*warning* deep discussion on microbevels

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › *warning* deep discussion on microbevels

- This topic has 28 replies, 5 voices, and was last updated 12/04/2013 at 3:46 am by

Josh.

Josh.

-

AuthorPosts

-

11/20/2013 at 6:37 pm #15823

Just from a grunt perspective, I’d say ultimately the style and shape of the relief face and angle as well as the face and angle of the edge will be determined by not only the use but by the steel.

For some great info and reading, here’s Jay Fishers page:

http://www.jayfisher.com/index.html

If anyone knows him, it would be great to get him to chime in 🙂

The info I’m finding on his site is intense and is peeking my interest in the roll of the relief face and angle.

His steel types explanations are great.

A note on my experience with steels that have been overly thinned by the common restaurant sharpener running them through a dual grinding wheel system, forcing a hollow grind on all knives with a thinned hollow body behind the relief . I run across these OFTEN here, there’s one notorious large sharpening company doing it. It seems they use the adjustment of the wheels to allow thinning sometimes half way up the blade body??!!

This may be relevant to your thinning experience Josh.One thing is consistent no matter what brand or steel when I get these.

My first reaction is to smooth out the body attempting to visually fix the blade body first, ignoring the edge.

What I found is consistent, and I don’t attribute it to heat, is that if I then try and put a convex edge or flat or micro with relief, the thinned steel fails and breaks away while sharpening and continues up the hollow thinned body.

My gut says it can’t hold any strength at that thinness and something with the metal has changed.What I now do is grind the edge flat, and grind until I hit hard metal, sometimes taking off quite a bit of the knife, but the point where hardness starts is definitive.

I then work on the body, thinning it as much as I dare in order to get a smooth finish, then test the now flat edge and double check the steel is still hard, and it usually is.

At that point I judge the relation to the knife’s use and what edge it will get.

If more thinning is required to properly transition to the edge, I will, testing that it doesn’t loose hardness and they usually don’t at that point, and then go on applying an edge that will hold.Why these quality knives all fail after they’ve taken the abuse of the mass market sharpener I still can’t say for certain, but feel they were overly thinned and somehow the metal changed … it even looks different as it comes off … sort of crystally and chromed.

My gut says its not heat, there is no discoloration really, and the color shift only happens as the grind knocks it off, but I may be off.

I attribute the breakup to metal fatigue.Does that help or make sense?

my 2 cents

Interesting observations Ziggy! I can’t say for sure I understand what you are talking about when it comes to “overly thinned restaurant knives” could you post a nice pic up for us? It would help me to better visualize… then again, I don’t sharpen hardly any restaurant knives =)

11/20/2013 at 7:05 pm #15825Here’s the knife I thinned…

as you can see (or not see) the actual edge is hard to see w/ the naked eye…

11/20/2013 at 7:20 pm #15827I like the look of it you have given it an apple seed (you have thinned it at the top as well which means it only has one point of contact okay not quite on this one but its good).You could now strengthen it up slightly by putting it on the WE and putting an 18Ëš bevel on it and I would do it lightly first and gradually go deeper until the blade is stiff enough or put more of a convex on it on the Kally or whatever you thinned it with.

It certainly looks like it was really really thick.Attachments:11/20/2013 at 8:11 pm #15829So the first paragraph above doesn’t really matter very much when it comes to strength of the actual edge, except that the steel behind the edge does support the very edge? I guess I am wondering if a knife should be zero ground with a super thin edge placed on after or it if would be more profitable to put a 10*/side edge with a micro bevel on it. Obviously ex. A would cut much better because it wouldn’t have shoulders on the edge, but it also wouldn’t last as long.

Now why is this though? If they are both finished at 20*/side? I suspect that it has something to do with the carbides being there to support the steel behind the very edge and prevent it from denting/rolling?

There are quite a few things going on here.

If you grind a knife to zero with a very low primary grind, say 1.5 dps and then micro-bevel with a large angle, say 20 dps and try to cut even moderately hard material (cardboard) you will see the edge ripple very easily behind the micro-bevel.

If you look at it under magnification then you will see the 20 dps micro-bevel (and likely apex) is still almost unharmed however the steel behind it warped as it was too thin in cross section to take the lateral loads during the cutting.

You have to increase the angle behind the microbevel to ensure it has enough strength to not ripple (or fracture depending on the steel).

A quality steel with a decent hardening will start to be stable on cardboard, ropes and such at about 5 dps (on foods and papers less about 2 dps, cross cutting woods is more about 8 dps). At this point the apex will become the failure point and it will start to wear, deform and twist, i.e. the knife just blunts.

