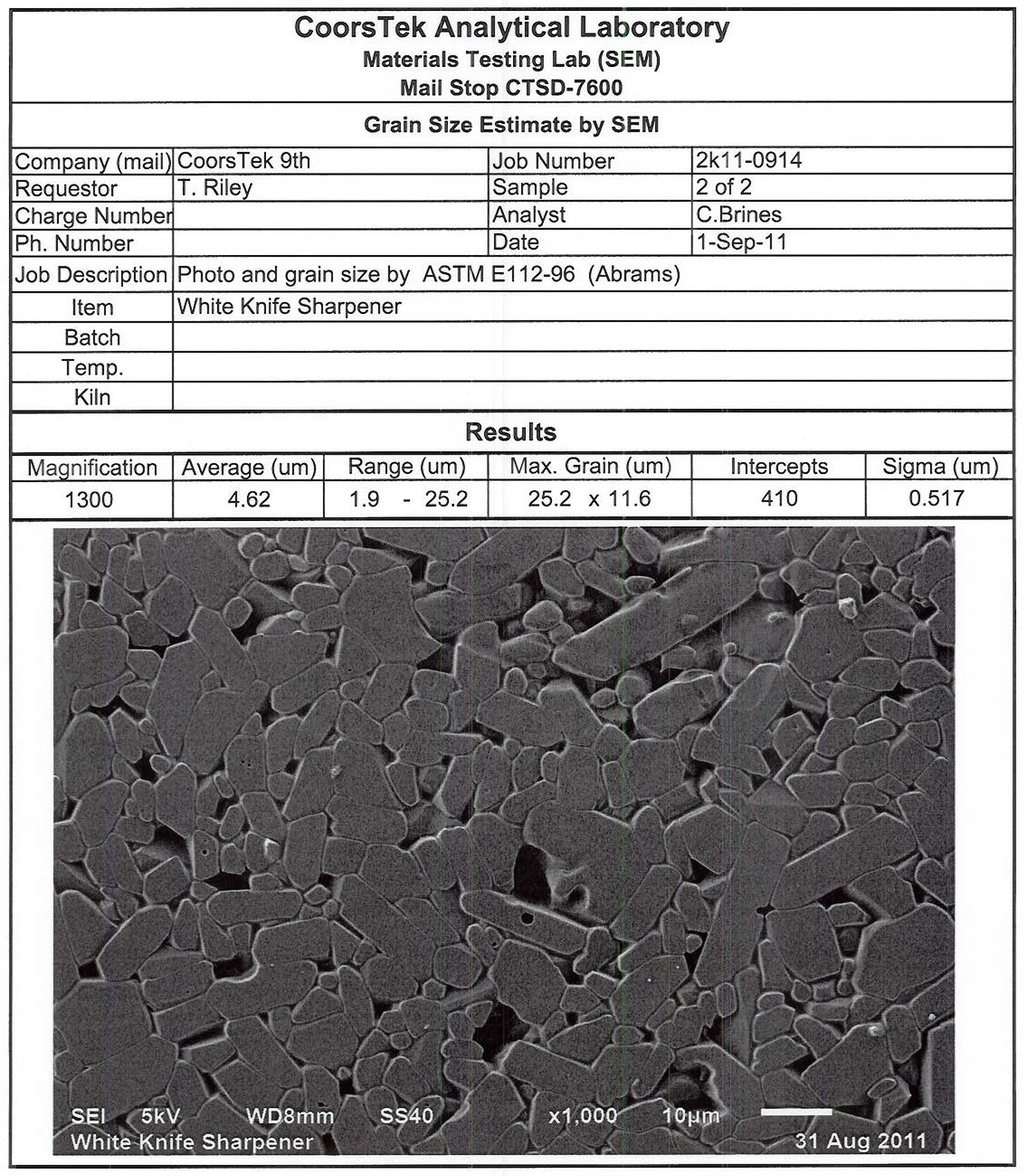

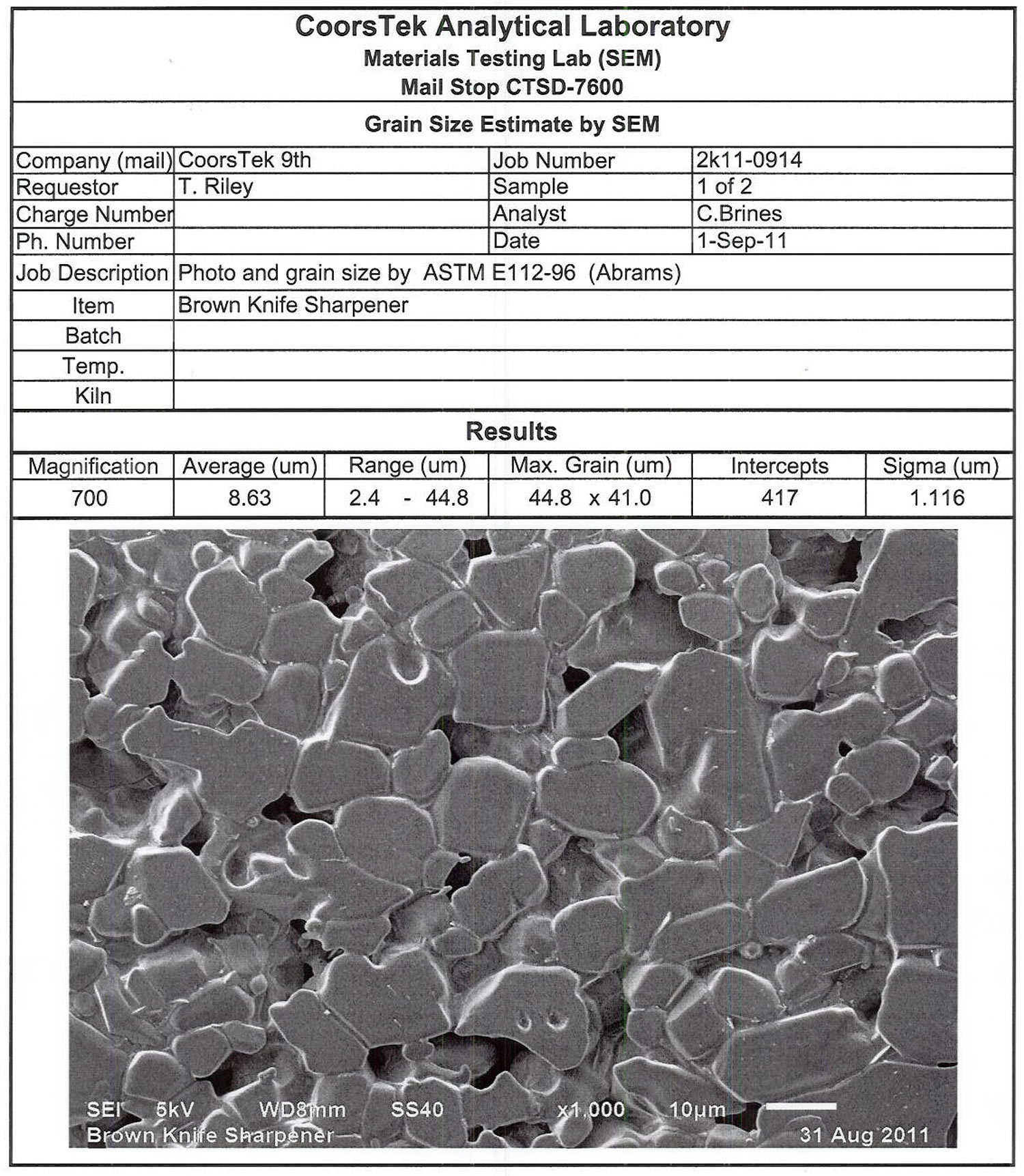

05/25/2017 at 11:29 am #39340I’m not sure Sal will even be able to answer that. The stones that Spyderco uses are made by Coorstek, the same manufacturer that makes our Micro-Fine stones. I dug up the SEM photos that Coorstek sent me when we first got started after I badgered them for a while about the grit. They originally gave me grit sizes of 1.4µ for the brown stones and 0.6µ for the white stones. I asked for more detailed information, which is when they sent me these images and explained that because the grain sizes vary so much as a result of the sintering process (they’re essentially melting and forming new structures), they prefer to grade the stones by Roughness Average (RA). They also explained that the surface texture can be changed and tuned through lapping and that the new texture creates a new RA for the stone, which will last a fairly long time before the peaks are eventually worn flat again. You’ll see that the grain size is a lot larger than the stated grit size:

I’ll look around for data sheets on each stone.

-Clay

Attachments:

You must be logged in to access attached files.

5 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.