When to switch to next grit?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Basic Techniques and Sharpening Strategies › When to switch to next grit?

- This topic has 21 replies, 6 voices, and was last updated 09/27/2016 at 11:04 am by

wickededge.

wickededge.

-

AuthorPosts

-

09/17/2016 at 12:06 pm #35038

How do you know that you need to switch to next grit? Many thanks to older posts that show that it is not the best practice to raise significant burr on each grit because too much metal will be shaved for no benefit. It is better to raise burr only on starting grit like 100 grit or 200 grit and on next grits only sharpen until scratches from previous grit are removed. Right?

Do you know from experience how many strokes for each particular steel and grit is needed?

Do you use magnification tools like loupe or USB microscope to see scratches, check visually and decide about next grit?

Do you feel by finger or fingernail?

What are your tips for switching to next grit?

09/19/2016 at 2:07 am #35045You’re right about not raising a burr on every grit. The number of strokes you need highly depends on the steel and the heat treatment, so it’s hard to give a general guideline.

But after the first grit you only need to wipe out the scratches from the previous grit. A simple loupe is perfect for observing this. I use something like this: http://www.miniinthebox.com/nl/60x-led-microscoop_p979843.html (it’s technically a microscope). It’s Chinese and cheap, but it works perfectly. With some experience you can even hear/feel when it’s time to go to the next grit level.

Molecule Polishing: my blog about sharpening with the Wicked Edge

3 users thanked author for this post.

09/19/2016 at 8:36 am #35047I have seen situations where a particular grit seems to have removed almost all the scratches from the previous grit, but doesn’t quite hit the apex completely. An error of just over one tenth of a degree can produce this effect. Having an easy-to-use handheld microscope or loupe makes it easy to catch such errors and a quick adjustment of the micro-adjust screw will put you back at the right angle. I use the Celestron 5MP ‘scope with an old laptop to check both sides between grits, but for grits up to 1000, I can also feel a burr. I use my finger tips to feel for a burr. I strongly recommend a handheld USB microscope. Even the cheapest will give you an excellent view at the lower magnification. I suggest that you watch the video I made on using a USB ‘scope.https://www.youtube.com/watch?v=T5zYbCpLwcQ

I generally figure five strokes for each inch of the blade, for lengths less than 5″, but it depends a lot on the condition of your stones and the hardness of the steel. It seems that I use my 400 grit stones far more than the others (it’s usually my starting grit), so about every 18 months the 400 and 600 get changed. As a stone is worn down (use tends to round off the sharpest bits of diamond, slowly reducing the cutting efficiency), you will probably need more strokes. A new stone which hasn’t been “broken in” will cut very rapidly (but not as uniformly), as compared to one which has some miles on it. As Marks says, you learn to feel and hear the differences in cutting efficiency.

I once sharpened a knife a fellow had made from a file and I could feel the stones dig in when I’d hit a soft section of the edge where the fellow had overheated the blade with his grinding.

Generally, having raised a burr along the full length of the blade is an indication that you’re ready for the next grit, unless you want a mirror finish. Please note that using alternate strokes (left-right-left-right etc.) will make it very difficult to detect a burr. Also, edge-leading strokes (down-strokes) produce less of a burr than edge-trailing strokes (up-strokes). If you are dependent on using a burr as your indicator, I’d use a different pattern, maybe 5 or 10 up-strokes on one side before switching to an equal number of strokes on the other side. When you feel a full-length burr on the opposite side of the stone you’ve just used, you can switch to the other side and continue with it until it too has produced a burr on its opposite side.

6 users thanked author for this post.

09/19/2016 at 12:29 pm #35048I have seen situations where a particular grit seems to have removed almost all the scratches from the previous grit, but doesn’t quite hit the apex completely. An error of just over one tenth of a degree can produce this effect. Having an easy-to-use handheld microscope or loupe makes it easy to catch such errors and a quick adjustment of the micro-adjust screw will put you back at the right angle.

Very interesting!!! Just one tenth of a degree!!! Gauge may not even catch such a difference. Is it possible to post a picture of the edge when it happens? Would be very interesting to see what it looks like in a microscope or a loupe.

2 users thanked author for this post.

09/19/2016 at 1:30 pm #35049I’ll be sharpening just a few knives this week, but I’ll try to pull it together.

2 users thanked author for this post.

09/19/2016 at 5:09 pm #35051I have seen situations where a particular grit seems to have removed almost all the scratches from the previous grit, but doesn’t quite hit the apex completely. An error of just over one tenth of a degree can produce this effect. Having an easy-to-use handheld microscope or loupe makes it easy to catch such errors and a quick adjustment of the micro-adjust screw will put you back at the right angle.

