New 1500 grit stone

Recent › Forums › Main Forum › Product Announcements › New 1500 grit stone

- This topic has 40 replies, 13 voices, and was last updated 06/16/2019 at 2:46 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

11/25/2016 at 12:47 am #35994

Has anyone tried out the new 1500 grit diamond stone already? Since they come from the same manufacturers as the 100-1000 stock stones (unlike the 300 grit DMT stone, which I don’t like), I have high expectations for them.

I think I’ll order a pair next Monday

.

.Who’s gonna be the first to report?

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

11/25/2016 at 2:28 am #35996I was looking hard at them yesterday.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162211/25/2016 at 7:49 am #35999Which lapping film micron size should be used after this 1500 stone? In theory it should be 6 micron, but Clay used 6 micron after 1000 grit stone.

11/25/2016 at 11:43 am #36003I actually just ordered them

. I think I’ll use the 6 micron diamond film after the 1500 grit stones, once they are broken in. 1500 grit should be equivalent to slightly more than 3 microns, so 3 micron should work if you follow the grit-size-only logic. However, different abrasives work differently (stones may be more irregular or make deeper scratches – a similar thing applies when moving from stones to strops), so it’s usually good to take a step back.

. I think I’ll use the 6 micron diamond film after the 1500 grit stones, once they are broken in. 1500 grit should be equivalent to slightly more than 3 microns, so 3 micron should work if you follow the grit-size-only logic. However, different abrasives work differently (stones may be more irregular or make deeper scratches – a similar thing applies when moving from stones to strops), so it’s usually good to take a step back.Molecule Polishing: my blog about sharpening with the Wicked Edge

4 users thanked author for this post.

11/28/2016 at 10:20 am #36052I’ll do some sharpening and study the results under the microscope today to examine the films after the 1500# stones. BTW, I love the stones.

