New User looking for Modification Tips

Recent › Forums › Main Forum › Welcome Mat › New User looking for Modification Tips

- This topic has 4 replies, 4 voices, and was last updated 02/17/2021 at 1:22 pm by

000Robert.

000Robert.

-

AuthorPosts

-

07/02/2020 at 12:21 pm #54453

Just got my Gen 3 Pro. I played around with it for a bit and noticed that lots of metal filings are getting into my swing arm ball joints and also in the blade clamp. I can hear the blade clamp making a grinding noise when I cam it over to lock in the blade.

I know some people have used RC dust boots to cover the swing arm ball joints, does anyone have a current link to some that will work?

Any tips to keep those metal filings from getting into the blade clamp mechanism?

First time I used it, the little swing arm ball joints weren’t screwed in all the way and I didn’t notice, so I accidentally ground down the paint off of the blade clamp. Whoops…

Attachments:

You must be logged in to access attached files.

07/02/2020 at 3:12 pm #54455Welcome to the Wicked Edge Forum and our sharpening community, Jacob Barlow.

While breaking in your new diamond stone set they will shed diamonds. I believe what your experiencing leading to the noise and rough feel in the clamping mechanism is more due to these lost diamonds then due to steel dust. But both, steel and diamonds, will contribute to your issue. My observation and personal experience is the problem is more related to using new stones then simply sharpening knives and steel dust because as time goes on the issue became less pronounced for me.

I’m inserting a PDF file showing disassembly instructions for the Gen 3 Pro Vise and clamping mechanism. You do have to remove the vise from your base to expose the screws to disassemble it. This PDF is from the previous model version Gen 3 Pro vise, from 2018-2019. Depending on your model, it may have some slightly different parts then those in the provided PDF. That shouldn’t matter the disassembly/assembly is the same.

I suggest you disassemble your vice to clean out the diamond and steel dust or grit. A can of “spray air” like used to blow dust out of computers and keyboards is helpful for this job. I like to apply a “dry teflon lubricant” to lubricate the parts when reassembled. After the first cleaning and lubricating I found I usually only need to repeat this once or twice a year, once the stones have been broken in.

A thin strip of blue painters tape, can be applied done inside the vise jaws from the top. This helps to shield steel and diamond dust from getting down in the vise works. I prefer to use a small rectangular patch of real leather chamois that’s used to dry cars after washing. I simply fold a small chamois patch over the knife spine as I lay the knife in the jaws. The chamois helps keep the grit out and also helps provide a more secure grip between the vise jaws and the knife.

Here is a link to an earlier forum thread with links to W.E. custom products these long time members, (including myself), sell for your W.E. sharpener including the RC Boots you’re requesting.

Marc

(MarcH's Rack-Its)3 users thanked author for this post.

07/02/2020 at 3:13 pm #54456Just got my Gen 3 Pro. I played around with it for a bit and noticed that lots of metal filings are getting into my swing arm ball joints and also in the blade clamp. I can hear the blade clamp making a grinding noise when I cam it over to lock in the blade. I know some people have used RC dust boots to cover the swing arm ball joints, does anyone have a current link to some that will work? Any tips to keep those metal filings from getting into the blade clamp mechanism? First time I used it, the little swing arm ball joints weren’t screwed in all the way and I didn’t notice, so I accidentally ground down the paint off of the blade clamp. Whoops…

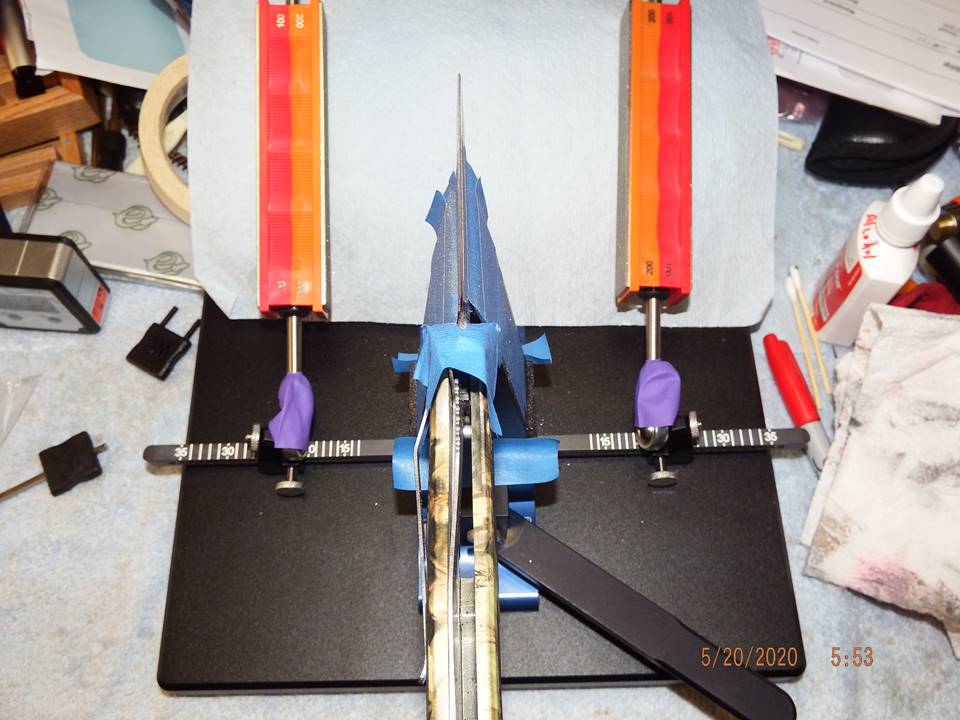

Hi Jacob, and welcome to the WE family! I use thumb tips off of nitrile gloves. Just cut them off about an inch long and poke a little hole in the tip. Then slide the thumb tip down the guide rod. I also tape my WE off to keep shavings from getting into other parts.

Edit. That is what I used so far. I am fixing to put in an order to NotSharpEnuff for some nice dust boots and other stuff.

-

This reply was modified 5 years, 1 month ago by

000Robert.

000Robert.

-

This reply was modified 5 years, 1 month ago by

000Robert.

000Robert.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

07/04/2020 at 12:01 am #54466Question from “Jacob Barlow”: Any Tips to keep those metal filings from getting into the blade mechanism?

I use Styrofoam ear plugs.

The ear plugs are to short just the way they are.So I stand one up on a cutting board, cut it down the middle but do not cut all the way so it folds open. Put it between the jaws sitting on the spring.

Do not lose the Styrofoam piece that came with Gen-3 vice.

4 users thanked author for this post.

02/17/2021 at 1:22 pm #56175A thin strip of blue painters tape, can be applied down inside the vise jaws from the top. This helps to shield steel and diamond dust from getting down in the vise works. I prefer to use a small rectangular patch of real leather chamois that’s used to dry cars after washing them. I simply fold a small rectangular chamois patch up around the knife spine as I position the knife in the jaws for clamping. The chamois helps keep the grit out of the vise, it protects the steel from getting scratched and also helps secure a better grip between the vise jaws and the knife.

Hi Marc. On my Kershaw Launch 1 that I reprofiled/sharpened the other day, I was thinking about you using chamois leather. I didn’t have any chamois so I tried some black pig leather that I use for lining holsters and sheaths. I used the thinnest part I had in the piece that is 0.0265″ thick. It worked great! Thanks.

1 user thanked author for this post.

-

This reply was modified 5 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.