Diamond stone photos

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Abrasives › Diamond stone photos

- This topic has 11 replies, 5 voices, and was last updated 12/15/2017 at 11:20 pm by

Justin Fournier.

-

AuthorPosts

-

12/10/2017 at 9:29 am #42567

Here are a few microscope photos, as I try out different settings:

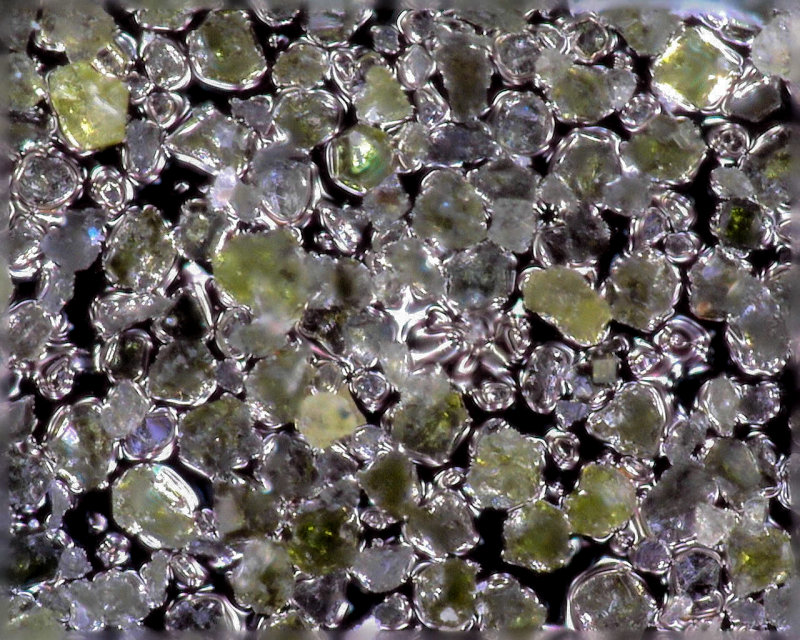

This is a 100 grit stone. It’s tough to get the lighting just right so that you don’t get saturated white blooming in some places and good color/focus in others. This turned out pretty well:

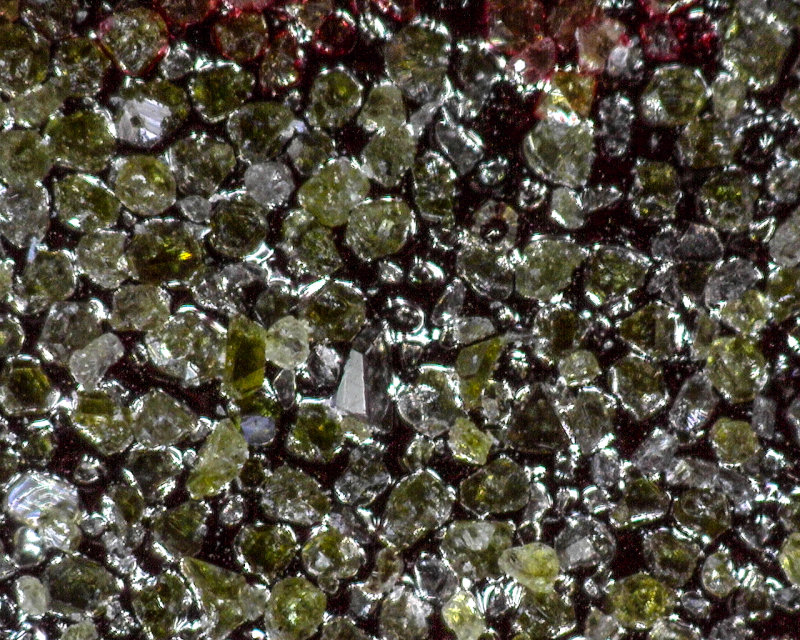

Speaking of “bloom” this larger bright white chunk was a trade-off in getting the rest of the image to be clear:

and here’s a zoomed-in view of the white chunk:

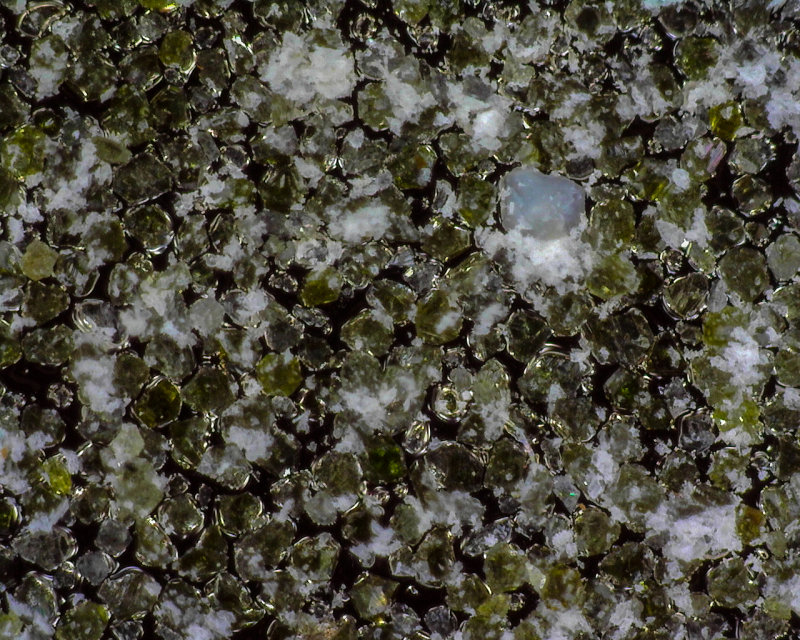

In the next one, I’m not quite sure what the white fluffy stuff that looks like snowflakes is. Diamond dust maybe? I tried brushing it off but it’s staying in place.

