Super Hold Micro-Adjuster Enhancement

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › MODS › Super Hold Micro-Adjuster Enhancement

- This topic has 4 replies, 3 voices, and was last updated 04/29/2021 at 11:32 am by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

AuthorPosts

-

04/26/2021 at 5:21 pm #56656

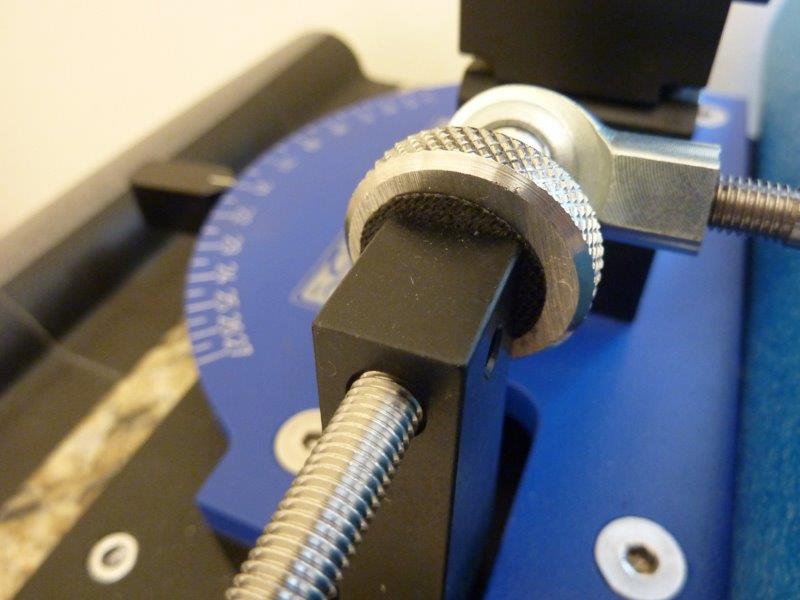

I have been suggesting and kicking around this idea for some time now. I tend to do that with most of my new concept/ideas. I had thought this was a perfect place to put to use something like a fishing reel drag washer to enhance the locking hold on the micro-angle adjuster. I use the upgraded adjusters from Ed K’s (NotSharpEnuff) micro-angle adjuster adapters on all my set-ups. Ed builds and offers them for sale.

My sharpeners are customized older set-ups with various upgrades, modifications. The micro-adjuster adapter kits just how Ed makes them lock and hold well. Still, it seemed like a good idea to add this simple part. I’m always thinking of ways to make my things work better. It’s like adding a disc break between the flat contacting surfaces.

Instead of driving around to tackle shops that repair spinning reels looking to find drag washers in a size I could work with, then overpaying for them. I purchased some carbon fabric material from Amazon.com. I simply punched out the diameter I want them to be. Then I center punched a hole so it fit on the 1/4″ adjuster screws. I placed them in the adjuster locks between the flat vertical surfaces where the adjusters lock by metal-on-metal contact. The carbon washers grab and hold just like I assumed they would. It insures a more positive hold and the adjusters don’t come loose until I intentionally back them off. It’s an easy mod to do and an inexpensive enhancement. Here’s what they look like:

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

04/26/2021 at 8:28 pm #56661Marc, looks like once, tightened, it’s less of a chance that it can come loose and screw up the sharpening angle. – Mike

1 user thanked author for this post.

04/26/2021 at 9:08 pm #56662Marc, looks like once, tightened, it’s less of a chance that it can come loose and screw up the sharpening angle. – Mike

Thats what I was looking to do. To add that little bit of friction and maybe some compressibilty between the flat surface. When you tighten the thumbwheels finger-tight you can feel the grab. When you twist the knob to release it you can feel how well it holds. I would expect the material should last a long time too. There’s no rotational friction and heat like in a fishing reel.

I think the concept should work just as well with the standard W.E. micro- angle adjuster designs, also.

Marc

(MarcH's Rack-Its)04/27/2021 at 1:18 am #56663Thanks, Marc. I sanded the surfaces flat on mine and don’t have a problem with mine loosening up. But I’ll keep it in mind just in case.

04/29/2021 at 11:32 am #56680I finally used these friction disc on my micro angle adjusters last night. It was the first real sharpening test using them.. The discs hold and lock very tightly. When the thumb wheel is locked down on the disc it grabs tight and holds fast. There’s no noticeable travel, rolling or sliding against the disc as the thumb wheel locks the adjuster settings. It didn’t appear there will be any wear or scuffing on the steel thumb wheel’s surface finish or wearing off the black anodizing on the W.E. end brackets.

Once contact against the disc is felt a little added thumb pressure tightens the adjusters rock solid and securely. They held locked-fast as wanted through out the entire time I used each grit. It does require a pretty good amount of applied thumb wheel pressure to rotate the locked micro adjuster to loosen them.

I prefer to use my angle cube to check, and make micro angle adjustments to my guide rod set angles, as needed, with each and every grit change. If you’re a user who chooses to set your bevel angles only once at the start of the sharpening session you can be confident your settings will stay put, just as set.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.