-Clay

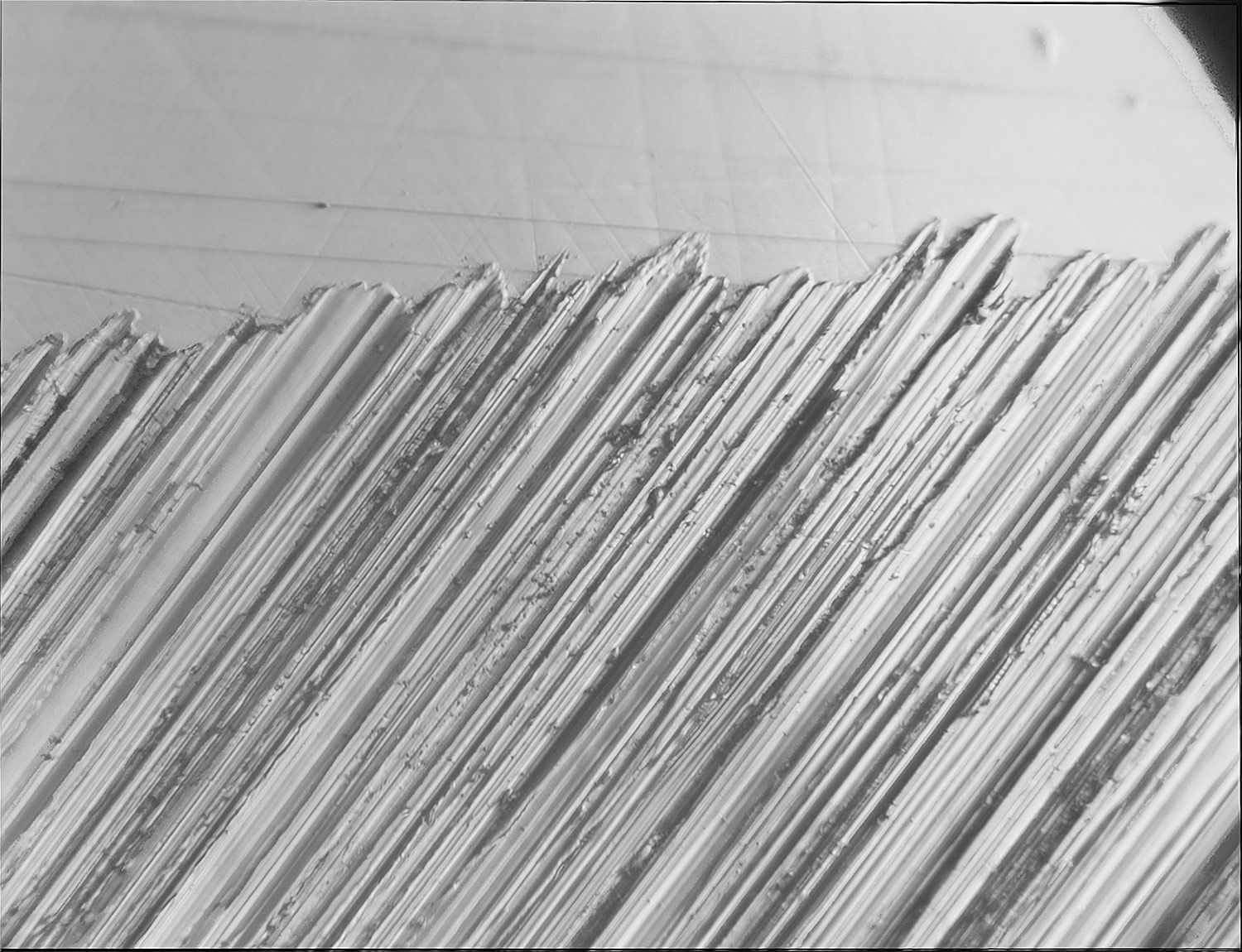

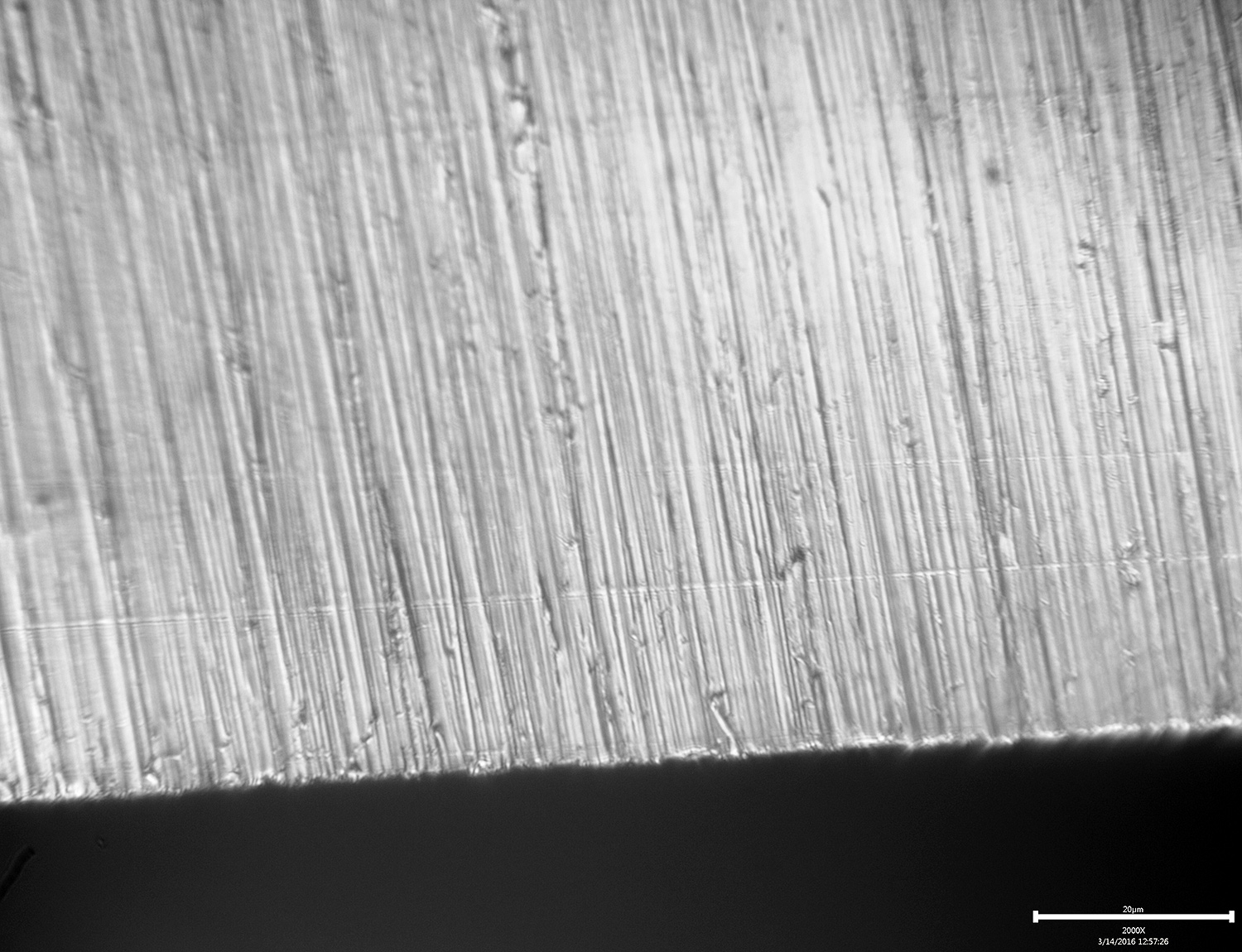

11/28/2016 at 1:33 pm #36061Here are some images of a blade sharpened with a moderately broken in 1500# stone at 2000x:

The image above shows the shoulder and bevel intersection. I polished the shoulder down to .5µ without spending too much time trying to make it perfect. Most of the widest scratches measured between 2.5µ and 3.5µ from ridege to ridge.

This images shows the edge at 2000x. The widest gaps between the teeth also measured between 2.5µ and 3.5µ from ridege to ridge.

Both images are stacked using the microscope softwares EoDF function which saves me a bunch of time from doing it in Photoshop. I only used 3 images for each stack.

Next I’ll use the 9µ on the bevel and image the results. After that, I’ll restore the 1500# scratch pattern and then use the 6µ film.

-Clay

Attachments:

You must be logged in to access attached files.

11/28/2016 at 2:35 pm #36066Looks good! 2.5µ – 3.5µ is about the range I’d expect the scratches to be.

Great pics by the way! That EoDF function works very good.

