AProblem with alignment guide and rods

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › AProblem with alignment guide and rods

- This topic has 16 replies, 9 voices, and was last updated 12/24/2016 at 6:04 am by

Frans.

-

AuthorPosts

-

11/02/2016 at 8:09 am #35664

Well, yesterday I received the package with the Alignment Guide and the 12″ rods but I am not happy to say the least….

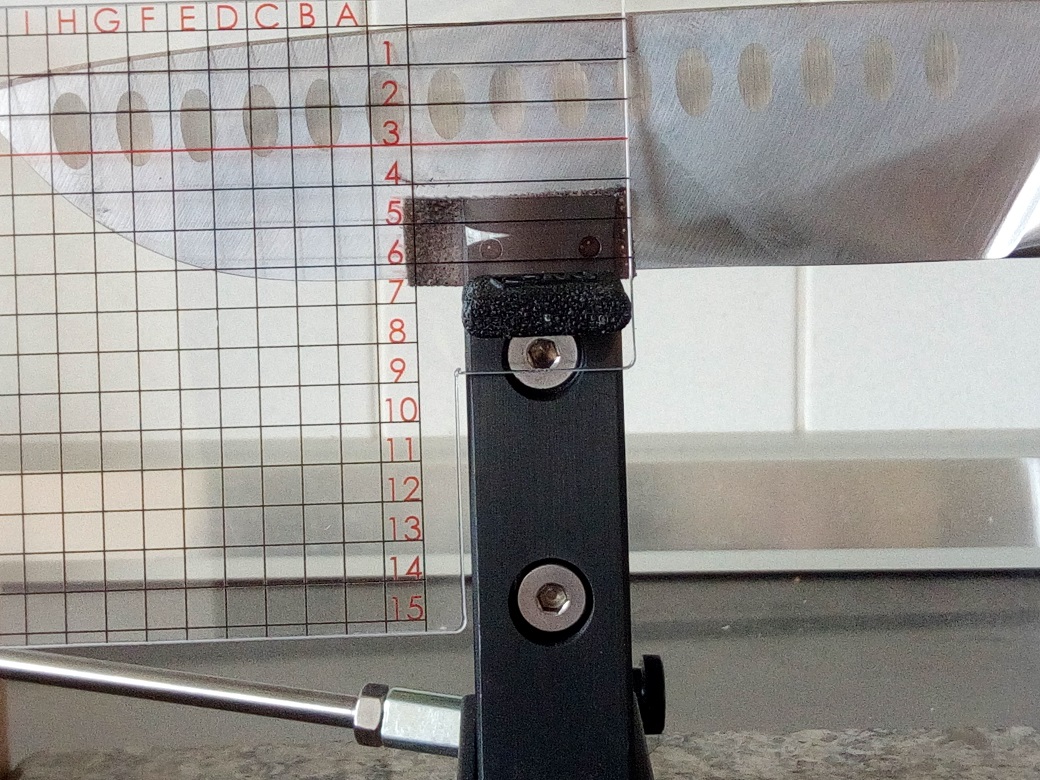

The Alignment Guide when used with the lower depth key holes, blocks the clamping screw making it almost impossible to tighten the knife while using the guide for the correct position.

The 12″ rods are 0.3 mm thicker than my 8″ rods which at first seems to be good because there was a little less play while used with the diamond stones but when I switched to the 3 micron/glass and the 1200/1600 ceramics, both had problems with one of the stones being to tight and not sliding smoothly.

I must admit that at this point I am beginning to feel disappointment about the whole system as this is not the first problem I have had.

When I bought the system years ago, I got the first version which had a problem with play in the rods for which a free fix became available but I choose to upgrade to the ball joint assembly. Unfortunately, I received the version which also had a problem Angle off by 3 degrees with upgrade set. – Wicked Edge Precision Knife Sharpener This problem was also fixed by sending me a new set .

The next problem I had was with the 1200/1600 ceramics which were chalky, chipped at the edges and had a big crack. Again this was solved by sending me a new set.

So, Wicked Edge has always solved the problems and I certainly have no complaints about the response or customer service and I still think it is a very good system. Maybe I just had bad luck but I am starting to loose confidence.

Attachments:

You must be logged in to access attached files.

11/02/2016 at 10:11 am #35667I suppose you could drill a hole in the AAG to give you access to the upper screw, but before you put the AAG in place, you should already have set the upper screw to its correct position; which is in most cases to set the gap at the jaws to the thickness of the blade. Then, with the blade held lightly by the upper screw, to move the blade to your desired AAG setting and then to tighten the lower screw.

11/02/2016 at 10:25 am #35668As for the rod being thicker than previous-generation rods, I think the handles are all the same part number. The colored plates are attached to the handle with screws.

I run with very tight tolerances between my rods and my handles, which have bronze bushings installed. I find it necessary to wipe the rods with a little alcohol once in a while, and occasionally I’ll run a .22 caliber bronze bristle cleaning brush with solvent through them to clean the bores of my handles. I suppose it is possible that you have a faulty handle, but less likely that the rod diameter is at fault. I’m sure it is the same diameter as WE is selling to everybody. I’m not aware of a diameter change – but it could be they increased the diameter to improve the level of precision. Since your other handles seem to work well, I’d focus on the bores of the sticky handles. Try cleaning them and let’s see what happens. And please tell us exactly what the new rod diameter is.

