New 1500 diamond stones, just got them.

Recent › Forums › Main Forum › Off Topic › New 1500 diamond stones, just got them.

- This topic has 17 replies, 10 voices, and was last updated 03/15/2017 at 8:10 pm by

Cheesehead_Slasher.

-

AuthorPosts

-

02/23/2017 at 3:20 am #37458

So yeah I just got the 1500 stones today and just touched up one of my knives.

I went through some of the lower grit as usual and when I got to 1000, it has a really nice shine. The moment I got onto 1500, oh boy it seems to cut quick! Reflection seems rougher than my “broken in” 1000, but it’s fine. I thought, must be because it’s new!

But I somewhat like the aggressive cutting of such fine stone! Feels “effective”. Now I’m wondering if I’ve worn down my old diamond stones a bit too much? Perhaps from extra pressures? Or they’re just well broken in like how they’re supposed to be?

I haven’t reprofiled anywhere near 100 knives but my 100 grit felt like it’s smoother than the 200. Under microscope, the diamonds are all intact, just a bit smoother now.

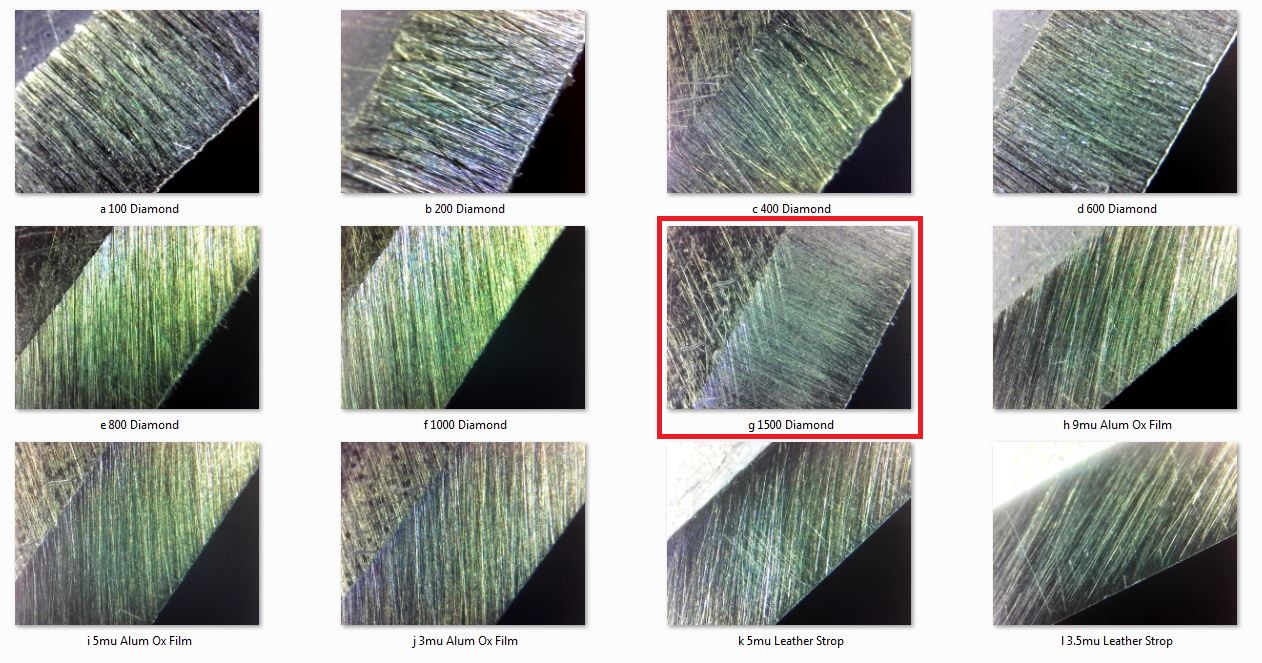

02/23/2017 at 8:47 am #37461I’ve done about 20 kitchen knives using my 1500 diamonds. It is my favorite. I did a composite a while back with my $35 USB scope. IMO, after 1500 you get into diminishing returns unless you are going for the mirror edge.

Attachments:

You must be logged in to access attached files.

7 users thanked author for this post.

02/23/2017 at 9:10 am #37463Great photos. I too like the new 1500’s

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

02/23/2017 at 10:44 am #37466I think the way to tell if your other diamond plates have become too worn is to see if there are any shiny / smooth spots on the surface of the plate. You would expect to see this toward the center of the plate as that is the area that gets the most use.

The new diamond plates definitely cut a great deal faster than when they are worn in. Others have said that they get around 400 knives before the plates are worn out, so I think you’re probably just feeling the difference between a new and old plate.

02/23/2017 at 2:46 pm #37471Great photo’s. Wait a bit until the 1500 is broken in. You’ll be surprised how fine it is and how well it fits after the 1000 grit stone (althought I think it is funde now already).

