Jamey Howard

Forum Replies Created

-

AuthorPosts

-

02/28/2014 at 3:18 am #17466

I’ve read through this whole thread but I still don’t get how the Swat thing works because I’m a dunce.

Please could anybody who has one (Clay? Curtis?) do a video of how to use it?

02/11/2014 at 8:54 pm #17052Sure there are… examples of a few

* J.A. Henckel Cermax MC66 knives, e.g. TWIN Cermax MD67

* Search zdp-189 in CKTG site

* konosuke zdp 189Cool, I’ll have a look around then.

Expect a forum post from me in future entitled “My new ZDP-189 knife won’t sharpen at 6 degrees per side and now I’ve ruined it”

02/11/2014 at 8:05 pm #17048Practically none below 15Ëšas said really fine angles are just not practical in general…

Well, I disagree with that, but obviously it does hinge on your own personal definition of “practical”.

What I will say is this… Almost every knife I have sharpened since I first got the WE has been below 15 degrees per side, even before I had the low angle adapter.

Most of the knives I have done have been between 12.5 – 14 degrees per side.

I much prefer them at this angle, they feel much sharper, much nicer to use and I’m careful with the way I use knives so they don’t get damaged too quickly.

Obviously they are going to need sharpening again sooner than if I used a flatter angle, but I don’t mind that… I bought the Wicked Edge because I enjoy sharpening, so I’m always happy to touch up knives to keep them working well, and I don’t mind doing it a little sooner in exchange for sharper knives.

Now a lot of my knives couldn’t handle any lower than the angles mentioned above but the few knives I have in good steels are ones I would expect to be able to go down to 10 degrees really. And like I said, my Akifusa Gyuto is/was fine with ten degrees per side and slices beautifully. But like I said that’s a PM steel, not a carbon steel.

So maybe the key is to use hard PM steels instead of hard carbon ones.

Sadly I don’t think anybody makes a kitchen knife in ZDP-189, do they?

02/11/2014 at 7:38 pm #17046Cheers, but I didn’t ask for an appraisal of my knife skills

I asked which steels (or which knives) can hold a low angle.

02/11/2014 at 5:36 pm #17041Cheers guys… My natural follow-up question is this… If carbon steel can’t handle low angles then what steel can?

I want to find something I can put a very low angle on, and ideally I want it to be a very hard steel (above 63 RC really) so it will be able to hold it for as long as possible before needing to be sharpened again.

I thought there were loads of Japanese knives that were single-sides (IE bevel on one side, other side is flat) that had really steep angles, around 15-17 degrees inclusive? What are they made from, and how do they avoid chipping?

As for this knife, I’ll probably ‘destress’ the edge as described in the other thread by Cliff Stamp, just make one or two cuts into a stone to remove the metal at the edge, then sharpen at 15 degrees per side. But I’m not sure how sharp that will be, as I said it wasn’t super-sharp out of the box.

I’m not going to bother convexing it because I’ve never been massively impressed by convex edges to be honest.

02/09/2014 at 3:33 am #16994Cheers Leo. If the white carbon steel can’t handle the low angles without chipping then how are you meant to thin behind the edge? How can you do a 7-degree shenogi, or any kind of secondary bevel if it just chips once it gets thin?

I’m not too fussed about convex edges so I’m happy to have a plain V-edge, and I guess 15 degrees per side is decent, but I was just hoping that this steel would be able to take and hold a very fine edge and I’m disappointed I guess.

Cheers though.

Sent from my iPhone using Tapatalk

01/22/2014 at 1:47 am #16537No worries Clay, all’s well that ends well.

01/21/2014 at 9:41 pm #16533Hi flyboy320, welcome to the forum.

There might be different opinions on this from other people but my personal view is that the 100/200 & 400/600 stones will be fine for kitchen use. In fact there have been a couple of times with my cheaper knives when I stopped at 400 or even 200 just to deliberately give the knife a rougher, toothier edge to slice with.

But the beauty of the WE system is that you can add stones later and upgrade parts without having to replace the whole thing, so if you decided you wanted the 800/1000 stones you could just buy them further down the line.

But for the kitchen I think you’ll be very happy with the basic kit, at least to begin with. It’s still better than any other sharpener I’ve ever used. just remember you do need to attach it to some kind of base. You don’t have to buy one yourself, you could make one, but it does need to be bolted down to something heavy in order to work.

