Micro Bevel How To

Recent › Forums › Main Forum › Welcome Mat › Micro Bevel How To

Tagged: micro bevel

- This topic has 24 replies, 9 voices, and was last updated 12/26/2015 at 4:28 pm by

Mark76.

-

AuthorPosts

-

12/25/2015 at 10:36 am #30029

How do you create a micro bevel, how many degrees per side more? Starting grit and progression? Number of strokes? Do’s and Don’ts?

I just sharpened a Wusthof kitchen knife to 17 dps to 1000 diamonds. I did the whole knife, primary and micro bevel using edge trailing/tip to heel strokes. It was pretty sharp, sliced news print cleanly. I did a micro bevel at 22 dps. I did 6 strokes per side with 400 diamonds then 4 with the 600’s. It won’t slice news print without snagging. What did I do wrong? I have sharpened this knife before and touched up as well and never had problems with just a single bevel. This is my first time doing a micro bevel.

12/25/2015 at 1:19 pm #30031Thanks for the post, Geo. I could use some schooling on this subject as well. I’ve had the same results as you, with the micro bevel, the knife isn’t as sharp. I must be doing something wrong…

Merry Christmas, everyone!

Alan

12/25/2015 at 5:01 pm #30034When I do a micro bevel on a kitchen knife, I do things pretty much the same, but I polish the primary (17 dps) bevel much higher, with strops or film. This reduces surface friction doing the slicing process. Then I put on a much smaller microbevel. Maybe three very light, alternating strokes with 1000 grit stones. More will just turn your microbevel into a minibevel.

I think that when you use 400 grit to start your microbevel, you create a very toothy edge which would require a lot of stoning with your 600’s to remove. I would expect that you’d end up with very little visible primary bevel. My experience is that putting on a true microbevel requires an absolute minimum of stoning and only one grit. Clay has reported tests showing excellent results with microbevels of even 200 grit, Very toothy edges can be very good for kitchen work. They slice tomatoes beautifully, but you can’t expect them to slice easily thru paper.

By the way, I have photos which show that even scalpels are made with a toothy edge. The packet I bought off Amazon is ground both sides with about 600 grit, and then polished only on one side to leave the toothy edge. This stands to reason as you need a toothy edge to bite into slippery tissue.

12/25/2015 at 5:11 pm #30036I would add to Tcmeyer’s suggestion. Edge leading, alternating strokes (minimize burr production), finest stone you used in shaping/sharpening or finer, stones wet/lubricated, clean(ed) stone, very light pressure.

i should say that the choice of grit used for micro bevel will depend on how toothy you want the final edge. 1000 seems good.

12/25/2015 at 6:20 pm #30037By the way, I have photos which show that even scalpels are made with a toothy edge. The packet I bought off Amazon is ground both sides with about 600 grit, and then polished only on one side to leave the toothy edge. This stands to reason as you need a toothy edge to bite into slippery tissue.

Completely irrelevant, but

Surgical scalpels should not have a toothy edge. It’s actually a big point of contention in the medical community with regards to obsidian scalpels, which have been proven in animal studies to drastically reduce healing time because under a microscope, a steel scalpel, no matter how sharp, will tear along the line of incision, whereas obsidian scalpels will actually cleave individual cells in half. Less damaged tissue, less inflammation, better healing. The reason we don’t have them in the operating theater yet us because of concerns that the obsidian blades can chip easily and leave slivers in the flesh. For biology slides, scalpels of glass are used for primary divisions and then slide cuts are made using diamond scalpels, which are prohibitively expensive but obviously very clean cuts at a cellular level. The idea is a bevel so fine that the friction line is so microscopic that it doesn’t even need a bite to sink through flesh. Also, flesh isn’t actually that slippery and incision points aren’t exactly trying to shave a tomato, all you want is clean cuts with a minimum of inflammation-causing tearing.

1 user thanked author for this post.

12/25/2015 at 6:36 pm #30039By the way, I have photos which show that even scalpels are made with a toothy edge. The packet I bought off Amazon is ground both sides with about 600 grit, and then polished only on one side to leave the toothy edge. This stands to reason as you need a toothy edge to bite into slippery tissue.

[ Also, flesh isn’t actually that slippery and incision points aren’t exactly trying to shave a tomato, all you want is clean cuts with a minimum of inflammation-causing tearing.]

Incision points aren’t slippery tissue. Have you ever disassembled the insides of a big critter?

