Need Help with Basics of Using Lapping Film

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Need Help with Basics of Using Lapping Film

- This topic has 114 replies, 12 voices, and was last updated 08/27/2017 at 11:32 am by

sksharp.

-

AuthorPosts

-

07/14/2017 at 1:01 pm #40124

Pinkfloyd, I got nylon collar stops from Zoro. I use those for upper bump stops. Thanks

Marc

Marc

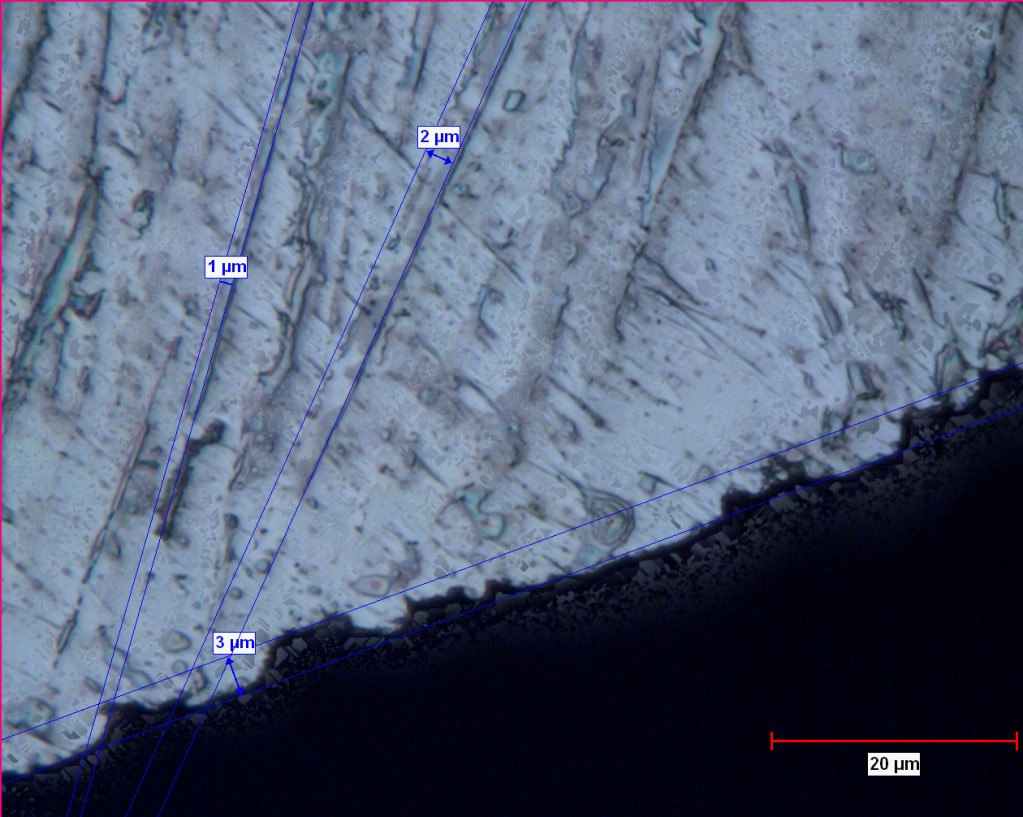

(MarcH's Rack-Its)07/15/2017 at 6:17 am #40139Another setback to my continuing saga to achieve the “perfect” polished mirror edge to an inexpensive EDC. I lost some edge metal again. This time I have no explanation, only a guess. As you can see from the 250X Microscope photo that the bevel is very well polished and I’m only down to 3 micron film.

After sharing my dilemma with a friend and frequent Forum contributor, I learned that some times a pocket of Vanadium in the knife blank can let go. Maybe that’s why. It doesn’t matter. Another do over. The search continues. I’m enjoying this exercise in technique and observation. Marc

After sharing my dilemma with a friend and frequent Forum contributor, I learned that some times a pocket of Vanadium in the knife blank can let go. Maybe that’s why. It doesn’t matter. Another do over. The search continues. I’m enjoying this exercise in technique and observation. Marc To me, that looks like an impact deformation… and there looks to be a scratch or two leading away from it (different than other scratches in the area), that indicate something happened in that area. (Just my guess from the picture).

