Low angle adapter screws (Solved: 10-32 UNF)

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › Low angle adapter screws (Solved: 10-32 UNF)

- This topic has 19 replies, 6 voices, and was last updated 01/22/2014 at 9:08 pm by

Mark76.

-

AuthorPosts

-

01/13/2014 at 3:48 am #16411

Hello all. Very quick question (hopefully) – am I right in thinking the screws in the low-angle adapter are 10-24 screws? Is there anything else I would need to know to search for some replacements in different lengths?

I’ve tried my new one out today but I need shorter screws and for the bottom hole I want one without a head. Is grub screw the right term? Anyway the hole isn’t countersunk so I want a short one with no head on it.

Have already pinged an email to Bob Oldawan (yet another shout out for amazing customer service, thank you Bob) but in the meantime thought I’d see if I can find some myself here in the UK despite being a bit of a DIY/tool dunce.

All help gratefully received. Ta.

01/13/2014 at 5:19 pm #16418Anyone? Official Wicked Edge staff peoples, can you confirm?

I’m standing by, ready to place an order for a couple of different lengths from this page:

http://www.a2stainless.co.uk/10-24-3-16-diameter_B23SRW.aspxJust need someone to confirm, pretty please? 🙂

01/13/2014 at 6:34 pm #16419Best off phoning since this will be you quickest route to an answer bear in mimd its still early in the morning I doubt they are in work yet

01/13/2014 at 9:52 pm #16421Cheers for the suggestion Leo, I called just now (would have been about 10:30am New Mexico time, was 5:30pm UK time) but it went to voicemail so I left them a message just asking if they could reply here on the forum as then everyone can see the answer and it’s searchable for the future.

01/13/2014 at 10:17 pm #16423Is WEPS at the Shot show this week?

Just checked the Home page. Most of WEPS staff is at the shot show this week, so, it may take a while to hear back from them.

According to this thread, they are 10-24

01/13/2014 at 10:47 pm #16424According to this thread, they are 10-24

Thanks Mikedoh, I’d read that thread before but wanted to double check here and make sure before I go ahead and order.

I did read elsewhere that 10-24 screws have a major diameter of 0.19 inches so might measure the ones I’ve already got with my caliper later and if they turn out to be 0.19 inches I may just go ahead and order anyway.

01/14/2014 at 3:50 am #16428Right well, being rather an impatient chap I’ve gone ahead and ordered some 10-24 screws. I went for some 3/8″ grub screws and some 1/4″ grub screws for the bottom of the LA adapter and I also ordered some 3/8″ countersunk screws for the top of the LA adapter.

I would have also ordered some 1/4″ countersunk ones but they don’t seem to sell them, maybe they’re just too short or something.

01/15/2014 at 6:15 pm #16457Ok, it feels a bit like I’m just talking to myself in this thread. I know it’s not the most exciting subject matter in the world though 🙂

Anyway… The new screws just arrived at my desk at work so haven’t had a chance to try them yet but right away just from looking at them I don’t think that these are going to be the correct thread size / pitch / whatever.

Obviously I’ll check when I get home this evening but my suspicion right now is that the LA adapter screws are not 10-24 but something else instead.

Which is a shame if true, because if anyone from the WE staff had been able to post a reply here this week it would have saved me a few quid but never mind, it’s not the end of the world.

Will post back this evening to let you all know in case anyone is following this thread and looking to get some replacement screws themselves.

01/15/2014 at 8:07 pm #16458I would take the original screws to a shop specialising in fastenings or an engineering company who can measure the thread pitch and sizes properly all too often people do not assume that there is only one size the correct size and will try to palm you off with something close to what you want at least in England there should still be a fair demand for imperial machine screws. If the thread looks wrong perhaps they have tried to give you something metric which is close.

If you can spare the time it may be necessary to go to an industrial estate (or a large old fashioned iron mongers if any exist near you)I am sure you will get it I would take the low angle adapter as well so that there can be no room for error this would be the way I would go and if one place cannot do it I would imagine they will point you in the right direction.

Only other suggestion would be to wait to the WE staff are back in the office (but nurturing a relationship with an engineering shop is not a bad thing ) good luck.01/15/2014 at 8:30 pm #16459Cheers Leo, the ones I ordered were definitely UNC 10-24, no doubt, they’re not metric.

I don’t really know where I might find a place like you describe, I guess there might be one around but I’ll have to look.