This next one was interesting. That bigger chunk was actually firmly attached.

And in this last one, I just thought the “pillars” of diamond slightly below the middle of the photo were interesting. I would guess that those will probably break off after a couple swipes across some steel:

6 users thanked author for this post.

12/10/2017 at 9:32 am #42568edit: missing photo of the “white fluffy stuff” from above (I’m not sure if editing posts has been fixed, so I’m posting it separately so I don’t have to redo it):

7 users thanked author for this post.

12/11/2017 at 12:59 am #42572Great photos. I just bought an entire new set of stones, and was contemplating potential methods to remove some of the big particles that tend to contaminate the stones without taking chips out of steel. I was trying to find a post I read somewhere about people rubbing them together.

Are you using a USB scope?

1 user thanked author for this post.

12/11/2017 at 8:50 am #42586Great photo’s, Graphite! Like Justin I’m interested in how you made them. (If you didn’t use a scope, what lens and settings did you use?)

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/11/2017 at 11:47 am #42593Yes, a USB microscope. Just got it and still learning how to deal with the various settings and different light diffuser adaptors that you snap on to the end of it. I’ve never had a digital microscope before so I don’t have anything to compare it to. This one is a Dino 4815ZT. Just like with digital cameras these days, a $150 camera can get nearly equivalent image quality to an $800 camera under good exposure conditions (or at least, nowhere close to 5 times worse). But the $800 camera can take quality photos under exposure conditions that the $150 camera might not even be able to achieve autofocus lock. Diamond stones are a challenge because of the angle-dependent bright reflections mixed in with details that are lost in darkness if you either reduced the lighting intensity or decreased the exposure time. This scope seems to have enough “knobs” to tweak so that you can get pretty reasonable results at all magnifications (20x-220x is its range). But as I mentioned, I don’t have a point of comparison and maybe I overspent and the $50 scopes can get the same results.

I still need to figure out how to use the built-in manual focus stacking for diamond stones. The automatic mode works well for larger objects with a range of depths and where the focus intervals are longer. But the automatic intervals are too long/far with diamond stones which are relatively flat regardless of grit (so the incremental automatic focus step in either direction goes too far and blurs the whole shot, and the compositing software just throws those out).

2 users thanked author for this post.

12/11/2017 at 1:26 pm #42596Thanks Graphite. I was looking at one lower model than that, less dynamic range, and polarized. Would you be OK exchanging emails regarding it, don’t want to derail the forums.

12/12/2017 at 8:48 am #42688Some of the photos show diamonds way bigger than they should be. I still do not understand why the OEM cannot take care of this for us. We should not have to deal with it. It would be like buying a knife with a burr on it and the first step is to remove the burr.

12/12/2017 at 9:23 am #42689Justin, sure, send me a PM with your email (if PMs are back working).

12/12/2017 at 9:27 am #42690Some of the photos show diamonds way bigger than they should be. I still do not understand why the OEM cannot take care of this for us. We should not have to deal with it. It would be like buying a knife with a burr on it and the first step is to remove the burr.

If you think about the time involved in scanning every square millimeter of every stone at high magnification and then using a dental pic or something to manually pry out every oversized diamond on a diamond-by-diamond basis, it’s not very practical and it would greatly increase the labor portion of the stone’s cost.

But maybe that’s not what you’re suggesting?

12/12/2017 at 9:38 am #42691Of course not, you don’t need that, simple rubs against something with a pass/fail criteria would do it. Why rely on the user (us) to find an old knife or risk gauging an expensive knife ? Its just silly to me.

They must screen these diamonds to size and deal with clumping (which Clay has an official term for), the OEM should have good ideas to solve this.

12/12/2017 at 12:34 pm #42704Of course not, you don’t need that, simple rubs against something with a pass/fail criteria would do it. Why rely on the user (us) to find an old knife or risk gauging an expensive knife ? Its just silly to me. They must screen these diamonds to size and deal with clumping (which Clay has an official term for), the OEM should have good ideas to solve this.

There is definitely a screening process for the diamonds and it works pretty well but most all suppliers will only offer a range of particle sizes. I think the reason for it is that the particles are not uniform in shape so a diamond that is longer than the screen size might still slip through if it’s narrow enough in another dimension. As far as agglomeration (clumping) goes, that is generally only an issue with very fine particles and happens with the small electric fields that develop while the diamonds are being plated. We’ve looked at including a step to break the diamonds in during manufacturing but have so far resisted it because we don’t want to reduce the lifespan of the stones. Another reason not to break them in at the factory is that they are much more aggressive at first which is a benefit to the new user who is trying to establish bevels on dull knives. The timing of the stones being broken in usually coincides pretty well with all their new bevels being cut and their technique getting polished. You could, though I don’t really recommend it, rub your new stones lightly together to knock off any big pieces or clumps, but there is a risk of reducing the life of your stones.

-Clay

6 users thanked author for this post.

12/15/2017 at 11:20 pm #43095Justin, sure, send me a PM with your email (if PMs are back working).

And still not working, give me an email please.

-

AuthorPosts

- You must be logged in to reply to this topic.