1 user thanked author for this post.

11/02/2016 at 11:17 am #35670Yes, I already thought about drilling a hole in the AAG which will solve the problem.

My 8″ rods are 6.3mm – 6.4mm and the 12″ rods are 6.5mm – 6.6mm but I do think that the problem is with the handles and not with the rods. I cleaned the rods and bores of the handles with rubbing alcohol and also tried a drop of oil but neither solved the problem and I do not feel like using a drill or a file to enlarge the holes.

Clay has already contacted me and offered help so I am sure it will be solved and compliments for the quick response, customer service is excellent once again but I still believe that quality control can be improved.

11/02/2016 at 11:23 am #35671…but I still believe that quality control can be improved.

No argument there. It’s premature to announce anything, but we’ve taken some huge steps in the last few months with our supply/manufacturing chain and we should see much fewer issues with QC. In the next few months we will be able to announce the changes but for now, I am comfortable saying that I’m really excited about where things are headed.

-Clay

1 user thanked author for this post.

11/02/2016 at 11:28 am #35672there was a little less play while used with the diamond stones but when I switched to the 3 micron/glass and the 1200/1600 ceramics, both had problems with one of the stones being to tight and not sliding smoothly.

We can send you new 3µ/glass stones but we’re going to be discontinuing that product because of quality issues with the DMT stones. We’re replacing those stones with 1500# diamond stones from the same source that supplies our other diamond stones and they’re much better. The new stones will be in by mid November and I’d love for you to have those instead if you can wait.

-Clay

3 users thanked author for this post.

11/02/2016 at 2:35 pm #35673We can send you new 3µ/glass stones but we’re going to be discontinuing that product because of quality issues with the DMT stones. We’re replacing those stones with 1500# diamond stones from the same source that supplies our other diamond stones and they’re much better. The new stones will be in by mid November and I’d love for you to have those instead if you can wait.

Great move!

The other stones are much better than the DMT stones.

The other stones are much better than the DMT stones.Molecule Polishing: my blog about sharpening with the Wicked Edge

11/02/2016 at 7:29 pm #35676We can send you new 3µ/glass stones but we’re going to be discontinuing that product because of quality issues with the DMT stones. We’re replacing those stones with 1500# diamond stones from the same source that supplies our other diamond stones and they’re much better. The new stones will be in by mid November and I’d love for you to have those instead if you can wait.

Great move!

The other stones are much better than the DMT stones.

The other stones are much better than the DMT stones. I will be on board for the 1500# stones as well. A great addition to the stable. Any thoughts on 1200# diamond stones before I commit to ceramics?

11/03/2016 at 6:09 am #35685I agree, I’ll buy them too. It will save some cost on the lapping film.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162211/03/2016 at 6:12 am #35686We can send you new 3µ/glass stones but we’re going to be discontinuing that product because of quality issues with the DMT stones. We’re replacing those stones with 1500# diamond stones from the same source that supplies our other diamond stones and they’re much better. The new stones will be in by mid November and I’d love for you to have those instead if you can wait.

Thanks Clay, I agree that there were quality issues with the DMT stones and I am glad to hear that you made the decision to switch to the 1500# stones from your current supplier as I think that the other stones from that supplier are absolute top quality. I can certainly wait and would be very pleased to receive the new ones instead.

11/03/2016 at 6:40 am #35687…but I still believe that quality control can be improved.

No argument there. It’s premature to announce anything, but we’ve taken some huge steps in the last few months with our supply/manufacturing chain and we should see much fewer issues with QC. In the next few months we will be able to announce the changes but for now, I am comfortable saying that I’m really excited about where things are headed.

That sounds very good, looking forward to the announcements.

11/03/2016 at 8:24 am #35691We’re replacing those stones with 1500# diamond stones from the same source that supplies our other diamond stones and they’re much better.

I’m curious! 1500 and glass blank combo or will it actually be something like 1200/1500 diamond combo?

11/03/2016 at 8:55 am #35692We’re replacing those stones with 1500# diamond stones from the same source that supplies our other diamond stones and they’re much better.

I’m curious! 1500 and glass blank combo or will it actually be something like 1200/1500 diamond combo?

I would vote for 1500/2000 combo. China makes these grits .

11/03/2016 at 5:11 pm #35698I would vote for 1500/2000 combo. China makes these grits .Dulledge: Have you tried these China-made stones yet?11/03/2016 at 7:55 pm #35699I would vote for 1500/2000 combo. China makes these grits .Dulledge: Have you tried these China-made stones yet?I do have them. But I am very rookie in sharpening and can’t judge them. And I have nothing to compare them with. I do not have WE yet. WE is still on my bucket list.

I just wanted to say that these diamond plates grits do exists, so WE can make them too.

-

AuthorPosts

- You must be logged in to reply to this topic.