Now a curious thing happens if you keep increasing the angle behind the microbevel, you will find that the edge durability/retention of the micro-bevel goes down at a given micro-bevel angle. This is because it takes more force to push this knife (with the heavier cross section) through the material and the higher angle behind the micro-bevel causes more distortion in the material being cut and thus more concentration of the force around the micro-bevel.

Thus if you do some experimenting you will find that the optimal geometry is the one which has *just* enough thickness to keep the knife from warping. If you go below this the knife will fail by warping that you will see. If you go above it then it will increase the rate of wear, deformation and fracture at the very apex.

You will also notice the same thing with micro-bevels directly.

If you apply a 45 dps micro bevel you will likely not get improved edge retention over a 20 dps microbevel (for most materials). The reason being is that the 20 dps micro bevel isn’t warping anyway so the extra strength of the 45 dps bevel isn’t helping and that heavier bevel will cause more force to be placed right at that very apex and the apex will also thicken faster under a given amount of wear.

Again it is a case of finding the “sweet spot” that maximizes the performance, too high or too low will cause problems. In general (very general) :

-the better quality the steel (less voids, segregations, impurities)

-the better the thermal processing

-the cleaner the grinds (even, symmetric)

-the more skilled the userthe more this “sweet spot” point will be thinner/finer.

Now as carbide volumes get high this means you have to take them into account because some steels have carbide loads which are so dramatic that if you under cut the steel and make it very thin there will not be enough steel to hold the carbides in place. It would be like trying to pour a slab of concrete 3″ thick if you had 4″ rocks in it. If you grind too thin for the carbides it is easy to see because the steel will just break apart. If you do it dramatically then it will form dramatic burrs in sharpening due to the heavy fracture.

This is a low carbide steel (5Cr15, 55 HRC):

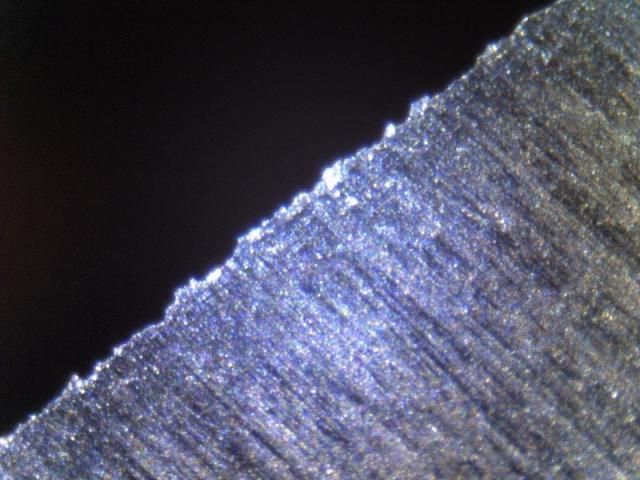

vs a high carbide steel (S35VN/60 HRC, Peters):

Finished on the same stone to the same angle (<5 dps). Note how one forms very clean and the other clearly is fracturing readily. The stone was a 700 X Bester.

So, if I understand right, you are saying that lateral forces will cause more damage than compressive forces, because the physics of the edge reveal that it is much stronger with a perpendicular cut than a lateral force on the very edge, right?

Yes, exactly.

So I guess the real question is, how do you figure out what is the optimal grind and microbevel of a given edge that will perform the best without giving diminishing returns (i.e. the strength to cutting ability ratio balance)?

Take a knife that you don't really care for and isn't that expensive and grind it to the point it obviously fails. This sets the lower bound for performance. Using the above cubic/quadratic rules you can then estimate what the points are that can be ground on other knives and as well how to modify knives which do fail.

11/20/2013 at 8:14 pm #15831I like the look of it you have given it an apple seed (you have thinned it at the top as well which means it only has one point of contact okay not quite on this one but its good).You could now strengthen it up slightly by putting it on the WE and putting an 18Ëš bevel on it and I would do it lightly first and gradually go deeper until the blade is stiff enough or put more of a convex on it on the Kally or whatever you thinned it with.

It certainly looks like it was really really thick.well, that was unintentional but i figured it would happen since i was doing it on a slack belt with no platen =) I just don’t know how much metal I should remove to strengthen the edge enough… i guess trial and error. I will try to get a pic of the current edge flex I am experiencing.

11/20/2013 at 8:29 pm #15832Thus if you do some experimenting you will find that the optimal geometry is the one which has *just* enough thickness to keep the knife from warping. If you go below this the knife will fail by warping that you will see. If you go above it then it will increase the rate of wear, deformation and fracture at the very apex….