Very interesting!!! Just one tenth of a degree!!! Gauge may not even catch such a difference. Is it possible to post a picture of the edge when it happens? Would be very interesting to see what it looks like in a microscope or a loupe.

This is why my personal belief is: don’t tighten everything down to the point where a 1/10 of a degree matters. Having a bit of “looseness” in the system, (I need a better word), allows the “stone to find the bevel”, so such minute changes won’t matter. (1/10 of a degree is like 1/100 of an inch… not what I want to deal with).

Just an alternative (or maybe just my) way of looking at it.

3 users thanked author for this post.

09/20/2016 at 7:58 am #35068This is why my personal belief is: don’t tighten everything down to the point where a 1/10 of a degree matters. Having a bit of “looseness” in the system, (I need a better word), allows the “stone to find the bevel”, so such minute changes won’t matter. (1/10 of a degree is like 1/100 of an inch… not what I want to deal with). Just an alternative (or maybe just my) way of looking at it.

I was thinking that the whole idea of WE is to have FIXED angle, otherwise it will be like sharpening by hand. Maybe I am exaggerating, but I would tighten as much as possible. If it loosens, then WE could come with more tight, more robust solution, me thinks.

09/20/2016 at 9:30 am #35069

09/20/2016 at 9:30 am #35069I was thinking that the whole idea of WE is to have FIXED angle, otherwise it will be like sharpening by hand. I would tighten as much as possible. If it loosens, then WE should come with more tight, more robust solution, me thinks.

It is the concept to have a fixed angle, but if you “tighten as much as possible”, especially to the point of having to adjust for 1/10 deg., I think the device can start working against you, (and this isn’t exclusive to the W.E.). Allowing a little bit of play (I’m not talking a lot, that’s why I said I probably need a better word than “looseness”) allows slight differences between stones, strops, etc. to be “self compensating”. Obviously, you reach a point where an adjustment needs to be made, and I’m not talking a large amount (don’t really have a fixed number in mind, but clearly a fraction of a degree)… but enough that small changes like this example, don’t affect the outcome. (And it will easily still be tighter than what most could do by hand).

1 user thanked author for this post.

09/20/2016 at 9:41 am #35070This is why my personal belief is: don’t tighten everything down to the point where a 1/10 of a degree matters. Having a bit of “looseness” in the system, (I need a better word), allows the “stone to find the bevel”, so such minute changes won’t matter. (1/10 of a degree is like 1/100 of an inch… not what I want to deal with). Just an alternative (or maybe just my) way of looking at it.

I think maybe the word you’re thinking of is “compliance,” but I’m not sure where you would “tighten” the system without modification. In a way, moving to film from strops is a “tightening,” as you’ve removed the compliance of the soft strop.

I certainly am guilty of tightening my system by going to bushings, but attention paid to technique can produce the same results. That said, I don’t think any of the few of us who have tried it (low tolerance handle bore-to-rod fit) would go back.

1 user thanked author for this post.

09/21/2016 at 6:03 am #35079Very interesting!!! Just one tenth of a degree!!! Gauge may not even catch such a difference. Is it possible to post a picture of the edge when it happens? Would be very interesting to see what it looks like in a microscope or a loupe.