I think I might just have to wait for the WE guys or Bob Oldawan to get back online. But I’m not sure if they have grub screws? Even a shorter screw for the bottom hole won’t really change much if it still has a head on it because it will still protrude a fair bit.

01/15/2014 at 9:36 pm #16460I would think that a decent hardware store, one that has a good assortment of nuts, bolts, screws would have thread checkers and gauges to determine the size you need from what came with the LA adaptor.

Our “big box” hardware stores ( Lowes, etc) have them, as should any good hardware store. Auto parts stores, mechanics, machine shops, etc would be other likely places to have thread checkers etc. I bought checkers for myself off amazon. Don’t have the LA adaptor, so can’t check for you.

If you do go out locally to find out your self, might want to take the adaptor and screw both along . Either can be checked with the proper tools.

You may still need to order online if what you are after is a bit uncommon.

01/16/2014 at 12:33 am #16464Confirmed, the LA adapter does NOT use 10-24 screws, these ones do not fit. I’ll post some pics later.

Sent from my iPhone using Tapatalk

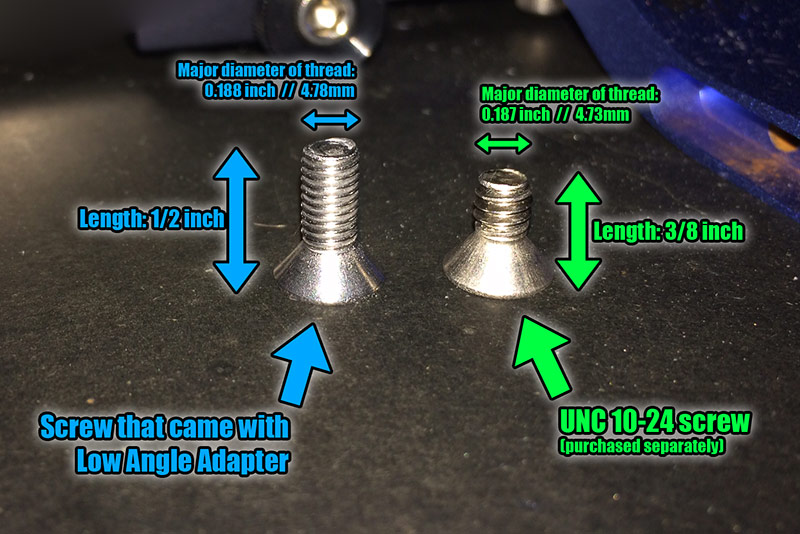

01/16/2014 at 2:00 am #16466As promised here is the pic for comparison. Like I said, I knew as soon as I looked at the thread in the flesh that they weren’t going to fit.

01/17/2014 at 11:05 am #16487

01/17/2014 at 11:05 am #16487The screws on my Low-Angle Adapter are 10-32 UNF; fine thread as opposed to the 10-24 UNC which is coarse thread. That also jives with your photograph.

Number 10 screws are supposed to be 3/16″ nominal, which is 0.1875″ diameter.

Generally, fine threads are used to get more engagement with the material. Coarse threads are used where pull strength is not that important, or where the material is soft. The shallower depth of fine threads would more easily shear and pull out of a soft material. In the case of the Low-Angle Adapter, the strength of the aluminum alloy is high enough that fine threads are the better answer. At least I’m assuming that whoever is doing Wicked Edge’s engineering has come to those conclusions.

My LAA also came with flat-head screws for both upper and lower positions, although there is no countersink at the lower position. A machine set screw would eliminate the head, but you’d need an additional wrench and a very small one at that. The wrench and socket may be too wimpy to produce the required torque. That all would explain why they used a flat-head screw. Same tool, more torque. Better to use the flat-head screw and grind away the unnecessary countersink flange. If the screw still sticks out too far, grind some length off the business end. Buy another 10-32 screw if you need to go back to the longer screw.

If you like, I have some stainless socket-head cap screws in 10-32. Send me a personal mail with your address and I’ll send you a couple.

01/17/2014 at 7:03 pm #16494Aha, 10-32 UNF !!

Of course, that makes sense now. Like an idiot I was looking in the UNC section of websites for number 10 screws with a higher thread count and coming up blank, but obviously I should have been looking in UNF sections, much more sensible.

Thank you, I should now have everything I need to purchase the right stuff for myself, much appreciated.

-

AuthorPosts

- You must be logged in to reply to this topic.