12/25/2015 at 10:25 pm #30040Tom, here is one of the “articles” I was thinking about… good read if you have time.

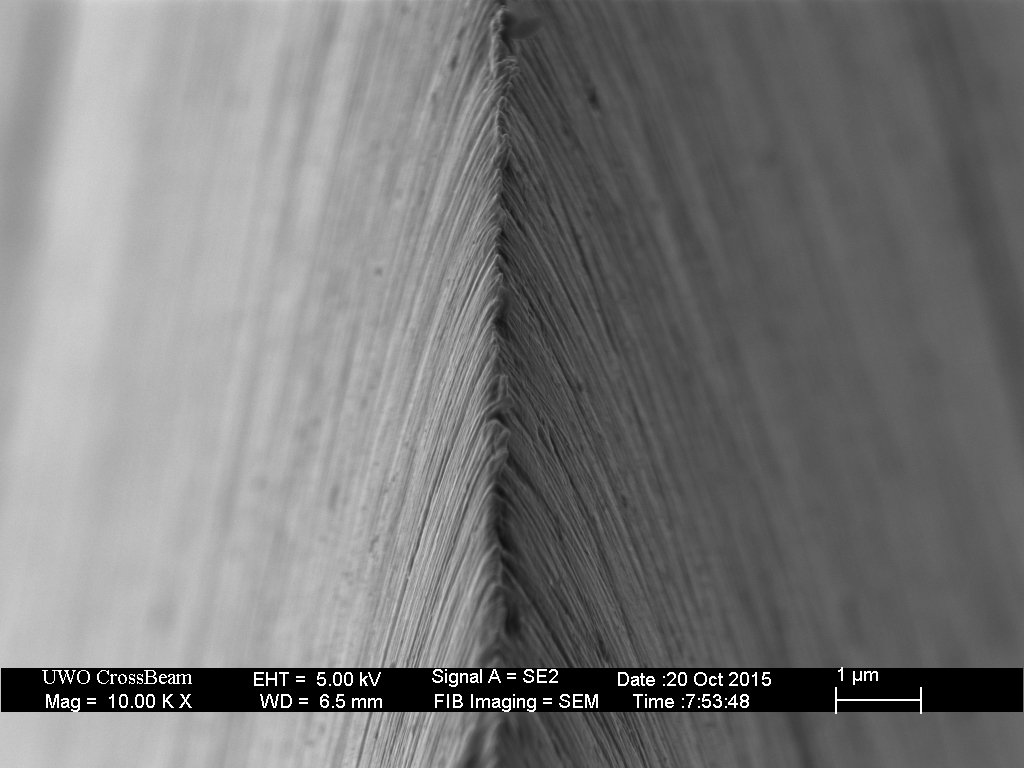

Here is a straight razor I finished up recently. This picture is done at whatever the angle was (don’t remember – don’t measure on straight razors usually) and taken through 3um lapping films. Yes, I micro-bevel my straight razors because I CAN on the wicked edge

And not only does it add strength, it gives the most consistent apex…. not that this apex was lacking lol.

And here is the same edge, w/ an increase of exactly 1 dps w/ the 1um lapping films, alternating, edge leading passes – no stropping yet.

I also recommend switching from edge trailing to edge leading if you want minimal burr/wire edge. I can’t remember where I saw Todd post this exactly (check out his blog!), but a few points that I have seen him say… 1. only a couple strokes with your highest grit stone (when micro-beveling) will lead to a wire edge until you do more and the micro-bevel both establishes and stabilizes. 2. edge leading will give you minimal burr removal but can lead to micro-chipping/irregularities.

keep in mind, todd is mainly dealing w/ straight razors and not knives (which are typically at much higher angles) but I think the research is still very important and relevent to this discussion =)

2 users thanked author for this post.

12/25/2015 at 10:47 pm #30042Incision points aren’t slippery tissue. Have you ever disassembled the insides of a big critter?

I’m really making a meaningless semantic argument, so I mean no offense.

I’ve dressed game. But I’ve also done my time in hospital rotations and field deliveries and all kinds of nasty trauma. Amputations aren’t a big deal. They’re slippery to hands, not knives sharp enough to shave hairs. It’s simple biology, less tearing is ideal on a living creature, damaged cells cause inflammation. Less damaged cells, less inflammation, faster healing. And surgical cuts are very different from field dressing game. Most slippery piece of flesh I’ve ever held is umbilical cord, and our OB scalpels melt right through them.