Just out of curiosity… was this something you could see/feel in use? (If so, how bad did it feel?) Or just noticed it under the scope?

07/15/2017 at 7:29 am #40140This I just noticed while sliding the scope to view along the edge. I had been using minimal pressure edge trailing strokes. I had no collisions to the edge that I know of.

I started over with a perpendicular longitudinal scrub over the apex from heel to tip to heel to remove any weak material. Then started again at 500 grit.

I called it done yesterday. I carried out the progression with the films only down to 1.0 micron. At this point I started to experience or observe fine scratches, (250X).

I can’t say if the scratches were applied, by me, or if they were underlying scratches finally making they’re way to the surfaces as I removed material while polishing. The edge at this point is incredibly sharp.

From here, I lowered my angle settings by 1-1/2 degrees per side to 18.5 degrees and stropped the edge. First with 1.0 micron diamond emulsion spray from WE on Cow Leather Strops. Followed and finished with 0.5 micron emulsion.

The edge is very cleanly polished and mirror reflective.

I have some things to look at to see if I can improve my results. Then I’ll try again on another EDC.Marc

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

07/15/2017 at 8:19 am #40145That’s a beautiful edge Marc. How long do you estimate that it took you starting from your final do-over?

1 user thanked author for this post.

07/15/2017 at 8:19 am #40146Something that small could have been there for a while, and just didn’t get worked out… or done without even knowing when it occurred. Just an option to consider.

At any rate… edge looks good!

1 user thanked author for this post.

07/15/2017 at 8:59 am #40147I probably had a couple hours in it. I just pittle along. I stop and inspect and photograph with the microscope. That’s tremendously time consuming since you’re visualizing only a very small swatch of the bevel at a time. For me it was a study in cause and effect and refinement of technique. I observe the scratch pattern as I vary my finger placement up and down along the stones while varying my pressure applied. I’ve had a pretty good idea of this correlation for sometime. I was verifying and documenting it, for what reason, I don’t know.

The knife is very very sharp and very shiny. It’s not the “perfect” polished bevel I was looking to achieve. I still haven’t gotten the answer to the question I posed to the true professionals, are your beautifully photographed mirror polished bevels without micro-scratches and blemishes? I don’t yet know how to capture a good bevel photograph. I have learned you can focus on the reflected image and avoid showing the flaws.

I’ll continue to practice and strive for my perfect polish.

Marc

(MarcH's Rack-Its)07/15/2017 at 10:26 am #40148I recently came across an interesting video on the USA Knife Maker web site. They demonstrate the use of foil and cryo in heat treating. Check it out at this link.

Scroll a bit down the page to find the video.

2 users thanked author for this post.

07/15/2017 at 11:09 am #40149That edge looks great, Marc! Thanks for sharing some of your methods.

1 user thanked author for this post.

07/15/2017 at 1:14 pm #40150Tom, I really doubt my Japanese Chef’s Knives are hardened to such exacting specifications!

Marc

(MarcH's Rack-Its)07/15/2017 at 1:21 pm #40151Hi Marc, interesting results! I see that you skipped the 0.5um and 0.1um films entirely? Also, is it not perfect polish? It looks like it’s pretty “scratchless” to me.

I just bought all the lapping films and 1.0/0.5 micron diamond emulsion sprays for the final polish. I hope to give them a try soon. Your results have been very interesting for me as I have intention to attempt scratchless, perfect mirror polish edges. I’ve done them in the past but I’m hoping the DLFs will work at higher efficiency than my previous methods.

1 user thanked author for this post.

07/15/2017 at 2:41 pm #40152Hi Marc, I think it’s nearly impossible to identify the reason for the deformation of the edge you showed last. It’s too long ago and you cannot remember any mistakes. Also, I have never had such deformations in my edges (as far as I am aware of), so there could be a couple of reasons you were not aware of.

But first the indent. I measure it as around 2 cm. With a magnification of 250, the indent is 8 mm or 0.8 cm. Is this correct? it sounds like rather large.

A couple of thoughts.

