Microbevel

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Microbevel

- This topic has 27 replies, 9 voices, and was last updated 11/29/2014 at 1:00 pm by

Mark76.

-

AuthorPosts

-

11/25/2014 at 5:24 am #21489

[…]

Will a lower angle have better edge retention?

It is critical here that you differentiate between push cutting and slicing as they are not dependent on apex angle the same way. Yes at some point the apex angle will be so low it will not have the strength and it will buckle, hence if you start decreasing the apex angle at some point the increase in slicing edge retention will reverse and at some point it will disappear completely. The same relationship is seen to a lesser extent in apex bevel thickness but in this case a lower thickness increases both push and slicing edge retention until the point it is too thin and it again collapses.

11/25/2014 at 5:30 am #21490This is confusing.

The main reason people get confused is because they meld sharpness and cutting ability together which leads into odd places when they start talking about things like edge retention which is how the sharpness changes, not the cutting ability.

…some steels could easily be made razor sharp but during use, the razor edge would go away fast but the edge would settle down and still have a very sharp “working edge” for a very long time.

All steels behave like this, it is just the math of how they wear. It comes out of the physics which at a basic level is due to the fact that the more blunt a blade is the harder it is to blunt it further. This when wrote as an equation has a solution which looks like this :

Sharpness (at material cut of length X) = Initial Sharpness / (1 + C * amount of material cut ^1/2)

In reality the power isn’t exactly 1/2 because of things like damage which are pseudo random in nature. I wrote an article on it a long time ago : http://www.cliffstamp.com/knives/articles/model_edge_retention.html .

11/25/2014 at 6:14 am #21494[…]

Will a lower angle have better edge retention?

It is critical here that you differentiate between push cutting and slicing as they are not dependent on apex angle the same way. Yes at some point the apex angle will be so low it will not have the strength and it will buckle, hence if you start decreasing the apex angle at some point the increase in slicing edge retention will reverse and at some point it will disappear completely. The same relationship is seen to a lesser extent in apex bevel thickness but in this case a lower thickness increases both push and slicing edge retention until the point it is too thin and it again collapses.[/quote]

I agree… it’s just a matter of finding the balance of low enough to maximize both edge retention and cutting ability while yet not making the edge too weak.

11/25/2014 at 6:17 am #21495This is confusing. But I think I get what he is saying.

And it coincides with what you said.

you can get a knife to feel and cut better with a lower angle apex but for how long during use will it stay sharp. I think what he is saying is if he took both them edges, steel being the same, abused them, the wider angle one would sustain less damage.

Is that right? Kind of what I took out of it.

to go along with this topic, I read somewhere where someone was talking about how some steels could easily be made razor sharp but during use, the razor edge would go away fast but the edge would settle down and still have a very sharp “working edge” for a very long time. Many of our carry knives are for working, cutting cardboard or rope and such..They still feel and are “sharp” but maybe not hair whittling sharp anymore after normal use but still very usable. The angle used depending on the steel and type of use all plays into this.

Maybe this post will help you understand it a bit better… it did me because i’m visual lol

11/25/2014 at 6:47 am #21497interesting. Never thought of it that way. the visuals do help.. I am also a visual person..lol.

11/25/2014 at 2:26 pm #21509As an aside, increasing the apex angle doesn’t lower the sharpness, it doesn’t do anything to the sharpness at all because sharpness isn’t a function of the apex angle.

I don’t understand… unless you are meaning it “scientifically”. But for all intents and purposes when you lower the apex angle (as long as you have a true burr free apex) then it will feel much sharper when cutting through any given medium…no?[/quote]

I would not presume to speak for Cliff Stamp but I think I may understand what he means. If so it would be helpful to think of sharpness (rather than over-all cutting ability due to geometry) as experienced by cutting something infinitesimally thin as there only the very edge (apex) is contacting the material. For example a relatively obtuse and wide edge on styling shears can still “pop” hair because hair is quite thin. Anything else is geometry behind the edge, not sharpness of the edge itself.

By this definition we spend only a small fraction of our time on a knife sharpening it; the rest is spent modifying the geometry in preparation for sharpening.

Obviously not everyone agrees on this definition. The author of the Science of Sharp blog uses different terminology. Quoting: http://scienceofsharp.wordpress.com/category/definitions/

sharp

adjective shärp

: having a thin edge that is able to cut thingskeen

adjective kēn

: having a fine edge or pointThese two adjectives will serve to describe

A ) The thinness of the edge (sharpness) as quantified by the edge width at 3 microns from the apex.

B ) The edge width or fineness of the edge (keenness) as measured at the very apex of the bevel.

11/25/2014 at 4:35 pm #21510If so it would be helpful to think of sharpness (rather than over-all cutting ability due to geometry) as experienced by cutting something infinitesimally thin as there only the very edge (apex) is contacting the material.

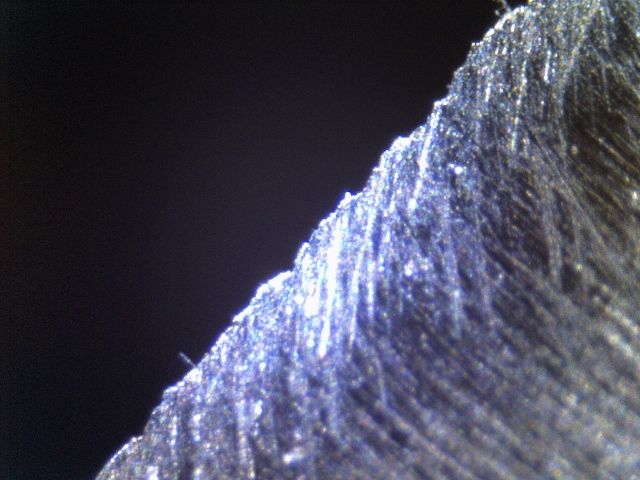

Exactly right, and that is why this is sharp :

and this is not :

But everything is the same geometry wise except for the condition of the very apex.

