Diamond Emulsion VS Stropping Paste

Recent › Forums › Main Forum › Stropping › Diamond Emulsion VS Stropping Paste

Tagged: hanging hair test, knife sharpener, strop, wicked edge

- This topic has 28 replies, 6 voices, and was last updated 04/03/2017 at 10:25 am by

wickededge.

wickededge.

-

AuthorPosts

-

03/28/2017 at 7:24 am #38000

Both sprays and emulsions apply easily – just spritz or pump

The spray does tend to radiate out, so you just need to keep the height from your stropping surface at an ideal distance so that the whole spritz lands on the strop. Emulsions pump out like hand cream, so it is a much more controlled release, which would be almost right on top of the strop.

The spray does tend to radiate out, so you just need to keep the height from your stropping surface at an ideal distance so that the whole spritz lands on the strop. Emulsions pump out like hand cream, so it is a much more controlled release, which would be almost right on top of the strop.The emulsion can be spread out pretty easily since it is a more solid base whereas the spray tends to pool more due to the watery base. It’s a trial and error process to see how much you can apply at any one time and there is the absorption rate of the stropping medium itself. Ultimately, both will dry out and you can load the strop again as necessary.

In general, the PASTES tend to come off very easily of the leather and roo strops. I think everyone here has experienced that at one point or another. Larger surface areas like bench strops tend to do better, but not much since the abrasive sits on top of the surface. The Jende Nanocloth Ultra strops, however, will hold the pastes, sprays and emulsions due to its honeycomb-like structure.

As for the emulsions and sprays on roo or cow leather, they both tend to stick better to the surface of the strop than pastes. I don’t really know why, but it could be the pores open on the leather when the wet abrasives are applied, or the liquid and base of the spray and emulsion act as a sort of glue layer from the residue as it evaporates, or some combination of both. You will still be pulling abrasive off the strop, just not as much per pass. Overall, the retention rate of the sprays and emulsion on leathers is greater than that of pastes.

I hope that helps…

1 user thanked author for this post.

03/28/2017 at 10:03 am #38001Tom, I’ve got a slightly different question, but now we’ve got you on board, I thought I might as well ask it. It was already asked in another topic, but no real answer came out of this.

My question is what you prefer and under which circumstances: diamond films or strops with (poly) diamond emulsion/spray. The diamond films WE sell are very consistent and remove metal at a good rate, so my gut reaction would be: use diamond films whenever they are available. But there must be circumstances in which strops are preferable. When do you use strops and why?

A second question is whether you prefer kangaroo strops or nanocloth strops? And when? Above you wrote nanocloth holds all sorts of stropping compounds well, but apparently so do kangaroo strops. An advantage I found out for kangaroo strops is that they have some burnishing effect, which I like.

(I asked this question somewhere else, too, and the answer I got from an Aussie was: kangaroo, of course, to reduce the kangaroo population. And indeed, when I lived in Australia, the father of a friend of mine was a kangaroo hunter. He was kicked into the hospital by a kangaroo…)

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/28/2017 at 11:14 am #38002I know that the strops do have applications that the diamond films are not well suited to. For example, if you want to create a convex edge you can sharpen the bevel with multiple facets and then blend them with the strops. This works because the leather is pliable and will conform to the facets as it passes over the bevel. Thinking about it just now, I suppose you could use the diamond films to do this but you’d need to mount them on a compressible surface rather than on the glass aluminium plates.

03/29/2017 at 12:17 am #38009Yes, it’s nice to be back!