Now as carbide volumes get high this means you have to take them into account because some steels have carbide loads which are so dramatic that if you under cut the steel and make it very thin there will not be enough steel to hold the carbides in place. It would be like trying to pour a slab of concrete 3″ thick if you had 4″ rocks in it. If you grind too thin for the carbides it is easy to see because the steel will just break apart. If you do it dramatically then it will form dramatic burrs in sharpening due to the heavy fracture.

This is a low carbide steel (5Cr15, 55 HRC):

vs a high carbide steel (S35VN/60 HRC, Peters):

Finished on the same stone to the same angle (<5 dps). Note how one forms very clean and the other clearly is fracturing readily. The stone was a 700 X Bester.

Ahhh that makes a lot of sense, thanks!

so what do you mean by having a thick-shouldered edge will cause it to "fracture"? I would think it would just wear away and become blunt, because the carbides would be supported in the wider steel matrix, right?

In your second picture, this is where the carbides in the steel have been ripped out because the dps angle was too low, right? Now… wouldn't the actual size of the carbides play a huge factor in this as well? Like s30v has very small carbides, which maybe could be supported in a lower dps angle, whereas D2 has larger, irregular ones so it could not? (I don't have the pics of each steel, but I have seen you post them before elsewhere)

11/20/2013 at 9:47 pm #15833so what do you mean by having a thick-shouldered edge will cause it to “fracture”? I would think it would just wear away and become blunt, because the carbides would be supported in the wider steel matrix, right?

In general all abrasive wear is a very violent process which includes tearing, ploughing and fracture. Just take the point of a knife and rake it down the face of a piece of hardwood and look at the surface created. All of this happens on a micro-scopic scale as well but we just can’t see it and it looks like the edge is smooth, but under high magnification it will be dented, deformed, torn, fractured etc. .

This is also why blades will have a curious response in that if you use them until they are very blunt, < 5% of optimal the sharpness will start to oscillate. What happens is that as they fracture this exposes sharp edges which give an increased slicing ability and then these jagged edges themselves suffer wear and the sharpness drops again. If the carbide volume is very high this is increased as the carbides can be torn out and also exposed in large pieces.

Now… wouldn't the actual size of the carbides play a huge factor in this as well? Like s30v has very small carbides, which maybe could be supported in a lower dps angle, whereas D2 has larger, irregular ones so it could not? (I don't have the pics of each steel, but I have seen you post them before elsewhere)

Yes, but you have to take care what exactly the carbide size means. This sounds kind of silly as it obviously means the size of the carbides but you have to consider how they form. For example PM in general will produce very small carbides, especially those that form MC type (like vanadium). These carbides will be on the order of 1 micron, and thus some makers/manufacturers promote them on that basis. However this ignores the fact that as the carbide volume increases then the aggregates (clumps of carbides) increase dramatically in size.

PM steels can have aggregates on the order of 10 times the size of the individual carbides easily and the volumes can be so high there is little steel to hold them in place at high volumes. Thus a very high carbide PM steel could easily have a lower edge stability than a ingot steel with "larger" carbides.

11/20/2013 at 11:37 pm #15838I have to ask both for myself and possible others what do you mean by “dps”?

I understand we have degrees minutes & seconds or we can decimalise it as often displayed on GPSs (and possible an engineers reference to gradians 400- 360Ëš) but I can find no reference to dps and since you have written so eloquently on this subject of thinning ,micro bevels , metallurgy and the Rockwell scale i should like to make sure I completely understand the reference to “dps” rather than possible making incorrect assumptions about the finer points made buy you.

It would be very helpful if you clarify what dps is referring to if it is an angle measurement it would simplify the text to stick to degrees since this is the measurement that the WE uses.

There was that disastrous episode on the space station when certain modules had been made using metric measurement and the other part it was to mate with was made using imperial measurement .

For my own part I struggle to grasp entirely what you are writing and would like to read it in more of a simpleton’s language.

Please do not take offence to this non is meant I have often been accused of explaining things in too technical terms whether it be navigation , trimming yachts or software.11/21/2013 at 12:13 am #15840There has been a near constant source of confusion over what people mean when they say sharpening angles as it isn’t an accepted and consistent terminology.

I started referring to it specifically as degrees per side (dps) and degrees include (di) a few years back. After using them for a few months on a few boards I dropped the long hand and now just say 15 dps (or 30 di).

This is also in reference to measurement from the mid-line not measurement from the primary grind, though that is a less common point of confusion. This terminology hopefully is fairly clear and fairly precise.