Molecule Polishing: my blog about sharpening with the Wicked Edge

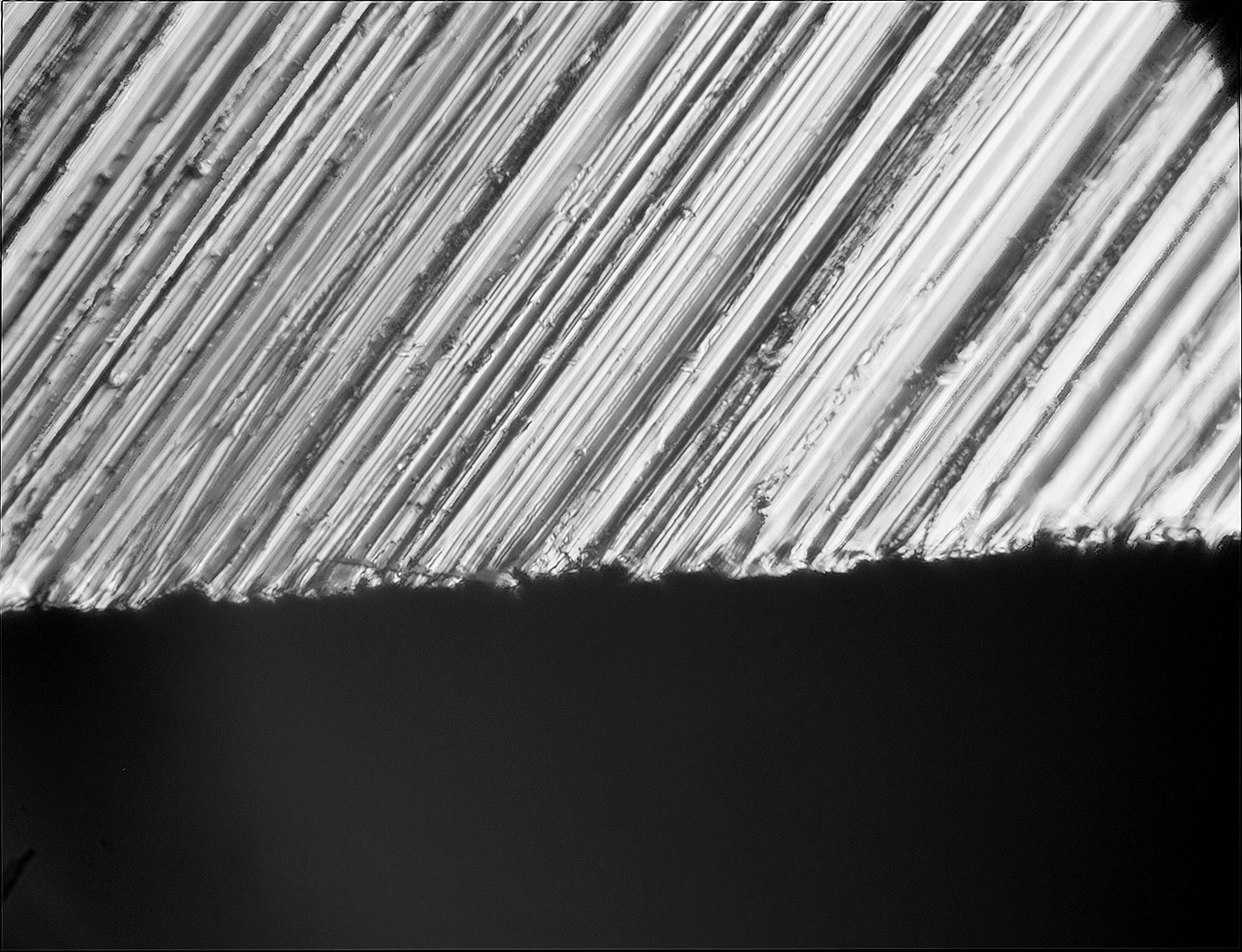

11/28/2016 at 3:06 pm #36068Here are the edge and shoulder after the 9µ films at 2000x:

The scratches mostly measure around 1 micron and you can see the edge is much cleaner. I’m surprised that the scratches are so small.

-Clay

Attachments:

You must be logged in to access attached files.

11/28/2016 at 3:20 pm #36071After that, I’ll restore the 1500# scratch pattern and then use the 6µ film.

What is the need to test 6µ film after 1500#? Wouldn’t be more logical to compare these photos:

1000#

1000# >> 1500#

1000# >> 9µ film

1000# >> 6µ film

with the same number of strokes.