12/25/2015 at 11:09 pm #30044As far as toothy vs polished for surgical scalpels…

I would say it depends on how the edge is sharpened. The thicknesses of the apexes being the same I personally believe the toothy edge would be much more effective but I do need to do some more comparisons when processing game.

From the Science of Sharp blog I posted above… This apex width is measured at 100 nm (nano-meters) and is finished, edge leading, on a DMT 325 plate (which would produce a toothy edge by definition)

Here’s an edge finished off of a 16k Shapton waterstone then stropped on loaded denim

Both have irregularities on a small enough scale, but I would think that the one w/ more but the finest apex width (without forming a wire edge) would peform the cleanest cut – but I may be wrong. I am not drawing any conclusions from my limited knowledge/research. As far as effectiveness goes I will be doing my own comparison in the near future when I process this next pig =)

12/26/2015 at 1:35 am #30046Without getting too much further into it, you’re also looking at the crystalline structure of the elements evolved beyond the sharpening when it comes to the obsidian vs steel argument.

It’s basically the works of ultramicrotomy starting to bridge into surgery. The diamond knives of ultramicrotomy are used to create 2000 radial cross sections of a single hair, or 100 cross sections of a single red blood cell. That’s how fine we’re talking when it comes to the obsidian and diamond knives. The edges are not sharpened, they are made using fracture lines.

12/26/2015 at 2:21 am #30050Josh, maybe I should better ask this question at the guy of Science of Sharp (sorry, forgot his name), but how can you exactly measure the width of an apex? I.e. where do you measure it. For example, if you do it at the exact top you might end up with a few molecules’ width. If you do it just half a millimeter lower, it will already be much thicker.

So how can the concept of apex width make sense without saying where you measure the width. (And this is even apart from measurement apparatus – unless you’ve got an electron microscope – and my hands simply not being exact enough to measure consistently at the same location for every knife.)

This is the reason that in my Japanese Kitchen knife Reviews blog I measure the edge thickness only at 5 mm above the edge. I simply cannot get it more exact.

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/26/2015 at 2:25 am #30051Geo, what I learned about microbevels was mainly from Clay and Jon Broida:

I cannot really answer your question, but I must say it works great on for example my Suisin Inox honyaki (on which Jon also recommends it).

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/26/2015 at 8:32 am #30052…..I have seen him say… 1. only a couple strokes with your highest grit stone (when micro-beveling) will lead to a wire edge until you do more and the micro-bevel both establishes and stabilizes.

This specifically refers to low angle primary (less than 10dps) where the apex will bend rather than abrade unless the micro-bevel angle is at least 5 dps higher. For example, micro-beveling a straight razor by adding tape gives inconsistent results because of this.

2. edge leading will give you minimal burr removal but can lead to micro-chipping/irregularities. …

Edge leading almost always prevents a burr on mid- to high-grit stones. Low grit results are quite variable, depending on the stone. The micro-chipping process is what removes the burr, so it is not a negative in this case.

1 user thanked author for this post.

12/26/2015 at 8:42 am #30053Josh, maybe I should better ask this question at the guy of Science of Sharp (sorry, forgot his name), but how can you exactly measure the width of an apex? I.e. where do you measure it. For example, if you do it at the exact top you might end up with a few molecules’ width. If you do it just half a millimeter lower, it will already be much thicker.

So how can the concept of apex width make sense without saying where you measure the width. (And this is even apart from measurement apparatus – unless you’ve got an electron microscope – and my hands simply not being exact enough to measure consistently at the same location for every knife.)

This is the reason that in my Japanese Kitchen knife Reviews blog I measure the edge thickness only at 5 mm above the edge. I simply cannot get it more exact.

Measuring the apex geometry (in 2 dimensions, ignoring “tooth” for now) requires two quantities. Edge width or more correctly the radius of curvature of the apex is what determines the pressure exerted by the blade on an object being parted and this is typically less than 100nm for any razor blade, utility blade or scalpel. Obviously this cannot be measured without an SEM. The second measurement must quantify the thickness behind the apex – this could be angle or the width at some distance behind the apex. If the bevel is not convex, these are directly related. The relevant distance from the apex will depend on the material being cut, for shaving I believe 3 microns behind is representative of the performance. For deeper cuts, the thickness further back is more relevant.

3 users thanked author for this post.

12/26/2015 at 8:47 am #30054 -

AuthorPosts

- You must be logged in to reply to this topic.