Molecule Polishing: my blog about sharpening with the Wicked Edge

02/23/2017 at 3:21 pm #37472after i sold my old WE and brought the newer WE Pro back i had no paddles to use for my gun show and williams – sonoma gig, i i called my buddy bob at oldawan and ordered all new, but only from 400 to 1000, but i did like the glass on the 1500 paddles.

so i pre-sharpen all my kitchen knives on my kalamazoo ……start with 400 and after 1000 i always in the past went to both sets of ceramics, but this new order i did not buy the 1200-1600 set…….i just liked going to coarse and fine the power leather.

last week before my 2nd williams-sonoma gig i sharpened a few shuns and 2 pocket knives and after the 1000s i tried the 1500……..impresses i was and still.

this past sunday at the WS gig i pre-sharpened all…….went thru the 1000s and then finished on the 1500s then power leather……….makes a fine blade on any kitchen knife – either for personal or to generate income from.

i posted a vid the other day on cheap china pocket knife i did on WE….some may have seen it……on that i stopped with 1000s, but then i went to the 1500s and spend extra time with them and onto the coarse/fine ceramics then power leather with japanese green………I Like the 1500’s – Nice paddles.

note: the japanese green is a bit $$$, but glory………woodcraft’s online store sells in “Japan WoodWorker”…..nice tooo

.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

02/24/2017 at 3:45 am #37487Why did you have no paddles? The Pro comes with them or doesn’t it?

Molecule Polishing: my blog about sharpening with the Wicked Edge

02/24/2017 at 7:00 am #37491Why did you have no paddles? The Pro comes with them or doesn’t it?

.

i purchases to save money without paddles………since i already had many paddles from original WE, but i sold it with all the used paddles, so i ended up with new WEPro sitting on a shelf with no paddles.

02/24/2017 at 10:21 am #37498Interesting responses guys! My main goal in what I do is mirror finish so how effective the diamond grit erases the previous scratches are really important to the efficiency of such goal.

Personally I have not jumped the gun on diamond films yet, but I have just used 2,000 grit EP lapping films on the glass platen on the 1500 paddles. It works wonders! I am heavily considering diamond films, but given my OCD, there’s a whole lot of glass platen paddles to get if I were to go for it.

At this point I’ve skipped the 1200/1600 altogether. I didn’t really like it.

My progression is usually like this: 50 – 80 – 100 – 200 – 400 – 600 – 800 – 1000 then 1.4um – 0.6um ceramics followed by 5um – 3.5um – 1.0um – 0.5um diamond paste on cereal box strips, tied onto the ceramic paddles.

One reason I use 50-80 is because I sharpen from no edge at all, on my own knife builds. So the 50/80 is totally necessary to establish a bevel. I think it is one of the reason why my 100 grit feels a little “too smooth” as I used that to establish bevels initially before I finally bought the 50/80.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

02/24/2017 at 1:08 pm #37500Interesting responses guys! My main goal in what I do is mirror finish so how effective the diamond grit erases the previous scratches are really important to the efficiency of such goal. Personally I have not jumped the gun on diamond films yet, but I have just used 2,000 grit EP lapping films on the glass platen on the 1500 paddles. It works wonders! I am heavily considering diamond films, but given my OCD, there’s a whole lot of glass platen paddles to get if I were to go for it. At this point I’ve skipped the 1200/1600 altogether. I didn’t really like it. My progression is usually like this: 50 – 80 – 100 – 200 – 400 – 800 – 1000 then 1.4um – 0.6um ceramics followed by 5um – 3.5um – 1.0um – 0.5um diamond paste on cereal box strips, tied onto the ceramic paddles. One reason I use 50-80 is because I sharpen from no edge at all, on my own knife builds. So the 50/80 is totally necessary to establish a bevel. I think it is one of the reason why my 100 grit feels a little “too smooth” as I used that to establish bevels initially before I finally bought the 50/80.

i bought edgepro first years ago and really liked the films……like you i still use them…..2000….3000….7000 and now with the glass…even nicer.

i used the 50/80’s at markets when i used WE at those events, but the deep scratches i never cared for…….sounds like your 100/200 did the same as mine…..maybe i push to hard.

it seemed i spend a lot of time trying to remove those, that is why i pre-sharpen certain blades today.

you have a fine looking ticket in this picture……nice job

1 user thanked author for this post.

02/24/2017 at 3:33 pm #37501Awesome polish on that blade!

I burned thru my 100 and 200 stones quick because of too mutch pressure.. now i only use the weight of the stones and they work just as fast.

Let it work, dont make it work

Kind regards

Martin3 users thanked author for this post.

03/04/2017 at 2:24 pm #37602Doesn’t the polish with the Edgo Pro (EP) tapes make the edge look like Mylar?

I still think it is very different looking than the diamond tapes and the Aluminum Oxide. What do you think?

I still think it is very different looking than the diamond tapes and the Aluminum Oxide. What do you think?Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162203/05/2017 at 11:25 am #37609Nice work! You did a great job at the tip, something I’m still having trouble with. Thanks for sharing.

03/08/2017 at 12:16 pm #37650Nice work! You did a great job at the tip, something I’m still having trouble with. Thanks for sharing.

Oh yes! The tip is in fact where I spent most time on. It’s really difficult to get the tip “perfect” and any roundness shows in the reflection once a mirror finish is achieved.

03/12/2017 at 11:54 am #37696Nice work! You did a great job at the tip, something I’m still having trouble with. Thanks for sharing.

Oh yes! The tip is in fact where I spent most time on. It’s really difficult to get the tip “perfect” and any roundness shows in the reflection once a mirror finish is achieved.

Would you be so kind to explain your process for making the tip “perfect”?

Thanks

-

AuthorPosts

- You must be logged in to reply to this topic.