01/21/2014 at 3:16 pm #16530Good news, the 10-32 UNF screws are indeed the correct ones.

Using a 5/16″ length grub screw I was able to get enough torque/clamping force to sharpen my Benchmade Griptilian despite the smaller size hex key that goes inside the grub screws compared to screws with a head on them.

But I bought a selection of headed lengths as well (both countersunk and rounded head)in case I want to try them. I suspect they’ll be handy for ‘taller’ blades like kitcken knives, where there’s more length between the edge and the spine.

01/20/2014 at 6:20 pm #16522Exciting news! I have the 10-32 UNF screws here at my desk and they look much more likely to fit. Will post another update later as I know you’re all on the edges of your seats waiting to find out the answer

I’ll see how the grub screws feel for torque, and whether the smaller hex key seems like it’s going to snap under the strain.

01/17/2014 at 7:03 pm #16494Aha, 10-32 UNF !!

Of course, that makes sense now. Like an idiot I was looking in the UNC section of websites for number 10 screws with a higher thread count and coming up blank, but obviously I should have been looking in UNF sections, much more sensible.

Thank you, I should now have everything I need to purchase the right stuff for myself, much appreciated.

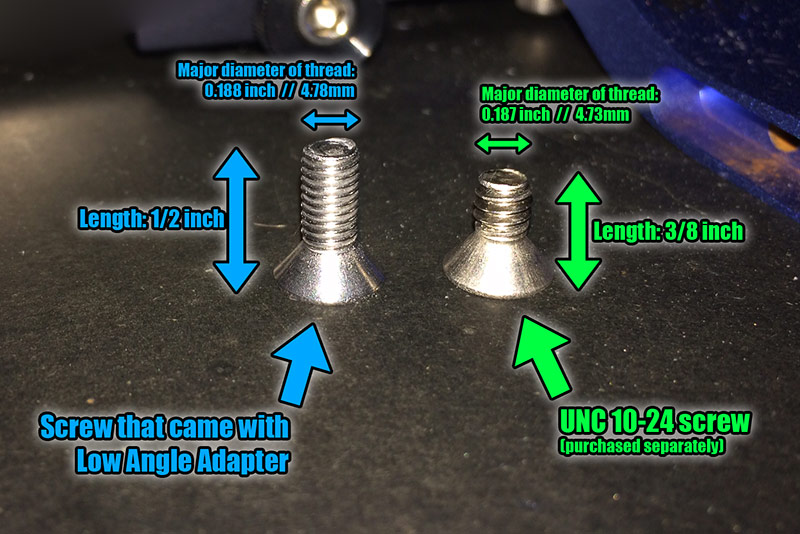

01/16/2014 at 2:00 am #16466As promised here is the pic for comparison. Like I said, I knew as soon as I looked at the thread in the flesh that they weren’t going to fit.

01/16/2014 at 12:33 am #16464

01/16/2014 at 12:33 am #16464Confirmed, the LA adapter does NOT use 10-24 screws, these ones do not fit. I’ll post some pics later.

Sent from my iPhone using Tapatalk

01/15/2014 at 8:30 pm #16459Cheers Leo, the ones I ordered were definitely UNC 10-24, no doubt, they’re not metric.

I don’t really know where I might find a place like you describe, I guess there might be one around but I’ll have to look.

I think I might just have to wait for the WE guys or Bob Oldawan to get back online. But I’m not sure if they have grub screws? Even a shorter screw for the bottom hole won’t really change much if it still has a head on it because it will still protrude a fair bit.

01/15/2014 at 6:15 pm #16457Ok, it feels a bit like I’m just talking to myself in this thread. I know it’s not the most exciting subject matter in the world though

Anyway… The new screws just arrived at my desk at work so haven’t had a chance to try them yet but right away just from looking at them I don’t think that these are going to be the correct thread size / pitch / whatever.

Obviously I’ll check when I get home this evening but my suspicion right now is that the LA adapter screws are not 10-24 but something else instead.

Which is a shame if true, because if anyone from the WE staff had been able to post a reply here this week it would have saved me a few quid but never mind, it’s not the end of the world.

Will post back this evening to let you all know in case anyone is following this thread and looking to get some replacement screws themselves.

-

AuthorPosts