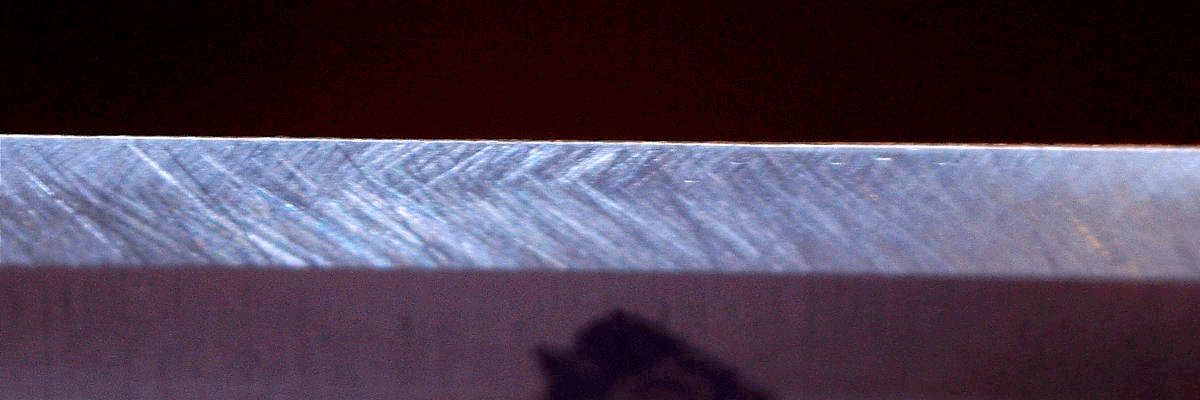

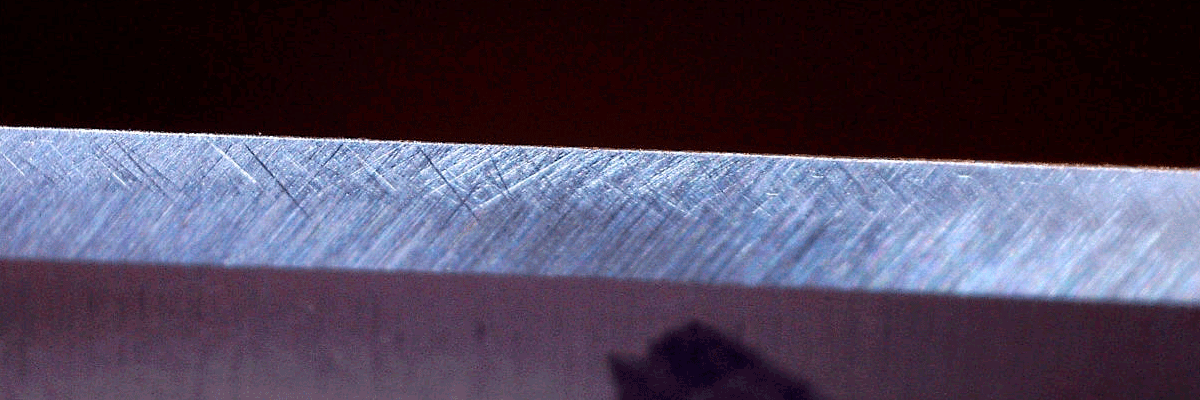

Here’s a photo I took to show the effect of a 0.1 degree change. I use a DXL360 angle cube, which has 0.02 degree resolution. First I stoned the bevel with a 1000-grit diamond stone. I then measured the angle very carefully at 19.96 degrees. I then changed to my 6 micro film (on a brass platen) and adjusted the micro-adjust screw to 19.86 degrees, before stoning for about 15 strokes. In the photo, you’ll see that there isn’t a sharp definition line between the two grits, but you’ll also see that the 6 micron bevel doesn’t quite reach the edge, which is the point of this discussion. In all honesty, I don’t think that 0.1 degree normally produces this result and that even my set-up has more “slop” than this and that the real difference might be something greater. https://tcmeyer.smugmug.com/organize/Wicked-Edge-Related-Stuff/Microphotos/i-WprLfBm

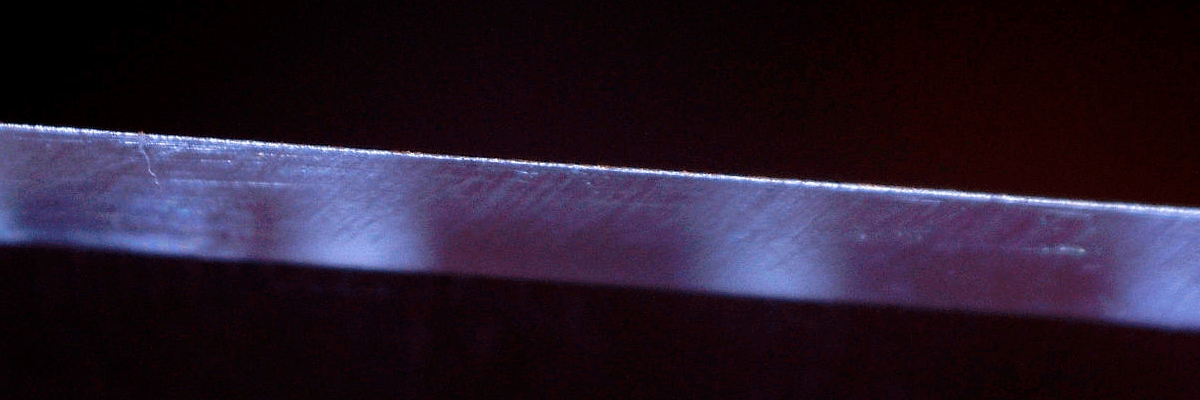

In my first comment above, I suggested that “An error of just over one tenth of a degree” would produce this result, so I tried to produce the effect by staying with the 1000-grit stone, first at 20.00 degrees:https://tcmeyer.smugmug.com/organize/Wicked-Edge-Related-Stuff/Microphotos/i-nzxHqB7