The first picture is the apex at 15 dps off of a new fine india stone (edge is at 5 dps). The second picture is ~500 slices through 1/2″ hemp later. The knife is much more dull (sharpness, < 1.5% of optimal) but the only thing which has changed is the apex itself.

11/25/2014 at 10:59 pm #21517As an aside, increasing the apex angle doesn’t lower the sharpness, it doesn’t do anything to the sharpness at all because sharpness isn’t a function of the apex angle.

I don’t understand… unless you are meaning it “scientifically”. But for all intents and purposes when you lower the apex angle (as long as you have a true burr free apex) then it will feel much sharper when cutting through any given medium…no?[/quote]

I would not presume to speak for Cliff Stamp but I think I may understand what he means. If so it would be helpful to think of sharpness (rather than over-all cutting ability due to geometry) as experienced by cutting something infinitesimally thin as there only the very edge (apex) is contacting the material. For example a relatively obtuse and wide edge on styling shears can still “pop” hair because hair is quite thin. Anything else is geometry behind the edge, not sharpness of the edge itself.

By this definition we spend only a small fraction of our time on a knife sharpening it; the rest is spent modifying the geometry in preparation for sharpening.[/quote]

Thanks for posting man… I think this helped clear things up in my head as to the definitions. So, while many things increase cutting ability (i.e. removing sap off of the blade, lowering the primary grind, handle ergonomics, etc) grinding metal away to actually apex the edge is what sharpens it. The apex itself is what sharpness is referring to.

So for example (much like cliff’s example). If I have one knife that is dull (edge blunted) such as a japanese knife with an extremely thin edge, and then have a western knife with a truly sharp edge but a thicker shoulder width, then even though the japanese knife would technically be dull it would have higher cutting ability than the western knife whereas the western knife would be sharper… correct?

11/26/2014 at 4:59 am #21526So for example (much like cliff’s example). If I have one knife that is dull (edge blunted) such as a japanese knife with an extremely thin edge, and then have a western knife with a truly sharp edge but a thicker shoulder width, then even though the japanese knife would technically be dull it would have higher cutting ability than the western knife whereas the western knife would be sharper… correct?

In my experience it’s not that simple. It depends on the material. I believe the western knife in the analogy would cut hair (shave) while the J knife would not. It would be able to push cut thin but tough cord cleanly while the J knife would not. On the other hand the J knife might cut cardboard more easily, depending on just how blunted “dull” is. And the J knife would be a much better choice as a cheese knife. Ben Dale (Edge Pro Inc.) had a demo where he easily cut a carrot with a putty knife to demonstrate that on some materials geometry is far more important than sharpness.

11/26/2014 at 5:34 am #21528On the other hand the J knife might cut cardboard more easily, depending on just how blunted “dull” is. And the J knife would be a much better choice as a cheese knife.

Exactly.

Think of cutting ability as that which measures how much force a blade requires to make a cut. It all gets pretty simple then as there are three basic forces :

-the force right against the apex, some materials are very hard to start a cut (sharpness)

-the force to push material apart, some materials are very rigid (blade cross section)

-frictional losses, some materials are very sticky (this is related to but not equal to the second term)

A carrot does not take much to start a cut, you can even just push your thumbnail into it, thus a blade doesn’t need to be very sharp to cut it well. But a carrot is very rigid and thus a thick blade will break the carrot and requires more force. A carrot in general isn’t very sticky and thus there are no frictional concerns.

A piece of rope is very hard to start a cut, you will not be able to push your thumbnail into it (unless you emit gamma radiation). A knife has to be decently sharp to cut rope well. However rope tends to fall apart much more so than a carrot and thus cross section isn’t as critical. Rope isn’t very sticky at all.

A wet potato also isn’t hard to start a cut, but is very rigid and also sticky (starch is used to make glues). Thus a very thin convex profile works very well (or a relief hollow ).

Ideally you want a knife which is sharp, doesn’t bind and is resistant to sticking to cut a broad spectrum of materials well. But specialty knives can ignore 1 or even 2 factors if they just cut very few materials.

—

As an aside, those properties of the materials are actually measured by the rupture pressure, Young’s modulus and coefficient of kinetic friction.

11/26/2014 at 5:51 am #21530Think of cutting ability as that which measures how much force a blade requires to make a cut. It all gets pretty simple then as there are three basic forces :

-the force right against the apex, some materials are very hard to start a cut (sharpness)

-the force to push material apart, some materials are very rigid (blade cross section)

-frictional losses, some materials are very sticky (this is related to but not equal to the second term)

This is perfect… simplifies it to my level =) Totally agree here.

11/26/2014 at 4:07 pm #21536Wow, two Exactly’s from Cliff Stamp. I may develop an ego. :whistle:

11/29/2014 at 1:00 pm #21639Think of cutting ability as that which measures how much force a blade requires to make a cut. It all gets pretty simple then as there are three basic forces :

-the force right against the apex, some materials are very hard to start a cut (sharpness)

-the force to push material apart, some materials are very rigid (blade cross section)

-frictional losses, some materials are very sticky (this is related to but not equal to the second term)

This is perfect… simplifies it to my level =) Totally agree here.[/quote]

Yep, the clearest explanation of cutting ability I’ve ever read! Many thanks, Cliff!

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.