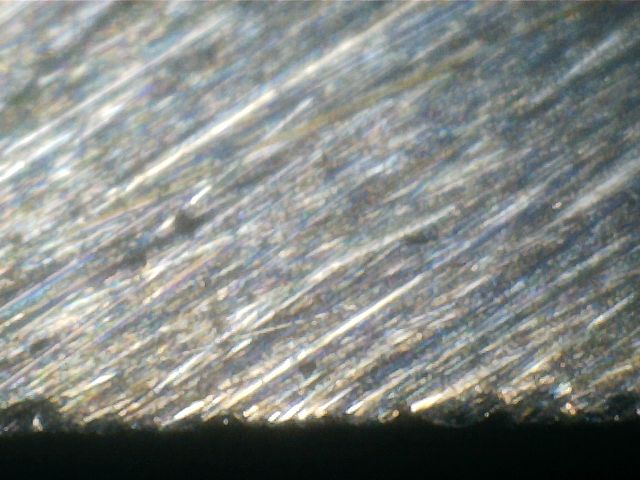

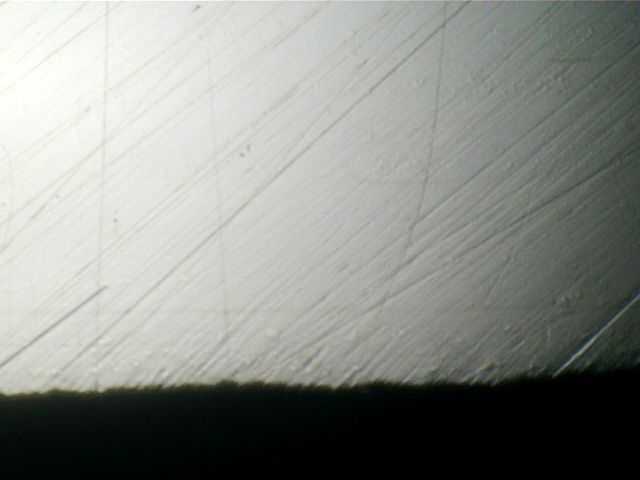

You’ve asked a tough question! I approach diamonds in terms of their depth of scratch. Diamond plates abrade the deepest, next are diamond films, then strops. This holds true regardless of the grit size. For example, if you take a 3 micron DMT diamond plate, a 3 micron film, and a 4 micron loaded strop, you will see the wide range of scratch differences. I’ve taken the liberty to do that for you…

The first picture is a control pic, having progressed (quickly and dirty) through a 400, 2K Chosera, then a 5K, 15K, 30K Shapton. Ignore the edge, as this was just a bevel experiment to show scratches. I hit the DMT EE for 50 strokes, then reset the edge with the 2K, 5K, 15K, 30K. Then 50 strokes with the 3 micron Jende Diamond Film, reset the edge again from 2K through 30K, and then used the Jende Nanocloth strop with 4 micron poly diamond emulsion for 50 strokes.

The 30K is the white part of the control picture. The residual scratches you see are from lower grits. Like I said, it was quick and dirty…You can plainly see the DMT aggression – the mirror finish is completely removed, and at the macro level, the scratches are very visible. With the 3 micron diamond film, you clearly have scratches that do not disrupt the mirror finish, and actually look much better than the control pic! and at the 4 micron poly emulsion (close enough to 3 micron), the scratches at the angle are there, they are just minimal depth.

So to put this all together, I like plates for aggression, films for general use, including minor aggression (we have 80 micron down to 0.5 micron, so it basically acts as sharpening stones, which are slightly more aggressive than films), and strops for finishing.

As for which strops when, I personally prefer nanocloth strops with emulsions or sprays, and I reserve the clean roo and cow for final stropping only.

I hope I answered the question..

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

03/29/2017 at 2:46 am #38018Thanks a lot, Tom. That all makes very good sense and gives good advice. (And I knew strops are a lot less aggressive than stones, but to be honest I had no clue about films.)

Still one question about the photographs of the film and the poly-emulsion. To be honest, the result of the 3 micron film looks at least as smooth to me as that of the 4 micron strops. I know the stropping compound is 4 micron and the film 3, but I’d expect the strops to result in a smoother surface. Is it my eyes? Or the focal depth of the photographs? Or something else?

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/30/2017 at 12:44 am #38043They are similar at this level. The nanocloth/emulsion scratches are slightly more shallow, but nothing like the DMT

The real difference will show at finer levels, especially around the 1 micron and finer. Also, 4/3 micron is the overlap between sharpening and polishing, and a lot of sharpening can end at 4 micron, or continue onward from that level. So if you sharpen your hunter skinner to 2K and strop with the nanocloth, you are polishing the 2K grooves, whereas you would be imparting a “true grit” edge if you used the 3 micron diamond film – which may or may not be what you want.

04/01/2017 at 10:04 am #38071Tom, if you are trying to go for HHT-5, what is your personal order of films and stropping compounds? (And which strop backings?)

Molecule Polishing: my blog about sharpening with the Wicked Edge

04/02/2017 at 2:18 am #38080Well, I’m a little biased toward Shapton stones, as you may know… If you are going for the ultimate HHT, I’m a firm believer that you need to use a flat surface as long as possible. I usually use stones up to 30K, then just tickle the edge of the edge with 0.1 or finer on Jende nanocloth for 5 strokes, then strop on clean leather/roo/horse for only 5 strokes to align the edge.