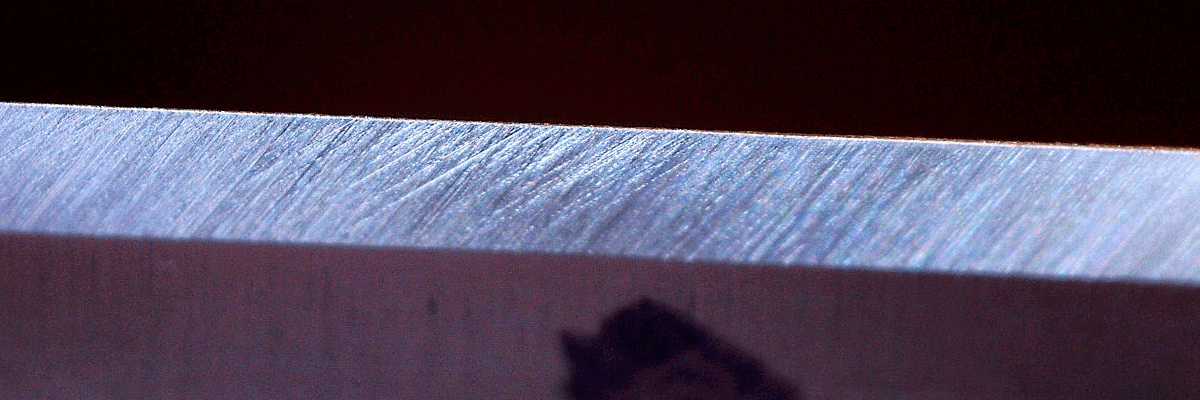

Then at 19.85 degrees:https://tcmeyer.smugmug.com/organize/Wicked-Edge-Related-Stuff/Microphotos/i-9sN9Tmh

Then at 19.70 degrees:https://tcmeyer.smugmug.com/organize/Wicked-Edge-Related-Stuff/Microphotos/i-fWDrLK4

In this last photo, the 19.70 stoning almost erases the 19.85 scratch marks – perhaps I took too many strokes with the last stoning. You’ll note that I applied a sharpie mark to let me photograph the same area and you can see scratches from the 19.85 stoning still there in the last photo.

2 users thanked author for this post.

09/21/2016 at 6:07 am #35080This is why my personal belief is: don’t tighten everything down to the point where a 1/10 of a degree matters. Having a bit of “looseness” in the system, (I need a better word), allows the “stone to find the bevel”, so such minute changes won’t matter. (1/10 of a degree is like 1/100 of an inch… not what I want to deal with).

I fully agree. I don’t think a bit of play is any problem at all. For example, this Victorinox knife was sharpened on a Lansky which I think we can all agree, has a lot of play

Original photo here: https://www.flickr.com/photos/fvdk3d/24869504791/

It has a very nice polish and it is as sharp as this Victorinox which was also sharpened on a Lansky

I love my WE with all the bells and whistles but learning how to use a particular system and how to get the most out of it makes more of a difference than 0.1 degrees of play.

just my $0.02

Frans

Attachments:

You must be logged in to access attached files.

09/21/2016 at 7:21 am #35083Now I know that some or all of you will snicker in disbelief that one can make such small adjustments and take angle-cube readings with that kind of accuracy. I know that because I have been using the same Igaging AngleCube that you are familiar with. Please allow me to explain. I’ve upgraded.

In April of this year, I bought a new angle-cube on Amazon; the DXL360, which is a two-axis device with resolution of 0.02 degrees. I tried to compare it with my Igaging unit and learned a little about how to get the most out of either unit. Most importantly, I learned that these devices are really sensitive to vibration and that both units benefited from a solid mount. Resting the unit on your diamond stone against the knife edge is not good enough. There apparently are enough ambient vibrations to cause instability in the sensor. Holding the stone solidly against the knife will dampen the vibrations an suddenly give you a stable, more accurate reading.

The Igaging unit claims an accuracy of 0.2 degrees and 0.05 degree resolution. The DXL360 has a claimed accuracy of 0.1 degree and resolution to 0.02 degrees. The manufacturer now offers the DXL360S, with the Amazon site claiming accuracy of 0.05 degrees and resolution down to 0.01 degrees. The comparison I did between my Igaging unit and my DXL360 seems to confirm these numbers, but I suspect that the Igaging does better than the 0.2 degrees of accuracy. If you believe the advertised numbers, the DXL360S is four times as accurate as the Igaging unit.

