zdp189 miyabi being a real pain

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › zdp189 miyabi being a real pain

- This topic has 5 replies, 6 voices, and was last updated 09/24/2014 at 1:49 am by

Mark76.

-

AuthorPosts

-

09/03/2014 at 3:03 am #20155

Hey there guys, I’m having some problems with some of my pm steels specifically trying to get them sharp, I’ve apexed the edge, obtained burrs on both sides, but the edge is very rough and not even close to hair popping. I started with 400 diamond all the way through 1200/1600, micron ceramics, 2000/3000 whetstone,and stoped from 14um to .25um from balsa, leather, to nano cloth. I apexed the edge at 800 grit and it still wasn’t even close to a proper edge. When I moved to the strops I lowered it two degrees from 14 degree each side to 12 degrees. This is the third time of gone at it with this knife and I’m starting to feel defeated. I looked up other people’s inquiries about zdp189 and found using light pressure and patience would help but I can’t seem to find the proper technique to sharpen this cool steel. Does anyone have any other suggestions when sharpening zdp189 or any other pm steels. Please help:(

09/03/2014 at 4:34 am #20158I have found that sometimes when I get frustrated and tired that it helps for me to leave the sharpening session for a bit and come back later…. Preferably after a good night of sleep

09/03/2014 at 7:50 am #20159I think your angles are too high.The angle of each blade is honed by an artisan to 9.5 – 12 degrees per side. The acute angle in concert with the Honbazuke method yields scalpel-like sharpness.

Another thought is that with low angles the blade flexes slightly so it is important to let the stones (plates) do the work so just enough to engage the grit otherwise the pressure may well be varying the angles as you work away resulting in all sorts of angles at the edge this could be what is happening to you.

I suggest going for an even pressure and speed and keep reviewing the edge with a loupe .09/22/2014 at 9:51 pm #20406Hey there guys, I’m having some problems with some of my pm steels specifically trying to get them sharp […]

Does anyone have any other suggestions when sharpening zdp189 or any other pm steels. Please help:(

I actually wrote about this recently on Spyderco’s forum about ZDP-189 specifically ( http://www.spyderco.com/forumII/viewtopic.php?f=2&t=64857 ). The basic point was that I find that softer stones generally are easier to work with when shaping that type of steel and by shaping I mean the early stages where you are just removing a lot of metal to set the edge at the right angle and remove any damage.

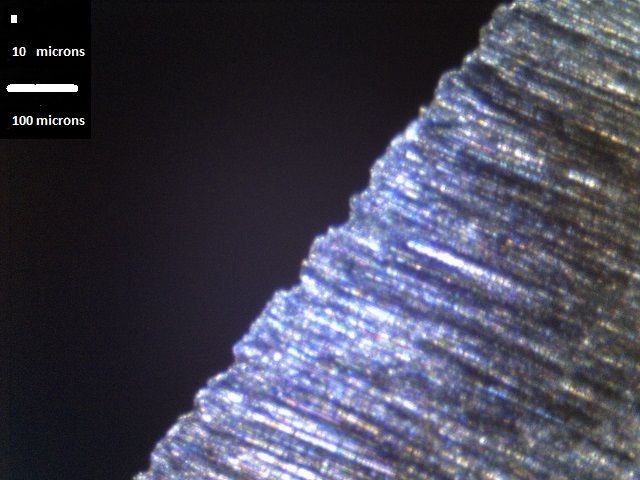

Why, well take a look at this edge on MaxaMet from a 700 X Bester :

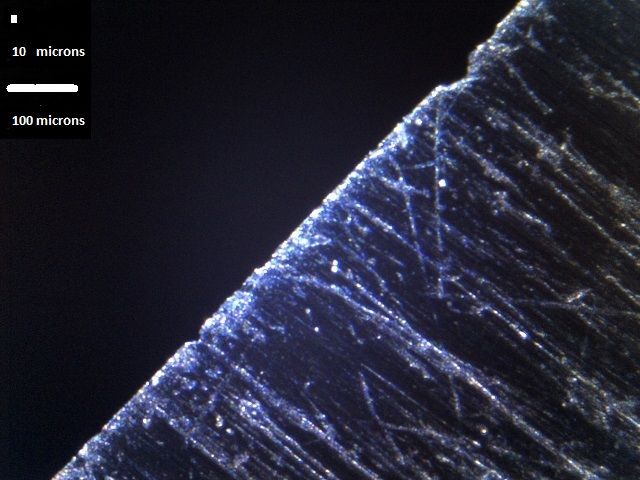

vs a 400X Naniwa Superstone :

The chunk missing on the Naniwa edge was from pre-existing damage, aside from that note how the apex forms much cleaner on the Naniwa (as to why I discuss it in the Spyderco thread in detail) even though the stones cut at very similar speeds. The Naniwa is a much softer stone and cuts in a very different manner from the harsh uni-directional scratches of the Bester.

The net effect is that if you start off with apexing with something like the Bester which is a hard stone on a hard/high-carbide steel you are very likely to fracture the apex. As you work through to higher grits these fractures stick around for a long time and are likely what is causing the problems. Now I am not saying you can’t do it and successfully work those steels on the hard stones, but it does take a little more involvement due to the way the edge fractures. The simplest way to deal with it is to just use the ability of the WE to continuously microbevel each time you change grits.

The critical part is that you have to get rid of the fractures at the apex with each grit, if you don’t and you skip the work you will end up with an edge which looks mirror polished but the edge will be very rough. For example if I start on a S30V blade with a Suehiro ‘Chemical’ 320 and apex it and then jump right to a Naniwa Aotoshi 2k the edge bevel will look reflective, you can easily read from it – but the apex looks like this under magnification :

Note even though the bevel is mainly going reflective (the dark parts are close to mirror), the very apex still has all the roughness of the 320 grit shaping stone. If I had micro-beveled with the Aotoshi instead of polishing the entire bevel this would not have happened. Of course you can polish the entire bevel and then micro-bevel as well.

09/23/2014 at 3:00 am #20413There’s certainly no questioning Leo’s explanation; it’s probably dead-on when it comes to hard edges which won’t seem to take a fine edge.

ZDP-189 is usually hardened to RC 64 or higher and is brittle enough that it’s often laminated inside a tougher, less brittle steel. As Leo suggests, coarse grits tend to chip out particles of the apex, requiring a great deal of work with the next grit stone to re-establish a new, clean apex. Hopefully, the finer grit will either not produce chips or produce smaller chips which are more easily removed.

I didn’t get a clear understanding of exactly what sort of knife you’re working on. If it’s not a kitchen knife, but rather an EDC type working knife, then I’d suggest that 14 dps is way too low. Very low angles exacerbate the aforementioned chipping problems.

09/24/2014 at 1:49 am #20433I think your angles are too high.

If it’s not a kitchen knife, but rather an EDC type working knife, then I’d suggest that 14 dps is way too low. Very low angles exacerbate the aforementioned chipping problems.

Interesting observations, gents 😛 .

Just kidding, I think they both make sense. As far as I know, Miyabi is the new brand by Zwlling Henckels and these are kitchen knives. Very nice knives, actually, and I’m considering to get one.

These knives should be able to carry very low angles. But, as Tom wrote, you’ve got to be careful with such a hard steel at a low angle, since it may (micro-)chip. That’s also why I think Cliff’s advice of using softer stones is sensible. That said, I personally would probably still start of sharpening with the 100 grit stones (using very light pressure).

And, indeed, if chipping becomes a problem, increase the angle, start with a higher grit stone or use a softer stone (Chosera!).

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.