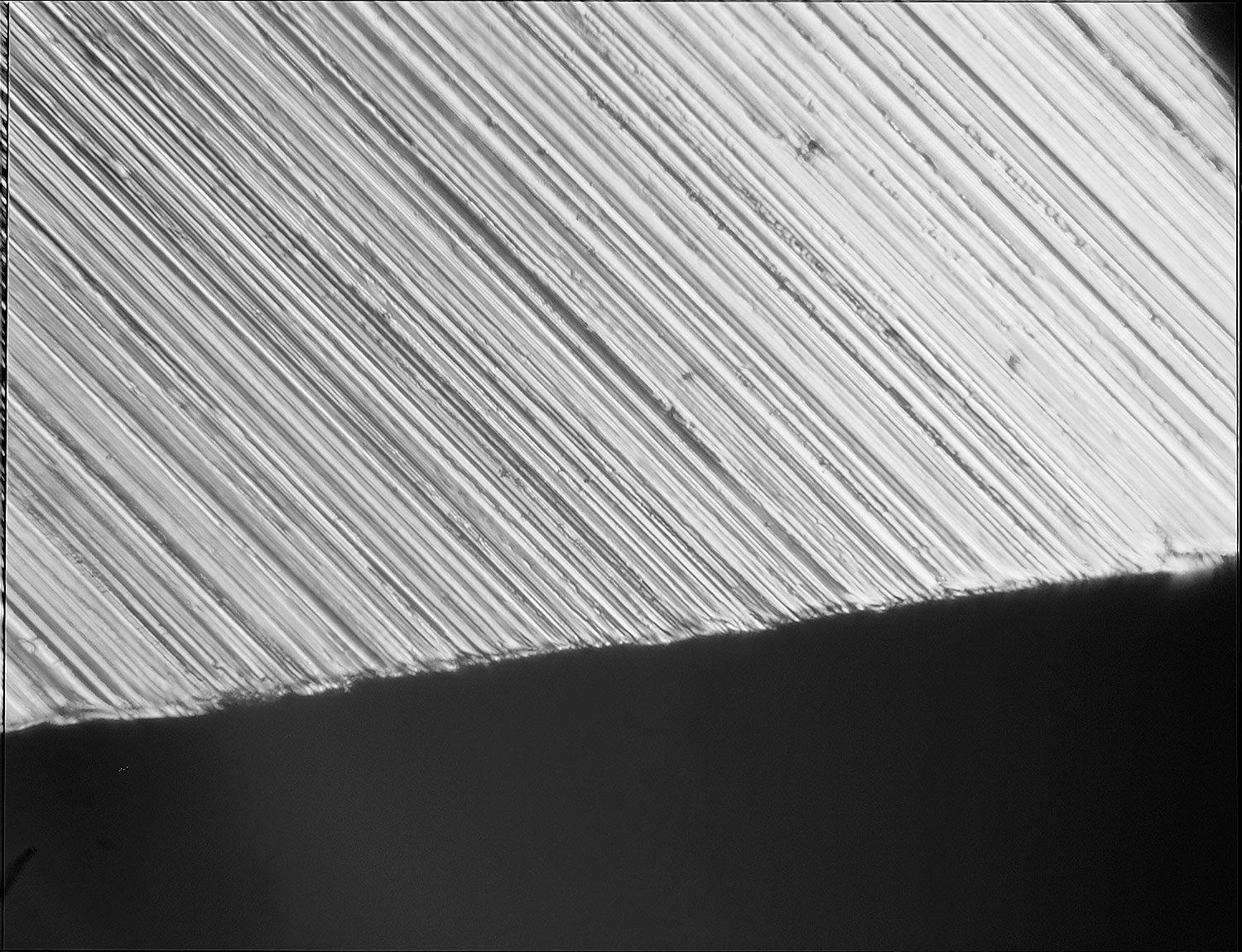

11/28/2016 at 3:41 pm #36072I reestablished the 1500# bevel and then did 10 strokes per side with a new set of 6µ films:

I didn’t quite reach the edge with the films so you see a little shadow of a micro-bevel left from the 1500# stones. All in all, I was pretty impressed with how the scratches were removed in only 10 strokes per side. I need to repeat the 9µ with new films and only 10 strokes per side as well to have a better comparison. For now, have a look at the 1500# scratch pattern and compare it to the 6µ scratch pattern:

-Clay

Attachments:

You must be logged in to access attached files.

11/28/2016 at 3:44 pm #36077The size of the scratches produced by the 6 micron films are between 0.70µ to 0.95µ.

-Clay

11/28/2016 at 3:55 pm #36078I just reestablished the 1500# bevel and then did 10 strokes per side with new 9µ sheets, which also erased the 1500# scratches and was very similar to the 6µ pattern just larger scratches. My conclusion is that the 9µ film is unnecessary if you have the 1500# stones and the jump to the 6µ films is appropriate. If you want to sharpen ceramic knives, then I’d definitely include the 9µ after the 1500#.

-Clay

2 users thanked author for this post.