At this point you have to ask what the intention of the edge is – are you actually going to shave with it, or are you just going for the HHT-5?

For shaving, Diamond films work very well for this precision up to about the 1 micron level. The 0.5 tends to be finicky in this application – with the PSA you get a small level of compression which is coupled with the actual cutting depth that may actually cut through the edge if it is that thin (especially for straight razors). This may help with the HHT 2-3, ironically. The 0.5 micron non-PSA has no compression, but any debris on the film can cause a bump in the action, which can microchip the edge. To be clear, on more robust edges, this is not so much an issue. It is mainly pertaining to straights. FWIW, I actually prefer the PSA over the non-PSA because of the slight convexing effect, which I find “softens” the cutting depth issue by adding a slight convex to the edge. Then transition to the 0.1 of finer Jende nanocloth for 5 strokes, then 5 strokes on clean leather/roo/horse.

If we’re talking other blades, like knives, that’s a different ball of wax – you will need to go to at least 0.25 micron in most cases to get the edge of the edge to be close enough together. Whittling hair is just not impressive…

Stones leave an edge too thick, even at 30K (we’re talking HHT5, so tree-topping is necessary). Diamond Films will get you there sooner since they basically leave a cleanly micro-serrated edge, so long as the edge stays intact and doesn’t microchip out.

04/02/2017 at 2:43 pm #38085Tom, I don’t quite get it. I understand your love for Shapton stones. But then your strop with 0.1 mu stuff or even finder and go back to 1 micron diamond film (shaving) or 0.25 mu. Won’t you destroy you the edge you made with the 0.1 mu stuff then?

And how should I interpret your last sentence? Are you saying diamond films only after the stones can get you to HHT5?

Molecule Polishing: my blog about sharpening with the Wicked Edge

04/03/2017 at 5:09 am #38101NOOOOOooooo!

After the 30K stone (0.5 micron) I will go to 0.25 or finer on the strop, not the diamond film. If I use the diamond film as a progression, I will go to up to 1 micron, then switch to the strops at 0.25 micron or finer.

To clarify, If I use stones, I won’t use films to finish an edge, but will use nanocloth strops.

1 user thanked author for this post.

04/03/2017 at 6:26 am #3810504/03/2017 at 9:39 am #38106For HHT-5, I go a different route. I first create the bevels I want with the regular progression of diamond plates. Then I switch to films -9µ> 6µ> 3µ> 1.5µ> 1µ> .5µ. Then I switch to emulsions or sprays on kangaroo, starting at 1µ and proceeding to .5µ then .25µ and finishing with .125µ. As Tom said, stones won’t quite get you to HHT-5 on their own. I find that the kangaroo is very effective in stretching the edge, pulling it up into a very fine peak like you do with whipped cream. Using light pressure in the final stages of lapping films and stropping is essential.

-Clay

5 users thanked author for this post.

04/03/2017 at 10:09 am #38110Thanks, Clay. That comes close to my attempts. (Though I still use some “old” HA and mono-diamond stropping sprays which I feel are not ideal.) I never got further than HHT-4.

And maybe not exactly the best place for this question, but I wonder why some people use the 9µ diamond film after the 1500 grit stones. Personally I always use the 6µ diamond film after this stone (based on grit ratings and microscopic images), but I’ve even seen very even scratch patterns on an edge on which I used the 6µ diamond film after the 1000 grit stones.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

04/03/2017 at 10:25 am #38111Thanks, Clay. That comes close to my attempts. (Though I still use some “old” HA and mono-diamond stropping sprays which I feel are not ideal.) And maybe not exactly the best place for this question, but I wonder why some people use the 9µ diamond film after the 1500 grit stones. Personally I always use the 6µ diamond film after this stone (based on grit ratings and microscopic images), but I’ve seen very even scratch patterns on an edge on which I used the 6µ diamond film after the 1000 grit stones.

I think the HA sprays are great and a good value. Jende’s emulsions appear to have a higher concentration of diamonds and seem more efficient.

I don’t always use the 9µ films after the 1500#. Usually I straight to the 6µ but when I’m going for HHT or a highly polished bevel, then I’ll use the 9µ films in the progression to further ensure that I’m getting the scratches out from the diamond plates. In day to day sharpening it’s not worth going the extra distance for me because the transition from 1500# to 6µ is good enough.

-Clay

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.