- Curtis’ first reply points to the scratches. This was something that also occurred to me. It could be something that went wrong during sharpening, even though you didn’t notice it. (And maybe it was a clump of vanadium or other material that got removed.) Anyway, an impact deformation to me still seems the most likely reason.

- It could still be an indent that was there originally already, but you didn’t notice it.

Whatever it is, I would redo the entire edge starting with the 100 grit stones. If you didn’t do this already, I’d certainly do it now. It could, of course, be something with the heat treat, but it seems unlikely to me.

I still haven’t gotten the answer to the question I posed to the true professionals, are your beautifully photographed mirror polished bevels without micro-scratches and blemishes? I don’t yet know how to capture a good bevel photograph. I have learned you can focus on the reflected image and avoid showing the flaws.

A good bevel photograph is very difficult also in my experience. The most difficult thing is not the focusing, but getting the light right. As you say, it is usually easily to create a shiny photograph that shows no scratches at all. I have only a little advice for you: to try a lot of angles, light sources, and backgrounds. Removing the knife from the clamp and putting it on some contrasting background often also helps. My personal experience is that there will always be very small scratches that show under a microscope, even if it’s only because I now have a 500x microscope. It’s very hard if not impossible to remove them all. However, when you’re out for a perfect mirror edge, the WE pastes help a lot. They don’t only sharpen, but also burnish, which really smoothes the edges.

I also wrote a number of blogs on stropping and related items that may be of interest: https://moleculepolishing.wordpress.com/category/stropping/.

But finally, you showed us a very good looking edge

.

.Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

07/15/2017 at 2:50 pm #40153I have seen that video and also read a lot of Verhoeven and others relative to cryo heat treatment and its effect on the steel and, therefore, the “edge”. Since the edge is what we are all dealing with using the WEPS, I personally feel that it is very important and I will not buy another knife unless I know what was done. I will spend $500 for a kitchen knife that is done right just like I will spend $12 or more for a six pack of IPA — cause it is worth it. That being said while I will risk a new unknown six pack at that price, I will not do the same for a $500 knife.

The 2 guys (acting like clowns) in the video are just dipping the knife in liquid nitro — that is not real cyro treatment.

I also think that people like us who spend $1000+ to put the most resilient edge on our knives would be very interested in the material we are sharpening. Poor steel and/or heat treating will give you issues all day long like in the attached photo below. I also attached a part of a Verhoeven paper and another very interesting pdf from Linde (although they are an equipment seller). The Americans and Germans do cryo, the Japanese pretty much do not (as far as I know). Just trying to generate good discussion.

So again I ask, do you know who I can trust to make me such a knife ?

https://drive.google.com/open?id=0B5t7FJ9Zmj1hQ0NlaDZwaVdia2chttps://drive.google.com/open?id=0B5t7FJ9Zmj1hSFk2MWdCN29qY1k

Verhoeven’s Heat Treatment for Bladesmiths: https://drive.google.com/open?id=0B5t7FJ9Zmj1hWEdoNFJ1SjdWSEU

General animation: https://www.youtube.com/watch?v=jFUI4kWs13U

07/15/2017 at 3:03 pm #40154I read in this stream “if they were underlying scratches finally making they’re way to the surfaces as I removed material while polishing”.

Is that possible ?

1 user thanked author for this post.

07/15/2017 at 3:06 pm #40155I don’t think scratchless, perfect mirror finishes are possible. It just depends on how strong your magnification is. You probably need to qualify “scratchless, perfect mirror finish” at ___x magnification.

07/15/2017 at 7:02 pm #40157Readheads,

Have you contacted any knife makers directly? The only way to know if they will do the heat treatment the way you want it done is to ask. I honestly don’t know which makers to direct you toward. I get that you feel it’s imperative to know what you’re paying for (which is far from unreasonable), but I have a feeling that you’re going to be hard pressed to get a knife maker to divulge their process or agree to change what they usually do to fit your request. My guess is that the majority of knife makers will not have read the materials science research that you’ve cited or have the equipment to properly execute the cryogenic heat treatment process. If you do find a knife maker that will do it for you, please share about it with us.

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.