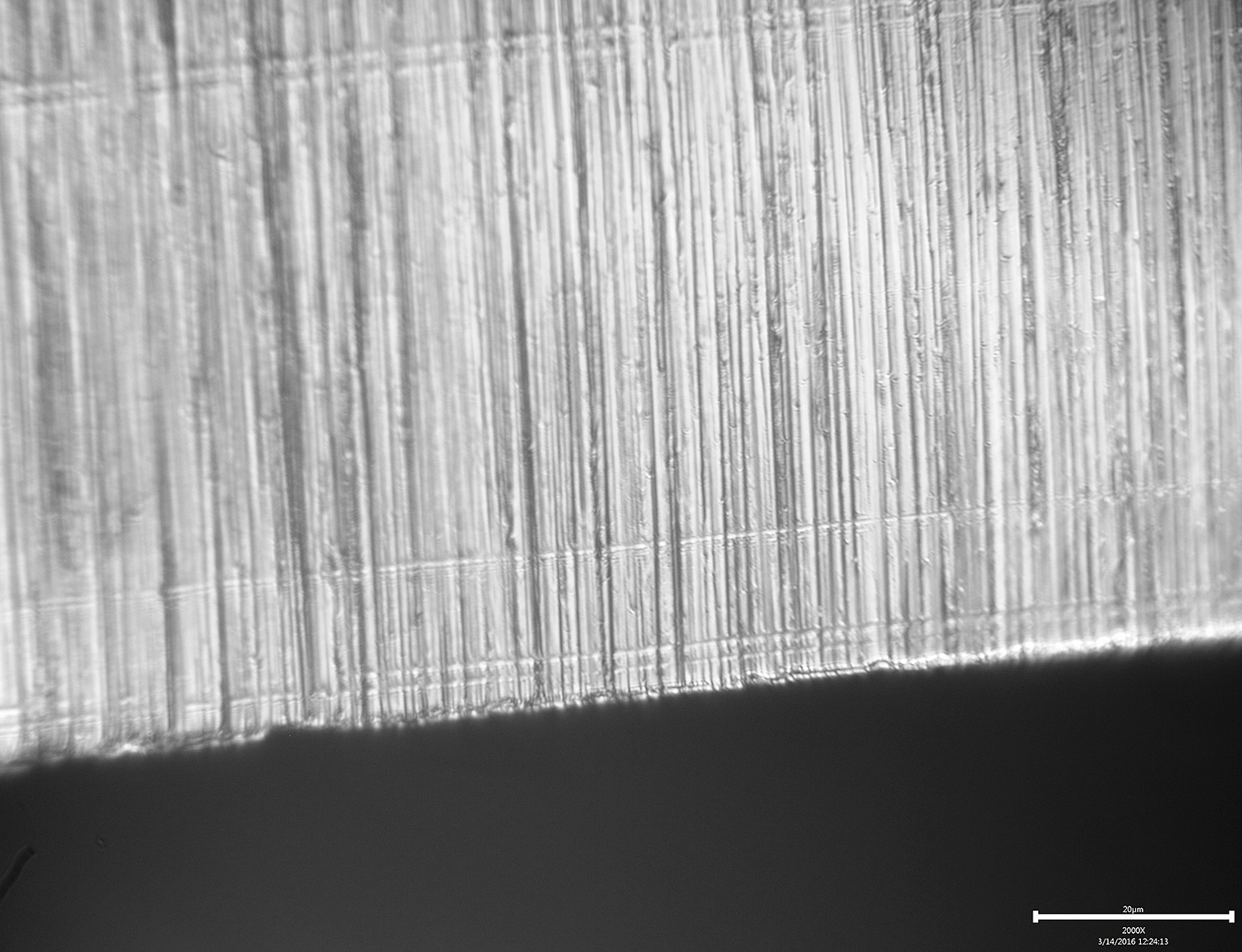

11/28/2016 at 4:09 pm #36079For fun, here is the 3µ film. I did 10 strokes per side in the following progression, switching direction each time: 1500#> 9µ >6µ >3µ:

I didn’t do a great job of cleaning the sample prior to imaging it, but it still gives the idea. The majority of the scratches with this film are between 0.20µ and 0.35µ. There were a couple of outliers at around 0.50µ.

-Clay

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

11/29/2016 at 12:59 am #36082Clay, are you using a oil immersion 100x microscope lens in these photos or a 100x Dry? They look great!

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162211/29/2016 at 3:48 am #36083As always, the diamond films really impress me with their speed and consistent patterns. I’m also surprised their scratches are so narrow, yet easily erase those of the 1500 grit stone. That stone also looks great. I think 9µ film after the 1500 grit stone is a perfect progression, even though 6µ seems to work as well.

I’m glad I just ordered the 1500 grit stone and the 9µ film

.

.Molecule Polishing: my blog about sharpening with the Wicked Edge

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.