The DXL360 and the DXL360S have a number of features which set them apart from the Igaging unit. Besides having two axes, it has magnets on five sides (top, bottom, left, right and back. The four sides (t, b, l, r) have V-grooves which allow you to hold position on an edge or a rod. This is especially useful in measuring the faces of a small FFG blade. I place a steel straight-edge (e.g. a 12″ scale) in the side V-groove of the DXL and hold the other side of the scale against any exposed face of the blade. If you have at least 1/8″ of exposed flat, you can measure its angle. You can do this with an Igaging uit, but you’ll need three, maybe four hands. It also allows you to read the angle of an edge without damaging it (the housing is non-metallic). If I have a blade which needs to be clamped at an angle, I place the V-groove at the heel and record the angle for future reference. A next feature is that it can be programmed to set alarms; clearly not needed in our WE world. Another feature is that when you lay it on its back, it automatically goes to “bubble mode”, showing angle readouts for both horizontal axes. Another feature is that when you turn it on, it remembers the last zero. This brings up one drawback; the back-lit display will eat the battery, so you should remember to turn it off. I’m still on my first battery. Another drawback is the amount of steps required to do an initial setup, but that’s a one-time thing.

Like the Igaging unit, it takes a few seconds for the readout to settle down. I’ve found that if I doubt a reading, I can tap the unit with a finger to get it to bounce, hopefully to settle down to a real final reading. Kind of like adjusting a rifle scope. This serves the same function as repeatedly lifting and replacing the AngleCube to get an average reading. Try tapping the Igaging unit. I haven’t yet done so, as I never use mine anymore.

See the DXL360 listed for $46 here:https://www.amazon.com/Floureon-Inclinometer-Protractor-Magnetic-DXL360/dp/B00IKDQHV0/ref=pd_sim_sbs_469_3?ie=UTF8&psc=1&refRID=KATC9BPG41Q7MCSC0KG0

See the DXL360S, listed for $66 here: https://www.amazon.com/Floureon-Inclinometer-Protractor-Magnetic-DXL360S/dp/B00IKDQHWO/ref=sr_1_1?s=hi&ie=UTF8&qid=1474463527&sr=1-1&keywords=DXL360S

2 users thanked author for this post.

09/21/2016 at 10:19 am #35085Below is reposted what Tom wrote. I just replaced links with images for easier visual reference. It is a great post. Tom, if it is not OK, let me know, I’ll remove the post.

* * * * * * * * * * * * * * * * * * * *

tcmeyer wrote:

Here’s a photo I took to show the effect of a 0.1 degree change. I use a DXL360 angle cube, which has 0.02 degree resolution. First I stoned the bevel with a 1000-grit diamond stone. I then measured the angle very carefully at 19.96 degrees. I then changed to my 6 micro film (on a brass platen) and adjusted the micro-adjust screw to 19.86 degrees, before stoning for about 15 strokes. In the photo, you’ll see that there isn’t a sharp definition line between the two grits, but you’ll also see that the 6 micron bevel doesn’t quite reach the edge, which is the point of this discussion. In all honesty, I don’t think that 0.1 degree normally produces this result and that even my set-up has more “slop” than this and that the real difference might be something greater.

In my first comment above, I suggested that “An error of just over one tenth of a degree” would produce this result, so I tried to produce the effect by staying with the 1000-grit stone, first at 20.00 degrees:

In this last photo, the 19.70 stoning almost erases the 19.85 scratch marks – perhaps I took too many strokes with the last stoning. You’ll note that I applied a sharpie mark to let me photograph the same area and you can see scratches from the 19.85 stoning still there in the last photo.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

09/21/2016 at 10:39 am #35090Now I know that some or all of you will snicker in disbelief

Tom, your pictures are absolutely awesome proof that 0.1 degree really makes a HUGE difference. I placed order for DXL360S immediately. Thank you very much!!!

Now I can understand reason why sometimes people complain that bevel can be mirror shiny, but edge is not sharp. You are right, if angle changed a tiny bit, stone may not reach the apex. One can save a lot of work with less strokes if angle is precisely fixed.

4 users thanked author for this post.

09/21/2016 at 11:06 am #35091Tom, how do you use the dxl 360 to make.a 0.1 accuracy? I am alreaddy happy if I mage to stay within 0.5 degrees with my angle cube.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.