Thus for example a standard Mora is sharpened at 10 dps, if you apply a 15 dps micro bevel it means the microbevel is 5 dps higher than the primary (or single) grind.

11/21/2013 at 12:34 am #15842Now I understand and dps makes perfect sense . The bevel terminology is another problem that often contradicts itself ; I quite like the Japanese knife terminology since as someone who does not understand Japanese the parts of the knife when referred to through labeled drawings seem to be a lot less ambiguous whether this is the case in Japan I do not know but all the reference to parts of Japanese knives seem more exacting than western terms bevel description been the worst of all.

I did start a post a few months to try to set a standard for bevel reference “Bevels -terminolgy” but it sort of fizzled out .I realise I misspelt terminology but you can cut & paste it into search to see what others & I had to say on it . I rather hoped we could standardise it at least in the forum .12/02/2013 at 8:18 pm #15938So I thought that this article this article was interesting (thanks for the research and works cited cliff) and I believe this has a large part to do with microbevels. It would seem like the microbevel serves 2 purposes: 1. Ease of Sharpening (use a low grit for back bevel and a higher grit for final bevel for quickest results) and 2. To ensure that there is enough of the steel matrix to support the carbides in the steel.

“As a point of clarification, carbides can be cut by a suitable abrasive, i.e., one which is harder than the carbides so it is not immediately obvious that a lot of carbide would so limit the ability to polish the edge. However as the abrasive cuts through the carbide there is an action/reaction force pair between the carbide and abrasive generated which in turn generates an action/reaction force pair between the carbide and the surrounding steel matrix, i.e., the non-carbide portion of the steel. As the edge angle of the cutting tool is reduced the carbides will be contained by less matrix volume and at some point there will no longer be enough matrix to sustain the action/reaction force pair and the carbides will get torn out of the cutting edge. Thus a steel with a higher carbide volume and larger carbide size requires a greater volume of steel matrix around the carbide to form a highly polished edge and keep that edge stable. A higher matrix volume around the carbides requires a greater angle as shown by Landes, Johnston and Elliot. As the abrasive is both harder and sharper there will also be less of an action/reaction force pair so the greatest edge stability will be found by using the hardest and sharpest abrasive as noted by Elliott.”

12/02/2013 at 8:20 pm #15939Cliff, I see a lot of terms like “edge stability, toughness, wear resistance” etc… Could you please define these? Or anyone else that has a reference. Thanks

12/03/2013 at 5:59 am #15940Cliff, I see a lot of terms like “edge stability, toughness, wear resistance” etc…

The first time I saw anyone reference edge stability was Alvin Johnson (knifemaker) on rec.knives in the late 90’s. He did not call it that, but he noted that certain steels could hold an edge far better than others even if they didn’t have the wear resistance advantage. He just referred to it directly as the ability to hold a very high sharpness in very thin cross sections.

Roman Landes, metallurgist and knifemaker, defined it in his published work and it is the ability of the steel to resist deformation and fracture under micro-loads on the edge. An edge which has a higher edge stability will thus take less damage at a given load, or will take more load to take a given damage. He noted that :

-increasing hardness

-reducing austenite grain size

-minimizing retained austeniteincreases edge stability and increasing carbide volume decreases it (as does the opposite of the previous properties). This steels which have very high edge stability are steels such as Japanese White steel, AEB-L, and similar steels often used as razor blade steels.

Wear resistance is the ability for a steel to resist being worn by an abrasive, i.e., how much steel is worn off in a given time under a given load and speed. A steel with a high wear resistance will have minimal steel removed in a given condition.

Wear resistance is broken down further into adhesive (steel vs steel) vs abrasive (steel vs something harder which can cut it directly). Abrasive is further subdivided into high load vs low load. High load abrasive wear is very dependent on toughness and thus S7 can have similar wear resistance to M4 under very heavy load but M4 will be superior under low loads when it doesn’t frature and just slow wears.

Ref : ftp://ftp.asm-intl.org/pub/MARC_Records/V07/asmhba0001587.pdf

Toughness is the ability of the steel to resist fracture which is basically the steel coming apart or separating. It is different from strength which is the ability of the steel to resist deforming where it changes shape but stays in one piece. For example if you bend a coat hanger then you have changed it shape but it is still in one piece, so you can checking strength. If you hit a piece of glass then it breaks and you can take the pieces and put them back in the same original shape but they are all apart, this is checking toughness.

I have given a very high level over view, these topics are quite involved, but hopefully that gives an understand of the basic meaning.

12/04/2013 at 3:46 am #15942Cliff,

Thanks a ton… That was very helpful and concise. I am sure I will be referring back to your post multiple times in the future 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.